Welch Equipment Company receives Toyota’s President’s Award

Toyota Material Handling announced Welch Equipment Company as a recipient of the annual President’s Award at the company’s annual dealer meeting in Phoenix, Arizona. The President’s Award recognizes the top Toyota forklift dealers in North America. The prestigious award recognizes the dealers who perform at the highest level in parts, service, equipment sales, customer satisfaction, and overall operations. “We are incredibly honored to receive the President’s Award,” said Chris Rice, President and CEO of Welch Equipment Company. “This recognition is a testament to the hard work and dedication of every member of our team at Welch. We strive to consistently deliver exceptional service and support to our customers, and this award reaffirms our commitment to excellence in every aspect of our operations.” The winners of the 2023 President’s Award are: Welch Equipment Company, Denver, CO Conger Toyota-Lift, Green Bay, WI Industrial Truck Service, Winnipeg, Manitoba, Canada JIT Toyota-Lift, Frewsburg, NY Mid Columbia Forklift, Yakima, WA ProLift Toyota Material Handling, Louisville, KY Shoppa’s Mid America, Kansas City, MO Southern States Toyotalift, Tampa, FL Summit Toyotalift, North Haven, CT Toyota Lift of Houston, Houston, TX Toyota Lift of South Texas, San Antonio, TX Toyota Material Handling Systems, Suwanee, GA Vesco Toyotalift, Hickory, NC Watts Equipment Company, Manteca, CA Brodie Toyota-Lift, Lawrence, MA “The President’s Award is the pinnacle of recognition at Toyota, reserved for those who exemplify superior dedication to providing customer service and solutions,” said Bill Finerty, TMH President & CEO. “Toyota Material Handling dealers have a long-standing reputation for going above and beyond for their customers, and these dealers represent the best of the company’s customer service standards.”

Nucor reports results for the First Quarter of 2024

Net earnings attributable to Nucor stockholders of $844.8 million, or $3.46 per diluted share Net sales of $8.14 billion Net earnings before noncontrolling interests of $959.0 million; EBITDA of $1.50 billion Nucor Corporation has announced consolidated net earnings attributable to Nucor stockholders of $844.8 million, or $3.46 per diluted share, for the first quarter of 2024. By comparison, Nucor reported consolidated net earnings attributable to Nucor stockholders of $785.4 million, or $3.16 per diluted share, for the fourth quarter of 2023 and $1.14 billion, or $4.45 per diluted share, for the first quarter of 2023. “Nucor’s performance continues to be strong even as steel market conditions have come off their post-pandemic record highs,” said Leon Topalian, Nucor’s Chair, President, and Chief Executive Officer. “We also took several bold steps to advance our growth, sustainability, and commercial strategies during the first quarter. We broadened our capabilities in the rapidly growing data center market, announced new partnerships to supply our customers with low-carbon steel and accelerate the development of cleaner forms of energy, and introduced the Nucor Consumer Spot Price for our hot-rolled coil products to provide our customers with more timely and transparent information.” Selected Segment Data Earnings (loss) before income taxes and noncontrolling interests by segment for the first quarter of 2024 and 2023 were as follows (in thousands): Three Months (13 Weeks) Ended March 30, 2024 April 1, 2023 Steel mills $ 1,102,251 $ 838,388 Steel products 511,559 970,802 Raw materials 9,581 58,140 Corporate/eliminations (398,050) (270,546) $ 1,225,341 $ 1,596,784 Financial Review Nucor’s consolidated net sales were $8.14 billion in the first quarter of 2024, a 6% increase compared to $7.70 billion in the fourth quarter of 2023 and a 7% decrease compared to $8.71 billion in the first quarter of 2023. Average sales price per ton in the first quarter of 2024 increased 1% compared to the fourth quarter of 2023 and decreased 3% compared to the first quarter of 2023. A total of 6,224,000 tons were shipped to outside customers in the first quarter of 2024, an increase of 5% compared to the fourth quarter of 2023 and a decrease of 3% compared to the first quarter of 2023. Total steel mill shipments in the first quarter of 2024 increased 7% compared to the fourth quarter of 2023 and decreased 2% compared to the first quarter of 2023. Steel mill shipments to internal customers represented 21% of total steel mill shipments in the first quarter of 2024, compared to 20% in the fourth quarter of 2023 and the first quarter of 2023. Downstream steel product shipments to outside customers in the first quarter of 2024 decreased 5% from the fourth quarter of 2023 and decreased 15% from the first quarter of 2023. The average scrap and scrap substitute cost per gross ton used in the first quarter of 2024 was $421, a 6% increase compared to $397 in the fourth quarter of 2023 and a 2% increase compared to $414 in the first quarter of 2023. Pre-operating and start-up costs related to the Company’s growth projects were approximately $125 million, or $0.39 per diluted share, in the first quarter of 2024, compared with approximately $127 million, or $0.39 per diluted share, in the fourth quarter of 2023 and approximately $82 million, or $0.24 per diluted share, in the first quarter of 2023. Overall operating rates at the Company’s steel mills increased to 82% in the first quarter of 2024 compared to 74% in the fourth quarter of 2023 and 79% in the first quarter of 2023. Financial Strength At the end of the first quarter of 2024, we had $5.54 billion in cash and cash equivalents, short-term investments and restricted cash and cash equivalents on hand. The Company’s $1.75 billion revolving credit facility remains undrawn and does not expire until November 2026. Nucor continues to have the strongest credit rating in the North American steel sector (A-/A-/Baa1) with stable outlooks at Standard & Poor’s, Fitch Ratings and Moody’s. Commitment to Returning Capital to Stockholders During the first quarter of 2024, Nucor repurchased approximately 5.5 million shares of its common stock at an average price of $180.79 per share. As of March 30, 2024, Nucor had approximately $2.32 billion remaining authorized and available for repurchases under its share repurchase program. This share repurchase authorization is discretionary and has no scheduled expiration date. On February 20, 2024, Nucor’s Board of Directors declared a cash dividend of $0.54 per share. This cash dividend is payable on May 10, 2024 to stockholders of record as of March 28, 2024 and is Nucor’s 204th consecutive quarterly cash dividend. First Quarter of 2024 Analysis Steel mills segment earnings in the first quarter of 2024 increased from the fourth quarter of 2023, primarily due to higher average selling prices and increased volumes, particularly at our sheet mills. Earnings in the steel products segment decreased in the first quarter of 2024 as compared to the fourth quarter of 2023 due to lower average selling prices and decreased volumes. Earnings in the raw materials segment increased in the first quarter of 2024 as compared to the fourth quarter of 2023. Second Quarter of 2024 Outlook We expect earnings in the second quarter of 2024 to decrease compared to the first quarter of 2024. The largest driver for the expected decrease in earnings in the second quarter of 2024 is the decreased earnings of the steel mills segment, primarily due to lower average selling prices partially offset by modestly increased volumes. The steel products segment is expected to have moderately decreased earnings in the second quarter of 2024 as compared to the first quarter of 2024 due to lower average selling prices, partially offset by increased volumes. Earnings in the raw materials segment are expected to be higher in the second quarter of 2024 as compared to the first quarter of 2024 due to the increased profitability of our direct reduced iron facilities and scrap processing operations.

