Enabling frontline workers to drive efficiency and cost reductions with lean manufacturing

When it comes to supply chain and logistics, efficiency takes center stage. Central to this pursuit is the practice of lean manufacturing, which identifies processes and practices to streamline operations, reduce costs, and engage frontline workers. However, multiple misconceptions surround lean, from its purpose to its impact on the workforce. Contrary to popular belief, lean does not typically result in layoffs and is not merely about trimming the fat. It’s a strategic growth initiative that demands investment and engagement at every level – including your frontline employees. Unlocking efficiencies through lean manufacturing requires active participation and support from frontline workers familiar with daily tasks and operations. Warehouses and manufacturing facilities can tap into their expertise by involving frontline workers in all aspects of lean training and instilling a deeper understanding of lean’s purpose and methodology. Recent surveys reveal a disconnect between the potential benefits of involving more employees and actual lean training practices. Historically, frontline workers have been left out of lean training even though 72% of manufacturers say production would increase, and 91% believe their workers would be more engaged in efficiency efforts if they understood lean principles and objectives. Yet only 40% of manufacturers provide lean training to frontline workers.* Let’s break down some of the positive outcomes of extending lean training to a broader set of warehouse and manufacturing employees. Strategic investments for tomorrow The beauty of lean lies in its ability to generate substantial cost savings that can fund employee-related initiatives such as enhanced training, upgraded tools, and new technology or wellness programs. By introducing these benefits, frontline workers can see the advantages of lean manufacturing firsthand. Redirecting lean savings back into the workforce creates a culture of loyalty and empowerment among frontline workers. Companies can build trust and provide a sense of belonging by showing they value employees enough to dedicate resources that improve their work environment. Skill-building programs, health and wellness programs and facilities, and employee assistance programs demonstrate commitment to frontline employees who become a driving force for long-term prosperity. Maximizing employee potential and growth As the lean process takes hold, a transformative shift occurs within the workforce. Enhanced efficiency gives employees more time and opportunities to explore other value-added tasks. Companies have more time to cross-train employees, giving them additional skills and opportunities for professional growth. Embracing the spirit of experimentation One of the most important facets of lean manufacturing is the willingness to embrace experimentation. Failure is necessary for continuous improvement and is one of the most critical factors in the overall success of the lean process. Every employee, from the frontline workers to managers to top executives, plays a pivotal role. Implementing lean processes requires managers and workers to introduce new ideas, some of which will work and some that won’t. Ideas that don’t work provide employees with valuable lessons. A good rule of thumb for all lean improvements is to plan, do, check, and adjust. Lean manufacturing uncovers new efficiencies and cost savings that can be reinvested to create a more engaged and empowered workforce. When employees are incentivized to find more savings, a never-ending cycle of improvements and efficiencies is created. *Source: Industry Survey, “The Regulatory, Economic, and Workforce Trends that Will Shape 2023,” Intertek Alchemy About the Author: Holly Mockus has over 30 years of experience in safety and quality assurance roles at companies like ConAgra, Kellogg, and Sara Lee, Holly currently serves as Director, Content and Industry Strategy at Intertek Alchemy, where she helps to create world-class workforce development solutions for large, complex operations within the manufacturing industry.

Monetize your value Part 2

I am preparing an intro for this month’s topic, and then we will jump into material prepared by Nathan Hawkins asking him to update the readers about the status of ESOPs in today’s economic environment. I asked him five questions about the state of the ESOP (Employee Stock Option Plan) market, how ESOPs could help with recruiting and employee retention, what’s changed since the Pandemic, how interest rates and inflation have impacted ESOP transactions and what the future holds for ESOPs. I also asked for a recap of the tax benefits generated by an ESOP transaction (spelled additional cash flow). Hopefully, we can include all of this material in this month’s publication. I am afraid Dean is going to charge me for the additional space I am asking for. I am doing this because the annual readers’ survey indicated that readers wanted to know more about ESOPs. So, here you have it. I believe this is an important topic since I keep reading about markets consolidating through M&A transactions. In other words, you can sell it to an outsider or to your employees. With the ESOP you can sell 100% or 51% and get tax benefits. You can also use the ESOP and a platform to build a larger company. If there is any interest going forward, I am sure we could put together a ZOOM meeting to address questions readers may have. We, of course, would not disclose who is asking the questions. 1.What is the state of the ESOP market, and what are some of the key components impacting decisions today? Growing Popularity: ESOPs have been growing in popularity as a succession planning and employee retention tool for business owners. ESOPs can help owners sell their businesses to their employees, ensuring continuity and preserving the company culture. Regulatory Environment: The regulatory environment for ESOPs can influence their prevalence and structure. Changes in tax laws and regulations may impact the attractiveness of ESOPs as a business transition strategy. Financing: The ability of employees to finance the purchase of company shares can affect the feasibility of ESOP transactions. Companies may use a combination of debt, seller financing, and contributions from the business to fund the ESOP. Valuation: Determining the fair market value of a company’s shares for ESOP transactions is critical. Professional valuation firms are often involved to ensure fairness and compliance with regulations. Employee Benefits: ESOPs offer employees an opportunity to accumulate ownership in the company. Employees may become more engaged and motivated when they have a financial stake in the business’s success. Exit Strategy: For business owners looking to retire or exit their companies, ESOPs can provide an alternative to selling to external parties or competitors. Industry Variability: The prevalence of ESOPs can vary by industry. Some industries, such as manufacturing and construction, have a long history of using ESOPs, while others may be less common. Challenges: ESOP transactions can be complex and require careful planning and execution. Challenges may include financing, governance, and managing the transition from owner to employee ownership. 2. How do ESOPs help businesses attract and retain employees? Employee Stock Ownership Plans (ESOPs) can be effective tools for attracting and retaining employees for several reasons: Ownership Stake: ESOPs provide employees with a direct ownership stake in the company. When employees have a financial interest in the success of the organization, they are more likely to be motivated and committed to achieving the company’s goals. This sense of ownership can lead to increased loyalty and dedication to the company’s long-term success. Financial Incentive: ESOPs offer employees the opportunity to share in the company’s financial success. As the company performs well, the value of their ESOP shares increases. This can serve as a powerful financial incentive, aligning the interests of employees with those of the company and its shareholders. Long-Term Perspective: ESOPs encourage employees to think long-term rather than focusing solely on short-term gains. This can be especially valuable for companies that prioritize sustainable growth and stability over quick profits. Employees are more likely to stay with a company that emphasizes long-term success. Employee Engagement: When employees feel like owners, they are more likely to be engaged and committed to their work. They may be more willing to go above and beyond to contribute to the company’s success because they directly benefit from that success. Retention Incentive: ESOPs often have vesting schedules, which means that employees must stay with the company for a certain period of time to fully vest in their ESOP accounts. This serves as a retention incentive, as employees who leave the company before vesting forfeit some or all of their ESOP benefits. Retirement Benefits: ESOPs can serve as a valuable retirement savings vehicle for employees. Knowing that they are building a significant retirement nest egg through their ESOP participation can be a strong incentive for employees to stay with the company for the long term. Competitive Advantage: Offering an ESOP can be a competitive advantage when recruiting new talent. It can set a company apart from competitors and attract candidates who value the opportunity to become company owners. Positive Company Culture: ESOPs can contribute to a positive company culture. They promote transparency, open communication, and a sense of teamwork among employees, which can enhance the overall work environment. Tax Benefits: ESOPs can provide tax benefits to both the company and employees. Contributions to ESOPs are often tax-deductible for the company, and employees may receive favorable tax treatment on the distribution of their ESOP benefits. Succession Planning: For companies looking to transition ownership from one generation to the next, ESOPs offer a structured way to do so while retaining the company’s legacy and culture. Overall, ESOPs can be a powerful tool for attracting and retaining employees who value ownership, financial incentives, and a long-term commitment to the company’s success. However, it’s important for companies to communicate effectively about the benefits of ESOP participation and provide ongoing education to employees to ensure they fully understand and appreciate the value of their ESOP ownership.

