RAYMOND announces 2024 funding recipients for University Research Program

University Research Program has invested more than $5 million in funding to advance the future of material handling The Raymond Corporation has selected three research proposals to receive funding through The Raymond Corporation University Research Program. Through the program, professors and student researchers are encouraged to apply their engineering and technical research to discover innovative solutions for the material handling industry. After reviewing innovative research ideas from more than 20 universities, Raymond has selected three proposals to receive financial support. The research proposals selected for funding are: RetroLifts: Low-cost Forklift Retrofits for Scalable Autonomous Brownfield Deployments Proposal Author: Associate Professor Rahul Mangharam, University of Pennsylvania (Penn Engineering) Real-time Mixed Human-Robot Teaming using Digital Twins Proposal Author: Associate Dean and Professor Silvia Ferrari, Cornell University Framework for Effective Human-AMR Communication Proposal Author: Associate Professor Clark Hochgraf, Rochester Institute of Technology (RIT) The University Research Program helps to drive the next generation of technology for the supply chain, logistics and material handling industries. The mission is to encourage professors and researchers to apply their knowledge of engineering and technical fields, drawing synergies and collaboration between collegiate research and The Raymond Corporation. The University Research Program has funded 18 projects from 20 leading universities across the country, totaling more than $5 million in funding. The selected applicants have been evaluated on several criteria, including their possible impact on the future of the material handling industry, timeline and feasibility of budget. “Our University Research Program embodies Raymond’s steadfast dedication to empowering the future leaders of the material handling industry,” said Mike Field, president and CEO of The Raymond Corporation. “By collaborating with the brightest minds in academia, we aim to tackle present-day obstacles while pioneering innovative technologies and automated solutions that will shape the industry’s trajectory for years. We eagerly anticipate the transformative contributions these individuals will bring to the forefront of our industry.” The University Research Program will begin accepting one page concept papers this summer with applications due by the end of October for the 2025 program.

TerraSource Global CEO, Kevin Hambrice, elected to Board of Conveyor Equipment Manufacturers Association (CEMA)

TerraSource Global has announced the election of CEO Kevin Hambrice to the Board of Directors of the Conveyor Equipment Manufacturers Association (CEMA) for a three-year tenure. He was elected at the organization’s Annual Meeting held in Orlando, FL, March 1-5, 2024. Kevin Hambrice, CEO at TerraSource Global, said, “CEMA is the voice of the conveyor industry, representing manufacturers, integrators, and designers of conveyor equipment. I am honored to join their Board of Directors to promote the growth of our industry and the advancement of material handling technology through a common commitment to standardization and safety.” Founded in 1933, CEMA is a trade association serving manufacturers and designers of conveyor equipment worldwide. Headquartered in Florida, the association consists of 140 companies that represent the leading designers, manufacturers, and installers of conveyors, conveyor components, and material handling systems. Member companies work together to create voluntary standards, safety, manufacture, and applications to promote growth in the industry.

METTLER TOLEDO launches new generation of laboratory balances

METTLER TOLEDO positions itself at the forefront of laboratory weighing when it comes to simplicity, performance, and robustness. With the introduction of the new Advanced and Standard Balance portfolio, including MX, MR, MA and LA lines, METTLER TOLEDO positions itself at the forefront of laboratory weighing when it comes to simplicity, performance, and robustness. The new balances provide even greater resilience, measurement performance, and a simpler user interface for a smooth, precise, and sustainable weighing experience. Laboratories from large enterprises, medium-sized companies, and startups worldwide will have a more comprehensive and superior selection of balances to ensure accurate weighing. Customers will benefit from a broad range of balance models that meet the needs of every user, industry, and workplace, from advanced weighing requirements to the most essential weighing needs. The new portfolio is engineered for enhanced user experience, designed with sustainability in mind, and built with the highest quality materials for trusted and durable performance. The MX balances boast weighing performance, effortless data management, and user-friendliness. With innovative engineering, these balances provide an ergonomic weighing experience and satisfy advanced weighing requirements. These balances include the SmartPan, StatusLight, ErgoDoors, Illuminated Draft Shield, and a wide range of GxP functionality. MR balances deliver consistently accurate results even in the harshest weighing environments. Thanks to their robust construction, these balances are the perfect choice whether you weigh in a busy lab or the challenging conditions of a production setting. A range of built-in applications and connectivity options make MR balances highly versatile. The MR balances are perfect for daily usage, exceptional durability, easy cleaning, and seamless integration. MA balances are designed with a focus on valuable, practical features, these reliable balances deliver quality without compromise. Touch control on a bright LCD screen, simple menus, guided applications, and easy result documentation make weighing a breeze. With a wide portfolio that features balances covering readabilities from 0.01 mg down to 1 g, including large platforms, and even portable and compact models, there’s an MA balance for all your everyday weighing tasks. LA balances offer simple functionality without compromising on quality. The robust construction and reliable load cell ensure you get accurate weighing results you can trust. These entry-level balances are an affordable, trustworthy solution for your essential weighing tasks. These balances feature a bright LCD display for optimal reading in all conditions. With an RS232 interface, you can connect to a printer, secondary display, or other device.

Kassow Robots Launches the KR Pulse Ecosystem

Kassow Robots, a manufacturer of easy-to-operate 7-axis lightweight robots, has launched its KR Pulse ecosystem. The aim of KR Pulse is to enable systems integrators and industrial end customers to seamlessly combine Kassow Robots cobots with end-of-arm tools and software solutions. Copenhagen-based Kassow Robots, majority owned by Bosch Rexroth, has added a new ecosystem section to their website. “The launch of KR Pulse is a milestone for Kassow Robots,” says Kristian Kassow, the company’s founder, co-owner, and CEO. “With our ecosystem for peripheral devices and software, our end customers and partners can now implement cobot solutions even more quickly. The easy integration of our cobots into automation processes has been an essential part of our business concept since the beginning. KR Pulse further strengthens this approach.” The approach to which Kassow refers is the core idea of his 7-axis lightweight cobots: to enable industrial end customers to automate more flexibly than is possible with conventional cobots. KR Pulse comprises components, application kits, engineering tools KR Pulse is made up of three segments: components such as grippers or vision systems, application kits such as hardware for applications like welding or dispensing, and engineering tools to foster processes such as simulation. Máté Olah pushes KR Pulse forward Máté Oláh, Business Development Manager for Kassow Robots, who has put major effort into developing KR Pulse says: “The open innovation culture among technology suppliers is the key to creating solutions that align with a flexible production environment. KR Pulse is the ideal ecosystem for this environment.” In 2024, Kassow Robots will continue to drive its systematic expansion of the KR Pulse ecosystem with strong partner companies ready to join in the coming months. C-Buns combine cobots with products from KR Pulse Kassow Robots C-Buns (compatibility bundles) are one of the most important building blocks of the KR Pulse ecosystem. They enable the seamless functional integration of other products with Kassow Robots cobots (plug and play), a capability that is in high demand for end customers today. Everybody knows how convenient it is, when you’re installing a printer at home, to be able to simply plug in the cord and activate the printer in the system settings. C-Buns allow plug and play functionality for partner solutions.