Forklifts Group earns the Diamond Award from the Bobcat Company

Bobcat Company recognized Forklifts Group as a top-performing material handling equipment dealer with a Diamond award at MODEX 2024. Dealers are recognized annually by Bobcat Company for their outstanding efforts and commitment within their respective regions. This year, Bobcat recognized 21 material-handling dealers based on sales, volume and other dealer engagement metrics. Forklifts Group was recognized at a reception held during MODEX 2024, the premier supply chain experience trade show in Atlanta, Georgia. “We are pleased to recognize such a deserving group of dealerships for their efforts and achievements,” said Jarrod Steck, Bobcat vice president of material handling products. “While forklifts are a new product offering within the Bobcat portfolio, these dealerships bring years of expertise and experience within the material handling industry, and we are thrilled to award these top performers and valued dealer partners.” Bill St. John, President of Forklifts Group, accepted the award on behalf of the entire organization. “I would like to thank Bobcat Material Handling for the recognition of our dealership’s outstanding performance with the prestigious Bobcat Diamond Award,” St. John said. “We are extremely proud to represent the Bobcat product and thankful for the support you provide. I also want to extend a huge thank you and congratulations to our dedicated team of parts, service, support and sales professionals who work hard each day to meet the needs of our loyal customers. We are extremely grateful for our customers’ continued partnerships and support, which keep us motivated to improve every day.” Bobcat’s lift truck, materials handling products and organization were rebranded to Bobcat, from the former name of Doosan this past year.

ASSP names Safety Professional of the Year

The American Society of Safety Professionals (ASSP) has named Matthew F. Herron its 2024 Safety Professional of the Year. The safety engineer and ergonomics specialist has been an ASSP member for 13 years and has helped advance occupational safety and health in many ways. Herron, M.S., P.E., CSP, CPE, is lead safety engineer for the Mechanical Engineering Division at Southwest Research Institute in San Antonio, TX. He has created numerous division-wide operating procedures and processes. This includes a safety initiative called “Safety 360” that empowers workers to identify, correct and report unsafe acts and conditions so everyone can return home safely at day’s end. “Matt has been instrumental to the safety culture in our operating division of more than 300 employees,” said Shane Siebenaler, director of the Fluids Engineering Department at Southwest Research Institute. “Our environment presents hazards that range from explosives to high-pressure hydrogen to radioactive sources. Matt developed many of the safety procedures we use daily. His enthusiasm and diligence to safety is contagious and has a direct impact on our employees, clients and visitors.” Herron is a nationally recognized speaker on ergonomics, having presented at ASSP’s Safety 2021 Professional Development Conference and Exposition in Austin, TX, and for the past three years at the National Ergonomics Conference in Las Vegas. He has been a guest lecturer at the Industrial and Organizational Psychology Department of St. Mary’s University, and Trinity University’s Engineering Science Department. Herron’s involvement and impact on the ASSP community is extensive. He was a 2022 recipient of the Society’s President’s Award and Charles V. Culbertson Outstanding Volunteer Service Award as well as the 2023 Council on Practices and Standards Safety Professional of the Year. He currently serves as vice president for Region III, deputy vice president for the Council on Region Affairs, standards chair for the Ergonomics Practice Specialty, social media chair for the Engineering Practice Specialty and member of ASSP’s Advisory Group. “Matt’s leadership skills shine brightly and ensure that all Region III chapters are not only functioning, but thriving in challenging times,” said Andrea Ball, CSP, ARM, vice president of ASSP’s Council on Region Affairs. “He is always willing to volunteer for projects and spearhead valuable programs.” Herron is known for cultivating technical knowledge, sharing best practices, fostering professional relationships, and educating employers on the value of occupational safety and health. He understands that the future of the occupational safety and health profession lies with today’s students. He is the student affairs chair for ASSP’s South Texas Chapter and previously was the assistant vice president for student affairs in Region III. Herron will be honored at ASSP’s Safety 2024 Professional Development Conference and Exposition, held Aug. 7-9 in Denver. The global event will bring together thousands of safety professionals to learn about best practices, industry trends and the latest product innovations in workplace safety and health. Each year, ASSP honors an occupational safety and health professional who demonstrates outstanding achievement in the safety field while making significant contributions to advancing the profession. Visit the Society’s website to see past recipients of the ASSP Safety Professional of the Year Award.

CLARK has announced the launch of the SE25-35 lithium-ion forklift

CLARK Material Handling Company has announced the launch of the SE25-35, a 5,000-7,000-pound indoor/outdoor pneumatic forklift. Powered by a 48V lead acid battery or a fully integrated 80V Lithium-Ion battery, the SE25-35 is the ideal solution for customers looking for a versatile, durable, and reliable forklift capable of handling indoor and outdoor conditions with ease. The latest addition to the S-SERIES lineup initially launched in 2017, the SE25-35 adds to the legacy of SMART, STRONG, and SAFE forklifts that define the S-SERIES line. With a 5.6” LCD SMART dash display with intuitive codes, an integrated Lithium-Ion battery, and three selectable performance modes to optimize performance, the SE25-35 is fully equipped with smart features designed to increase productivity and efficiency. Safety is at the forefront of all product design at CLARK, which is why the SE25 series comes equipped with several operator-focused safety features including an automatic parking brake, which engages when the truck comes to a stop, or the operator leaves the seat. Additionally, the ergonomic vinyl suspension seat, large operator compartment, and counter-rotating wheels on the SE25 series all contribute to a comfortable operation of the truck, promoting operator safety throughout the duration of the shift. And, as always, the SE25-35 was designed with the most durable, reliable components, including the CLARK-standard Nested I-Beam mast, fully welded frames, and a six-roller carriage with side thrust rollers to improve durability and reduce mast deflection. CLARK S-SERIES trucks are Built to Last and overengineered to meet the demands of even the most challenging of applications. “We are excited to bring this new S-SERIES electric product to the market,” commented Brandon Bullard, Director of Sales and Marketing at CLARK North America. “Customers need the flexibility to transition from indoor to outdoor spaces seamlessly and should hold their equipment to high standards when it comes to durability, reliability, and versatility. The SE25-35 answers the call and fits the ever-changing needs of our customers extremely well.” “The S-SERIES lineup continues to be our hallmark series, and we are pleased to introduce another fantastic electric truck to that line,” added Mike Binnie, COO of CLARK North America. “As we continue to see a shift from IC to Electric in the market, we know our customers will appreciate the IC-feel of the SE25-35 without the emissions or noise level of a traditional IC truck.”

Shurtape Technologies, LLC, has announced Senior Vice President of Marketing

Mark Hodgins brings unique experience and expertise to lead Company’s global marketing efforts Shurtape Technologies, LLC has announced the addition of Mark Hodgins as its new Senior Vice President of Marketing. In this role, he will oversee the Product Management & Marketing, Insights & Innovation, and Marketing Communications & Media teams, as well as initiatives for the Company’s brands domestically and globally. Mr. Hodgins’ arrival came as Bill Kahl, Executive Vice President of Marketing and son of Duck Brand® founder Jack Kahl, announced his retirement, bringing an end to an illustrious and impactful 40-year career with the Company. Offering a broad view of global markets, Mr. Hodgins’ expertise in global and omnichannel strategy development and execution, in addition to his ability to cultivate strong, long-lasting relationships with internal and external partners, will contribute to Shurtape’s continued growth and operational success. He joins Shurtape following a long-term career with the 3M Company, where he honed his skill set in idealizing and implementing productive portfolio initiatives and brand strategies, along with new product development and product launches. “Mark is a passionate and collaborative leader who develops high-performing sales and marketing teams and designs and executes world-class sales. His global expertise, combined with both consumer and commercial go-to-market strategies, will play a crucial role in the continued growth and success of the Company,” states Vuk Trivanovic, CEO of Shurtape Technologies, LLC. He added, “At the same time, our Shurtape family acknowledges the end of an era with the retirement of Bill Kahl. We wish him the very best in his much-deserved retirement after so many years of inspiration and innovation to Shurtape and to our surrounding communities.” “Joining this organization is truly an honor and a privilege. But first, I’d like to acknowledge Bill for his exceptional leadership and commitment to the business throughout his impressive 40-year career,” says Hodgins. “I have big shoes to fill, but I welcome the opportunity to work hand-in-hand with Bill for the next several months. My goal will be to follow his lead and develop global and domestic strategies to take the organization into the future.”