Know your Key Performance Indicators in rental management

As the calendar turns to November, it’s hard to believe that it’s been over a year now since becoming a regular contributor in this Aftermarket column. In last month’s edition, I wrote about the topic of relational capital; the intangible asset that encompasses the network of relationships you build with your customers, partners, and employees. My personal relational capital has allowed me to regularly get inspiration for content to contribute to this monthly column. So, with that, this month’s inspiration came from my attendance at the recent MHEDA Rental and Used Equipment Management Conference in Chicago. The goal of the conference was not only to enhance rental and used equipment management skills, but also to increase the profitability of said departments. A common topic shared after speaker presentations and during round-table discussions was the topic of having dedicated technicians for your rental equipment. Let us further explore this topic. Many dealerships I visit tend to have a dedicated rental equipment department. The rental department managers are responsible for making the service and parts decisions for the equipment within. Many of the rental management professionals I spoke to at this conference shared the same sentiment: When it comes to managing a rental fleet, where efficiency and reliability are paramount, the role of dedicated technicians cannot be overstated. Whether your dealership rents forklifts, construction equipment, or any other type of machinery, having a team of specialists solely focused on maintaining and servicing your rental fleet can be a game-changer. Three important rental management KPIs that are related to aftermarket parts and service include: Maintenance Costs: Monitoring the expenses related to maintaining your rental fleet. Costs include technician labor, spare parts, as well as any other 3rd party maintenance costs. Regular maintenance can extend the lifespan of your equipment and reduce long-term costs. Employee Productivity: It is important to regularly measure the productivity of your staff involved in the rental process, including sales, customer service, maintenance and logistics. Downtime: Monitoring the amount of time your rental equipment is out of service due to maintenance, repairs, waiting on spare parts, and other reasons. Reducing downtime is crucial for maximizing profitability. These three KPIs (Key Performance Indicator) are why it’s recommended to have dedicated technicians servicing your rental equipment. Dedicated technicians are the heart and soul of your rental fleet maintenance. They are the ones who will know the intricacies of your equipment. By specializing in the specific make and model of forklifts or any machinery within your fleet. They can develop an intimate familiarity that extends far beyond the operator’s manual. Their expertise enables them to swiftly diagnose issues, execute efficient repairs, and minimize downtime. These specialists are the guardians of your machinery, ensuring it operates at peak performance. Consistency is a cornerstone of dedicated technician teams. With a singular focus on your rental fleet, they adhere to a standardized maintenance and inspection regimen. Every forklift, aerial work platform, or other machine receives the same meticulous care, enhancing reliability, safety, and unwavering quality assurance. Technician efficiency is a precious commodity. With dedicated technicians, you gain an edge in efficiency. These specialists are not distracted by the demands of everyday service calls with a wide array of customer owned equipment. Their undivided attention translates into quicker turnaround times for maintenance and repairs, ultimately benefiting your bottom line. Preventive maintenance is the key to cost savings and a well-run rental fleet. Dedicated technicians excel at identifying and rectifying issues before they escalate into costly problems. By proactively addressing maintenance needs, they keep downtime to a minimum and ensure that the machines in your fleet remain reliable money-making machines. Dedicated technicians create accountability and clear lines of responsibility. With a specialized team in place, it’s easier to pinpoint who is responsible for the condition of each machine. This accountability fosters a culture of excellence and ensures that your forklifts or other equipment are consistently kept in optimal working condition. These dedicated technicians also maintain meticulous records of all maintenance and repair activities for each piece of equipment in your rental fleet. This documentation is invaluable for tracking the history of each machine, adhering to maintenance schedules, and ensuring compliance with safety regulations. Dedicated technicians are the driving force behind your rental fleet’s success. Their expertise, consistency, and commitment to excellence ensure the continued reliability of your equipment and elevate your service quality. In the competitive landscape of equipment rentals, dedicated technicians are a strategic investment that propels your business towards operational excellence and customer satisfaction. By having a team of dedicated technicians responsible for servicing your rental fleet, you not only ensure the well-being of your equipment but also elevate the overall quality of service you provide to your valued customers. In the competitive world of equipment rentals, dedicated technicians are an investment that pays dividends in operational excellence. Downtime is lost time. So, look to employ dedicated technicians for your rental equipment to ensure operational efficiency, profitability, and customer satisfaction. The presence of dedicated technicians instills a sense of accountability and excellence in the management of your rental fleet, making them an indispensable asset for success. About the Author: Chris Aiello is the Business Development Manager at TVH Parts Co. He has been in the equipment business for 16-plus years as a service manager, quality assurance manager, and business development manager. Chris now manages a national outside sales team selling replacement parts and accessories in various equipment markets such as material handling, equipment rental, and construction/earthmoving dealerships.