ASSP recruiting safety instructors for three events

The American Society of Safety Professionals (ASSP) is seeking a diverse group of occupational safety and health professionals to join its team of instructors now being formed for three education events. The world’s oldest professional safety organization is a longtime industry leader in providing continuing education for workplace safety and health professionals around the world. ASSP’s call for instructors includes courses to be delivered at SafetyFOCUS Fall 2024 on Oct. 21-25 online; SafetyFOCUS Winter 2025 in February; and Safety 2025 pre- and post-conference in July 2025 in Orlando. “It’s a terrific opportunity for safety and health experts to contribute to the development of their colleagues while advancing our industry, which ultimately will help us better protect workers everywhere,” said ASSP President Jim Thornton, CSP, CIH, FASSP, FAIHA. “Being a course instructor is truly a rewarding experience.” Courses range from a half-day to three days and focus on business and leadership skills, construction, fall protection, risk assessment and management, safety management systems and worker well-being. Prospective instructors must identify emerging issues, develop strategies for overcoming safety challenges and aim to expand attendee knowledge and professional skills. ASSP members serving on the Society’s Council on Professional Development will evaluate all instructor proposals against the following criteria: Degree to which the proposed course meets ASSP’s education objectives. Instructor’s presentation skills and teaching experience. Interest and need for the topic within the occupational safety and health profession. Interested instructors must submit a separate application for each course, with a maximum of four submissions per instructor. Please direct questions to ASSP’s professional development staff at safetyfocusinstructor@assp.org. Course proposals for all three events must be submitted online by April 12. ASSP will notify successful applicants via email by the end of May.

Delta’s 30 kW Wireless Charging System for electric forklifts, heavy-load AGVs, and yard trucks

Delta has recently obtained Federal Communications Commission (FCC) approval and METus* certification. The M∞Vair 30 kW model boasts 95% contactless power conversion efficiency and can be applied to large industrial e-vehicles, such as electric forklifts, heavy-load AGVs, yard trucks, and airport ground support equipment. Dave Morse, Vice President of Delta Americas’ Industrial and Automation, said, “As Industry 4.0 continues to evolve, Delta has leveraged its core competence in high-efficiency power electronics to develop innovative wireless charging systems capable of supporting the surging demand for electric forklifts and AGVs in smart factories. Our state-of-the-art 30kW wireless charging model is ready to enhance productivity and energy efficiency of electric industrial vehicles used in the logistics and manufacturing industries across the U.S. market.” Delta’s M∞Vair Series Wireless Charging Systems adopt industrial wireless charging technology, which is licensed by WiTricity, a U.S. wireless charging technology company. The Series features 1 kW and 30 kW models, along with the 3.3 kW and 10 kW ones, expected to arrive later this year. Each model is composed of a primary unit, which is connected to the AC supply, and a secondary unit for battery connection in industrial vehicles. The Series allows wireless charging over a gap of 20 mm to max. 150 mm for various batteries with 93% – 95% power conversion efficiency to reduce unnecessary energy waste for clients. The Series’ FCC and CE certifications are testaments to the safety and stability of its inductive coupling for power transmission and the use of the wireless communication Pad-to-Pad Link (PPL). The PPL communication is developed exclusively by Delta for wireless electrical transferal. It successfully solves the cross-talk issue of WIFI devices and allows a secondary unit of the Series to communicate only with the primary unit at a distance of 200 mm, ensuring the control of the wireless transfer of 30 kW power. This innovation demonstrates both Delta’s capability of cutting-edge technologies and the reliability of our wireless charging solutions. *Note: METus mark indicates that a product has met the minimum requirements of the applicable safety standards. It also validates the product’s continued compliance with these standards as evidenced by periodic factory follow-up inspections.

ALPS Inspection unveils BenchPlus™ Manual Leak Testing System

BenchPlus™ Manual Leak Testing System is ideal for off-line, supplemental testing, random sampling, R&D for new container development, and select slow production processes. ALPS Inspection is a manufacturer of non-destructive, in-line leak inspection equipment for empty plastic containers of all sizes, shapes, and materials. ALPS Inspection has announced the introduction of its latest innovation, BenchPlus Manual Leak Testing System. BenchPlus represents the value of manual leak testing, offering a compact, budget-friendly, and highly efficient solution tailored for various applications: off-line supplemental sampling, R&D new container development, and select slow production processes. Designed with versatility and precision in mind, BenchPlus is a benchtop system for manufacturers requiring reliable leak-detection capabilities. Its compact size offers a simple yet valuable addition to existing in-line inspection operations, facilitating testing of new designs or periodic calibration checks of in-line systems without downtime. It’s also a worthy investment for select slow production processes. “As we continue to push boundaries to provide the most advanced solutions, we’re acutely aware of the challenges our customers face in maintaining the highest quality leak inspection standards,” said Jill Shearer, General Manager with ALPS Inspection. “With the introduction of BenchPlus, we’re not just offering a leak-testing system; we’re providing a way to overcome critical obstacles in detection. Whether it’s accelerating product development or enhancing quality control, BenchPlus is designed to deliver precise results and actionable insights that directly address our customers’ unique needs.” The quick installation and uncomplicated operation of BenchPlus allows users to quickly switch between container sizes without the need for tools, with easily adjustable height and locator positioning. Capable of testing a variety of containers ranging from 1 ounce to 5 gallons, BenchPlus combines flexibility with performance. Additional key features of BenchPlus include: Compact and portable design, perfect for lab settings or the production floor. User-friendly manual operation with a single-button start. Intuitive Human Machine Interface (HMI) with advanced software features for effortless operation. Quick recipe loading and spin-off probe assemblies for efficient changeovers. A versatile tool for R&D, quality control, or slow applications. Shearer added, “The BenchPlus Leak Testing System unlocks valuable insights that drive improvement across the manufacturing process. From verifying the feasibility of new container designs to enhancing quality assurance through random sampling, BenchPlus provides the data manufacturers need to optimize production performance.” The ALPS BenchPlus Manual Leak Testing System is adept at supporting a wide range of blow molding processes. From Injection Stretch Blow Molded (ISBM), or Reheat Stretch Blow Molded (RSBM) PET containers, and Injection Blow Molded (IBM) pharma bottles to Extrusion Blow Molded (EBM Shuttle) bottles, BenchPlus offers advanced precision and reliability across diverse applications.

