Episode 442: Green Cubes Technology – A decade of advancing Lithium-Ion power in warehousing

In episode 442 of The New Warehouse podcast, Kevin talks with Michael Walsh, CEO of Green Cubes Technology. The company, a provider of electrification solutions for the past thirty-five years, is celebrating the tenth anniversary of its SAFEFlex battery. Green Cubes Technology has successfully deployed over 10,000 SAFEFlex batteries, significantly supporting the warehousing and material handling industry. Walsh shares insights into the company’s journey, the impact of lithium-ion technology, and future trends. Transforming Warehousing with Lithium-Ion Technology Michael Walsh reflects on Green Cubes Technology’s ten years of manufacturing lithium-ion systems for warehousing. “We’re now in the aftermarket model where customers say, ‘Hey, great, they’re still cooking. They’re still doing well,’” Walsh notes, highlighting the batteries’ longevity and performance. Total Cost of Ownership: A Key Driver for Lithium-Ion Adoption Walsh emphasizes the importance of total cost of ownership (TCO) in driving the adoption of lithium-ion technology. “The only reason it takes off is the total cost of ownership. We have the proof points; you’re seeing batteries last longer and have fewer maintenance cycles,” he explains, illustrating lithium-ion batteries’ financial and operational benefits in warehousing. Lithium-Ion Batteries in Material Handling: Lessons Learned Reflecting on a decade in the business, Walsh shares learnings and the performance of their batteries. “Every site is different. Every application is different. The faster we lean into saying exactly what you have for your charging infrastructure, your electrical infrastructure, the better,” he says, emphasizing the importance of understanding customer needs and site specifics. Key Takeaways Durability and Longevity: Green Cubes’ lithium-ion technology has proven its durability and longevity in warehousing operations. Focus on TCO: The adoption of lithium-ion is largely driven by its lower total cost of ownership compared to traditional power solutions. Customized Solutions: Understanding the unique needs of each site and customer has been crucial for Green Cubes in delivering effective lithium-ion solutions. The New Warehouse Podcast EP 442: Green Cubes Technology – A Decade of Advancing Lithium-Ion Power in Warehousing

Women In Trucking Association announces its December 2023 Member of the Month

The Women In Trucking Association (WIT) has announced Deb Beecher as its December 2023 Member of the Month. Beecher is an area risk manager I for J.B. Hunt Transport and recently celebrated 40 years with the company. Raised by a 3-million-mile safe driver, Beecher was familiar with the trucking industry and had an appreciation for drivers and the work they do across the nation. She remembers passing by J.B. Hunt on her way to church every Sunday and shortly after graduating high school, her best friend’s father who was a vice president of transport at the time encouraged her to apply. The decision was easy as the passion for the industry was already there. Celebrating 40 years with the company in 2023, Beecher did not start her time there thinking she was going to make a full career out of it. “My intention was to go into nursing, but I ended up on a different path,” said Beecher. “Since the start, I have really enjoyed working at J.B. Hunt. I look back now, and know transportation is where I was meant to be. I have held various roles at this company but have always come back to the operational side and working with the heart of our company, the drivers.” Beecher understands the importance of safety within her company and values deeply the opportunity to provide safety resources to its drivers. “Many drivers have connected with me to say thank you and I love that about my role,” said Beecher. “Whenever our drives utilize new safety resources, it’s like a lightbulb turns on for them and it’s not just a good feeling, it’s a great feeling.” A fond memory of her time at J.B. Hunt was before driver load sheets were digital and one that was essential to an important load has been misplaced. Mrs. Hunt personally took the time to help Beecher look for the load sheet until it was found. She enjoyed the time she got to spend with Mrs. Hunt saying, “she has always had a heart for the drivers of J.B. Hunt and would do whatever it took to make sure their time at the company was successful.” In 2018, Beecher received the Rodney Horton award that is given in recognition and appreciation of commitment to J.B. Hunt and compassion for others. The award is in honor of Rodney Horton who was a long-time employee and exemplary person who passed while employed with J.B. Hunt. In this same year, Beecher and her team received the Pillar award for Q1 for Truckload Support category. Beecher is a champion for women in the trucking industry saying, “I encourage women within our industry to show up to work, do your job well, and you will be recognized for your work. Believe in yourself and never think you aren’t capable.”