The secret formula is React, Respond, Recover, +1

You do something wrong. The customer gets mad. You apologize and try to fix the problem, make nice, and hope they don’t go someplace else next time. Want to buy some “Customer Insurance?” Sure, you do. How do you get “Customer Insurance”, you ask? Easy, you already have it. The problem is that most people (companies) don’t use it. Reason? Insurance costs a little extra. It’s called Plus One Insurance and here’s how it works: When the customer is angry, or you can’t deliver the way they expect, the formula that will make them forgive you, continue to do business with you, and tell others about you is React, Respond, Recover, +1. Here’s what that means. Let’s say you’re late for a delivery, or you deliver the wrong thing, or you make an error in something personalized, or you miss a deadline, or you deliver bad food to the table. In short, you make a business mistake that irritates (or angers) the customer. Now, you must react, respond and recover from the mistake. When you’re done with your dance of apology and making amends, that’s when the customer STARTS talking. They will say something good, nothing, or something bad about you depending on what you said, how you said it, what you did, and how you did it. IMPORTANT NOTE: The customer’s story was crafted by your words and deeds. How much is a positive story worth? How much is a saved customer worth? How much does a negative story cost? How much does a lost customer cost? The answer is “Plus 1.” All you have to do to ensure that the story will be positive, and the customer will be saved is to add a “+” to the end of the transaction. Something extra that the customer was not expecting. Something that will add a smile. Something that will add some “good” to the situation and make a pleasant surprise the last memory the customer has. For example, if your customer: goes into your store for a sale item and you’re sold out. checks into your hotel and their room isn’t ready. orders something and you deliver it wrong. You figure if you just get the customer what they need, you’re out of the woods and they’re “satisfied.” And you figured it wrong. You may be out of the woods, but you may still be in the dog house. You need to add the extra. The “Plus.” You need to add a surprise. You need to add the memory. You need to add a reason to say something good about you. Because the risk of NOT doing it is too large. Let’s take the three examples above and elaborate. Let’s assume you can meet their fundamental needs and recover from the wrong. The real question is: what can you ADD to the situation that will make it a memorable one? Here’s how to add the “+” and create a WOW! You go into the store for a sale item, and they’re sold out. The clerk gives you a “raincheck” to ensure you get the item. AND (the plus) the clerk calls other stores, locates the item and has it delivered to your home at no extra charge. AND (another plus) the clerk gives you a “private sale” card that lets you purchase anything else in the store today only at a 15% discount. You check into a hotel and your room isn’t ready. The clerk says, “Mr. Gitomer, you’re in luck! Your room isn’t ready. That means you get to eat breakfast for free AND (the plus) use our business canter for free. Wow!” You order something and it’s delivered wrong. The correct response when confronted is NOT an excuse. The correct response is, “OH, THAT’S HORRIBLE.” Followed by a statement of what will be done and when. Followed by some bonus that has verbiage something like this: “Mr. Gitomer, you are in luck. You have qualified for our “Wrong delivery, customer bonus” program. Here’s how it works………” The “PLUS” is the difference between satisfactory and loyal. The “PLUS” is the difference between a positive and negative story retold. And the story will be retold. The only question is which way. I hope you’re willing to invest in the “plus” customer insurance premium. Some fools aren’t. About the Author: Jeffrey Gitomer is the author of twelve best-selling books including The Sales Bible, The Little Red Book of Selling, and The Little Gold Book of Yes! Attitude. His real-world ideas and content are also available as online courses at www.GitomerLearningAcademy.com. For information about training and seminars visit www.Gitomer.com or email Jeffrey at salesman@gitomer.com or call him at 704 333-1112.

Port of Long Beach has strongest September on record

Cargo rises due to labor pact, heightened consumer confidence The Port of Long Beach achieved its busiest September on record, boosted by consumer demand for holiday-related goods, recent ratification of a labor pact between dockworkers and management and an ongoing effort to showcase the business attributes of the Port of Choice. Dockworkers and terminal operators moved 829,429 twenty-foot equivalent units (TEUs) in September, up 11.8% from the same month last year and surpassing the previous record set in September 2020 by 78,849 TEUs. September also marked the Port’s first monthly year-over-year cargo increase in 14 months. Imports rose 19.3% to 408,926 TEUs, while exports declined 10.3% to 101,248 TEUs. Empty containers moving through the Port grew 11.5% to 319,255 TEUs. “Consumer confidence is on the rise and shippers can rely on the Port of Choice now that we have a ratified contract in place with our waterfront workforce,” said Port of Long Beach CEO Mario Cordero. “We look forward to a moderate rebound in cargo volume through the end of the year.” “Offering the best service and facilities anywhere while supporting our labor and industry partners remains our top priority,” said Long Beach Harbor Commission President Bobby Olvera Jr. “Merchants and consumers can prepare for the holiday season with confidence in our ability to deliver goods reliably, quickly and sustainably.” The International Longshore and Warehouse Union and the Pacific Maritime Association announced a tentative agreement on June 14. Dockworkers of the ILWU ratified the six-year contract on Aug. 31. The Port has moved 5,822,666 TEUs during the first nine months of 2023, down 20.7% from the same period last year. Cargo volume this year has been on pace with pre-pandemic levels, when the Port of Long Beach moved more than 5.7 million TEUs through September 2019. Additionally, the Port processed 2,089,990 TEUs between July 1 and Sept. 30, down 10.5% from the third quarter of 2022. For complete cargo numbers, visit polb.com/statistics.

Take safety to new heights

The American Ladder Institute (ALI) is seeking sponsors for next year’s National Ladder Safety Month. New for 2024, the enhanced Top Cap Sponsor becomes a leading voice on ladder safety at work and at home. The sponsorship is a valuable brand extension for any company invested in the manufacturing of ladders or their safe use. Companies with employees working at heights fully understand the value of emphasizing safety and its impact on accident prevention and saving lives. Observed every March, National Ladder Safety Month is the only program dedicated exclusively to promoting ladder safety at home and work. Each year, tens of thousands are injured and hundreds die in accidents caused by improper ladder usage. The reach of National Ladder Safety Month only thrives with the support of its sponsors. They are the driving force behind helping to raise awareness on safe use and decreasing these tragic numbers. ALI, the only approved developer of safety standards for the U.S. ladder industry, is the presenting sponsor for National Ladder Safety Month. Other major sponsorship opportunities are also available and can be found here. The Top Cap Sponsor will be designated as the exclusive title sponsor of National Ladder Safety Month and will receive an array of promotional consideration, media impressions, and other perks. These include recognition on the National Ladder Safety Month virtual Save the Date (sent to over 3,000 safety managers and professionals), logo placement on all event promotional materials, a dedicated press release, including a quote, in March 2024 (average views of 2,000 per release), and recognition in the February 2024 press release (average views of 2,000 per release). This is in addition to a dedicated email blast to ALI’s database of more than 23,500+ contacts, dedicated social media posts (audience of 2,000+) with tagged recognition on ALI and National Ladder Safety Month channels (Facebook, Twitter, and LinkedIn) between January and March 2024, the company logo and link on National Ladder Safety Month website, a 300-word article on the ALI website, and a company video hosted on the National Ladder Safety Month website. To become Top Cap Sponsor or other level sponsor, contact marketing@laddersafetymonth.com. For a list of other National Ladder Safety Month sponsorship levels, visit https://www.laddersafetymonth.com/.