Nowicki Food Machinery is Now NOMA

As the global food processing industry turns to automated solutions to answer the world’s growing demand, BAK Food Equipment has announced a related change from one of our most valued partners. Effective immediately, Poland-based Nowicki Food Machinery has become NOMA. NOMA reflects the Nowicki family’s 50-year commitment to the food processing industry by combining the two core pillars of their business: the Nowicki family name and modern “machinery” for the food processing industry. The Nowicki family has been committed to providing high-quality solutions for food processing for more than half a century, and BAK Food Equipment has been proud to be their North American partner for a significant portion of that time. “We are a longtime representative of NOMA equipment and are excited for this next phase of our partnership,” said John Bobak, president and founder of BAK Food Equipment. “NOMA’s passion for innovation and commitment to quality have made it easy to be a committed partner in North America. We’re proud to represent this brand and provide value to our customers.” As the exclusive North American distributor of NOMA, BAK Food Equipment provides a range of NOMA equipment, including tumblers, meat injectors, meat grinders, and more. With a dedicated team of knowledgeable sales staff, talented engineers, and expert service technicians, BAK Food Equipment provides installation, design, engineering, and service for NOMA equipment nationwide.

Carolina Handling named a 2024 Raymond Dealer of Distinction

For the 33rd year in a row, Carolina Handling has been named a Dealer of Distinction (DOD) by The Raymond Corporation. The DOD award is given annually to the top performers among Raymond Solutions and Support Centers throughout North America. Carolina Handling, the exclusive Raymond Solutions and Support Center for the Carolinas, Georgia, Alabama and Florida’s Central time zone territory, is among only seven Raymond dealers to receive the designation for 2024. Being named a Dealer of Distinction is based on points scored in categories covering virtually all areas of the business including sales, service, parts, rentals, leasing, power and intralogistics solutions. The award signifies strength in the marketplace and operational excellence that drives growth and continuous improvement. “Carolina Handling’s DOD performance year after year is an endorsement of the elite level of service and support that we provide our customers,” said Carolina Handling President & CEO Brent Hillabrand. “The top scores consistently received in so many different areas of the business are a testament to our associates and the teamwork that allows us to achieve a high level of success, even as the material handling industry continues to evolve.” A continuing U.S. labor shortage and customer demands to meet an ever-growing consumer thirst for online shopping have spurred exponential growth in the warehousing and distribution segment, with an emphasis on new technology and automation to move products faster and more efficiently. As the material handling industry constantly evolves, Carolina Handling continues its evolution from a forklift-only provider to an end-to-end intralogistics solutions company offering a broad range of consulting, connected technologies, material handling equipment and service to support the growing and changing needs of the industry. A leading material handling equipment supplier in the Southeast, Carolina Handling this past January received the 2024 Most Valuable Partner (MVP) Award from the Material Handling Equipment Distributors Association (MHEDA), a recognition achieved by fewer than 10 percent of MHEDA’s 600 members.

What is the Reality of Selling? The way you do the things you do

Jeffrey, what’s the easiest way to make a sale?Jeffrey, what’s the best way to make a sale?Jeffrey, what’s the fastest way to make a sale? Same answer: there is none. There is no easy, best, fast way to make a sale. There are a million ways to make a sale but it’s not with a method or system. There are elements that get you there. Here are 13.5 strategies and principles (elements) that will help you get to the substitute for an easy, best, fast way to make a sale – a way to earn the sale. 1. As in life, you start with a philosophy. Mine is…I give value first, I help other people, I do my best at what I love to do, I establish long-term relationships with everyone, and I have fun (and I do that every day). What’s yours? Do you have one? Your core philosophy is what drives you into the sale and leads the prospect to an understanding of why you’re there. 2. The most important word in selling is YOU. Prospects don’t buy products and services. First, they buy salespeople. The first sale that’s made is “YOU.” Are they buying you? 3. Know “why you’re selling”, know your own WHY first. Your “why” supports and strengthens your belief system. When “why” is clear, everything is clear. NOTE: Your real why may be 3 or 4 “why’s” deep. Why are you in sales? “I’m in sales to make more money.” Why? “I need more money to support my family.” (closer) Why? “Two of my kids start college in the next two years, and I want them to be able to choose a school based on quality of education not price of education. (Aha! the real “why!”) Before you can affect others, you must get real with yourself. Do you know your real why? 4. The sale is in your head. The mindset by which you approach the sale will determine its outcome more than any other element of the selling process. Do you think “yes”? 5. Develop a belief system that can’t be penetrated. Believe in your company, your product, and yourself, or you won’t sell. Do you believe in you? 6. Develop a selfish attitude about being the best. Know who the most important person in the world is you. Unless you’re the best you can be for yourself, you’ll never be the best you can be to serve others. Don’t cheer for athletes’ cheer for yourself. You deserve it. Are you always striving to be your best? 7. Be your own Santa Claus. Provide your own gifts and toys. Give yourself whatever you want. Most of us don’t get what we want for Christmas unless we tell someone what we want or if you’re like me, go buy it yourself. For me, every day is Christmas, know why? I deserve it. What gifts have you given yourself? 8. Know “what you sell” in terms of the customer not in terms of you. People don’t care what you do unless they perceive it helps them. The way you explain your business and product determines the buying interest you create say it in terms of the prospect, not your company. Are you selling, or are they buying? 9. Sell it as if you were selling it to your own son or daughter. Give advice with it, help learn it, and the advantages of using it. Protect them. Who are you selling to? 10. Know your competitive advantages; learn them from your customers. The definition of competitive advantage is something that’s extremely important to your customers at which you excel (competitive advantage has nothing to do with the competition). Do you know your competitive advantages? 11. People buy for their reasons, not yours. Find out theirs first. Establishing their “why” is the basis of determining their true need(s). When you’re presenting, is it more than 50% about them? 12. Ask the wrong questions and get the wrong answers. The way you question will determine the way you sell. Refine yours every week, until their power is evident by the increase in your sales. Any questions? 13. Develop and ask questions that make the prospect think about themselves and answer in terms of you. Make them evaluate new information. Get them to give you answers in the form of information about themselves in terms of your product or service. What questions are you asking? 13.5 Transition from a salesperson to a resource. Become valuable. The more value you bring, the higher you’ll go. To become valuable, you must give value first and make the prospect perceive greater value than price, quality, and service. If two people offer the same product at the same price and give the same service, the one with the greater perceived value wins. How much value do you bring to your prospects and customers? Selling is a never-ending learning process. There is no one way to sell. If you seek to master the science of selling, you must master the elements one by one. Learn one a day and in five years, you will be the master of more than 1,000 elements and still take weekends off. About the Author: Jeffrey Gitomer is the author of twelve best-selling books including The Sales Bible, The Little Red Book of Selling, and The Little Gold Book of Yes! Attitude. His real-world ideas and content are also available as online courses at www.GitomerLearningAcademy.com. For information about training and seminars visit www.Gitomer.com or email Jeffrey at salesman@gitomer.com or call him at 704 333-1112.

