Technology is rapidly reshaping the way business is conducted, particularly for manufacturers. Robotics are poised to transform the entire manufacturing industry, and many business leaders are finding themselves faced with difficult decisions in regard to automation and robotics in their manufacturing facilities.

At the core of these decisions is the calculation of what type of return on investment a robotic integration would provide. Here are seven factors to look at when evaluating potential ROI from the integration of robotics in your manufacturing facility.

- EFFICIENCY

Efficiency is one of the most important measurables in business, and a robotic integration is likely to meet or exceed your expectations. Improved efficiency is often experienced in critical areas such as manufacturing processes, product throughput, uptime, and energy.

- RELIABILITY

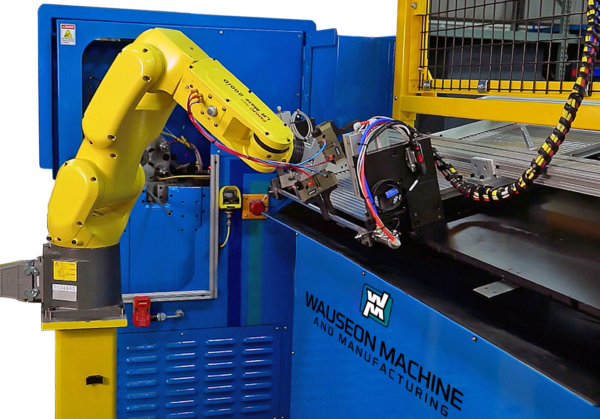

Reliability is an essential part of your production and planning process, and by choosing a robotic solution over fixed automation, your potential failures are minimal. The mean-time-between-failure of a FANUC robot, for example, is documented at 78,000 hours, depending on the model.

- UPTIME

Uptime associated with a FANUC robotic turnkey system designed, built, and integrated by Wauseon Machine is very high when proper preventive maintenance practices are followed.

- FLEXIBILITY

Flexibility of our turnkey systems allows you to not only reprogram your robot as required when processes change, but also allows you to retool, redeploy, or redevelop your equipment in a more cost effective manner than other fixed automation solutions.

- QUALITY

Quality is built into every robotic system we deliver. Our vertical integration provides us with control over the design and build of a complete system, including components that are typically outsourced. Your project stays with us from start to finish.

- REPEATABILITY TOLERANCES

Repeatability tolerances unachievable by a human operator can be reached with a robot. Companies who choose robotic automation may experience quality and employee safety improvements throughout the entire process flow.

- PRODUCTIVITY

Productivity improvements will be witnessed quickly. Your downtime will decrease, throughput will increase, and total hours in production will be higher when compared to traditional human labor.

About The Author:

Wauseon Machine and its sister company, McAlister Design & Automation, are industry leaders in robotics automation, tube fabrication equipment, and build-to-print precision machines parts. With 40 years of experience, the company has four separate focus plants dedicated to Tube-Forming Technologies, Robotic Automation, and Precision Machining. Across their plants, they focus on tool development, machine building, automation, and providing contract CNC production machining of volume and custom precision piece parts and components for other companies. Wauseon Machine / MD&A are best in class suppliers of system integration to incorporate automation into a variety of industries, applications and cutting edge technologies for manufacturing. For more information, visit https://www.wauseonmachine.com.