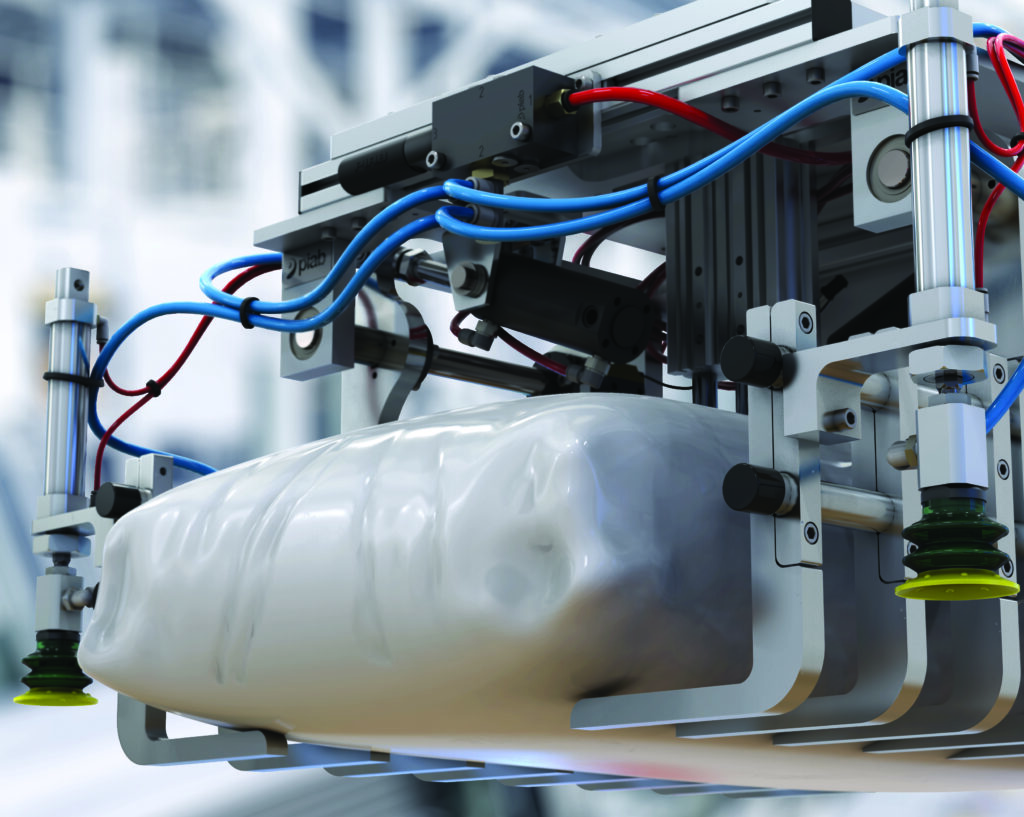

Piab strengthens its grip on palletizing with the LBG-50

Piab strengthens its grip on the palletizing solutions market with a lightweight bag gripper, the LBG-50. The new gripper easily lifts sacks and bags with weights of up to 50 kg [110 lbs]. As it is a pre-engineered tool, valuable development time can be saved An unavoidable challenge when defining a new bag gripping system in a palletizing line is to get the exact measurements to align with the conveyor rollers for a smooth lifting and releasing process. This demands time-consuming analysis and design and, later, even more time for adaptation and adjustments. Furthermore, additional solutions may have to be considered, e.g., for slip sheet handling, which prolongs the implementation process and may interfere with the original set-up and purpose of the gripper. Piab‘s newborn in the palletizing tool family, lightweight bag gripper LBG-50, solves all that. “LBG-50 is the result of our long experience from developing custom palletizing End-of-Arm-Tooling (EOAT)”, says Madeleine Sheikh, Product Manager at Piab Vacuum Automation Division. “What we have here is a complete pre-engineered bag gripper that is easy to install, adjust and maintain. It offers flexibility to fit any roller conveyor on the market, and slip sheets are handled just as easy by our vacuum-based upgrade option with Duraflex® suction cups and COAX® technology.” Handling sacks normally poses a challenge as they are heavy and flexible, yet with a surface that is sensitive to pinching, puncture or rough treatment. LBG-50 avoids that by providing a gentle but firm lift while a built-in top clamp plate secures the bag from above during motion. This, in turn, allows higher cycle speed. Both the arm and the framework of LBG-50 are made of aluminum, which makes it robust yet lightweight. Other positive features are flexible width and finger positioning and generous mounting options. Flexibility also goes for the valve package, which can be configured with either Discrete I/O, Ethernet/IP or Profinet.

Eliminating waste over increasing efficiency

Efficiency is fundamentally about using less input and getting more output.When CEOs talk about increasing “worker efficiency”, it usually means getting fewer workers to do more work. You can have the most efficient workforce in the world, but if the company, the system, and the process they’re working in are wasteful, none of it really matters. Eliminating waste is actually way more important than driving efficiency. Efficiency will help you, but waste will crush you. To waste means to use or expend carelessly, extravagantly, or for no purpose. In business, this usually manifests as time spent on things that don’t matter. This could be anything from an executive’s pet project to utilizing hundreds of hours to tweak and modify documents that never end up seeing the light of day. There are also things that might look like waste but aren’t. Waste is not an idea explored that ultimately doesn’t make the cut. Waste is not an effort that fails. Waste is not a canceled project, no matter how much went into it. Waste is not a prototype abandoned along the journey to a solution – there’s always a portion of things that can get naturally lost in the process. (In making whiskey, this is called the “angel’s share” – a portion of the product that’s lost in the production process.) But when we allow actual waste to occur, we’re draining our organization culturally, competitively, and financially. Typically, there are four common causes of waste within an organization. First is bad communication – Say you come out of a leadership meeting energized with clear direction. You and your team charge ahead and make a ton of progress. Then, you hear from leadership the direction has already changed. Days ago, in fact. The problem here isn’t the fast pace of change, it’s bad communication or even the lack thereof. Is bad communication worse than no communication? Who cares. They both create excessive waste. Second is no framework — When a team gets handed strategic direction without any framework, they’re guessing what will meet expectations. They will bust their butts only to find out they’ve misunderstood the goalposts or worse, the goalposts have changed. When teams have to guess to understand strategy, objectives, or success measures, they’re mining rubies with a spoon and flicking them into the ocean. Third is bottlenecks — A bottleneck is a place in the work process where progress gets stuck. It might be because progress can’t happen without meeting with someone who’s double booked until 2050 or hasn’t looked at their inbox in months. Bottlenecks can force teams to sit on their hands until the bottleneck is resolved. What’s even worse is when ambitious teams decide to push on with the work anyway, only to find out only they were on the wrong track, and now you didn’t just generate waste but also destroyed souls at the same time. Fourth is fake urgency — Say you’re just wrapping up for the day when you get a message from the boss asking you to drop everything because something urgent is needed before the next morning. Your team pulls an all-nighter and gets it out the door. Then crickets. You never hear back and only later find out it wasn’t really needed at all. When we create false urgency, often it’s theater. It’s like when your boss’s boss slightly mentions that it’d be interesting to see some data, and your boss is already lighting up to get your team to produce it. Some people will see this as “an issue with leadership” and that it should be remedied by conducting a slew of leadership training exercises. I’d argue it’s not just leaders, but organizational culture. It’s likely most leaders aren’t thinking about waste on a day-to-day basis. But most organizations also haven’t created a culture to continually define, examine, and discuss waste, or define success metrics that actively measure the amount of waste in the organization versus how much has been eliminated. By ignoring organizational waste, you’re also wasting employee enthusiasm and morale. You’re also wasting opportunities for employee growth and learning. And ultimately you’re wasting employee loyalty. Most people are actually willing to work extremely hard. When it’s rewarding, they feel it. But when they see their good work wasted for no good reason, they’re left with animosity, angst, and frustration. And that’s what puts one foot out the door. About the Author Andrea Belk Olson is a keynote speaker, author, differentiation strategist, behavioral scientist, and customer-centricity expert. As the CEO of Pragmadik, she helps organizations of all sizes, from small businesses to Fortune 500, and has served as an outside consultant for EY and McKinsey. Andrea is the author of three books, including her most recent, What To Ask: How To Learn What Customers Need but Don’t Tell You, released in June 2022. She is a 4-time ADDY® award winner and host of the popular Customer Mission podcast. Her thoughts have been continually featured in news sources such as Chief Executive Magazine, Entrepreneur Magazine, Harvard Business Review, Rotman Magazine, World Economic Forum, and more. Andrea is a sought-after speaker at conferences and corporate events throughout the world. She is a visiting lecturer and startup coach at the University of Iowa, a TEDx presenter, and TEDx speaker coach. She is also an instructor at the University of Iowa Venture School. More information is also available on www.pragmadik.com and www.andreabelkolson.com.