MODEX 2024 exceeds all expectations

MHI’s MODEX 2024 saw a record-shattering number of registered manufacturing and supply chain professionals, reaching a total of 48,733. The event, held March 11-14 in Atlanta, saw attendees engaged with 1,200 exhibitors showcasing the latest supply chain technology and innovation across three halls and 580,000 net square feet at the Georgia World Congress Center. This was the largest MODEX event to date for MHI, with 32% more registered visitors than MODEX 2022. “From attendance to exhibition space and educational sessions, MODEX 2024 exceeded all expectations, delivering our largest and most comprehensive supply chain event to date,” said John Paxton, CEO, “The success of this event is a testament to the industry’s ongoing vitality, dedication to innovation, and delivering world-class solutions for supply chain operations. It was a massive win for the entire industry.” “The excitement on the show floor and the engagement in educational sessions is a sign of the overall power of the supply chain industry and the demand for the latest solutions and technologies in the space,” added Daniel McKinnon, EVP of Exhibitions at MHI. “Attendees representing the Fortune 500, the top 100 retailers, and top 100 consumer goods firms brought large teams to MODEX with plans in hand and budgets in place to make large supply chain investments.” The biggest trends at MODEX surrounded digital supply chain solutions including automation, robotics, artificial intelligence, autonomous vehicles, augmented reality, the Internet of Things, and data analytics. “We’re seeing a big acceleration in the adoption of these technologies to build resilience, sustainability, and real-time responsiveness into operations,” said Paxton. “The solutions on display and the education offered this year reflected this trend.” The MODEX Supply Chain Conference sessions included 200 educational seminars and five keynotes. On March 11, Bill Seward, President, UPS Supply Chain Solutions, spoke on the lessons he has learned at the front lines of UPS’s supply chain efforts. The March 11 afternoon keynote tackled the future of smart ports with representatives from the Ports of Rotterdam, Long Beach, and Virginia. Futurist Gerd Leonhard discussed the exponential change we will see in the coming age of AI in his March 12 keynote. The March 13 keynote featured Coach Nick Saban who delighted and inspired the audience with tales leadership from his storied football career. During the March 13 afternoon keynote, MHI’s John Paxton and Deloitte’s Wanda Johnson released the findings of the 2024 MHI Annual Industry Report: “The Collaborative Supply Chain – Tech-Driven and Human-Centric.” during a panel discussion with four industry thought leaders. The report includes new insights into trends and technologies that are transforming supply chains and the priorities of the people who run them. The report can be downloaded here. MHI Industry Night with comedian Colin Jost was an exciting and entertaining evening. Five thousand dollars in proceeds from the event were donated to Atlanta’s Chattahoochee Riverkeeper and $63,200 was donated to the Material Handling Education Foundation to fund scholarships and programs for students and educators in our industry. Gig and Take was awarded the 2024 MHI StartUp Award at Industry Night. The StartUp Pavilion is a specialized area on the MODEX show floor where companies showcase emerging supply chain tech and innovation. This award was chosen by supply chain professionals at the MODEX event. Gig and Take impressed the judges with their software solution, showcasing a user-friendly interface and the capability to offer flexible, accessible schedules to workers, effectively mitigating concerns related to labor shortages. During this event, MHI announced the winners of the 2024 MHI Innovation Awards during MODEX. The MHI Innovation Awards serve to educate and provide valuable insights on the latest manufacturing and supply chain innovative products and services. The awards had 193 submissions from MODEX 2024 exhibitors, and the winners were: • Best Innovation of an Existing Product – ForwardX Robotics • Best IT Innovation – Configura, Inc. • Best New Innovation – Slip Robotics • Best New Innovation in Sustainability – Avery Dennison Student Day at MODEX introduced 367 high school and university students and educators to career opportunities in material handling, supply chain and logistics through hands-on learning and networking with industry professionals. This year’s Student Day combined an interactive educational session with a dynamic guided tour of the MODEX show floors. On-demand content from the event, including keynote sessions, educational sessions and video presentations will soon be available online at modexshow.com via MODEX Digital Entry. The next MHI-sponsored trade event will be ProMat 2025 held March 17-20 in Chicago’s McCormick Place. For more information on exhibiting at ProMat, or to register as an attendee, visit promatshow.com. The next MODEX will be held at the Georgia World Congress Center in 2026.

Fairchild Equipment unveils new facility in Cloquet

Fairchild Equipment has announced the relocation of its Duluth, Minnesota facility to a new, more expansive location at 1308 18th Street in Cloquet, Minnesota. This strategic move marks a significant milestone in Fairchild Equipment’s mission to deliver unparalleled material handling services and reinforces its commitment to customer satisfaction and community engagement. Spanning an impressive 20,300 square feet, the new Cloquet, Minnesota branch is specifically designed to support a larger material handling equipment parts and rental inventory, provide comprehensive in-house shop service, and accommodate the company’s broad product offerings. “Our steadfast dedication to our customers and the community is what drives our expansion,” said Mike Wolf, Director of Operations for the Western Division of Fairchild Equipment. “The Cloquet facility embodies our commitment to excellence and enables us to serve as a vital partner in the community, contributing significantly to local business success and strengthening community ties.” The new facility represents a leap forward in Fairchild Equipment’s ability to offer swift equipment maintenance and repair services, an expanded rental fleet, and a venue that better accommodates the company’s extensive product range. Doug Larsen, Fairchild Equipment’s Sales Director for Minnesota and North Dakota, expressed his enthusiasm about the opportunities the new location offers. “We are thrilled to unveil our new premises to our customers. This move not only allows us to better meet the needs of our customers in northern Minnesota but also showcases our commitment to delivering unparalleled service. The enhanced space, services, and product offerings at our new facility are a testament to the trust we have built with our customer base.” The Cloquet facility is now open and ready to serve the diverse needs of the material handling sector, promising an era of increased productivity, innovation, and community partnership for Fairchild Equipment.

