Listen to this article

Reliable detection, advanced safety functions, combined with simplified selection, installation, and maintenance

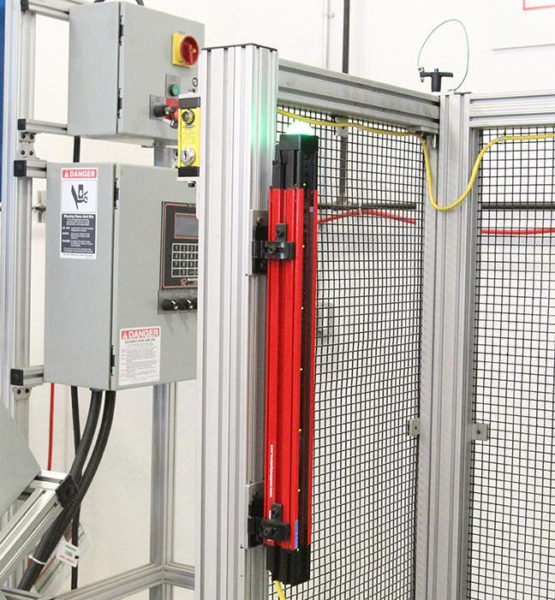

Rockford Systems, LLC has introduced its new Protector Series Light Curtains for safeguarding personnel near industrial machinery with the potential to cause injury. Protector Series Light Curtains feature bi-color alignment indicators, simplified resolution settings, automatic diagnostics, remote fixed blanking, and can be interconnected in a cascading configuration. Built for ease of use, they also provide for hassle-free installations that eliminate the software, DIP switches, and expensive components from the process. Brackets and connecting cables are all included, as a kitted solution, for faster, more cost-effective light curtain installations.

“Protector Series Light Curtains are the latest example of Rockford Systems’ unmatched ability to provide end-to-end safety solutions, from industry-leading OSHA training and more than 6,000 innovative safeguarding products to comprehensive on-site audits,” said Matt Brenner, Vice President and General Manager-Rockford Systems Machine Safeguarding. ”Rockford Systems has drawn on decades of applications expertise to enhance the light curtain selection and integration process resulting in an improved overall user experience.”

Faster Set-Up, Easier Maintenance

Designed to reduce setup and maintenance time, Protector Series Light Curtains feature bright bi-color alignment indicators that run the length of the receiver window. In the event, a sensor is not aligned properly or if the window requires cleaning, green lights will switch to red to instantly identify the problem area. Optional remote indicators can be purchased for long-distance monitoring of light curtain status to further support safety and productivity goals.

Protector Series Light Curtains employ dual-scan technology that makes its photodiodes highly immune to EMI, RFI, ambient light, weld flash, and strobe lights that may compromise sensor performance. Damage from impact is greatly reduced by a design that recesses the unit’s windows 5mm into the housing to prevent direct contact with the sensors. Emitters and receivers are both contained inside of 3mm thick industrial grade aluminum housings with durable metal end-caps.

For those applications that require multi-sided protection where mirrors cannot be used, up to four Protector Series Light Curtain systems of any length, resolution, and beam number can be easily configured. Cascading Protector Series Light Curtains minimize wiring while simplifying the safety circuit, resulting in a lower Total Cost of Ownership.

Protector Series Light Curtains are also ideal for industries subject to frequent washdowns or water sprays, such as food, beverage, and pharmaceutical processing. They are rated IP65/IP67 so they offer total protection from low-pressure water jets and more substantial liquid ingress or immersion.

Simplified Ordering

Customers can select whichever features best suit their application. Protector Series Light Curtain designs will accommodate more than 90% of all point-of-operation applications, coming in a choice of three common resolutions — 14mm (finger detection), 23mm (hand detection), and 40mm (body detection) — for each light curtain length. All three resolutions have a range of up to 12 meters (39 feet) coinciding with the needs of most manufacturing settings. Rockford System’s customer service professionals are ready to assist online, on-site, or over the phone in helping specify the proper light curtain for the application.

Brenner commented: “As demand for machine safeguarding continues to expand, so does the need for manufacturers to employ the proven performance of light curtains as a risk reduction measure. Ensuring simple, yet advanced solutions in light curtains also extend to their selection, purchasing, and installation process.”