Toyota Motor Corporation among global multinational companies using MiR autonomous mobile robots to optimize workflows for agile production; Industry first mover adds “mobile robots as a service” offering to help more companies benefit

Mobile Industrial Robots, the first mover and market leader in autonomous mobile robots (AMRs), has announced a second year of 160 percent revenue growth in 2018, a target the company established after accomplishing the same growth rate in 2017. The company’s success results, in large part, from MIR’s multinational customers, including Toyota Motor Corporation that is investing in fleets of mobile robots to optimize internal logistics and to gain competitive advantages in the production and supply chain. Thirty percent of MiR’s 2018 sales come from the Americas (27 percent in the United States and 3 percent in Latin America).

“Large multinational organizations, who are happy with the benefits they’ve received after trying one of our robots, are now investing in fleets spread across more of their plants, with some purchasing as many as 15 to 25 MiR robots at a time,” said Thomas Visti, CEO of MiR. “Our robots make it easy for these companies to follow the increasing shift to a mass-customization model, where they manufacture a higher number of customized products in smaller batches, requiring an agile production facility with flexible and easily adaptable logistics. Our user-friendly technology fits this model well.”

Growth from new products and new “robots as a service” offering to help more companies benefit

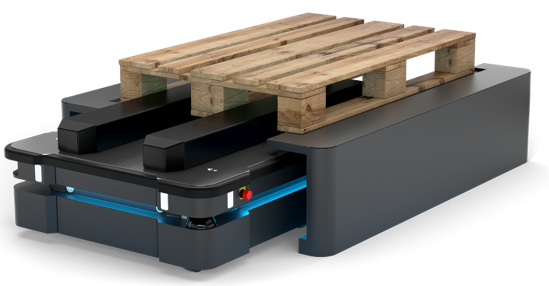

In addition to increased sales of multiple robots to companies like Toyota, which already uses MiR robots to optimize logistics in plants in the U.S. and Asia, the company’s growth in 2018 also came from the launch of the MiR500. Forty percent of sales of the MiR500, which can pick-up, transport, and deliver pallets, have come from U.S. companies. The continuous growth worldwide means that MiR expects 2019 will bring even more new products, along with 100 new employees and new offices in the U.S., China, and Japan. According to Visti, the company also expects to increase revenue as much, if not more, over the next year, while expanding the types of companies that can benefit from autonomous mobile robots.

“In 2019, we’ll continue to focus on delivering solutions that companies are requesting,” he said. “That means we’ll also support companies that are used to leasing equipment such as electric forklifts and AGVs by starting a new ‘mobile robots as a service program’ via our external partners. Now we can lower the initial investment required to make it easier and more attractive for these companies to get started with our collaborative autonomous mobile robots.”