PLA announces appointment of Steve Clark to Chief Executive Officer

Leadership change reflects the company’s focus on expanding supply chain services offerings. PLA, a portfolio company of Silver Oak Services Partners, LLC, has announced the appointment of Steve Clark as Chief Executive Officer. Steve joined the PLA leadership team in 2022 when Propak, the supply chain services company he founded in 1999, was acquired by PLA. This leadership transition comes at a time of increased demand for the company’s integrated pallet and logistics service offerings. “Steve’s experience building out innovative reverse logistics, 3PL, and freight capabilities uniquely positions him to lead PLA during this exciting phase of growth,” said Wade Glisson, Partner at Silver Oak, “We look forward to leveraging his unique skill set to realize the full potential of PLA’s service offering.” Clark added, “Our focus remains on supporting the needs of our customers as they continue to grow in this rapidly evolving market, and I’m honored to lead such a talented team of industry experts into the future of the pallet and logistics space.”

U.S. Rail Report for the Week Ending March 16, 2024

The Association of American Railroads (AAR) has reported U.S. rail traffic for the week ending March 16, 2024. Total U.S. weekly rail traffic was 474,596 carloads and intermodal units, up 6.7 percent compared with the same week last year. Total carloads for the week ending March 16 were 219,586 carloads, down 0.6 percent compared with the same week in 2023, while U.S. weekly intermodal volume was 255,010 containers and trailers, up 13.8 percent compared to 2023. Seven of the 10 carload commodity groups posted an increase compared with the same week in 2023. They included grain, up 3,638 carloads, to 21,108; chemicals, up 2,186 carloads, to 33,134; and petroleum and petroleum products, up 1,836 carloads, to 9,954. Commodity groups that posted decreases compared with the same week in 2023 were coal, down 12,033 carloads, to 55,990; metallic ores and metals, down 903 carloads, to 18,683; and forest products, down 92 carloads, to 8,431. For the first 11 weeks of 2024, U.S. railroads reported a cumulative volume of 2,344,887 carloads, down 4.1 percent from the same point last year; and 2,759,413 intermodal units, up 9.0 percent from last year. Total combined U.S. traffic for the first 11 weeks of 2024 was 5,104,300 carloads and intermodal units, an increase of 2.5 percent compared to last year. North American rail volume for the week ending March 16, 2024, on 12 reporting U.S., Canadian, and Mexican railroads totaled 332,985 carloads, up 1.0 percent compared with the same week last year, and 338,651 intermodal units, up 12.1 percent compared with last year. Total combined weekly rail traffic in North America was 671,636 carloads and intermodal units, up 6.3 percent. North American rail volume for the first 11 weeks of 2024 was 7,138,853 carloads and intermodal units, up 1.8 percent compared with 2023. Canadian railroads reported 96,016 carloads for the week, up 6.5 percent, and 71,109 intermodal units, up 7.6 percent compared with the same week in 2023. For the first 11 weeks of 2024, Canadian railroads reported a cumulative rail traffic volume of 1,721,727 carloads, containers, and trailers, down 1.1 percent. Mexican railroads reported 17,383 carloads for the week, down 7.5 percent compared with the same week last year, and 12,532 intermodal units, up 6.6 percent. Cumulative volume on Mexican railroads for the first 11 weeks of 2024 was 312,826 carloads and intermodal containers and trailers, up 7.7 percent from the same point last year. View the charts.

Raymond West celebrates 75 years as a Raymond Dealer

Raymond West is celebrating a significant milestone marking 75 years as a Raymond Intralogistics Solutions Provider. Raymond West has grown from an office in a Beverly Hills’ kitchen and the trunk of a Studebaker into a leading provider of forklifts, warehouse automation equipment, loading dock equipment, storage solutions, conveyor equipment, and much more. Raymond West Intralogistics Solutions boasts more than 1,400 employees, $831 million in annual revenue, and 21 branches across the West Coast. “As we mark our 75th year anniversary and partnership with the Raymond Corporation, we celebrate not just a milestone in time, but a journey of innovation, dedication, and growth,” said James Wilcox, President of Raymond West. “From the humble beginnings of a one-man operation in Southern California to becoming a leading end-to-endless intralogistics solution provider in the West, our success is a testament to the hard work and commitment of every member of our team, past and present.” “We’ve come far and will continue to aspire to set the standard for our clients in that whatever they need, the problem or challenge they have in their facility with material handling, we have the solution to Store, Move, and Optimize their operations,” added Wilcox. The company’s relationship with the Raymond Corporation began on March 15, 1949, when the W.T. Billard Company became a Raymond dealer. This partnership was further solidified in 1950 when Raymond introduced the narrow-aisle forklift, leading Billard to focus exclusively on Raymond products. Over the years, the company expanded throughout the region, opening branches in San Diego, Las Vegas, and Ontario. In 2002, the Raymond Corporation purchased W.T. Billard, and the company was rebranded as Raymond Handling Solutions. Under the leadership of James Wilcox, who became president in 2010, the company acquired Handling Systems Inc. in 2014 and Raymond Handling Concepts Corporation in 2018. This significantly expanded their sales and service footprint and gave them a presence in eight states, opening opportunities to store move and optimize your operations. In 2021, the three companies combined and rebranded as Raymond West Intralogistics Solutions. As Raymond West Intralogistics Solutions looks to the future, the company remains committed to providing the highest quality products and services to its clients, continuing the legacy that began 75 years ago.