Is your dealership embracing technology?

I recently attended MODEX 2024, and this year’s show was highly anticipated by professionals across our industry. Automation, robotics, software solutions, artificial intelligence, and more were all on display providing a glimpse into the future of our industry. With connected smart automation solutions aimed at streaming supply chain operations it made me think of different areas where a lift truck dealership could streamline their operations to gain efficiencies and improve their customer experience. This led me to the topic of ERP (Enterprise Resource Planning) integrations. ERP is your business system software where business activities such as procurement, work orders, accounting, operations, etc. are performed. There is a numerous amount of ERP providers that provide their version of a dealer management platform. Additionally, there are many legacy systems out there, however, these days, many dealers are migrating to a modern dealer management platform that allows for integrations. By definition, an ERP integration allows your operation to streamline business processes, improve efficiency, and facilitate seamless communication and data exchange between different systems, ultimately leading to enhanced decision-making and the ability to adapt to external and internal changes. In last month’s edition, I wrote about the importance of ‘data-driven decision making’ where I noted that in our ever-changing industry, the ability to make informed decisions swiftly and accurately can be the difference maker in running a successful dealership and remaining competitive in the market. A modern ERP system that allows for integrations will assist your management team in decision-making about productivity and profitability. Non-integrated systems result in manual data updates, meaning that information isn’t promptly integrated into the ERP system as it arises in ‘real-time.’ Consequently, you will have to have someone within your company dedicate time to manual data transfer and uploads, resulting in wasted time. As labor resources are at a premium these days, that wasted time could be better spent on sales growth activities. There are various methods to achieve ERP integration between your platform and other systems. One of these methods is an API, or Application Programming Interface, which is a set of rules, protocols, and tools that allows different software applications to communicate with each other. In addition to API, other methods include middleware, file transfer, web services, and EDI, or Electronic Data Interchange. While this is not a programming and technical monthly column, you should be aware of these methods of integration and discuss them with your current and/or prospective ERP providers. You will also want to make sure your ERP system can integrate with your various business systems (such as CRM software) and your various suppliers. Let’s explore the benefits of ERP integrations as they relate to your parts and service departments. Parts Department Does your current platform allow for direct communication between your suppliers and your ERP system? Having the ability to connect to integrate with your suppliers will help streamline your order and procurement process with real-time, instantaneous feedback on product, pricing, and availability. Other benefits for your parts department operation include: Eliminating pricing and stock count discrepancies No need to request or manually upload new price files, tapes, etc. Ability to work on one system (your ERP system) and not have to go back and forth to the supplier portal to check product information, price, availability, etc. The ability to provide end-to-end visibility into the supply chain, from suppliers to customers, is key to your parts department being competitive in your market. Your parts department managers can track the movement of parts, monitor lead times, and identify bottlenecks or breakdowns in the supply chain. They can then proactively address any issues because they will have better visibility of supply chain performance. Another great benefit of having your ERP system integrated with your suppliers is the ability to sell products online. If you currently have an e-commerce platform or are thinking about creating an e-commerce platform to sell your products online and grow your parts counter sales, this integration will be vital to the success of setting up or updating your e-commerce site. Service Department ERP integrations can equip your service managers with real-time data that allows them to manage service technician productivity and profitability more effectively. It will also allow you to streamline processes and enable data-driven decision-making. Other benefits for your service department operation include: Many modern ERP systems offer mobile applications that allow technicians to access work orders, customer information, and inventory data from their phones or tablets while in the field. If your ERP system does not have built-in mobile applications, there are mobile applications that can integrate with many legacy ERP systems as well. Mobile accessibility will empower technicians to work more efficiently, without needing to return to the office for information or updates. Integrations can also provide your technicians with access to detailed information about customer history, equipment specifications or manuals, and equipment service history. This allows your technicians to diagnose issues more accurately, order the right parts, and complete repairs right the first time, reducing rework. If your sales department and/or other departments operate on a CRM (Customer Relationship Management) platform, an ERP integration with the CRM can lead to enhanced communications with your customers. This facilitates more personalized and effective communication, which leads to improved customer relationships and loyalty because each customer experience touchpoint that your customer has with your business is uniform. Integrating your ERP systems with other software solutions and your supplier’s systems, will eliminate data silos, reduce manual data entry and errors, streamline processes, enhance visibility into your business operations, and ultimately improve productivity for all departments within your business. You will also foster collaboration amongst your various departments, which is crucial because it promotes cross-functional communication, teamwork, and employee engagement. About the Author: Chris Aiello is the Business Development Manager at TVH Parts Co. He has been in the equipment business for 17-plus years as a service manager, quality assurance manager, and business development manager. Chris now manages a national outside sales team selling replacement parts and accessories in various equipment markets

Future Business Silos

You have been following your standard business silos for many, many years. Let’s see, what do we have now: New sales Used sales Parts Service Short-term rentals Rentals with maintenance Rent to own (maybe) Other revenues and consulting I am not going to get into the GP Margins, since today’s numbers are all screwed up because of the pandemic and material and chip shortages that in turn increased your cost and thus your margin dollars even if you sold units below your expected margin percentage. And then the digital age hits you suggesting that you will have to modernize your systems and procedures to get more productive and thus improve your major KPIs. And then AI hits you and everybody telling you what you need to do to further improve the use of your data to increase sales, manage inventory, manage service and parts transactions, upsell other work and equipment, train and manage employee levels, and complete this upgrade while you are still managing to get back on track once inflation cools down to a level you can work with. Not only do you have to educate and plan for the future needs of your customers, OEMs, bankers, and employees, but your customers finding themselves in the same boat as you are going to expect guidance from you on how to upgrade their warehouse facilities whether they be a distributor or manufacturer. There are tons of emails and webinars to suggest how to adopt both the digital and AI worlds and receive financial results that will make you and them more profitable because of being more competitive in your markets. Competitive meaning your costs are lower, and your transactions are completed faster, with systems now available to customers to allow them to find, order, buy, receive, and pay for what they ordered when they need it. And, if possible, they would like this to happen without having to talk to anyone. Now you know what you must plan for. An example of what will be coming down the pike is provided by a company called Symbotic. They provide automation technology that reimagines the supply chain by developing technology that uses AI-powered robotics and software to provide the most efficient warehouse solution on the planet. Walmart, Target, and Albertsons are customers. Symbotic uses four steps to manage a warehouse. The Inbound Cell, where they process incoming pallets into storage. They can process 1700 cases per hour, compared to manual operations where 90-250 would be the norm. The Storage Structure, where products move at 25 miles per hour and are packed in ways that maximize vertical and horizontal storage density. As a result, customers can increase storage volume without increasing their real estate footprint. Case Retrieval comes next where orders are moved to outbound lifts and sequenced to Outbound Cells. Outbound Cells receive goods that have been ordered that are then palletized by density and stability at a cell rate of 1350 cases per hour. The ROI is outstanding because of LOWER OPERATING COSTS, 5-9x OUTBOUND EFFICIENCY IMPROVEMENT, 30-60% FOOTPRINT REDUCTION, INCREASED PALLET CAPICITY, LOWER TRANSPORT COSTS, FASTER INVENTORY TURNS AND 99.99% TASK ACCURACY. Sure, this is not cheap to do at present, but I can assure you that it will be available for more users sooner than you think. As your distributor or manufacturing warehouse customers read about results like this using robots and systems to reduce costs that would make them more competitive in their market, they will want data and input about these types of systems, which in many cases will fall into your lap for answers and suggestions. Now, knowing these changes are coming, let’s go back to your silos and see how they may change. The BIG change I see is in the CONSULTING AREA. Customers want more from their vendors. Customers will expect a lift truck dealer to provide ideas and suggestions on how to reduce costs and improve efficiency. If you cannot do that, they will find someone who can. Many dealers provide services regarding warehouse operations using internal staff or “partners’ that have more technical expertise to improve upon the systems and procedures currently being used. I assume OEMs would also want to participate in ways where their equipment could be used as more digital changes come into the marketplace. As far as the other silos are concerned, I can see new units that can provide robotic drivers would be in demand at much higher price levels. I can also see that the parts and service business would need to keep these units working and have a very high utilization rate. I don’t see these types of units being utilized through short-term rental but more in line with rental with full maintenance, priced at a premium because these units need to be working at maximum utilization. So, you need a very good group of techs. Maybe the warehouse consulting group has its own parts and service department. Your parts fill rate will also have to be close to 100%. Partnership arrangements of some sort would have to be made with warehouse system developers that could engineer a change in the AI world. There is going to be a lot of money to be made to help distributors and manufacturers reduce their overall material handling requirements. But these opportunities will cost the dealer as well and they develop the expertise to service their customers to a new level of profitability. About the Columnist: Garry Bartecki is a CPA MBA with GB Financial Services LLC and a Wholesaler columnist since August 1993. E-mail editorial@mhwmag.com to contact Garry.

