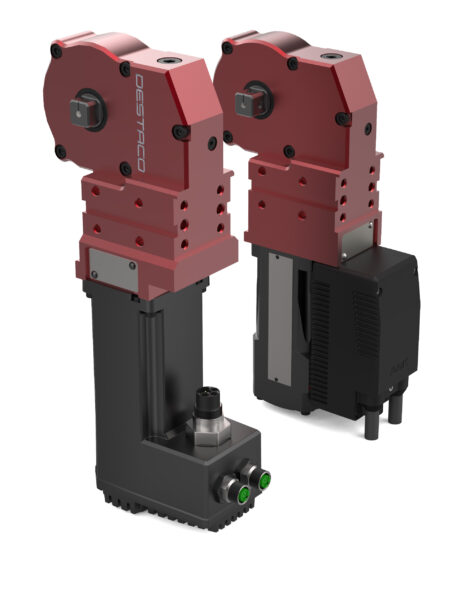

The 92W Series Power Clamp saves costs, CO2 and energy on the way to Industry 4.0

DESTACO, a provider of automation, clamping, and gripping solutions, has introduced the new intelligent 92W Series Electric Power Clamps. Operating completely without compressed air, the 92W power clamps set a new standard for efficient and environmentally friendly production operations. They reduce energy consumption and CO2 emissions – and as a plug-and-play solution, they pave the way for exceptionally flexible production processes.

“Electric drives have clear advantages over pneumatic drives,” explained Christian Schubert, Global Product Manager for DESTACO. “They reduce CO2 emissions and energy costs by up to 85%. Their use of electric motors helps eliminate the need for lossy compressed air lines and associated pneumatic equipment. Electric drives also offer a high degree of flexibility, which significantly reduces the need for an expansive spare-parts inventory.”

The 92W power clamp’s integrated intelligence also reduces the need for additional components, as it provides essential data for process optimization even without external sensors. Even during installation, these values allow the user to conveniently adjust the speed, positioning and/or torque to “fine-tune” production. During subsequent operations, the values are used to analyze process quality.

The control of the electric clamps is decentralized and attached directly to the production devices, which reduces cable lengths and cabling costs. In this way, all automation functions can be implemented decently. This not only frees up space, but also ensures seamless integration of the clamping technology into the production system. Reliable voltage, signal, and data management also facilitate digital planning, along with providing quick and easy installation and commissioning. All of these features save time and, together with process optimization, reduce labor costs. Higher initial investments are therefore amortized in one to three years, depending on the configuration.

The advantages of the new 92W power clamps will be able to help many manufacturing companies switch their production from pneumatic to electric drives. Many innovative companies are already using the first 92W power clamp units in their production processes and achieving excellent results.

The powerful 92W electric power clamps hold workpieces in several positions; for example, during the production and assembly of body shells. Thanks to the power clamp’s integrated component control, no external sensors are required. In combination with the unit’s integrated tolerance compensation, this enables the control and production of different component types.

In parallel to the smart electric clamps of the 92W Series, further economical variants of the series are being launched to the market. DPE/RPE Grippers, GTB/RPE Servo Positioners, and EcoCup Vacuum Cups also feature the advantages of electric drives.