Episode 471: A deep dive into AI in warehousing with Standard Insights’ Jerry Abiog

This episode of The New Warehouse Podcast features Jerry Abiog, CEO of Standard Insights, discussing the pivotal role of AI in warehousing. Standard Insights was a pioneer in leveraging AI before its mainstream adoption and offers innovative solutions to common industry challenges. This discussion, grounded in Jerry’s rich background and the evolution of AI in business, illuminates the path forward for warehouses seeking efficiency and growth in an increasingly digital landscape. The Genesis of Standard Insights Jerry traces the foundation of Standard Insights to his experiences in the AI and machine learning sectors. This experience eventually led to the conception of an AI-driven marketing platform to enhance customer retention. “This was in 2018-2019…I flew from Atlanta to the retail show out in Denver, Colorado, and came back with two beta clients,” Jerry recalls, emphasizing the novelty of AI at the time. The firm has since evolved, leveraging AI to give businesses a competitive edge by predicting customer behavior and optimizing inventory management. He shares, “Our first partners came from the fulfillment space because they knew they were dealing with lots of customers and data.” AI’s Role in Addressing Industry Challenges AI’s integration into warehousing operations marks a pivotal shift in tackling perennial issues such as labor shortages and inventory management. “We help businesses leverage that first-party data…leverage sales data and product data to make predictions,” Jerry explains, highlighting the potential of AI to transform vast data sets into actionable insights. By predicting customer profitability and purchase likelihood, AI enables more precise inventory forecasting and customer targeting, which is crucial for enhancing top-line and bottom-line growth. The Future of AI in Warehousing Looking ahead, Jerry envisions increased adoption of AI in warehousing, driven by the imperative to overcome operational inefficiencies and stay competitive. “I think with more education…they’re gonna get buy-in,” he speculates, pointing to the gradual but inevitable shift toward digital solutions. This transition, however, requires warehouses and 3PLs to navigate the learning curve associated with new technologies, underscoring the importance of choosing the right AI partner to mitigate business pains and harness the full potential of their data. Key Takeaways on AI in Warehousing AI can revolutionize warehousing by turning data into predictive insights for customer behavior and inventory needs. Standard Insights’ approach demonstrates the tangible benefits of AI in improving decision-making and operational efficiency. The future of warehousing hinges on adopting AI and other digital technologies to address critical challenges and enhance competitiveness. The New Warehouse Podcast Episode 471: A Deep Dive into AI in Warehousing with Standard Insights’ Jerry Abiog

Locus Robotics and GEODIS bring warehouse AMR automation to Mexico

New site is first GEODIS location in Latin America with this technology and features the Locus solution operating across three-level mezzanine Locus Robotics has announced a new implementation with GEODIS to bring high-performance, next-generation robotics automation to Mexico to fulfill e-commerce and retail orders for a major global apparel brand. The new site, GEODIS’ first in Latin America to feature Locus Robotics technology, is located in Cuautitlan Izcalli, Mexico, and features a fleet of Locus’s award-winning Origin bots operating across all levels of a three-level mezzanine structure, efficiently controlled by the innovative LocusOne warehouse execution platform. LocusOne enables efficient pick-and-pass, multi-level functionality while delivering real-time operational visibility and management insights to ensure high productivity and a fast ROI. “We are thrilled to work with GEODIS to bring the power of Locus’s warehouse automation to Mexico,” said Rick Faulk, CEO of Locus Robotics. “This deployment represents a significant expansion of our footprint into Latin America and enables us to support GEODIS in setting the new benchmark for e-commerce fulfillment efficiency in the region.” “Locus allows us to unlock significant productivity improvements while also creating an engaging work environment for our teammates,” said Kevin Stock, Executive Vice President of Engineering at GEODIS in Americas. “We are excited to deploy the Locus solution at this flagship site in Mexico where we will provide transformative workflow automation and management insight for a globally admired brand.” In August 2022, GEODIS announced a new expansion agreement to deploy a total of 1,000 LocusBots at GEODIS’ worldwide warehouse locations over the next 24 months. The announcement represented one of the industry’s largest AMR deals to date.

Kenco grows its next-generation material handling equipment capabilities with new offering

Automation Guidance, a service proven to save customers on average more than $2.5m annually, joins the Kenco MHE Solutions™ portfolio Kenco has announced it will launch Automation Guidance, a consulting offering dedicated to helping operations managers upgrade their existing facilities with automated material handling equipment (MHE) assets, which have become increasingly critical to their success. With the addition of Automation Guidance, an offering within Kenco MHE Solutions, supply chain professionals now have access to a complete lifecycle of MHE benefits. Market demands have created a need for faster, more efficient technology across the facility floor, and Automation Guidance will help managers envision, execute, and maintain upgrades to their existing infrastructure – from forklifts and pallet jacks to conveyors and robotic picking tools, and everything in between. “The reality for most supply chain professionals is that the “warehouse of the future” isn’t new construction – it’s the step-by-step automation of existing facilities, which can be an arduous process when tackled alone,” said Denis Reilly, CEO of Kenco. “Kenco is already known for our robust MHE maintenance and planning solutions, so we’re well positioned to help facility managers not only design an achievable MHE automation strategy but also execute in the long term.” The Kenco team designed Automation Guidance on the company’s deep pool of operational analytics, gathered from supply chains across North America. By combining its decades of experience with operational data from more than 110 distribution centers, Kenco can guide customers through a proven roadmap to maximize automated MHE efficiency. “For years, customers have pointed to Kenco’s trove of real-world data as one of our key differentiators. It gives us the ability to not only help customers manage their MHE day-to-day but also counsel them on the best approach to MHE automation for their specific needs,” said Jeff Burns, President of Kenco MHE Solutions. “Executing automation can feel like a Herculean task, but when customers apply our data pool to their project, it’s easier to find the needle in the haystack – the automated MHE tools that will make the biggest difference in their operations.” Kenco MHE Solutions has already made a measurable impact on existing customers – with some seeing as much as a 26% average reduction on total MHE spending through benefits from asset optimization, asset tracking, damage reduction, and increased equipment life. Through Automation Guidance, customers will see benefits for years to come.

AutoScheduler CEO Keith Moore discusses warehouse trends, innovation, and entrepreneurship