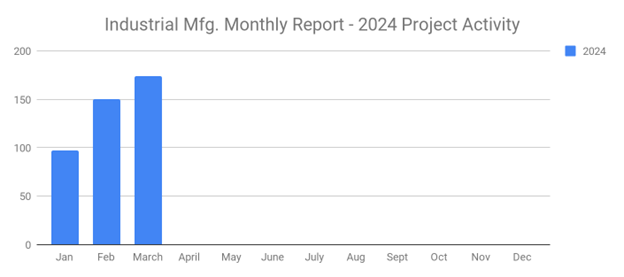

Q1 2024 Ends on a strong note with March producing 174 new Industrial Manufacturing planned projects

Industrial SalesLeads just released the March 2024 results for the new planned capital project spending report for the Industrial Manufacturing industry. The Firm tracks North American planned industrial capital project activity, including facility expansions, new plant construction, and significant equipment modernization projects. Research confirms 174 new projects in the Industrial Manufacturing sector as compared to 150 in February 2024. The following are selected highlights on new Industrial Manufacturing industry construction news. Industrial Manufacturing – By Project Type Manufacturing/Production Facilities – 154 New Projects Distribution and Industrial Warehouse – 71 New Projects Industrial Manufacturing – By Project Scope/Activity New Construction – 60 New Projects Expansion – 46 New Projects Renovations/Equipment Upgrades – 74 New Projects Plant Closings – 16 New Projects Industrial Manufacturing – By Project Location (Top 10 States) Texas – 18 Indiana – 16 Michigan – 14 North Carolina – 12 California – 10 Ohio – 9 Arizona – 7 Illinois – 6 Ontario – 6 South Carolina – 5 Largest Planned Project During the month of March, our research team identified 25 new Industrial Manufacturing facility construction projects with an estimated value of $100 million or more. The largest project is owned by Intel Corporation, who is investing $28 billion for the construction of a manufacturing and office campus in NEW ALBANY, OH. Completion is slated for late 2026. Top 10 Tracked Industrial Manufacturing Projects SOUTH CAROLINA: EV battery MFR. is planning to invest $1.5 billion for the expansion of its manufacturing facility in FLORENCE, SC. They have recently received approval for the project. Completion is slated for 2027. MICHIGAN: Specialty glass and ceramic product mfr. is planning to invest $900 million in the construction of a solar component manufacturing facility in RICHLAND TOWNSHIP, MI. They are currently seeking approval for the project. Completion is slated for 2028. WASHINGTON: Steel company is considering investing $860 million for the construction of a manufacturing facility and currently seeking a site in WA. Watch SalesLeads for updates. INDIANA: Construction equipment MFR. is planning to invest $725 million for a 300,000 SF expansion and equipment upgrades on their manufacturing facility in LAFAYETTE, IN. They have recently received approval for the project. Completion is slated for late 2027. CALIFORNIA: A pharmaceutical company is planning to invest $562 million for the renovation and equipment upgrades on a 427,000 SF processing, laboratory, warehouse, and office facility at 1000 New Horizons Way in VACAVILLE, CA. They are currently seeking approval for the project. OHIO: Graphite product MFR. is planning to invest $435 million in the construction of a manufacturing facility in NILES, OH. They are currently seeking approval for the project. CALIFORNIA: Startup battery MFR. is considering investing $400 million for the construction of a manufacturing facility and currently seeking a site in NORTHERN CALIFORNIA. Watch SalesLeads for updates. NORTH CAROLINA: Pharmaceutical packaging and containment solutions provider is planning to invest $371 million for the construction of a manufacturing facility in WILSON, NC. They are currently seeking approval for the project. Construction is expected to start in late 2024, with completion slated for 2027. KANSAS: Roofing products MFR. is planning to invest $300 million for the construction of a 275,000 SF manufacturing facility in NEWTON, KS. They are currently seeking approval for the project. Construction is expected to start in Summer 2024, with completion slated for 2027. TEXAS: An aerospace company is planning to invest $272 million for the renovation and equipment upgrades on a 447,000 SF manufacturing facility at 15100 N. Beach St. in FORT WORTH, TX. They are currently seeking approval for the project. About Industrial SalesLeads, Inc. Since 1959, Industrial SalesLeads, based in Jacksonville, FL is a leader in delivering industrial capital project intelligence and prospecting services for sales and marketing teams to ensure a predictable and scalable pipeline. Our Industrial Market Intelligence, IMI identifies timely insights on companies planning significant capital investments such as new construction, expansion, relocation, equipment modernization, and plant closings in industrial facilities. The Outsourced Prospecting Services, an extension to your sales team, is designed to drive growth with qualified meetings and appointments for your internal sales team. Visit us at salesleadsinc.com.

Nucor announces appointment of Nicole B. Theophilus as Executive Vice President of Talent and Human Resources

Nucor Corporation has announced the appointment of Nicole B. Theophilus to the newly created position of Executive Vice President of Talent and Human Resources, effective April 29, 2024. In this role, Ms. Theophilus will focus on Nucor’s enterprise talent development and human resources strategy. Ms. Theophilus, 54, most recently served as Executive Vice President and Chief Human Resources Officer of Wabtec Corporation, a global provider of equipment, systems, digital solutions and services for the freight and transit rail sectors. Her previous leadership roles include serving as Chief Human Resources Officer of West Corporation and ConAgra Foods, Inc. Prior to joining ConAgra, she was a partner with the law firm of Blackwell Sanders Peper Martin, LLP (now known as Husch Blackwell). “Niki is an accomplished leader who will be a strong addition to our executive team,” said Leon Topalian, Nucor’s Chair, President and Chief Executive Officer. “In keeping with our culture of taking care of our team, we created this executive-level position to better serve our teammates. We look forward to welcoming Niki to Nucor and working alongside her in advancing the important work already underway on the growth, retention and development of all Nucor teammates.”