Know the differences and functionalities of battery management systems

Batteries used in forklifts and other material handling equipment often look very similar, with no obvious differences in design or features. A vehicle’s voltage, Ah capacity, and other technical indicators must meet the requirements of the main vehicle standard. However, there are often significant price differences between brands, not only due to the functionality of the battery management system (BMS) but also because of other parts of the “total product”: delivery and installation, integration with forklifts and chargers, and support, service and parts availability. For optimal performance and longevity, it is crucial to choose a lithium forklift battery that is reliable and safe. Your organization’s efficiency can be maximized by choosing the right battery for your device. How do cheap industrial lithium batteries remain cheap? When production expands, cheap overseas labor may be a major factor in retail prices. Material handling, however, is a relatively niche market. This advantage is offset by higher shipping costs and longer delivery times. After that, what happened? First and foremost, it is the limited functionality of non-automotive-grade high-quality battery modules and base-level BMS. Secondly, the CAN bus system is unstable and the components are of high quality. Industrial lithium batteries are affected by these factors. The battery core is the heart of the battery, according to BSLBATT. We work hard to extend the life of our batteries and increase their energy and power density by using only the highest quality batteries with the safest technology. Even in extreme weather conditions, it operates over a wide temperature range. Furthermore, advanced BMS prevents battery degradation by providing real-time diagnostics, adjusting individual cell charging, and protecting and optimizing the battery. Furthermore, the Advanced Controller Area Network (CAN bus) is the battery’s nervous system for communication. In addition to communicating battery condition information to the BMS system, the CAN bus functions as a central network hub. Additionally, high-quality components prevent overheating during high-current charging and discharging. In order to maximize the performance of the battery system, BSLBATT forklift lithium batteries are designed with the highest quality components. Process of charging and discharging. The lithium battery module, BMS, CAN bus system, and high-quality components cannot be adjusted according to the customer’s actual working conditions. Moreover, there are no advanced features, which may result in a price advantage, but may also cause battery users problems. As you will see in the practical example below provided by David Zabala, a professional electrical engineer and top forklift expert at one of BSL’s distributors in Mexico, cheap industrial lithium batteries purchased online from overseas arrive at your doorstep just as easily as forklift batteries. The TV remote control requires AAA batteries. No, it isn’t. A second forklift or crane is required to remove the old battery, and a technician must be trained to connect and test it. Inspections include connectivity, safety, and operational aspects. BSLBATT’s high-quality lithium battery brand price usually includes installation and setup costs. Due to potential service needs, labor costs for initial installation will continue to rise. In the best case, the downtime cost is equal to the rental cost while you wait for the spare parts to arrive. The cost of downtime to business operations is the worst-case scenario if a replacement is not made quickly. An industrial lithium battery purchased online had a problem This is the story told by David, a professional electrical engineer and top forklift expert at a BSL distributor in Mexico. BSL distributor in Mexico provided a quote for 15 5,000-pound electric forklift batteries to a customer in Monterey. It turned out that BSL’s distributor in Mexico quote was $1,200 higher than “the Internet’s” price, so it lost the bid. David’s personal profile: https://www.lithiumforkliftbattery.com/bsl-batteries-north-america.html A month later, the customer received a 20HQ industrial lithium battery and lithium battery charger from the public transportation company, but the old battery in his forklift couldn’t be replaced. If he orders through BSL’s distributor in Mexico, the new battery will be delivered and installed, and the old battery will be removed and properly disposed of. Instead, customers pay BSL’s distributor in Mexico $220 per battery for installation. The customer experienced battery failure approximately 90 days later, contacted the manufacturer, and had a replacement battery accessory shipped to him. In this call, the customer asks David for help with replacing the damaged parts for a service fee of $500. While customers waited for their units, the only forklift stopped again. The rent ended up costing him nearly $600. He also experienced headaches and downtime, as well as the time it took to overcome these obstacles. “So we spent an extra $1,500 upfront, so he bought the battery from the Internet,” David said. Once all is said and done, the customer shows that he understands local support for the product and won’t make the same mistake again.” What is the best strategy for industrial lithium batteries? According to David, most forklift dealers in Mexico do not use lithium technology at all. Many of them are making their own batteries or relying on artisanal battery producers who have not yet fully developed the technology they use. There are significant safety concerns with these batteries, and many battery systems today look as if they were cobbled together with jumper cables. Today, too many companies are playing with fire! To help more forklift dealers choose the best industrial lithium battery, I feel it is necessary to elaborate on four points. It’s not comprehensive, of course, but if a vendor can’t answer your questions in these areas, then they aren’t worth working with. Safety is more important than price ● There is a wide range of battery technologies available in terms of cost and safety. I recommend paying the premium. Battery accidents are dangerous and, in my experience, more expensive in the long run than buying safe, high-quality batteries. For the peace of mind of our customers, all BSL products have passed the most stringent UL2580 test and every product is covered by PICC insurance! UL2580 test certification video: https://www.lithiumforkliftbattery.com/lithium-forklift-battery-ul2580.html ● Contact the

New Leuze location in the USA

As part of its global growth strategy, Leuze in the USA is moving to new premises. The US Leuze Sales, Production and Development departments will in the future be located in Duluth, Georgia. Duluth in the northeast of Atlanta, Georgia, will in the future be the new Leuze location in the USA. “After careful consideration, we have decided to move our office to a new, more modern and more spacious US location,” says Ibrahim Zuva, VP Operations and Technology Americas. This decision is consistent with Leuze’s long-term strategic growth targets. “The new location also provides a more favorable environment for cooperation with our customers, distributors and partners,” emphasizes Zuva. Everything under one roof A further advantage: Sales, production and development will in future all be under one roof. Leuze will relocate the Sales, Operations and Development departments currently based in New Hudson, Michigan, by the end of 2023. “At the beginning of 2024, US production will also be moved to the new location. The formal opening of the new Leuze location is planned for March 2024,” says Zuva. Extensive range of high-tech sensors Leuze offers its customers in the USA an extensive range of high-tech products, which include a large number of different sensors for automation technology. For example, switching and measuring sensors, identification systems as well as solutions for data transmission and image processing, and everything needed for safety at work: safety components, safety services and safety solutions. The new on-site training center provides the company’s employees, customers, and distributors with many possibilities for further training. “We greatly value the good relationship we have with our customers, distributors, and we are convinced that the relocation will further consolidate our cooperation,” says Aaron Henry, President Leuze USA. “Local production brings us closer to our customers and will allow us to supply them with products faster and more efficiently,” he emphasized.

Charging Station to Power Electric Trucks in Port of Long Beach

The growing fleet of electric trucks serving the Port of Long Beach will be able to charge at a new depot scheduled to begin construction in mid-2024 along Pico Avenue just north of the Long Beach International Gateway Bridge. The Port is partnering with Forum Mobility, a leading zero-emission drayage trucking solutions provider, to offer 19 dual-port chargers and six single-dispenser chargers at the new station, capable of charging heavy-duty electric trucks in about 90 minutes, depending on battery size. The depot, located at 260 Pico Ave., is scheduled to go online in fall 2024. “Forum Mobility is taking the next step toward helping the Port achieve its goal of having 100 public charging stations in the Port available for heavy-duty trucks by 2026, which will help us transition away from diesel fuel and move toward a zero-emission future,” said Port of Long Beach CEO Mario Cordero. “We are proud to be an industry leader in the sustainable movement of goods as we continue to make dramatic reductions in air pollution.” “We thank Forum Mobility for delivering the necessary infrastructure to help us become the world’s first zero-emissions port,” said Long Beach Harbor Commission President Bobby Olvera Jr. “We have a duty to enhance air quality for our surrounding communities and an obligation to assist our local truckers with cost-effective solutions to operate more sustainably.” “With the support of the Port of Long Beach, Forum is building the infrastructure for heavy-duty trucks to transition from diesel to electricity,” said Matt LeDucq, CEO and co-founder of Forum Mobility. “This partnership provides drayage truckers a solution to comply with California Air Resources Board regulations at a convenient location and at a competitive cost. Forum is building a network of charging depots at the ports, along freight corridors and near distribution centers to serve owner-operators and carriers of all sizes in the transition to zero emission vehicles. We make it easy to go electric.” In addition to the Port of Long Beach, Forum Mobility has eight charging depots in advanced stages of development scheduled to open within the next two years at seaports and along goods movement corridors throughout California. The announcement comes as the California Air Resources Board will require any new drayage trucks registered to serve the San Pedro Bay ports complex as of Jan. 1, 2024, to be zero-emissions and for the entire drayage fleet to be zero-emissions by 2035. In an effort to assist truck drivers with making the transition, the Port of Long Beach is partnering with the Port of Los Angeles, CARB and CALSTART to make $60 million in Clean Truck Fund Rate funding available for vouchers toward the purchase of zero-emission, Class 8 drayage trucks operating within the San Pedro Bay ports complex. With funds collected by the San Pedro Bay ports, up to $436,000 per truck is available through the California Hybrid and Zero-Emission Truck and Bus Incentive Project. Funding information can be found at https://californiahvip.org/. Truck drivers can drop-in and ask questions to learn about CARB’s new regulation and the incentive program during an event scheduled for 8:30 a.m. to 4 p.m., on Tuesday, Dec. 12 at the Port of Long Beach Terminal Access Center, 1265 Harbor Ave., Long Beach (southwest corner of Harbor Avenue and West Anaheim Street).