Legacy Systems Still Exist; it’s Time to Augment Their Capabilities Making Them Faster & Smarter. Keith Moore, CEO of AutoScheduler.AI discusses with Joe Rule on a Bold Visions podcast, current warehouse trends, and Keith’s entrepreneurial journey. Joe interviews people who work with disruptive technology and how they use the power of storytelling to turn vision into reality. “Logistics technology has gotten extremely popular since COVID,” says Keith Moore, CEO of AutoScheduler.AI. “It has moved from a cost center to a boardroom conversation.” A summary of the podcast discussion follows: There is much automation out there, and executives must discern which is best for their business. Robotics are being deployed everywhere, but not to replace people. Instead, companies can’t hire the people they need to do a specific job, so robots are helping fill the gap. Many legacy systems exist in companies, especially for mission-critical operations like the supply chain. Nobody’s willing to put the legacy system on hold for six months to install a new solution. Most companies may try to do this, but it’s like trying to change your tire while driving down the freeway. It is more valuable to be complementary to the existing systems. Replacing systems lengthens the sales cycle. The best way to sell a supply chain solution is “in addition to.” People replace their systems once every 5 – 10 years; some don’t even upgrade their software. When starting a company, it is hard to get your share of voice, but if you work with an industry analyst group, people will listen to them. Ensure you understand where companies get their information from and ensure the information is messaged appropriately through these sources. When these sources start writing about you, you become a trusted voice, and you can start building trust with everybody. Hire an industry-specific, outside PR firm. These agencies understand your industry, know the analysts and editors, and work closely to get your company in the stories that target your audience and make you a thought leader. New sales are great, but supporting current customers is better. AutoScheduler’s business mentality is to lose a sale to ensure an existing customer is supported and successful. Invest in partnerships to help your business grow. Based on how the warehousing landscape runs, every unique site has its own WMS. So, if a company has 250 sites, each site will have its own WMS with five to ten people per shift, ensuring the system is running and doing what it should. AutoScheduler’s objective is to centralize the planning and optimization of all the different sites in one location, with a team of 5 to 10 people managing all 250 sites. Keith’s entrepreneurial journey started while he was in college when he would buy a $5 pizza and sell it for $1/slice. He always knew he wanted to work for a startup, so he got a degree in Engineering. While working at National Instruments, he created a company in fantasy soccer. The company was growing but was shut down by the Attorney General for gambling. He then worked for Spark Cognition as a product manager, focusing on data analytics and machine learning. Then his dad, Tom Moore, CEO and Founder of ProvisionAi, told him about a tool he built while consulting for P&G. Tom said, “We’ve built this tool called AutoScheduler. Does it have any value? Is it something that could be used elsewhere?” So, Keith obtained the technology and decided to launch AutoScheduler.AI. AutoScheduler, a warehouse resource optimization platform, manages all the work coming in and out of the warehouse to streamline operations and improve efficiencies. It answers questions like, “What work must I do? How many people do we have to do it? How much space do you have? What inventory do you already have? What are the time-critical components, meaning what do I need to ship outbound to a Walmart now? AutoScheduler acts as the brain of the operation, which says, “Here’s exactly how you need to distribute all of your people at every point in time and exactly what they need to work on.” Keith uses a “Keith Moore Bar Test” to measure awareness. When he first started the company, if he went into a bar and people asked him where he worked, no one would know of AutoScheduler. Today, he can walk into a bar, and people will have heard of AutoScheduler.

Changing landscape

And that is the problem. Inflation or no inflation. GDP growth or inadequate GDP growth. Job claims that help and worker shortfall that does not. Interest rates too high or not high enough. Consumer spending to slow because of increasing personal debt balances. Just what are economic factors telling us that provide comfort because you feel the “conclusions” our “guesses” are reasonable? As you know I read many economic reports and follow the markets closely to get a feel for the industries I follow. One of those is drafted by John Mauldin who I read religiously every Friday evening. It is a free publication, prepared for anybody who needs to get a feel for what is going on in the economy, which I hope then will assist with your ability to make both personal and business decisions. John’s February 17, 2024, letter is titled CHOOSE YOUR OWN ECONOMY, primarily to explain the complexities in today’s economic environment whereby economists are having a hard time deciding what data sets to select to be able to produce a meaningful forecast, which is almost impossible to do. In short, recent forecasts have not been close and thus leave us hanging from a planning perspective. I tell myself there must be a report that works better than most that explains where we are heading, and I find the CB Leading Economic Index dated February 24. The LEI is made up of several indicators that anticipate turning points in the business cycle, which then in turn can anticipate where the economy is headed. On average, there are usually 10.6 months between a peak and a recession. This report has been in place for many years with the last peak in 2021 and we are 12.8% off the 21 peak, which puts us 25 months off from the 21 peak without a recession. With 10.6 months being the average for a recession to follow a peak, 25 months from the last peak in 21 makes me think we are closer to a recession than we think. POINT #1 for this month is to plan thinking there is trouble on the way. The next issue I found interesting this month is the reshoring movement to bring more manufacturing back to the US and the rest of North America. GOOD NEWS for lift truck dealers because these shops will require lift trucks for both the manufacturing and warehousing of materials or finished products. POINT #2 for this month is to research the possibility of who may be coming into your territory to do this work. I would ask the sales team to question customers as well as OEMs about any activity coming your way. City officials would normally have leads related to permits or any approval process required to do the work in that City. Contractors may also have leads if properties need to be upgraded for a new tenant. Another important issue arising is the use of AI to better provide services and products for less cost than those not using AI. This topic was all over the February/March Forbes talk about AI and robots to do work for less cost compared to current methods being used. The important point is that larger firms are spending to accomplish this goal to better compete with firms that are not. Usually, a smaller firm has an advantage cost-wise. That may not be true any longer. AI is also being used to close the union versus non-union gap from a cost standpoint. POINT #3 for this month is to decide if your major customers are at risk because another major dealer can now compete on a product and service basis. After all, they are now more efficient and can reduce costs. I see this as a major threat for many dealers who do not have the time or funding available to produce AI to reduce costs and improve customer service. This is happening NOW and should be considered when you ponder what your company may be worth a year from now. There is, however, some good news that could help you mitigate these problems. I have a couple of sale deals working and in reviewing the M&A markets I see that Private Equity firms are moving into situations where they want to keep investments longer to set up platform companies and then acquire add-ons to grow the operation and increase the value to produce a healthy ROI. Sellers could sell 100% and be paid off. Or they could leave a piece of the deal and play the growth game for bigger returns when the deal is finally turned over. Or dealers with the financial ability could become a platform, take on add-ons, and sell to a PE firm. There are many options available. A shareholder could take a lifestyle approach and take as much out every year as possible. Or take an investment approach to grow the company and increase overall wealth. POINT #4 for this month is to spend some time to see how you fit into this CHANGING LANDSCAPE. Put in the time, effort, and funding to protect your investment or invest to grow wealth. There appears to be plenty of opportunity coming down the line stemming from the government programs and reshoring efforts being made by manufacturers to reduce costs. This potential business, however, will go to the most professional firms, with high levels of customer service and competitive cost, which may not be one of the smaller dealers in town. A lot to think about. About the Columnist: Garry Bartecki is a CPA MBA with GB Financial Services LLC and a Wholesaler columnist since August 1993. E-mail editorial@mhwmag.com to contact Garry.