Shoppa’s received awards from Toyota Material Handling

Shoppa’s has announced that Toyota Material Handling (TMH), its main brand manufacturer, has awarded Shoppa’s Mid America the Toyota President’s Award in recognition of excellence in parts, service, equipment sales, overall operations, and customer satisfaction. This coveted award is the highest honor a Toyota Material Handling dealership can receive. Only fifteen (15) winners from across North America were announced at Toyota’s annual forklift dealer meeting in Phoenix, Arizona last week. “I’m thrilled and delighted that our Shoppa’s team has brought home the prestigious Toyota President’s Award,” says Jim Shoppa, president of Shoppa’s Material Handling. “Our mission is to be the best partner for our customers in the material handling industry and this recognition speaks to our success.” Shoppa’s Mid America was also awarded the Parts Excellence Award for excelling in parts inventory management, parts sales, training, parts market share, and customer satisfaction. Shoppa’s Material Handling, headquartered in Fort Worth, TX, was awarded the Sales Excellence Award, Sales Elite Award, and the Toyota Material HandlingHeavy Duty Dealer of the Year Award. “These awards speak to how seriously everyone in the Shoppa’s organization takes their responsibility to put the customer first,” said Jim Shoppa. He continued, “Our goal is to be the premier material handling solutions provider in all our locations.” “Toyota Material Handling dealers have a long-standing reputation for going above and beyond for their customers and the [awarded] dealers represent the best of the company’s customer service standards,” said Bill Finerty, TMH president & CEO.

U.S. Rail Report for the week ending April 13, 2024

The Association of American Railroads (AAR) reported U.S. rail traffic for the week ending April 13, 2024. Total U.S. weekly rail traffic was 466,463 carloads and intermodal units, up 1.5 percent compared with the same week last year. Total carloads for the week ending April 13 were 208,381 carloads, down 8.2 percent compared with the same week in 2023, while U.S. weekly intermodal volume was 258,082 containers and trailers, up 11.0 percent compared to 2023. Four of the 10 carload commodity groups posted an increase compared with the same week in 2023. They included motor vehicles and parts, up 1,420 carloads, to 16,288; petroleum and petroleum products, up 1,352 carloads, to 10,403; and farm products excl. grain, and food, up 788 carloads, to 17,002. Commodity groups that posted decreases compared with the same week in 2023 included coal, down 17,826 carloads, to 45,218; metallic ores and metals, down 3,095 carloads, to 18,658; and nonmetallic minerals, down 1,301 carloads, to 31,631. For the first 15 weeks of 2024, U.S. railroads reported a cumulative volume of 3,191,350 carloads, down 4.5 percent from the same point last year; and 3,767,729 intermodal units, up 9.1 percent from last year. Total combined U.S. traffic for the first 15 weeks of 2024 was 6,959,079 carloads and intermodal units, an increase of 2.4 percent compared to last year. North American rail volume for the week ending April 13, 2024, on 10 reporting U.S., Canadian and Mexican railroads totaled 318,299 carloads, down 6.3 percent compared with the same week last year, and 343,760 intermodal units, up 9.7 percent compared with last year. Total combined weekly rail traffic in North America was 662,059 carloads and intermodal units, up 1.4 percent. North American rail volume for the first 15 weeks of 2024 was 9,789,570 carloads and intermodal units, up 2.2 percent compared with 2023. Canadian railroads reported 91,978 carloads for the week, down 2.9 percent, and 73,043 intermodal units, up 8.2 percent compared with the same week in 2023. For the first 15 weeks of 2024, Canadian railroads reported a cumulative rail traffic volume of 2,383,956 carloads, containers and trailers, down 0.0 percent. Mexican railroads reported 17,940 carloads for the week, down 1.4 percent compared with the same week last year, and 12,635 intermodal units, down 4.9 percent. Cumulative volume on Mexican railroads for the first 15 weeks of 2024 was 446,535 carloads and intermodal containers and trailers, up 10.5 percent from the same point last year. View the report here.

ASSP honors Bobick for work on safety standards

The American Society of Safety Professionals (ASSP) has named Thomas G. Bobick the recipient of the 2024 Thomas F. Bresnahan Standards Medal for his extensive work in developing and advocating voluntary national consensus standards in occupational safety and health, including a groundbreaking heat stress management standard that is expected to save many lives. Bobick, Ph.D., P.E., CSP, CPE, is a safety engineer and ergonomist who is president of Bobick & Associates Consulting in Spokane Valley, WA. His wide range of practical experience covers more than 50 years in safety and health research with the federal government, including two decades of ergonomics research. For the past three years, Bobick served as chair of the A10.50 subcommittee that wrote the first voluntary national consensus standard on heat stress for workers in construction and demolition operations. ASSP published the new standard in February. Hundreds of thousands of workers face outdoor hazards such as high heat and humidity. “Workers have died from exposure to excessive heat, but there is no federal regulation focused on heat stress,” said John Johnson, CSP, chair of the ANSI/ASSP A10 standards committee on safety in construction and demolition operations. “Tom’s leadership on this important initiative was invaluable. The new standard outlines industry best practices and proven solutions to protect workers who do strenuous jobs in challenging conditions.” As a 20-year member of the A10 committee, Bobick has been directly involved in 10 safety standards subcommittees that have addressed workplace risks such as falls from height, musculoskeletal problems and hearing loss. He also was a member of the ASSP Standards Development Committee for four years. Bobick worked for 19 years at the U.S. Bureau of Mines and the Mine Safety and Health Administration, and 33 years at the National Institute for Occupational Safety and Health (NIOSH). His mining areas of focus included ventilation studies, noise abatement, methane gas control to eliminate underground explosions, and the redesign of tasks to reduce upper extremity and low-back injuries. With NIOSH, Bobick was involved in safety projects in meatpacking, wood products manufacturing, apple harvesting, residential construction and warehousing. Bobick was the project officer for a team of NIOSH researchers who designed a new guardrail system in residential construction. The patented system was lab and field tested for more than five years, and is now a life-saving commercial product that has prevented workers from sliding off steep-sloped roofs. “Tom’s entire career has been focused on preventing worker injuries and fatalities through consensus standards development, process modifications and equipment redesigns,” Johnson said. “He understands that government regulations are slow to change and often out of date, so federal compliance is not sufficient to protect workers. With his enthusiasm and tenacity, Tom has helped get key standards created or updated in a timely manner.” Bobick will be honored at ASSP’s Safety 2024 Professional Development Conference and Exposition, held Aug. 7-9 in Denver. The global event will bring together thousands of safety professionals to learn about best practices, industry trends and the latest product innovations in workplace safety and health. The Thomas F. Bresnahan Standards Medal recognizes an ASSP member who actively participates in developing voluntary national consensus standards that advance worker safety. The award is named in honor of Thomas F. Bresnahan, a former ASSP staff member and Fellow who reinvigorated the Society’s standards development program and helped position the organization for growth in this strategic area.