Gorbel®wins rare Platinum Distinction at 2023 Greater Rochester Quality Council Awards

Victor, NY based manufacturing company receives seldom-presented Platinum Award in Team Excellence for their Destuff-itTM Portable Ergonomic Conveyor Implementation Project Gorbel®, a provider of cranes and ergonomic lifting solutions in the material handling industry, has announced that it has been honored with a Platinum Award in Team Excellence from the Greater Rochester Quality Council (GRQC) at their annual Performance Excellence Awards at the Locust Hill Country Club in Pittsford on October 11. The mission of the GRQC and purpose of this event is to celebrate local organizations that have demonstrated outstanding performance and continuous improvement. Awards are divided into three categories: gold, silver, and bronze. On rare occasions, a platinum award is granted to organizations that exceed the stringent criteria set forth by the GRQC. Gorbel® received this award in recognition of the Destuff-itTM Implementation Project, which involved acquiring the Canadian conveyor system and bringing it to production in the United States during the COVID-19 pandemic. This project was completed in just six months and was meant to sustain the company through a period of economic uncertainty. “This remarkable achievement is a testament to the dedication, hard work, and exceptional teamwork exhibited by members of our organization,” wrote Franklin Allen, Director of Quality and Continuous Improvement at Gorbel®. “We are committed to delivering the highest quality products and services to our customers and will continue to innovate and excel in the years to come.”

AMT’s Michael Horth honored with prestigious PMMI ‘On the Rise’ Award

Michael Horth, Senior Controls Engineer at AMT, honored with an On the Rise Award from the Association for Packaging and Processing Technologies (PMMI) during PMMI’s Annual Meeting on October 16, 2023 Applied Manufacturing Technologies (AMT), has announced Senior Controls Engineer Michael Horth has been selected as one of the honorees of the On the Rise Award from the Association for Packaging and Processing Technologies (PMMI). Horth was previously named a “2021 Engineering Leader Under 40” by Plant Engineering.nb The On the Rise Awards are hosted by PMMI’s Young Professionals Network (YPN), a group welcoming entry- to mid-level engaged young professionals in packaging and processing. The annual On the Rise Awards recognize ten distinguished professionals under age 35 who have demonstrated exceptional leadership potential in the industry. These awards offer honorees opportunities to further their careers, meet others in the industry, and learn more about PMMI. Horth’s award, announced at the PMMI’s Annual Meeting on October 16 in Stone Mountain, Georgia, was followed by recognition at the Chairperson’s Dinner, and an interview to be published in OEM Magazine. Horth, who started his journey with AMT as an entry-level automation engineer in 2013, has exemplified a commitment to innovation and industry advancement. Over the past decade, he has ascended the ranks to become a senior controls engineer, earning a strong reputation both within AMT and throughout the broader industry. “Mike truly embodies our AMT Core Values. He is always willing to embrace new challenges and drive our company forward, but Mike’s biggest contribution lies in his mentorship,” said Engineering Group Leader Jason Markesino, Horth’s manager. “Employees cherish their time with Mike; he is patient and understanding. His knack for simplifying complex topics into learnable chunks greatly enhances retention, ultimately making our team stronger.” “Michael Horth is a shining example of a bright and dedicated professional,” said Mike Jacobs, founder of AMT. “He is not only a willing mentor but also has a pleasant and easy smile that often lights up the room. Michael’s exceptional ability to describe complicated operations in terms others can grasp makes him very deserving of this award. His contributions continue to shape our industry positively.” Horth’s contributions to AMT encompass software development, technology integration and mentorship. In his current role, he has significantly contributed to controls engineering, particularly in the integration of Allen Bradley PLC programming and FANUC robotics programming. His expertise in controls and robotics automation has led to improved automation solutions for the company’s clients. He has notably advanced the course of AMT in his experimentation with new technologies including AI powered 3D vision solutions for depalletizing, enabling the company to expand into new markets. “In my day-to-day engineering career, I use Horth’s mentality of how to explain a new topic, program, and guide others to become a stronger, more efficient engineer,” noted AMT Controls Engineer Darin Shillair. “It has been an honor working under and alongside Michael Horth.”