Navigating the Shift: Adapting to the changing forklift market

In the ever-evolving landscape of the forklift industry, staying ahead of market trends is crucial for resellers to maintain a competitive edge. Recent data on our platform indicates a significant shift in the market dynamics compared to January 2023, with the number of machines available for sale experiencing a notable 40% increase. Since mid-2023, the market for forklifts has transitioned from being predominantly seller-driven to favoring buyers, marking a substantial shift in dynamics. This shift has not only expanded the options available to buyers but has also instilled a sense of caution due to prevailing economic uncertainties. Consequently, we are observing an initial decline in prices, further exacerbated by rising interest costs. We even observe consolidation trends with bigger dealers swallowing up smaller ones. Considering these developments, forklift dealers must strategize and adapt to this new reality to optimize their sales and capitalize on emerging opportunities. Thanks to modern technology today, operational excellence is not limited to big corporations only. Let’s look at six strategies that can help forklift dealers in today’s: 1. Excel in your local market: If your website only shows outdated equipment or no equipment at all, visitors will not give you a call but jump to the next website they find on Google. In light of more available choices for buyers, make sure your website is up to date with available equipment including good images and complete technical data. Big dealers have their own staff for that but that is not mandatory. Modern marketplace solutions have built-in features to effortlessly integrate your used stock into websites and make your website and local business perform stronger than ever. 2. Expand your markets: Staying in your area is comfortable, but keeps you limited. Of course, it’s your favorite choice as a dealer to sell locally as you can add services. In a buyer’s market, this comfort is illusionary. Selling outside your area and selling to other dealers makes your company sell equipment faster and gain new customers. 3. Competitive Pricing and Timely Selling: In response to the shifting market dynamics, resellers are encouraged to advertise their inventory at competitive prices. Selling now enables resellers to leverage the proceeds to invest in “new” used equipment later at potentially lower prices. Even if it’s hard to accept lower margins, waiting too long to adjust will only result in less profit. 4. Optimized Advertisements: Enhance the visibility of listings by optimizing advertisements with high-quality images and compelling pricing. This proactive approach attracts more clicks and inquiries, maximizing the chances of successful transactions. 5. Agile Trading Approach: In a market characterized by fluctuating prices, agility is paramount. Resellers should prioritize swift transactions over maximizing margins on individual devices. By promptly listing and selling equipment in its current condition, resellers can capitalize on market fluctuations and maximize profitability. 6. Market Awareness and Price Adjustment: Stay vigilant of market trends and adjust pricing strategies accordingly. Every day a listing that remains active incurs costs, particularly with rising interest rates. Regularly updating prices to align with market conditions is essential to optimize returns. Bonus: Get expert support Navigating the complexities of a shifting market landscape can be challenging, but you don’t have to do it alone. If you are a small to medium-sized dealer with the challenges above, let’s set up a free one-hour consultation – limited to the first 20 dealers who contact us at dmillius@MHWmag.com Together, let’s navigate the changing tides and unlock new opportunities for growth and profitability. About the Author Chris Schmid is the CEO of Motus Group, the company behind Forklift-International.com, the largest international marketplace for used forklifts and material handling equipment. Before joining Motus, he led Sales & Marketing for a technology incubator, releasing and marketing software and e-commerce products. He was COO of a tech startup in Switzerland and San Francisco. Chris holds a master’s degree in international management from Reims Business School in France as well as the European School of Business in Reutlingen, Germany, and lives with his wife and three kids in Regensburg, Germany.

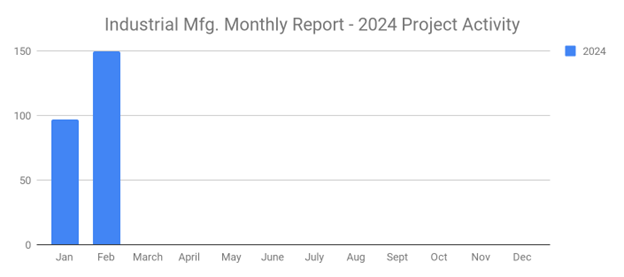

February 2024 jumps to a strong 150 new Industrial Manufacturing Planned Projects

Industrial SalesLeads has announced the February 2024 results for the new planned capital project spending report for the Industrial Manufacturing industry. The Firm tracks North American planned industrial capital project activity, including facility expansions, new plant construction, and significant equipment modernization projects. Research confirms 150 new projects in the Industrial Manufacturing sector as compared to 150 in January 2024. The following are selected highlights on new Industrial Manufacturing industry construction news. Industrial Manufacturing – By Project Type Manufacturing/Production Facilities – 134 New Projects Distribution and Industrial Warehouse – 61 New Projects Industrial Manufacturing – By Project Scope/Activity New Construction – 46 New Projects Expansion – 38 New Projects Renovations/Equipment Upgrades – 68 New Projects Plant Closings – 15 New Projects Industrial Manufacturing – By Project Location (Top 10 States) Ohio – 16 Indiana – 12 Georgia – 10 New York – 9 Texas – 8 Illinois – 7 Massachusetts – 7 Michigan – 7 North Carolina – 7 Quebec – 7 Largest Planned Project During the month of February, our research team identified 19 new Industrial Manufacturing facility construction projects with an estimated value of $100 million or more. The largest project is owned by Micron Technology Inc., which is planning to invest $100 billion for the construction of a 7.2 million sf manufacturing complex in CLAY, NY. They are currently seeking approval for the project. Construction will occur in phases, with completion slated for 2030. Top 10 Tracked Industrial Manufacturing Projects NEW YORK: Semiconductor MFR. is planning to invest $12 billion for the construction of a 358,000 SF manufacturing facility on their manufacturing campus in MALTA, NY. The project includes the expansion of their existing plant. Construction is expected to start in 2025. NORTH DAKOTA: A mining company is planning to invest $2 billion in the construction of an iron manufacturing facility in UNDERWOOD, ND. They have recently received approval for the project. NEW YORK: EV MFR. is planning to invest $500 million for the expansion of its manufacturing facility in BUFFALO, NY. They are currently seeking approval for the project. SOUTH CAROLINA: Battery MFR. is planning to invest $500 million for the construction of a 500,000 SF manufacturing facility in GREENVILLE, SC. They are currently seeking approval for the project. Construction is expected to start in early 2025, with completion slated for late 2027. FLORIDA: Clean hydrogen and solar technology company is planning to invest $450 million for the construction of a hydrogen processing and solar panel manufacturing facility in KISSIMMEE, FL. Construction is expected to start in Summer 2024, with completion slated for 2027. GEORGIA: Solar panel glass mfr. and recycling company is planning to invest $344 million for the construction of a manufacturing facility in CEDARTOWN, GA. They are currently seeking approval for the project. Completion is slated for 2026. WISCONSIN: Plumbing equipment MFR. is planning to invest $340 million in the construction of a manufacturing facility in DICKEYVILLE, WI. They have recently received approval for the project. Completion is slated for 2026. MARYLAND: Biopharmaceutical company is planning to invest $300 million for the renovation and equipment upgrades on a recently leased 84,000 SF processing facility at 9950 Medical Center Dr. in ROCKVILLE, MD. Completion is slated for 2026. WASHINGTON: Wood pellet MFR. is planning to invest $250 million for the construction of a manufacturing facility in PORT OF LONGVIEW, WA. They are currently seeking approval for the project. Construction is expected to start in Summer 2024, with completion slated for early 2025. INDIANA: Recycled paper products mfr. is planning to invest $130 million for the construction of a 350,000 SF manufacturing and warehouse facility on Park Rd. in ANDERSON, IN. They are currently seeking approval for the project. About Industrial SalesLeads, Inc. Since 1959, Industrial SalesLeads, based in Jacksonville, FL is a provider in delivering industrial capital project intelligence and prospecting services for sales and marketing teams to ensure a predictable and scalable pipeline. Our Industrial Market Intelligence, IMI identifies timely insights on companies planning significant capital investments such as new construction, expansion, relocation, equipment modernization, and plant closings in industrial facilities. The Outsourced Prospecting Services, an extension to your sales team, is designed to drive growth with qualified meetings and appointments for your internal sales team. Visit us at salesleadsinc.com.

