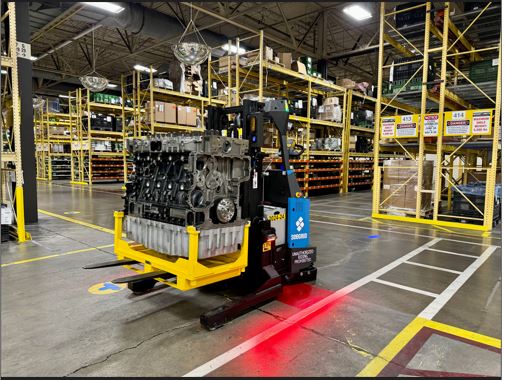

Vision-Guided autonomous lift truck boosts safety, efficiency, and productivity

Seegrid highlights its Lift RS1 AMR. This autonomous lift truck is designed to transform material handling workflows, providing unmatched productivity, efficiency, and safety to manufacturing, warehousing, and logistics operations.

Seegrid’s Lift RS1 AMR is capable of a 6-foot lift height, making it ideal for low-lift processes across the most prevalent industrial facility applications. With a payload capacity of 3,500 pounds, it enables facilities to handle heavy loads more efficiently, boosting overall operational productivity. The RS1 demonstrates exceptional reliability, consistently performing tasks with precision and minimal downtime, ensuring seamless material handling operations.

The RS1 has been built with the same proven technology stack that has enabled Seegrid AMRs to log over 15 million autonomous production miles to date in customer facilities. With its vision-guided technology, Seegrid’s Lift RS1 can safely and reliably navigate even the most dynamic environments without the need for infrastructure such as magnets or reflectors. Moreover, the RS1 helps simultaneously address staffing shortages and respond to customer demands by providing facilities with a dependable autonomous solution.

The RS1 features Seegrid’s pioneering Sliding Scale Autonomy, a unique-to-Seegrid innovation that blends the agility of autonomous mobile robots (AMRs) and the predictability of automated guided vehicles (AGVs). This allows the truck to navigate differently based on what is best suited for the specific customer application at hand. Whether performing long-haul routes or dynamically executing picks and drops, the RS1 excels by providing both the predictability and agility required by modern manufacturing, warehousing, and logistics environments. Equipped with LiDAR-based SLAM technology, the RS1 plans dynamic routes based on real-time perception feedback ensuring reliable picks and drops without explicit training. Sliding Scale Autonomy offers a level of capability unmatched by competitors, empowering customers to optimize their material handling workflows in ways traditional AMRs and AGVs cannot.

Safety is a top priority for Seegrid, and the Lift RS1 offers 360° safety coverage. The truck has both primary and secondary safety sensing capabilities, a standout feature in the industry. While many systems rely solely on primary obstruction detection, which can only sense objects within 6 inches of the ground, Seegrid’s secondary obstruction detection technology provides precise scanning of the drop area prior to payload release. This guarantees an extra layer of safety, ensuring accurate pallet drops and further reducing the risk of errors. Seegrid continues to deploy its proven and trusted AMRs in live customer environments—with hundreds of successful deployments and thousands of AMRs—all transforming the way customer facilities operate, without a single reportable or recordable safety incident to date.

Beyond offering pioneering autonomous solutions, Seegrid prides itself on its ongoing service and support, proven implementations, and industry-leading ROI. Supporting more than 50 global brands, Seegrid continues to revolutionize the way facilities operate. As seen in one customer manufacturing facility, more than a hundred Seegrid AMRs are responsible for nearly 80% of their non-conveyed material moves, cutting inventory levels by up to 30% and expected to deliver positive ROI in less than 18 months. And with fast deployment times of weeks, not months, the RS1 can be fully integrated into facility operations without any disruption to existing workflows, allowing for its benefits to be experienced almost instantly.

The Lift RSI AMR is designed to not only meet, but exceed the ever-increasing demands of today’s modern manufacturing, warehousing, and logistics industries that rely heavily on palletized material handling. Seegrid’s pioneering autonomous lift trucks continue to bring real value to customers today, and as industry innovators, will continue developing new technology to enable its customers to automate their material handling workflows more than ever before.