Zero-Emissions Cargo Handlers debut at Port of Long Beach

A fleet of 33 new human-operated, zero-emissions battery-electric yard tractors were officially unveiled Wednesday at a Port of Long Beach container terminal where the cargo-handling machines have replaced traditional gasoline and diesel-powered models. The deployment – the largest of its kind on the West Coast – was led by terminal operator SSA Terminals LLC, a joint venture between SSA Marine and Matson Navigation Company. It is partially funded by a $50 million grant from the California Air Resources Board for the Sustainable Terminals Accelerating Regional Transformation, or START project, a sweeping, transformative demonstration of a near-zero and zero-emissions supply chain. The START project is part of California Climate Investments, a statewide initiative that puts billions in cap-and-trade dollars to work by reducing greenhouse gas emissions, strengthening the economy and improving public health and the environment – particularly in disadvantaged communities. Additional funding for the equipment was provided by a U.S. Environmental Protection Agency Targeted Airshed Grant award. The new machines increase the percentage of zero-emissions equipment being used at the Port of Long Beach to approximately 20%. The percentage will continue to increase as more zero-emissions equipment is rolled out at the Port. This equipment also accelerates Pier C’s progress toward zero-emissions operations, a process that will continue further as SSA Terminals works to integrate zero-emissions, human-driven top handlers. “Meeting our aggressive zero-emissions goals is not possible without the support of our partners, and this project is just another example of the shared commitment at the Port of Long Beach to a zero-emissions future,” said Port of Long Beach CEO Mario Cordero. “I’d especially like to thank SSA Terminals for leading zero-emissions efforts at Pier C, Southern California Edison for prioritizing zero-emissions infrastructure projects and CARB for the funding to make these types of projects possible.” “This project is exciting, and we commend all parties involved for balancing the need for zero-emissions technology and infrastructure while bolstering the efficient movement of cargo by the hardworking dockworkers,” said Long Beach Harbor Commission Vice President Bonnie Lowenthal. “We are excited to see the Port of Long Beach moving in this direction, consistent with Matson’s goals of achieving a 40% reduction in Scope 1 greenhouse gas fleet emissions by 2030 and net zero GHG emissions by 2050,” said Matson Chairman and CEO Matt Cox. To turn idea into reality, SSA Terminals closely collaborated with the equipment developers to create machinery and infrastructure that could withstand the intensity of a full workday on the docks. The equipment is capable of running a two-shift operation with a once-per-day opportunity charge. Both the Port and SSA Terminals worked with Southern California Edison to bring the project to fruition. SCE’s Charge Ready Transport program supports heavy duty electrification projects and was vital to the success of the project.

Association of Diesel Specialists Convention will feature session on Technician Retention

George Arrants, Vice President, ASE Education Foundation will present “What Makes Technicians Leave? and How to Stop Them” at the 2024 ADS Convention in Grapevine, Texas The Association of Diesel Specialists (ADS) has announced a new speaker for the 2024 ADS International Convention, George Arrants. Arrants will present “What Makes Technicians Leave? And How to Stop Them” at the Gaylord Texan Resort & Convention Center. The convention runs from January 21-22, 2024 immediately preceding Heavy Duty Aftermarket Week (HDAW) and features the latest industry education sessions as well as numerous networking opportunities. When an ADS service member has a quality technician leave, it creates a major void that is difficult to fill. This session will address the challenges of retention and recruitment of technicians. ASE Foundation’s Arrants will share his insights into what really motivates technicians to leave employers. It’s more than just pay. He will offer practical and actionable tips on how ADS members can strengthen relationships with existing technicians and create relationships with technical schools to supplement their workforce effectively. “We look forward to having George present at the 2024 ADS International Convention,” stated ADS CEO Scott D. Parker. “Losing talent is difficult, particularly in today’s employment environment. Every ADS member will benefit from this session with real takeaway retention ideas.” During the ADS International Convention (January 21-22), ADS members will receive diesel specific industry education and training as well as networking opportunities with hundreds of their peers in the diesel sector. Immediately following the ADS International Convention, HDAW kicks off (January 22-25). ADS members will interact with more than 2,500 executives and managers at the largest North American gathering of light, medium and heavy duty aftermarket professionals in the industry. HDAW also features a trade show with over 300 exhibitors. Register for both the ADS International Convention and HDAW now for lower pricing.

Central Rent-A-Crane of Indianapolis wrapping up expansion

Big changes are coming soon to Central Rent-A-Crane of Indianapolis, a member of the ALL Family of Companies, as the branch is in the final phase of an expansion project to better serve its customers. It will soon move to a new 14-acre property in nearby Fairland. Construction is wrapping up on a new 17,000-square-foot facility at the property. It features five service bays, including one 30-foot-wide wash bay, 55-foot ceilings, and heated floors. Another 6,000 square feet is dedicated to offices, 4,000 square feet for parts on the mezzanine level, and 4,000 square feet will be reserved for future expansion. The surrounding acreage provides plenty of space for cranes. The office space includes a breakroom large enough for 60 people, which will double as a safety training space. “The new facility is a service dream,” said Kevin Hileman, general manager of Central Rent-A-Crane of Indianapolis. “With the high ceilings, we’ll be able to extend crane booms for service indoors, and the heated floors will make a huge difference for our service technicians.” Hileman says the new facility speaks to ALL’s commitment to service. “The market has granted us huge success because they’ve responded to our customer-first approach to business,” said Hileman. “At our present rate of growth, we’re building this facility to accommodate future expansion.” A grand opening celebration will be scheduled to mark the formal opening of the new branch headquarters. The Indianapolis branch is one of 33 ALL Family branches throughout North America. In Indiana, ALL also operates Central Rent-A-Crane branches in Fort Wayne and Hammond.