Felling Trailers’ chosen for Atlas Foundation Company’s specialized trailer needs

Atlas Foundation Company is a deep foundation and earth retention solutions provider. Founded in 1968, the company started strictly as a pile-driving company but quickly expanded into caissons (drilled piers), micropile, earth retention, and helical piers. Atlas’ Micro Pile Division had acquired an overseas manufacturer to design and build a custom water pump to be used for extremely specialized deep foundation drilling applications, the only pump of its kind in the United States. For this custom application, the pump needed to be mounted to a trailer for ease of transport to and from jobs, as well as maneuverability on job sites. This trailer would need to be designed and engineered around the specifications of the water pump, along with incorporating usability and safety for the crew operating it. Atlas Foundation’s Superintendent of Maintenance and Shop Repair, Larry Boeke, had previously worked with Felling Trailers and knew they were the right manufacturer for the project. Atlas Foundation has close to a dozen Felling trailers currently in their fleet. Larry had worked with Felling’s Mike Wolff, who at the time was part of the Service team, to set up the refurbishing of five of their trailers over 5-10 years; most of these trailers are 20+ years old. “After decades of experience using and maintaining Felling Trailers, it was an easy choice for me to reach out to Mike. Mike had done a fantastic job with us on previous projects. I knew I only wanted to work with Felling,” said Larry. Larry contacted Mike, who was now in trailer sales, and explained the scope of the project to him. “Mike immediately put me in contact with T.J. Schwartz, Felling’s OEM trailer specialist, to get the ball rolling,” said Larry. The three met together multiple times to review the requirements and specifications that would need to be incorporated into this trailer build. An FT-20 WD (wide deck) was selected as the base model for the trailer. Mike, T.J., and Felling’s Engineering team collaborated with Larry’s team at Atlas along with the overseas water pump vendor through the duration of the design process. “It was a needs team effort, and Larry was very accommodating in helping us (Felling) to understand what the application was, what environment the trailer would be utilized in, and what features needed to be incorporated for operator safety and functionality for the Atlas team,” said Mike Wolff. Throughout the design process, there were many changes; some were small, like shortening up the overall trailer length. Others were more detailed, like incorporating pull-out steps/platforms and handrails, for the crew to access the deck safely. “The selection of Grat-X decking was made in place of standard decking for crew safety. When the unit is used in cold weather environments, the crew must disconnect water lines and drain the pump at the end of each shift to prevent freezing. The Grat-X decking allows for the water to pass through to the ground below, preventing water/ice build-up, greatly reducing the likelihood of the crew slipping,” said Schwartz. Attention to the fine details was key. With the pump still in production, the teams worked off drawings and maintained continuous communication with the overseas vendor. “We worked closely with the pump vendor to verify the water pump’s overall size and weight and determine the center of gravity for proper axle placement. We had to really pay attention to the smaller details and plan for things like compartment door clearance for mounting a spare tire, clearance for personnel to access the deck from all sides, and so on,” said Boeke. With the design process completed the trailer then moved onto the production floor. Built to spec, this high-pressure water pump trailer was constructed with Grat-X (expanded metal) decking with custom mounting provisions for the skid-based water pump, 8’ pull-out grip strut side steps on curbside, roadside, and along the rear tailboard. Rear stabilizer jacks, along with two heavy-duty storage boxes provided by Atlas Foundation Co., were mounted on the rear of the trailer. Once assembled and inspected, the finished trailer was delivered to Atlas Foundation, Co., where the one-of-a-kind pump was mounted to the trailer and put into service. “In my opinion, Felling builds the best construction equipment transport trailer on the market. They are extremely heavy-duty from front to back. I would say that my experience with Felling has always been positive. From their parts and service department to the refurbish division, to now having had the chance to work with their engineering and design team, and then finishing up with the production division. Every interaction has been positive and professional. I was impressed with how knowledgeable Mike and T.J. were throughout the entire process. I would recommend anyone that hasn’t given Felling a try yet to take a look and see how the team at Felling can help with a specialized project like ours,” said Boeke.

The five ways AI is changing service provision forever in 2024

Machine learning and Artificial Intelligence are increasingly becoming must-have options to assist the growing number of operations and processes in the service industry. Here, Mark Brewer, VP Service Industries at IFS, highlights his five industry predictions—all influenced by AI—for the upcoming year, and the opportunities these new trends open up for the delivery of service, ultimately leading to better customer experiences forever. In as little as two years, half of contact centers will rely on an AI copilot Customer contact centers have always had staffing issues. A global survey by NICE WEM found the contact center attrition rate was an astonishing 42%. Almost a third of agents surveyed were actively looking for a new job, and of those only 60% wanted another contact center role. That’s a lot of disaffected agents. A move to AI-enabled tech stacks in call centers can change this. It’s poised to increase customer satisfaction and help ease the pressure from rising voice call volumes by keeping agents supported, interested, and engaged. Gathering the information needed to resolve a customer call about a vehicle breakdown or a broken boiler is not easy. It’s high-stress and complex for the agent. The necessary details and logistical variables may well be held on multiple systems, yet all must be considered together to achieve a call resolution in real time. Enhancing agent processes with AI applications AI provides a way to support agents with a virtual assistant—a copilot—in real-time as they work processing calls. For example, an AI copilot could automatically triage, and visually prioritize, the most urgent calls for agents on a dashboard, based on voice recognition of key phrases mentioned in a request. Similarly, it could display context-sensitive information as the call is in progress—for example, prompts to try and diagnose a fault, or the proximity and travel time of the nearest qualified engineer. Here, intelligent autonomous technology is not replacing, but instead augmenting the agent, empowering them to deliver a better, more reassuring, and efficient customer experience. Supported by an AI-powered copilot, every agent becomes an expert—including those staff who are new or relatively inexperienced in the role. “Circular by Default” will be the new norm for 70% of service organizations by 2026 With increasing global scrutiny on sustainability, consumers and businesses alike want to retain products and equipment for longer. The circular economy has seen a shift in the sustainability model from stick to carrot: mandatory compliance with regulations has turned into active enthusiasm to become inherently sustainable. Organizations know that consumers now want to buy from environmentally conscious companies. Equally, the outcome-based service model is also becoming more attractive. As consumers start to subscribe to offers such as heating-as-a-service, suppliers can afford to optimally maintain assets to maximize their lifetime, reducing emissions, waste, and recycling. I also expect we will start to see self-healing capabilities being designed into new products such as appliances and vehicles, eliminating the cost, time, and environmental impact of unnecessary field service visits. Computer Vision will enable 30% of asset-centric organizations to see, observe, and understand the world better by 2027 Where AI enables computers to think, computer vision enables computers to see, observe, and understand. For example, in a manufacturing or process environment, AI can be trained to analyze and detect video imagery that would indicate a fault or safety hazard. Already, computer vision is being used in both the oil and gas and the maritime sectors to monitor and detect corrosion, informing timely manual inspections and preventative maintenance, whilst multi-camera-equipped autonomous robots monitor operations in factories and warehouses. Increasingly, passenger and commercial vehicles are now equipped with cameras, capturing video as they drive. By applying suitable image recognition algorithms, this stream data can be used for computer vision, and reporting maintenance issues for infrastructure. Examples include road signs obscured by overgrowth, tree growth abrading overhead cables and phone lines, and vehicles automatically detecting and reporting locations for potholes. Almost one-third of service organizations will introduce autonomous vehicles to boost productivity initiatives One of the key metrics in field service has always been productivity (utilization): the amount of a field engineer’s time actually spent on the job. This ‘wrench time’ typically ranges from anything between 50% and 95%, but most organizations are aiming for around 70 to 80% utilization. Driving can easily occupy 30% of an engineer’s day, with administration adding a further 20-30%. But with the introduction of autonomous vehicles, travel is no longer downtime. With an autonomous vehicle managing the driving, engineers can prepare for their next visit, ensuring they are prepared. Because autonomous journeys are digitally planned and routed, they are exceptionally efficient and take into account EV range and charging needs. Human drivers need help to perform this well. AI-driven IFS Planning & Scheduling Optimization (PSO) removes all the guesswork. As well as planning the optimum schedule and routes, the application uses real-time vehicle telemetry data to dynamically make changes—for instance stopping to charge for 10 minutes, allowing an engineer to reach two more extra jobs, increasing the engineer’s daily productivity by 50%. AI will become the preferred fleet manager for 4 out of 10 asset-centric service providers by 2026 Streamed video data from assets, interpreted by computer vision, will increase the visibility of what the fleet manager can see. For example, wind turbines are routinely equipped with IoT remote sensing. Turbine manufacturers have access to real-time performance and operational data from thousands of assets sold and maintained at hundreds of customer wind farm installations. Thanks to AI, intelligence from cameras, sensors, service records, and digital twin models can give fleet managers ultimate visibility. AI can quickly identify any wind farm that is performing more efficiently and generating more energy than other comparable sites. Moreover, it can compare specifications to pinpoint why: for example, because a site uses a different, and more effective, gearing calibration. At this point AI has identified a competitive advantage, and a sales opportunity for the manufacturer. It automatically generates a proposal to the operator of the under-performing wind farm site,