Boosting efficiencies in the warehouse in a tough labor market

Ken Ramoutar sees productivity as a multi-dimensional concept. Ramoutar, chief marketing officer at Lucas Systems, said when he started in the industry over two decades ago, few would have anticipated the coming labor force challenges. “I’m not sure warehouse workers were viewed as a huge value and asset, and now they are,” said Ramoutar, who said the pandemic has accelerated this view. Now, the focus is on how to compete for the workforce, he said. “It’s more than productivity,” said Ramoutar, who said the traditional concept of more work for lower expenses has expanded. “There’s a whole notion of what can I do, not to make everybody work faster, but how do I make the jobs easier. If I make the job easier, I am more likely to have a workforce that wants to be here and stay here,” he said, adding that this calculation includes labor competition from other warehouses. Lucas Systems offers warehouse optimization solutions using AI, smart software and voice, according to the business website. The company’s tools are in over 400 warehouses worldwide, Ramoutar said. “We talk to customers all day long. The number one issue is the workforce,” he said. Working smarter Lucas Systems’ Jennifer™ software is the heart of the company’s software system, according to Ramoutar. “It’s the Alexus or Siri of the Lucas Systems,” he said, adding that the AI-based system incorporates a real voice and is somewhat like a hand-free system for a personal phone. “A distribution center is a busy place. Instead of looking down at screens or paper, workers can do their work and feel liberated,” Ramoutar said. He said the system helps avoid errors and bolsters efficiency. “There are a couple of things Jennifer does really well. One is around travel pass optimization,” said Ramoutar, who said the system is constantly computing the most efficient travel path inside the warehouse to get the work done, sometimes coordinating pathways for 100 to 200 workers at a time. Ramoutar said running smarter instead of faster using a system like Jennifer can help boost productivity in the range of 20 to 40 percent. Lucas Systems tends to work with mid-size to larger companies, and the sizes of warehouses are increasing, Ramoutar said. “The warehouses are getting bigger. And everybody loves e-commerce. Where’s that all going? That’s accelerating,” he said. Meanwhile, the labor needs are not going away. “All of the data around the labor issue suggest it’s not going to get better,” said Ramoutar, noting that the retiring Boomer generation is 4 million greater than Generation Z. Added to those numbers is the need to appear to younger workers. “Tech plays a pretty big role,” said Ramoutar, who said handing a new employee a clipboard and sending them into the warehouse is not going to appeal to many younger workers. “Companies are going to have to get better at attracting and keeping the labor,” he said. Software and tools like those provided by Lucas help check multiple boxes of need, Ramoutar said. “Software is the fastest thing you can do to get returns,” he said. “As soon as you start running, you’ll get returns right away.” Jennifer was designed to be user-friendly, and Ramoutar said workers typically find that after a few hours that they are comfortable with the technology. The system includes automatic speech recognition and includes over 30 language options. “This is a big deal for some operators. They may have a fairly multicultural workforce. With Jennifer, they can speak their native language and still work in the warehouse,” said Ramoutar, adding that this is appealing for workers. “It’s also attractive for the workforce. We’re going to give you stuff easy for you to use,” he said. The next wave of worker engagement will be using more video game mechanics in the tools, Ramoutar said. “There’s a lot of things that have come out of the gaming industry that can be applied in a service environment,” he said, naming features like competing against oneself or other workers, getting feedback and earning incentives. “It’s kind of making work fun. We think there’s a big opportunity for that,” he said. It all adds up to making the warehouse more dynamic, especially as warehouses handle ever-larger volumes of orders, according to Ramoutar, who said Lucas Systems’ will continually recalculate while operating. “We are constantly making sure everything is optimized,” he said. Productivity at the end of the line At SupplyOne, productivity is also a key area of focus. The company, a distributor of end-of-line packaging equipment, operates in both manufacturing and distribution centers. Chip Reavley, senior vice president of packaging automation, handles oversight and responsibility for the packing equipment and automation team, which includes equipment engineers and factory certified technicians. End-of-line packaging can also be referred to as secondary packaging, according to Reavley. “They’re really synonymous,” he said, noting the wide array of automation points covered by secondary packaging. The company bills itself as the largest independent supplier of custom corrugated and other value-added packaging products, equipment, and services in the U.S. SupplyOne offers a full gamut of automatic and semi-automatic case erecting and case sealing systems, strappers, banders, palletizing and wrapping equipment, as well as associated consumable including custom or stock corrugated films, tapes, strapping, and other materials, according to a SupplyOne press release. The company provides mid-sized manufacturers, food processors, and medical and e-commerce companies “leading packaging programs and complete packaging solutions,” the statement said. SupplyOne’s approach is to offer best-in-class solutions to customers, according to Reavley. “It allows SupplyOne to offer state-of-the-art proven solutions,” he said. The pressure of the labor market continues to influence industry developments, Reavley said. “The labor market has, and continues to be, challenging,” he said, referencing both finding and retaining skilled workers. While labor eliminations were originally a concern with automation, Reavley said the current trend for many is to implement automation to allow for labor reallocation. “It’s so hard to find good labor. They’re redeploying into other areas and automating,” he said. The interest in automation, overall, has been on the rise, according to Reavley. For those unsure about pricing on solutions, he will sometimes ask

H&E relocates branch in Pompano Beach Florida

Effective October 18, 2023, H&E Equipment Services Inc. (H&E) has announced the relocation of its Pompano Beach, FL, branch. The facility is now located at 1660 N. Powerline Road, Pompano Beach, FL 33069-1623, phone 954-781-3099. The newly renovated property includes a fully fenced yard area, offices, and a separate repair shop and carries a variety of construction and general industrial equipment. “Our Pompano Beach location is just 2.6 miles northwest of our previous address. The newly renovated facility provides a comfortable environment, has a larger, more efficient yard to hold a variety of fleet, and maintains direct access to I-95 to move equipment quickly,” says Branch Manager Anthony Wallace. “And with our Hollywood branch just 17 miles south, we can work together to quickly locate available equipment and provide faster response time to job sites throughout South Florida.” The Pompano Beach branch specializes in the rental of aerial lifts, earthmoving equipment, telescopic forklifts, compaction equipment, generators, light towers, compressors, and more and represents the following manufacturers: Allmand, Atlas Copco, Bomag, Case, Club Car, Cushman, Doosan, Gehl, Generac Mobile, Genie, Hamm, Hilti, Husqvarna, JCB, JLG, John Deere, Kobelco, Kubota, LayMor, Ledwell, Lincoln Electric, Link-Belt Excavators, MEC, Miller, Multiquip, Polaris, Sany, Skyjack, SkyTrak, Sullair, Sullivan-Palatek, Tag, Towmaster, Unicarriers, Wacker Neuson, Yanmar, and others.

US Rail Traffic for the week ending October 14, 2023

The Association of American Railroads (AAR) has reported U.S. rail traffic for the week ending October 14, 2023. For this week, total U.S. weekly rail traffic was 492,781 carloads and intermodal units, up 0.5 percent compared with the same week last year. Total carloads for the week ending October 14 were 225,405 carloads, down 2.0 percent compared with the same week in 2022, while U.S. weekly intermodal volume was 267,376 containers and trailers, up 2.8 percent compared to 2022. Six of the 10 carload commodity groups posted an increase compared with the same week in 2022. They included petroleum and petroleum products, up 1,774 carloads, to 10,583; motor vehicles and parts, up 955 carloads, to 15,712; and miscellaneous carloads, up 809 carloads, to 8,786. Commodity groups that posted decreases compared with the same week in 2022 included coal, down 4,787 carloads, to 62,138; grain, down 2,049 carloads, to 22,176; and metallic ores and metals, down 1,705 carloads, to 18,137. For the first 41 weeks of 2023, U.S. railroads reported cumulative volume of 9,234,003 carloads, up 0.3 percent from the same point last year; and 9,862,159 intermodal units, down 7.7 percent from last year. Total combined U.S. traffic for the first 41 weeks of 2023 was 19,096,162 carloads and intermodal units, a decrease of 4.0 percent compared to last year. North American rail volume for the week ending October 14, 2023, on 12 reporting U.S., Canadian and Mexican railroads totaled 335,745 carloads, down 2.9 percent compared with the same week last year, and 347,146 intermodal units, down 1.4 percent compared with last year. Total combined weekly rail traffic in North America was 682,891 carloads and intermodal units, down 2.1 percent. North American rail volume for the first 41 weeks of 2023 was 26,749,075 carloads and intermodal units, down 3.6 percent compared with 2022. Canadian railroads reported 94,482 carloads for the week, down 2.4 percent, and 69,104 intermodal units, down 12.1 percent compared with the same week in 2022. For the first 41 weeks of 2023, Canadian railroads reported cumulative rail traffic volume of 6,507,594 carloads, containers and trailers, down 3.5 percent. Mexican railroads reported 15,858 carloads for the week, down 15.7 percent compared with the same week last year, and 10,666 intermodal units, down 20.0 percent. Cumulative volume on Mexican railroads for the first 41 weeks of 2023 was 1,145,319 carloads and intermodal containers and trailers, up 2.8 percent from the same point last year. To view the rail charts, click here.