The Future of Electrification Conference returns for its third year

ZAPI GROUP drives discussions on achieving an All-Electric Reality with industry experts and futurist Stefan Hyttfors ZAPI GROUP, a global provider in vehicle electrification, announced the 2024 dates of its Future of Electrification virtual conference taking place on February 7-8, 2024. Following the success of the first two years, the conference will bring together industry leaders and experts in industrial and commercial vehicle electrification to discuss the practical steps to achieve an all-electric reality. Presented by ZAPI GROUP, an electrification leader since 1975, the conference will provide insights into the latest technology, industry trends, and geopolitical and regulatory factors driving the electrification revolution. With the consumer automotive market-leading electric adoption, the event’s focus will facilitate conversations showcasing the practical path to electrification for industrial and commercial vehicles and machines. “We are actively working with customers in industries such as construction, commercial eMobility and material handling to realize wide adoption in all motive industrial markets. Our purpose is to make the electric dream a reality,” said Lloyd Gomm, Global Marketing Director for ZAPI GROUP. “We are excited to host our third annual virtual event where we can discuss our shared challenges and opportunities with thought leaders across the electrification business.” Attendees can expect a dynamic program that features a keynote presentation from renowned futurist Stefan Hyttfors titled Electrification as the Catalyst for a New Eraand a special presentation about the future of motor sport with Formula E’s Maserati MSG Racing Team. Presenters from leading organizations such as Ubiquicom, RISE AB, Discover Energy Systems, Flux Power, Trojan Battery, Stafl Systems, Inventus Power and SUNCAR AG join the ZAPI GROUP team to share their visions, challenges, and success stories in their journeys towards an all-electric world. Prominent industrial media leaders Becky Schultz, Vice President, Content, KHL Power Group; Darrell Proctor, Senior Associate Editor, Power Magazine; and Sara Jensen, Technical Editor, Power & Motion, bring their experience and perspectives across industries as moderators for some of the event’s panel discussions. Registration for The Future of Electrification 2024 is now open and free of charge. Visit www.futureofelectrification.org to register and for more information.

Gordon Report: Skills and Jobs in America: Past – Present – Future

First the good news: Over the past decade (2011-2020) investment in corporate training has grown by about 30 percent. The caveat is that professionals and executives received the lion’s share of these programs. (Development Dimensions International, 2023). The current skills-jobs picture paints a different reality. Seventy-five percent of U.S. employers now struggle to find skilled talent (worldwide it is 77 percent). This is the highest figure in 17 years. (ManpowerGroup 41 Country Survey, 2023). By 2030 U.S, talent shortages may lead to a loss of nearly $2 trillion from unrealized revenue. This will coincide with an estimated decline in the labor participation rate from 62 percent (2020) to 60 percent (2030). (Korn Ferry, “The Global Talent Crunch,” 2018). The worker pipeline is being squeezed because too many skilled workers are retiring and too few younger people are entering the workforce. Until 2029, 10,000 U.S. workers will retire each day. At least one-third are skilled workers. Unfortunately, the following generations are smaller and many of them lack the educational attainments needed to fill the high-skill jobs of the Fourth Industrial Revolution. In 2023 the ACT scores of U.S. high school seniors was the lowest in 30 years. Grade inflation at both the high school and college levels is masking the real educational accomplishments of today’s students. TALENT-DEFICITS CONSEQUENCES Here are some examples of the ways that current education and talent deficits are affecting the economic growth and social welfare of today and tomorrow. The post-COVID surge in airplane travel is stressing the aerospace sector. Airlines have ordered more planes, but both Boeing and Airbus have fallen behind in filling these orders. They have heavily invested in new aero-space technician training programs to replace retirees and expand capacity. Yet, poorly educated trainees are dropping out of these programs or creating quality issues on-the-job. Also, airplane part-suppliers are not delivering parts in a timely manner. They also are experiencing the same inability to find and skill more workers. The shortage of new planes in turn is forcing airlines to ramp up their repair and maintenance services on older aircraft. They also face shortages of trained mechanics and spare parts. This is reducing the number of airplanes in service at a time of increasing demand. Nearly 600 rural hospitals (30 percent of the total) are in danger of closing. (Center for Healthcare Quality and Payment Reform, 2023). A chronic shortage of doctors, registered nurses, and other skilled medical personnel and rising costs mean that many lack the resources to keep operating. Factories or fabs for advanced chip manufacturing are now being constructed in several locations across the United States. Many of these fabrication companies have already begun training and education programs for the engineers and technicians who will be needed to staff these plants. However, the Semiconductor Industry Association is predicting that up to 58 percent of the projected 115,00 jobs that will be added by 2030 may not be filled due to an insufficient number of students completing degrees in science and technology programs. The future U.S. labor economy needs more long-term talent investments. Demographic declines and increased job skills demands are not going away. Unless we do more to address skilled worker shortages, we can expect pay rises chasing a declining pool of qualified workers. This will complicate the U.S. inflation fight and raise the risk of a prolonged recession. About the Author: Edward E. Gordon is the founder and president of Imperial Consulting Corporation in Chicago. His firm’s clients have included companies of all sizes from small businesses to Fortune 500 corporations, U.S. government agencies, state governments, and professional/trade associations. He taught in higher education for 20 years and is the author of numerous books and articles. More information on his background can be found at www.imperialcorp.com. As a professional speaker, he is available to provide customized presentations on contemporary workforce issues.

BSLBATT and EVE sign battery cell strategic cooperation agreement

BSLBATT®, a China manufacturer of forklift lithium batteries specializing in the material handling industry, has announced that it has partnered with a global lithium battery company with core consumer technologies and solutions EVE Energy Co., Ltd signed a strategic cooperation agreement. The agreement will see BSLBATT add EVE’s LFP Cell to its current offering of innovative lithium battery solutions for forklift manufacturers and dealers looking to improve their forklifts. According to the official agreement, EVE Energy Co., Ltd will provide BSLBATT with a full range of Prismatic LFP Cells. “EVE Energy Co., Ltd is proud of the battery cell supplier partnerships we have with innovative partners like BSLBATT. We see the advantages of lithium iron phosphate power and the high-quality products they produce. We look forward to helping BSLBATT’s Customers increase uptime and lower the total cost of ownership of their material handling equipment by using EVE Energy’s cells.” – Rico Huang, EVE Energy Co., Ltd General Manager BSLBATT Battery leads the industry with innovative power options, with many forklift dealers turning to lithium batteries for high power applications such as Electric Forklifts, Multi-Directional Forklifts, Heavy-Duty Forklifts, Narrow Aisle Forklifts, Walkie Pallet Jacks, Electric Tow Tractors etc. BSLBATT’s lithium batteries are able to withstand harsh environmental factors while being maintenance-free and efficient. They allow warehouse managers looking for Refrigerated Storage to worry less about whether batteries are sustainable. “We are excited to bring our high-quality LFP Cells to BSLBATT customers around the world,” said Henry Shao, sales director of EVE Energy Co., Ltd. “Both BSLBATT and EVE believe that by providing quality products and excellent customer service, we can achieve greater success in Accelerate material handling throughput without breaking the bank. We look forward to working with the BSLBATT team to continue to expand its service offering with innovative technology and operational approaches adapted to today’s customer challenges.” BSLBATT’s forklift lithium batteries have a good track record and have been used with more than 12,000 Hster-Yale, Crown, Toyota, Manitou, Clark, Raymond, Combilift, Jungheinrich, Doosan, Linde, Nissan, Hyundai, Caterpillar, JCB, Bobcat, KION group , UNICARRIERS, KOMATSU, HELI, HANGCHA, BYD, Mitsubishi and many other electric forklift brands are integrated. They are plug-and-play and integrate seamlessly into the truck. Additionally, using BSLBATT’s fuel gauge and remote button, users can easily monitor battery charge status and turn the battery on and off as needed. BSLBATT lithium batteries are very efficient and can provide rated capacity at any discharge rate. This means operators will get longer working hours, with power continuously provided throughout the discharge process, and recharging in half the time compared to lead-acid batteries. The entire battery pack of BSLBATT battery has also passed UL2580, IEC62619 and UN38.3 certification, and the LFP Cell has passed UL 2580 certification, CE, IEC and UN38.3 certification. UL2580 test certification video: https://www.lithiumforkliftbattery.com/lithium-forklift-battery-ul2580.html Eric Yi, CEO of BSLBATT Battery, added: “We are seeing growing interest and adoption of lithium battery solutions across many industries. We are committed to bringing lithium batteries to market that address not only the challenges of lead-acid batteries, but other lithium batteries as well So. Providing this smart, seamless power solution supports our mission and provides the industry with an advanced approach to lithium batteries.” Interested in learning more about BSLBATT lithium-ion batteries and why they are so far removed from traditional solutions and their cloud platforms? Contact a BSLBATT energy expert today.