Data-driven decision making

One of the MHEDA’s 2024 Material Handling Business Trends states, ‘Technology is profoundly impacting the material handling industry including artificial intelligence, digital automation, data-driven decision-making, and the integration of advanced systems that optimize efficiency, productivity, and safety. Members must have a clear understanding of emerging technologies.’ Let’s dissect that statement, in particular explore the topic of ‘data-driven decision making.’ In our ever-evolving industry, the ability to make informed decisions swiftly and accurately can be the difference maker in running a successful dealership and remaining competitive in the market. Nowhere is this more apparent than in the operations of your service department. The service department is tasked with maintaining, repairing, and optimizing the end customer’s equipment to ensure the customer’s warehouses and logistics operations run smoothly. The service manager is responsible for managing the department’s productivity and profitability. Therefore, the importance of data-driven decision-making cannot be overstated. Gone are the days when service departments relied solely on intuition or past experience to address maintenance issues or plan repairs. Today, the availability of data and advanced analytics tools empowers service managers and technicians to leverage valuable insights in real-time, leading to increased efficiency, reduced downtime, and ultimately, improved customer satisfaction. However, most dealerships I visit live with silos of data that do not integrate. The cost and difficulty of properly connecting all these data sets becomes a struggle for even the largest dealerships. If you must deal with orderly silos of data, it is important to identify the purpose of each data set. Then inside of those data sets identify what things need to be managed the most. Often service managers are tasked with manually running their own data reports to analyze. In today’s fast-paced environment, waiting for managers to manually run reports can result in missed opportunities and delayed actions, meaning by the time the manager has time to run or review the report, oftentimes it is too late. Also, if the output is long lists of data or actionable items, this can be overwhelming to the service staff that already have a full day of work fielding inbound calls and everyday tasks and projects that get longer by the week. Let’s look at Work-in-Process (WIP) reports from your business system as an example. Instead of running a report that generates the entire list of current WIP, look to generate a ‘subscription’ type report model that can provide the 10 oldest work orders by open date and have it auto generated each Monday to start the week. Additionally, you could set up another subscription report to show the 10 oldest work orders by the last day of labor date posted to the work order. Essentially, your Service Manager should get this data ‘pushed’ to them automatically in subscription form and then the data-informed decision-making process makes it obvious the next 10 things to address and work on. As my industry colleague, John L. Gelsimino (President, All Lift Service, and MHEDA’s Immediate Past Chairman), says, “Call it actionable data – easy-to-digest information that allows the manager to quickly identify problems to jump in on.” He will tell you that this type of strategy can be used for any type of dealership management data. Furthermore, data-driven decision-making fosters continuous improvement and innovation within your service department. By regularly monitoring key performance indicators (KPIs) and benchmarking against industry standards, your service manager can identify areas for improvement and implement strategies to enhance efficiency and productivity. For example, if data analysis reveals that the average time taken to complete a repair is higher than industry norms, your managers can investigate the root causes of delays and implement process improvements to streamline workflows. By charting out revenue per technician in a rolling 12 format you can better determine the technician’s performances and how they are trending. Here are some other tips to optimize data-driven decision-making in your service department: Dashboard Visualization: Develop user-friendly dashboards that provide at-a-glance insights into critical performance indicators. These dashboards should be accessible to all relevant parties at your dealership, allowing them to quickly assess the status of operations and identify areas requiring attention. Predictive Analytics: Leverage advanced predictive analytics algorithms to forecast customer equipment failures and maintenance needs. By analyzing historical data and identifying patterns, these algorithms can anticipate potential issues before they arise, empowering your service department to proactively address them. Additionally, this will give you an advantage over your competition and help maintain customer loyalty. Mobile Applications: Provide service technicians with mobile applications that enable them to access relevant data and documentation on the go. This allows technicians to quickly retrieve information, input data, and communicate with your service department from the field, minimizing delays and improving responsiveness. In conclusion, data-driven decision-making is paramount in today’s landscape for forklift service departments seeking to remain competitive and efficient. By leveraging data and analytics tools, Service Managers and technicians can proactively address maintenance issues, optimize resource allocation, enhance safety, and drive continuous improvement. Ultimately, embracing a data-driven approach not only ensures the smooth operation of your customer’s equipment but also contributes to the overall success and profitability of your dealership. About the Author: Chris Aiello is the Business Development Manager at TVH Parts Co. He has been in the equipment business for 17-plus years as a service manager, quality assurance manager, and business development manager. Chris now manages a national outside sales team selling replacement parts and accessories in various equipment markets such as material handling, equipment rental, and construction/earthmoving dealerships.