Episode 429: Following the path to Warehouse Automation with Zion Solutions Group

In the latest episode of The New Warehouse Podcast, Jim Shaw, President and Co-Founder of Zion Solutions Group, joins the show. With over 25 years of experience in the warehousing and logistics industry, Jim discusses his journey from his early days at UPS to eventually co-founding Zion Solutions Group, a company specializing in optimizing supply chain logistics. Rooted in deep industry experience and guided by his values of faith, family, and meaningful work, Jim offers a unique perspective on today’s warehousing challenges. Tune in to the episode for an in-depth look at Jim’s background and insights that could reshape how you think about supply chain optimization. Tackling Warehouse Efficiency and the Labor Equation Jim candidly addresses the multi-faceted challenges warehouses are currently facing. “How do I store more in less space? How do I use fewer people to get more out the door while maintaining my quality? And the biggest problem we’re seeing is labor,” he says. These concerns span various sectors, from retail to healthcare, and Jim suggests that the solution lies in “intelligent change.” He says it’s about “meeting the customer where they’re at, what problems they need solving,” whether that involves simple gravity conveyors or advanced robotics. Justifying Warehouse Automation Jim discusses the dilemma many warehouses face when considering high-end automation and robotics. “they may need some sortation, but their rates don’t qualify for the higher level sortation today,” he explains. Jim advocates for a more deliberate approach, cautioning against rushing into flashy, expensive solutions that may not serve immediate needs. “We’re looking for long-term meaningful partnerships… It’s not turning away work. It’s just more of an education process,” he notes, emphasizing the importance of starting with traditional material handling that can grow into more advanced systems. Jim adds, “Ultimately, you have to put your head on your pillow at night and feel good about how you solve a problem for a customer and did you do the right thing.” Navigating the Investment Horizon in Warehouse Automation Jim delves into the complexities of deciding how far ahead to plan when considering investments in automation and robotics. “I don’t know that there’s a right answer because every company has a different perspective,” he notes. According to Jim, businesses with their own distribution and fulfillment can potentially look at an extended investment period based on a clear understanding of their product’s future. For companies that don’t have a long-term commitment, like 3PLs, “the more flexible the automation, the more flexible the technology that you’re putting in,” advises Jim. Jim underscores the importance of partnering with trusted integrators or OEMs to navigate these decisions. “Find a partner that you can trust. Put your trust in that has your best interest in mind,” he says. In an environment where technology is rapidly evolving, Jim suggests a cautious approach, especially for more risk-averse companies. “You can be a fast follower… we spend it like it would be our money. If I was putting my money in my check and writing it, we take that pretty seriously because you can cripple somebody’s supply chain and ruin their business if you make wrong decisions.” Key Takeaways on Warehouse Automation Jim emphasizes the importance of “intelligent change” to address current challenges in warehouse efficiency, including labor and space constraints. A deliberate approach to automation is crucial; rushing into high-end, expensive solutions may not always serve a warehouse’s immediate needs. Flexibility is critical for long-term investments in automation, especially for companies without a long-term commitment to distribution and fulfillment, like 3PLs. EP 429: Following the Path to Warehouse Automation with Zion Solutions Group

Green Cubes celebrates ten years of Motive Power Technology leadership with continued investment in Innovation & Operations

Milestone marks a decade of manufacturing safe and reliable Li-ion technology for motive equipment with its Lithium SAFEFlex Battery solutions Green Cubes Technology (Green Cubes), the provider in producing Lithium-ion (Li-ion) power systems that facilitate the transition from lead-acid batteries and Internal Combustion Engine (ICE) power to green Lithium-ion (Li-ion) battery power, has announced it is celebrating ten years of motive power technology leadership for material handling and ground support equipment. For over 35 years, Green Cubes has been on the forefront of electrification innovations and this marks ten years of success with its flagship suite of Lithium SAFEFlex Battery solutions designed to meet the cost, performance, efficiency, and durability requirements of the rugged warehouse, distribution, and airport environments. Lithium SAFEFlex industrial lithium battery systems are designed as drop-in replacements for traditional Lead acid batteries. They eliminate the need for watering and battery swaps and increase equipment up-time with fast opportunity charging. With a lower total cost of ownership for electric equipment, industrial companies can capture cost-saving and greenhouse gas emission-reduction opportunities by planning the electrification of their operations, while increasing overall productivity. According to Allied Market Research, the forklift battery market is projected to reach $7.4 billion by 2026, growing at a CAGR of 7.04%. Green Cubes is poised to be an integral part of these projections. “As a pioneer in the Motive space for over a decade, Green Cubes has provided the industry with the solutions to modernize and optimize material handling power with Lithium SAFEFlex, our Lithium-ion battery power system that has dual benefits of improved ROI (Return On Investment) and decreased environmental impact,” said Michael Walsh, Chief Executive Officer for Green Cubes. “We will continue to invest in technology innovation and manufacturing excellence while expanding our service and customer application infrastructure. For 35 years we’ve made a positive impact on the Indiana economy and will continue to do so as we expand our footprint in Kokomo, creating more jobs in clean energy.” Green Cubes recently added a 36,000-square-foot facility to produce Lithium SAFEFlex batteries and house engineering and service talent to support customer applications. Additionally, Green Cubes established a new Technology Center in Switzerland, to focus on product innovation. Together these teams are working to improve technology and service offerings based on a decade of field learning and experience.

Industrial Forklifts ushers in “New Chapter” with new headquarters & full rebrand

The Southwest has a new forklift brand to help it grow. Industrial Forklifts, Inc., the sole distributor of the Heli forklift brand in the Western United States, has completed its move from Denver, CO, to Phoenix, AZ. In the process they’ve acquired a totally new facility in the Papago Industrial District, off 48th Ave and Van Buren. The facility boasts parts storage, a state-of-the-art training room, and of course, a full showroom of material handling equipment. The Phoenix facility sites on 1.12 acres, with 36,000 sq. ft. dedicated to parts, service, and a showroom floor. Who’s it for? To strengthen their Dealer and Rental Network coverage across the U.S. “Everything’s new about our Phoenix location,” says Dan Summers, Director of Aftermarket Sales at Industrial Forklifts. “Due to the rapid expansion of Industrial Forklifts’ customer base, and the success of the Heli forklift line in America, we came to Phoenix for a new chapter.” To cap off the expansion, the new Industrial Forklifts building sports a brand-new logo. Industrial Forklifts began as a part of FMH Material Handling Solutions in 2006, based in Denver. Through a series of acquisitions and business choices, the Industrial Forklifts brand and team split from FMH in 2022. With the new Phoenix location, Industrial Forklifts has a new showcase to continue its mission of introducing Heli forklifts to all businesses. “We’re open and here to help,” says Nick Gushue, Vice President. “Everyone’s welcome to come by!”