Dynamic forces in action: A look at the challenges and opportunities in warehousing today

As the nerve center for many material handling operations, warehouses provide an essential role. This month, Material Handling Wholesaler asked a few businesses in the industry about the latest trends in the dynamic environment of warehouse operations. Warehouse solutions At LD Systems, a company that helps warehouse operations find solutions, CEO Bob Sutphen said there have been three areas typically addressed recently. Those are space needs, needs to improve productivity, and a desire to cut down on errors. Sutphen said to address those concerns, LD Systems will first work to determine a company’s culture and customer expectations. “Once we’ve identified that, the next thing we want to do is look at their data,” he said. “Every time we do that, we almost always find things that surprise the customer.” While warehouse operators often are busy looking at production numbers, LD Systems can help identify areas of improvement, according to Sutphen, who said the company has worked on over 500 projects within 75 to 80 different industries. “We’ve learned what things to look for and what data we need to collect,” he said. As system integrators, LD Systems works to develop solutions that will address the needs and concerns based on the data. In the current environment, Sutphen said automating is often advisable. “If there’s an opportunity for automation, we definitely recommend that,” he said, noting one of the problems many warehouses are currently facing is attracting and keeping good labor. E-commerce continues to grow, but Sutphen said the associated costs burden some companies. “We have developed many solutions that can make people efficient, including reducing shipping costs,” he said, adding that he believes e-commerce will keep expanding. “It opens up all kinds of options,” said Sutphen, noting opportunities for packaging and other ways of reaching the end user. But while the volume of e-commerce will likely continue on an expansion track, Sutphen added that he expects some moderation in the pace. “People don’t necessarily always insist on next-day delivery,” he said. “There’s been some moderation in that because of the way parcel companies are charging for their services.” In general, Sutphen said the ideal timeframe for a project with LD Systems is six to nine months. As space becomes more expensive, reimagining existing space is a solution for many warehouses. “I rarely walk into a facility that we can’t do more in the same space,” Sutphen said. He encouraged warehouse operators to keep thinking in terms of innovation. “If you don’t do anything, your costs will increase,” he said, adding that each business’ competitors will continue evaluating how to meet the costs and expectations of the environment. “If you want to be one of the leaders, you have to innovate,” Sutphen said. Efficient and sustainable solutions With recent studies showing that 67% of organizations have environmental KPIs for their supply chains*, a key area of focus for warehouses is sustainability. At Enersys, Samuel Shiroff is Senior Director of Global Sustainability. The global battery manufacturer has set and is pursuing its own climate, energy, and water goals, according to Shiroff, who said the business’ energy use per kilowatt hour of storage is down more than 15 percent and water usage is down 2.5 percent versus 2020. “We are walking the walk,” he said. Shiroff noted that when talking about climate goals, there are three areas of focus or scopes. The first is what is burned, like gas or petroleum. The second is utility-related burns and the third is what is burned in the business value chain. “Scope 3 is very difficult to measure. Everybody is somebody else’s scope three,” Shiroff added. At EnerSys, the aim is to reach neutrality on scope 1 by 2040 and on scope 2 by 2050, according to Shiroff. He said the business’s carbon footprint overall has been lowered by over 4 percent year on year with its Scope 1 (direct emissions) down nearly 25% since 2019. Pursuing sustainability objectives adds value to the company and helps meet the expectations and interests of customers, shareholders, employees, and other stakeholders. The best people in the world don’t want to work for a company that harms the planet,” said Shiroff. In addition, such measures meet or exceed emerging regulations. Shiroff noted that expanding on what regulations demand can be beneficial. “If you do it just for the sake of compliance, you are leaving value on the table,” he said. “The distance between risk mitigation and opportunity creation is incremental.” For those starting out in a sustainability action plan, Shiroff recommended prioritizing aspects of each goal. He added that the internal person or staff working on corporate sustainability can help bring along others in the company. However, there is still a need for those involved to understand the details of what is required. Those businesses obligated to report to the European Union, for example, which Shiroff noted is estimated as at least 7,000 American companies, there are certain sustainability requirements. Shiroff noted that despite legal challenges to the new SEC climate disclosure rules, it would be risky to simply assume that they will be overturned. “The SEC was very careful about what they did,” Shiroff said. For Shiroff it is clear that energy efficiency is a key area of focus, but eventually, we will meet a point where that is maxed out. He notes that we will always need energy, but we do not need to get it from fossil fuels. Shiroff added that rooftops and adjacent property can be viewed as a key resource. “And energy sources within warehouses are also key, such as batteries like those offered by Enersys”, Shiroff said. “Our products themselves enable our customers to reduce their own carbon footprint,” said Shiroff, who said thin plate pure lead batteries are approximately 20 percent more efficient and lithium-ion approximately 25 percent more efficient than lead acid. “Add to that a more efficient charger and just by switching battery technology you can gain more than 30 percent efficiency in energy cost as well as reducing carbon,” Shiroff said. Also key in the pursuit of sustainability is knowing

OTR announces opening date for Mexico facility

OTR Engineered Solutions (OTR) has announced that its new facility being built in Mexico is scheduled to commence business operations on August 1, 2024. Located in Apodaca, a city in the Monterrey metropolitan area, the building site was strategically selected to supply OEM customers with products and services such as tire mounting, sequencing, just-in-time supply, and warehousing on a local basis. These value-added services are a specialty of OTR. Located on a 9.75-acre lot, the 152,738-square-foot building is comparable in size to OTR’s domestic facilities in Rome, Ga., and Fort Worth, Texas. In addition to its proximity to strategic OEM customers, the site offers convenient access to main roads and public transportation, helping to attract skilled labor and maximize distribution efficiency. Construction of the new facility is on schedule. The building has been erected, and tenant improvements are currently being made, including the installation of electric, lighting, compressed air and fire suppression systems, as well as offices. “We’re eagerly anticipating the August opening of the Apodaca facility so we can begin working even more closely with multiple OEMs operating in the Monterrey area,” said Tom Rizzi, President and CEO. “This move exemplifies OTR’s commitment to customers and dedication to serving our business partners.” Upon completion, the Mexico location will mark OTR’s 32 nd facility worldwide.