Association of Diesel Specialists announces free Technical Training during Annual Convention

Kevin Looney will present “2nd Generation HEUI for International & Ford 6.7 troubleshooting and repair” for EPA 04, 07 and 10 at the 2024 ADS Convention in Grapevine, Texas The Association of Diesel Specialists (ADS) announces that the technical training session at the 2024 ADS International Convention will be presented by Kevin Looney. Kevin will present ” 2nd Generation HEUI for International & Ford 6.7 troubleshooting and repair” at the Gaylord Texan Resort & Convention Center. The convention runs from January 21-22, 2024 immediately preceding Heavy Duty Aftermarket Week (HDAW) and features the latest industry education sessions as well as numerous networking opportunities. The Association of Diesel Specialists will be hosting a three-hour technical training class at no charge for registered attendees at the 2024 ADS Convention in Texas on January 21, 2024. Industry expert Kevin Looney will present information related to 2nd generation HEUI for International and on the 6.7 Ford troubleshooting and repair. It will include a discussion of the unique fuel delivery system found on these engines and some tips for diagnosing them. This will cover EPA 04, 07 & 10. Variable geometry turbocharging (VGT) and general aftertreatment principals will be included. Engine performance issues that commonly lead to aftertreatment concerns will be discussed as well. “We look forward to having Kevin Looney as the ADS Technical Training presenter,” stated ADS CEO Scott D. Parker. “Kevin has been maintaining and repairing equipment and vehicles for nearly 40 years, with a primary focus on domestic light, medium, and heavy duty diesel vehicle diagnosis and repair. ADS is committed to providing quality technical training for its members and this session is another example of that commitment.” During the ADS International Convention (January 21-22), ADS members will receive diesel specific industry education and training as well as networking opportunities with hundreds of their peers in the diesel sector. Immediately following the ADS International Convention, HDAW kicks off (January 22-25). ADS members will interact with more than 2,500 executives and managers at the largest North American gathering of light, medium and heavy duty aftermarket professionals in the industry. HDAW also features a trade show with over 300 exhibitors. Register for both the ADS International Convention and HDAW now for lower pricing. Kevin Looney has been maintaining and repairing equipment and vehicles for nearly 40 years, with a primary focus on domestic light, medium, and heavy duty diesel vehicle diagnosis and repair. Repairing everything from classic/historic trucks and equipment, to the latest computer controlled fully networked vehicles, Kevin has built a business known for getting the job done right. As a both a shop owner and working technician, he brings a unique combination of technical expertise, subject knowledge and hands on experience to the classroom. Building on a collaborative relationship with Bruce Amacker’s Turbo Training has allowed Kevin to expand his skill set to include educating. Kevin now splits his time between his shop in Phoenix Arizona, and a busy training schedule. Registration for the 2024 ADS Convention & Trade show is now open. Visit www.diesel.org/2024ADSConvention for more information.

Episode 441: Building supply chains with Izba

In episode 441 of The New Warehouse podcast, Kevin is joined by Aaron Alpeter, founder of Izba. Izba, a multifaceted company in the supply chain and e-commerce space, aims to assist startups in scaling their operations effectively. In this insightful episode, Alpeter shares his expertise on the fulfillment side of e-commerce, the evolving brand-provider relationships post-COVID, and the unique offerings of Izba. Building Supply Chains for Startups with Supply Chain Expertise Investors expect businesses to be stable and profitable from day one. Alpeter discusses how Izba started as a consulting business and evolved into a multi-company entity focused on helping founders scale their businesses and build their supply chains. “It’s actually three companies in one, with a mission to help founders start, scale, and exit their businesses,” Alpeter explains. Enhancing E-Commerce Operations Izba’s acquisition of Sourcify and the development of Capabl software are vital components of its business model. Alpeter elaborates on how these tools empower brands: “Capabl helps brands hold their 3PLs accountable and provides validation for 3PLs doing good work.” He highlights the efficiency and accountability brought to e-commerce operations through these innovative solutions. “Sourcify helps brands lower their COGS. So if you’ve got a widget you’re making for $10 today, we’ve got a network of about 3000 factories from around the world capable of making it at a lower price.” The Future of E-Commerce and Fulfillment Looking ahead, Alpeter predicts a more conservative growth approach for 3PLs. He suggests that success will come from focusing on performance rather than just technological aspects or marketing. “Letting your performance be what makes you special,” Alpeter remarks, highlighting the importance of delivering quality service and building a reputation based on reliability and efficiency. Aaron Alpeter discusses consumer demand for faster fulfillment: “We have figured out how to do 15-minute fulfillment… but nobody demands that. So that product is going away.” While rapid fulfillment is feasible, the consumer need for fast turnaround times is not as prevalent, leading to a shift away from such services. Alpeter emphasizes the need for 3PLs to focus on specific customer types or commodities to stay competitive. “The best thing 3PLs can do in 2024 is to go through their portfolios and prune brands that don’t fit their Ideal Customer Profile (ICP),” he advises. By doing so, 3PLs can ensure they’re providing the highest level of service to brands that align with their capabilities and philosophies. Alpeter encourages 3PLs to consider joining the Izba Exchange. “By integrating with Izba, 3PLs can have their performance fully audited, leveraging data from platforms like Shopify to provide a comprehensive operational scorecard. This integration will be a key differentiator in the Izba Exchange, showcasing empirical performance data, such as shipping 99% on time for many brands, helping them stand out in a crowded market of fulfillment providers.” Key Takeaways on Building Supply Chains Comprehensive Startup Support: Izba’s unique blend of consulting, sourcing, and software services provides holistic support for startups in supply chain management. Innovative Tools for E-Commerce: Integrating Sourcify and Capabl into Izba’s offerings enhances operational efficiency and accountability in e-commerce. Future-Oriented Approach: Alpeter’s insights into expanding applications for their technology indicate a forward-thinking strategy for Izba in the evolving landscape of e-commerce and fulfillment. The New Warehouse Podcast EP 441: Building Supply Chains with Izba