JLG® announces Executive Leadership changes

Frank Nerenhausen to retire effective November 13, 2023. Mahesh Narang named successor. Tim Morris appointed Chief Commercial Officer JLG Industries, Inc., an Oshkosh Corporation business and global manufacturer of mobile elevating work platforms and telehandlers, has announced the retirement of Frank Nerenhausen, executive vice president of Oshkosh Corporation and president of its Access segment. Mahesh Narang will succeed Nerenhausen effective November 13, 2023. Nerenhausen will serve as an advisor to the company through August 2024. Nerenhausen is retiring after more than 37 years with Oshkosh Corporation. Since joining the company as an intern in 1986, his career has included a range of management and leadership assignments of increasing responsibility across business segments. He was named the company’s Access segment president in 2012. “Frank has built a world-class team, successfully leading JLG to great heights for more than a decade. During his tenure, the Access segment has achieved significant growth and profitability, while introducing progressive innovations that leave our business in an outstanding position with a bright future,” said John Pfeifer, president and chief executive officer of Oshkosh Corporation. Narang is an accomplished global executive. Most recently he served as vice president and president of Components at Cummins Inc., where he developed the strategic direction and led all operational aspects of the Components business. Further, he executed a forward-looking strategy to grow in core diesel markets while expanding into new and fuel agnostic adjacent markets. Narang also led the acquisition and integration of several companies, helping grow the Components business by over 50% and prepare for future technologies. He holds a Bachelor’s degree in Engineering from the University of Mumbai, India, as well as Master of Business Administration and Master of Engineering Management degrees from Northwestern University. Pfeifer continued, “In addition, we are taking this opportunity to align the commercial activities of JLG Americas to prepare for future growth.” Tim Morris, who has been with JLG since 1992, has been appointed chief commercial officer for JLG Americas. He will be responsible for overseeing all JLG whole goods and aftermarket commercial business initiatives in the Americas region. Pfeifer concluded “We have an exceptionally strong bench of talent at our Access segment. Mahesh’s diversified experience combined with the longevity of Tim’s experience and deep customer relationships will allow us to continue our growth trajectory and maintain our market leadership.”

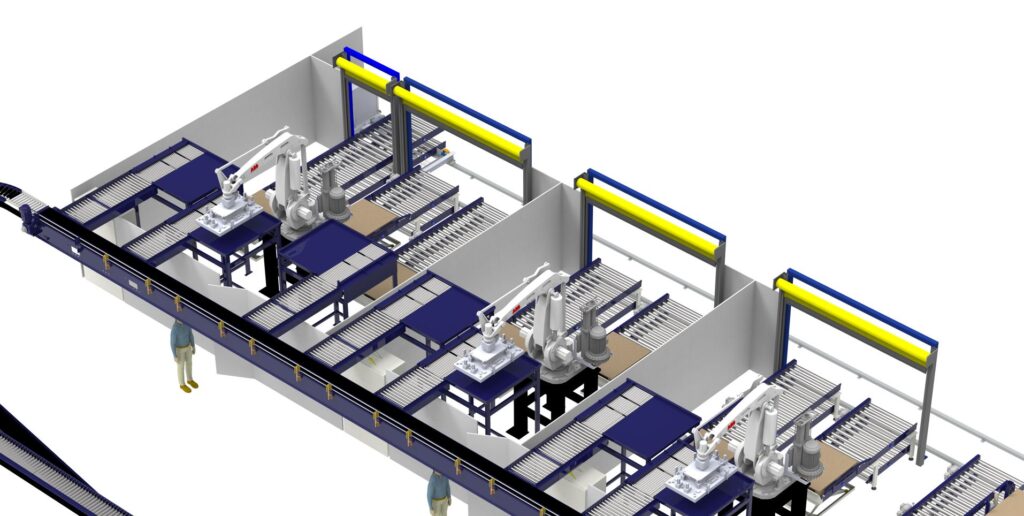

CKF recently started the install of the third central palletizing project for iconic snack manufacturer

CKF Systems are delighted to have started the installation of another Robotic Central Palletising system for a world leading snack manufacturer at one of their large state-of-the-art, modern facilities, building further on the company’s 25-year strong working relationship. This latest install will provide fully automated palletisation, taking cased product from seven existing production lines. Elements of the systems design were carried over from the two large Robotic Central Palletising systems already supplied and commissioned by CKF for them at another of their plants. CKF are providers in automated robotic solutions with more than 30 years’ experience supporting different industries including Food & Beverage, Logistics, Pharmaceutical and Automotive. This new multi-million-pound system is the latest robotic system to have been delivered and commissioned by the experienced engineering team at CKF, aiding our client’s drive for the improvement and automation of the operations within their manufacturing facility. This system is a full turnkey solution from CKF Systems incorporating CKF’s own range of pallet and case conveyors along with ABB robots, Apollo Spirals and Intralox ARB equipment. CKF are ABB Value Providers and are the only company in the UK to hold a full Preferred Partnership agreement with Intralox giving CKF a license to manufacture Intralox’s ARB equipment in house. Jamie Quinton CKF Managing Director said “CKF Systems have built an established and successful relationship with our customer spanning more than 25 years. We’re delighted that they have again chosen CKF Systems to help automate their operations and further drive their ambitions to increase productivity, streamline their operations and reduce manual handling through effective use of automation and robotics. The length of the relationship shows how much trust has has been established between our two companies and the confidence they have in the reliability of our solutions”

Women In Trucking Association announces continued Gold Partnership with Walmart

The Women In Trucking Association (WIT) announced that Walmart has renewed its Gold Level Partnership for the fourteenth year, supporting the nonprofit organization as it attracts more women to the transportation industry and empowers them to be successful. Since 2009, Walmart has supported WIT at the Gold Level, making them the longest-standing top-level sponsor. In addition to financial support and regularly sponsoring the Driver of the Year program, the company actively participates in the association. Walmart’s Ryan McDaniel, vice president of transportation, serves on the WIT board of directors. “Walmart is proud to renew our partnership with Women in Trucking, a 14-year commitment that reflects our dedication to creating an environment of belonging,” said Ryan McDaniel, vice president, transportation at Walmart. “Together, we aim to drive positive change and ensure a more prosperous future for all that empowers women within the transportation industry at large.” “Walmart has shown a long-standing commitment to WIT’s mission, gender diversity and creating opportunities for women across the transporation sector,” said Jennifer Hedrick, WIT president and CEO. “We’re pleased to continue our strong partnership.”

Raymond West hosts 10th annual Pink Pallet Jack project to benefit Breast Cancer awareness

Raymond West will hold the 10th annual Pink Pallet Jack Project auction in support of Breast Cancer Awareness Month from Oct. 18 through 29 Raymond West, an authorized Raymond Solutions and Support Center, will hold the tenth annual Pink Pallet Jack Project online auction in support of Breast Cancer Awareness Month from Oct. 18 through 29. The 11-day auction will begin Oct. 18 at 12 a.m. PDT on Auctria.com (auctria.events/pinkpalletjack), where participants can bid on three pink Raymond® 8210 powered pallet jacks from suppliers. The auction will end Oct. 29 at 12 a.m. PDT. Winning bids will be announced the first week of November, with all proceeds from the auction being donated to The Tina Fund, Breast Cancer Angels and Northwest Hope & Healing. The Raymond 8210 powered pallet jack, part of The Raymond Corporation’s intralogistics solutions portfolio, is ideal for retail store, wholesale delivery and food processing applications that require navigation in tight and/or congested areas. The lift truck also will include Raymond’s exclusive Click2Creep™ design, which automatically reduces maximum travel speed, providing a tighter turn radius for pinwheeling or right-angle turning. Raymond’s Pink Pallet Jack Project has raised more than $175,000 for breast cancer over the past nine years.