Warehouse automation market to return to growth in 2024

Following a slowdown in revenues in 2023, the global warehouse automation market will experience some growth in 2024 and return to high growth in 2025. Brownfield sites and upstream vertical markets are driving the market for warehouse automation. Interest rates are having a significant impact on vendor’s investment decisions for warehouse automation. According to the latest research by market intelligence firm Interact Analysis, warehouse automation order intake will begin to grow again in 2024 after the market suffered a tough 2023, albeit at a low rate. From 2025 onwards, revenues are expected to return to double digit growth. Warehouse automation revenues will increase in 2024 and return to high growth rates from 2025 onwards. As a result of the pandemic and record low level interest rates in 2019/2020, we saw a significant increase in e-commerce orders which led to an uptick in warehouse construction and therefore, an increase in warehouse automation sales. However, now that e-commerce sales have slowed down and interest rates have gone up, the market has seen a decline in warehouse construction which has led to a corresponding slowdown in warehouse automation investments. Order intake for fixed automation will have contracted by around -8% in 2023, but order intake for mobile automation is expected to grow by 38% over the year, providing a buffer against the overall market decline. The slowdown is being felt most in vertical markets with high exposure to e-commerce such as general merchandise, grocery, and apparel. These are often referred to as downstream verticals because they are downstream in the supply chain and closer to the consumer. On the other hand, upstream verticals like durable manufacturing have performed relatively well, driven by the trend towards near-shoring and the resulting construction of factories in the US and Europe. The durable manufacturing sector in fact is expected to have been the fastest growing vertical market for warehouse automation in 2023 with a revenue growth of 6%. Rueben Scriven, Research Manager at Interact Analysis, comments, “The rise and fall of warehouse construction has led to a corresponding increase and decrease of end-to-end warehouse automation solutions. Greenfield sites are well suited for large and complex end-to-end solutions, while brownfield sites are better suited to smaller point solutions that automate particular workflows, such as mobile robots. Because the share of brownfield sites has now increased, the share of point solutions (relative to end-to-end solutions) has also increased. Therefore, automation vendors that can provide solutions for brownfield sites and distribution center automation projects will fare well in the short term. “Overall, our projections for 2024 and beyond are pessimistic. Although we expect interest rates to remain high next year, warehouse construction will increase and result in an uptick in warehouse automation order intake in the latter half of 2024 and in to 2025.” About the Report: The 5th edition of our Warehouse Automation report guarantees to provide the most comprehensive and detailed analysis of the market. To produce the report, we’ve spent months conducting more than 100 in-depth research interviews and analyzed more than 120 companies, looking specifically at their past, present, and future investments in warehouse automation. Available as a Standard and Premium version. The premium version contains a mid-year update to adjust forecasts made in the standard version, six months after initial release. It also contains access to product news and financial databases to reduce efforts spent by internal marketing teams in collecting this data themselves. Also included is a Warehouse Automation Services Excel which breaks out the after-sale services and provides forecasts into the different services. About the Author With over 200 years of combined experience, Interact Analysis is the market intelligence authority for global supply chain automation. Our research covers the entire automation value chain – from the technology used to automate factory production, through inventory storage and distribution channels, to the transportation of the finished goods. The world’s leading companies trust us to surface robust insights and opportunities for technology-driven growth. To learn more, visit www.InteractAnalysis.com

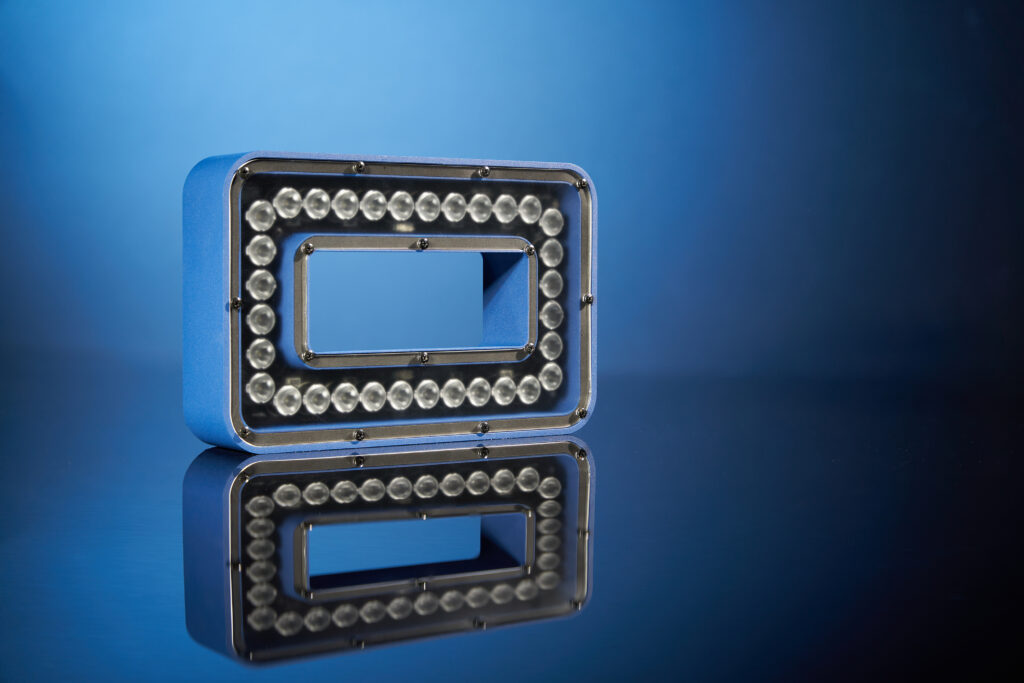

Smart Vision Lights launches JWL225-DO Lightgistics Machine Vision Light with hidden strobe technology

Smart Vision Lights (SVL) launched the JWL225-DO Lightgistics series light, which combines a linear light footprint with ring light functionality to deliver brighter, fast lighting at working distances of up to 2,000 mm. The light features Hidden Strobe technology, which enables the use of powerful LED strobing without annoying and potentially hazardous flashes. With Hidden Strobe technology, LEDs internally self-trigger thousands of times per second, pulsing faster than the human eye can perceive, creating the illusion of continuous light. The technology allows machine vision systems to benefit from powerful overdrive modes of LEDs while ensuring a safer and more comfortable environment for nearby employees. “As speed and throughput requirements in the logistics industry grow and evolve, systems integrators need LEDs capable of delivering bright light pulses to freeze images of fast-moving objects, but these strobing lights can create uncomfortable and potentially dangerous working environments,” says Steve Kinney, director of training, compliance, and technical solutions at Smart Vision Lights. “Hidden Strobe technology mitigates this issue, allowing high-speed machine vision systems to capture the optimal image without unintentional environmental hazards and without shielding.” Brighter, Faster LED Lights for Logistics Lightgistics LEDs were designed specifically to overcome the challenges of performing accurate barcode reading and optical character recognition at high speeds with highly reflective plastic wraps or shipping bags. The lights feature Dual OverDrive technology — which combines SVL’s Deca OverDrive and standard OverDriveTM engines and allows end users to attach polarizers that retain exceptional light output at any speed. “Achieving the level of speed and accuracy required in today’s automation applications in the logistics industry becomes difficult when trying to capture images through polybags and plastic wraps,” says Kinney. “Lightgistics lights are designed specifically for this issue, delivering light pulses that are 10 times brighter than standard continuous mode to help improve overall track-and-trace capabilities.” Equipped with an onboard charging capacitor designed to ensure powerful bursts of energy with a low consistent electrical draw, the JWL225-DO also features 10-, 14-, and 30-degree lens options. In addition, the IP65-rated bright field light’s integrated camera mount is compatible with most common machine vision cameras and can be directly connected and controlled through a camera’s trigger output.

Fairchild Equipment recieves tenth consecutive industry award

Fairchild Equipment has been awarded the prestigious MVP (Most Valuable Partner) Award for its outstanding achievements in 2023 by their industry trade association, The Material Handling Equipment Distributors Association (MHEDA). This achievement marks the 10th consecutive year that Fairchild Equipment has achieved the Award. The MVP Award is a coveted accolade within the industry, with fewer than 10% of MHEDA’s member organizations earning this distinction. Fairchild Equipment’s continued recognition as an MVP within the industry underscores a commitment to excellence, professionalism, and responsible stewardship in the business world. To qualify for the annual MVP Award companies must provide evidence of their commitment to their partners in business including their customers, employees, and suppliers. They must satisfy criteria in the following important areas: Industry Advocacy Customer Service & Safety Practices Business Networking Continuing Education Business Best Practices “We find immense value in our MHEDA membership and take great pride in being one of the members who values employees, customers, and the communities we serve,” Van Clarkson, Fairchild Equipment’s President and 2023 Chairman-Elect of MHEDA, shared. “It’s a true testament to our commitment to our core values, and always striving for continuous improvement in these areas!” Clarkson continued. “The MVP Award recognizes the best-of-the-best in our industry and is displayed with honor. To check all the boxes from education, industry best practices, awards, networking, employee engagement, giving back and much more, MHEDA is proud to have so many companies achieve this award. MHEDA appreciates the dedication to MHEDA and being a leader in this great industry that we are so blessed to be in.” John L. Gelsimino President of All Lift Service Co. Inc. and 2023 MHEDA Chairman.

Plastics Industry Association (PLASTICS) issues 2023 Q3 committee on Equipment Statistics Report

The Committee on Equipment Statistics (CES) of the Plastics Industry Association has just released the third-quarter shipment data for primary plastics machinery, encompassing injection molding and extrusion, in North America. According to the initial estimates for the third quarter of 2023, the shipment value stands at $345.8 million, marking a 1.5% decrease from the revised figure of $351.0 million in the previous quarter. In comparison to the same period last year, there’s been a 2.3% decrease in the value of shipments. Within the realm of primary plastics machinery types, single-screw extruders have seen a notable surge, with a 30.5% increase in quarter-over-quarter (Q/Q) analysis and an even more substantial 75.3% increase year-over-year (Y/Y). Twin-screw extruders also demonstrated a robust 30.3% Q/Q increase, though with a more moderate 2.9% Y/Y increment. On the other hand, injection molding continued its decline in shipments, experiencing a 2.3% decrease Q/Q and an 8.0% decrease Y/Y, marking the third consecutive quarter of decline. “At the start of this year, there was a double-digit decline in primary plastics machinery shipments. Following a 1.5% gain in shipments during the second quarter, there was a reversal, resulting in a 1.5% loss in the third quarter,” observed Dr. Perc Pineda, Chief Economist at PLASTICS. “The decline in shipments seems to have moderated on both a quarterly and year-over-year basis, aligning with the rising economic output from the first to the third quarter of this year.” In the most recent quarterly survey conducted by CES among plastics machinery suppliers to gauge their outlook on market conditions and equipment expectations, the results indicated a rise in participants anticipating an improvement in market conditions over the next twelve months compared to the previous year. The percentage of those expecting conditions to either remain the same or improve rose to 56.1%. In Q3 2023, U.S. exports of plastics equipment surged impressively by 7.2% from the previous quarter, marking a substantial 36.3% increase from a year earlier, totaling $270.9 million. More than half of these exports (55.4%) were directed to Mexico and Canada, totaling $150.1 million. Meanwhile, imports saw a decrease of 16.5% from the previous quarter and 9.5% from a year earlier, resulting in a total of $383.0 million. This shift led to a significant 45.5% decrease in the plastics equipment trade deficit, which reached $112.1 million. In the foreseeable future, the trajectory of plastics machinery will continue to be influenced by the prevailing high-interest rate environment, especially the inversion of interest rates. Despite the resilience displayed by the U.S. economic output, primarily propelled by robust consumer engagement, the economy’s transition toward a consistent output growth and a stable inflation rate has been somewhat delayed. While the demand for plastics is anticipated to remain steady, fluctuations in manufacturing could impact business investment decisions,” remarked Pineda.

U.S. Rail traffic for the week ending November 25, 2023

The Association of American Railroads (AAR) has reported U.S. rail traffic for the week ending November 25, 2023. For this week, total U.S. weekly rail traffic was 415,332 carloads and intermodal units, up 2.4 percent compared with the same week last year. Total carloads for the week ending November 25 were 195,948 carloads, down 2.5 percent compared with the same week in 2022, while U.S. weekly intermodal volume was 219,384 containers and trailers, up 7.1 percent compared to 2022. Four of the 10 carload commodity groups posted an increase compared with the same week in 2022. They included petroleum and petroleum products, up 1,034 carloads, to 8,642; metallic ores and metals, up 880 carloads, to 18,457; and chemicals, up 505 carloads, to 27,582. Commodity groups that posted decreases compared with the same week in 2022 included miscellaneous carloads, down 3,804 carloads, to 6,256; nonmetallic minerals, down 1,701 carloads, to 21,525; and grain, down 1,328 carloads, to 17,961. For the first 47 weeks of 2023, U.S. railroads reported cumulative volume of 10,587,945 carloads, up 0.2 percent from the same point last year; and 11,412,394 intermodal units, down 6.3 percent from last year. Total combined U.S. traffic for the first 47 weeks of 2023 was 22,000,339 carloads and intermodal units, a decrease of 3.3 percent compared to last year. North American rail volume for the week ending November 25, 2023, on 12 reporting U.S., Canadian and Mexican railroads totaled 302,649 carloads, down 2.3 percent compared with the same week last year, and 299,802 intermodal units, up 6.1 percent compared with last year. Total combined weekly rail traffic in North America was 602,451 carloads and intermodal units, up 1.7 percent. North American rail volume for the first 47 weeks of 2023 was 30,823,776 carloads and intermodal units, down 3.0 percent compared with 2022. Canadian railroads reported 91,357 carloads for the week, down 4.5 percent, and 69,360 intermodal units, up 0.5 percent compared with the same week in 2022. For the first 47 weeks of 2023, Canadian railroads reported cumulative rail traffic volume of 7,500,788 carloads, containers and trailers, down 3.3 percent. Mexican railroads reported 15,344 carloads for the week, up 17.5 percent compared with the same week last year, and 11,058 intermodal units, up 25.4 percent. Cumulative volume on Mexican railroads for the first 47 weeks of 2023 was 1,322,649 carloads and intermodal containers and trailers, up 4.3 percent from the same point last year. To view the weekly traffic charts, click here.

Raymond welder wins gold for 2nd consecutive year in global Toyota competition

The Raymond Corporation proudly announced that Jordan Taft, a welder at Raymond’s Greene, New York, facility, has won gold in the welding category of the international Toyota Material Handling Group (TMHG) Skills Competition and Chris Vrba, a welder at Raymond’s Muscatine, Iowa, facility, placed sixth among global contenders. Competitors from other members of the Toyota Industries family of companies based in China, France, Italy, Sweden and the United States were in attendance. Taft’s win is a testament to Raymond’s centurylong reputation of dedication to honoring continuous improvement and prioritizing the professional development of its employees. The end-to-end solutions provider maintains a constant focus on delivering the utmost quality and works for continuous improvement in every aspect of its business, including ensuring employees have the tools to be successful in developing their skill sets. “The Raymond Corporation heartily congratulates Jordan Taft on this prestigious achievement. The passion and dedication our welders such as Jordan Taft bring to the craft is inspiring and is a testament to the empowering culture we strive to cultivate at Raymond,” said Mike Field, president and CEO of The Raymond Corporation. “For an industry that touches almost everything, there will always be a need for skilled workers who provide essential services to help keep the supply chain moving. Our skilled team members are a major part of what has helped Raymond be a leader in the material handling industry for the past 100 years.” The competition consists of welding a steel pressure vessel, which required performing tack welding, executing semiautomatic welding and finishing the vessel’s surface. “It was an honor to represent Raymond in the competition and secure the gold,” Taft said. “I’m proud to work for a company that values the skilled trades, such as welding, and provides opportunities for skills advancement.” Raymond’s internal welding competition began in 2015 with the goal of helping promote friendly competition and enhancing skills and knowledge among Raymond’s welding teams. Since then, Raymond welders have earned invitations to compete in the TMHG Skills Competition. In the Assembly category of the global TMHG Skills Competition, assembler Jessica Vargus represented Raymond’s Muscatine facility and assembler Tom Morrison represented Raymond’s Greene facility. Vargus and Morrison performed well in the competition, taking fourth and fifth place, respectively. “At Raymond, we are committed to providing opportunities for professional growth and career development,” said Tony Topencik, vice president of operations, quality, and environmental health and safety at The Raymond Corporation. “I am profoundly impressed by Raymond’s welders, who have consistently excelled in the TMHG Skills Competition. Jordan, Chris, Jessica, Tom and previous Raymond participants in the TMHG Skills Competition embody the unwavering dedication to enhancing their skills and motivating others within our organization to strive for continuous improvement and development. We are so proud of the performances from all the competitors proudly representing Raymond on this global stage.” Taft has been invited back to Japan in March 2024 to compete against other gold-winning welders in the international Toyota Industries Corporation (TICO) Welding Skills Competition.

Norwalt executive appointed to key committee by Packaging Machinery Manufacturers Institute

Kyle Seitel, Vision Engineering Manager & Marketing Coordinator for Norwalt, named to PMMI’s Emerging Leaders Committee Norwalt, a specialist in custom-built automation and line integration machinery for complex manufacturing applications, has had one of its promising young executives appointed to a key industry organization committee. Kyle Seitel, Vision Engineering Manager & Marketing Coordinator for Norwalt, has been named to the Packaging Machinery Manufacturers Institute’s Emerging Leader Committee. During the four-year term, Mr. Seitel will lend his expertise and insight toward the Board’s development of policies and programs. Meanwhile, the Emerging Leaders Committee serves as an outlet for networking and mentorship for the younger set of executives comprising its membership. With facilities in Randolph, New Jersey and Tampa, Florida, Norwalt is a supplier of concept-to-completion manufacturing equipment solutions. The company’s engineers design, construct, validate and install premium production equipment whose functionalities include – but are by no means limited to – packaging and product assembly, post-mold automation, modular automation cells and robotics systems. Norwalt serves customers in a wide array of sectors, from medical devices and food & beverage applications to personal care and household items. PMMI is a global resource for the packaging and processing industry that aims to unite the sector across the manufacturing supply chain. Its members promote business growth in a variety of industries by developing innovative manufacturing solutions to meet evolving consumer demands. PMMI membership represents more than 1,000 manufacturers and suppliers of equipment, components and materials, as well as providers of related equipment and services to the packaging and processing industry. “It’s a privilege to have one of our talented young executives appointed to the Emerging Leaders Committee of our industry’s most effective, well-respected organization,” said Keith Harman, Director of Business Development & Technical Sales for Norwalt. “Kyle is an exceptionally dedicated equipment professional and represents the next generation of leaders here at Norwalt. This is a well-deserved distinction that will only further strengthen his skillset.”