Container trading and leasing rates decline in China ahead of the Golden Week

China to US container leasing rates drop by 35% Average container trading prices in China decreased for the second consecutive month in September; remained 25% higher than last year’s average. This month’s China market update is packed with developments that could potentially disrupt supply chains both within China and from China to key markets like the U.S. and Europe. Typhoons slow down berthing times and container operations in key Chinese ports Last week, China experienced its worst typhoon in 75 years, making landfall on the east coast. Hapag-Lloyd reports that ships are now facing delays of 36-60 hours to berth in Shanghai, while Ningbo faces waiting times of 24-48 hours. This bottleneck is expected to worsen as Typhoon Pulasan approaches, potentially exacerbating the already strained situation. Several ports in Ningbo and Shanghai have announced the suspension of container operations. (As on 20 September 2024) East Coast labor strikes affecting U.S.-bound shipments On the U.S. front, the ongoing threat of labor strikes at East Coast ports has created uncertainty. These strikes are expected to affect operations at the ports in the east coast. This has led to an acceleration in orders over the past two to three months, with businesses pulling forward shipments to mitigate potential delays. “In light of the recent robust U.S. economic growth, particularly in consumer spending (expected to rise 2.4% in 2024), businesses have been pulling forward shipments to mitigate potential delays. This consumer demand, coupled with a projected 3.8% increase in imports in 2024, represents the significance of timely shipping from China.” shared Christian Roeloffs, cofounder and CEO of Container xChange, an online global container trading and leasing marketplace based in Hamburg, Germany. Golden week approaching; another factor for slowdown Our regular surveys indicate that demand for U.S.-bound shipments from China remains strong, especially with Golden Week looming. Golden Week, starting October 1, traditionally causes a temporary slowdown in logistics activities across China, with a noticeable dip lasting between seven and ten days. With these events in combination—the U.S. labor strikes, upcoming Golden Week, and port suspensions—the China-to-U.S. shipping route is set to be volatile and uncertain over the next 20 days. Container market conditions in China: Softening demand and container prices Despite these uncertainties, no significant congestion or market is tightening within China itself. Several customers have reported a drop in container prices and lower COC (Carrier-Owned Container) rates, suggesting a softening demand for exports from China. Average container prices on a downward trend As of September 2024, average container prices in China have maintained their downward trajectory, with declines accelerating ahead of the Golden Week holidays. This drop reflects a broader reduction in demand for container shipments. Prices have fallen by 25% year over year, from $3,012 in September 2023 to $2,525 in September 2024. This year, container prices peaked at $2,603 in July 2024 and have been decreasing for two consecutive months. Chart 1: Average container price chart in China Leasing rates decline for the second month Overall, China to US average one-way container leasing rates dropped by 35% from $1221 in the first week of August 2024, to $787 as on 23 September 2024. Chart 2: Average one-way container leasing rates drop by 35% from Aug -Sep’24 Average one-way leasing rates for containers from Shanghai to Los Angeles have fallen for the second consecutive month. Rates dropped from $1,149 in July to $786 in August, and to $732 as of mid-September. Despite this decline, current rates remain elevated compared to the same period in 2023, when rates were $479. We anticipate these prices to stay relatively high through the rest of the year due to uncertainties surrounding U.S. East Coast strikes and the broader economic climate. Chart 3: Average one-way container leasing rates from Shanghai to Los Angeles: July–September 2024 Industry insights and market outlook The current challenge in the China market is the low Carrier-Owned Container (COC) rates, making it harder to send units to the U.S. This is compounded by high Pickup Charges (PUC), which have resulted in fewer Shipper-Owned Containers (SOC) reaching the U.S. Consequently, we might see rising prices for U.S.-bound shipments. Container leasing demand is expected to slow as Golden Week approaches. Much of the Christmas and Black Friday inventory has already been shipped, with deliveries typically taking 30 to 60 days. Despite the ongoing challenges, there are no major reports of port congestion in China, though general trade volumes are declining, indicating a tougher economic environment. At present, securing containers is not an issue, though this may change as market conditions evolve.

Advance Lifts highlights innovative container dumper series

Optimize workflow efficiency with versatile and reliable container dumping solutions Advance Lifts continues to offer cutting-edge solutions with its comprehensive Container Dumper Series. Container dumpers are used to empty containers’ contents onto various receivers. This series includes a range of high-performance products designed to meet the dumping needs of various industries, including package and letter handling, food processing, material handling, automotive, manufacturing, and warehousing. The Standard Container Dumpers (DP) are compact and ideal for medium-duty applications where space is a premium. With a 125-degree dump rotation and versatile dump heights, these models are perfect for operations requiring efficient and reliable dumping capabilities in confined spaces. The front-mounted cylinders and compact power units make DP models the go-to choice for tight spaces. For more demanding tasks, the Heavy Duty Container Dumpers (HDDP) are engineered to handle continuous use with enhanced mechanical advantages. These units feature angled cylinders straddling the bins for added strength and stability, a 135-degree dump rotation. They are designed for higher cycle rates, making them ideal for operations requiring robust and reliable performance. High Reach Container Dumpers (HRDP) is tailored for applications that need elevated dumping heights. These models offer a dumping carriage that can be raised to heights between 72” to 120”, ensuring exceptional versatility in reaching different containers or processing equipment. The HRDP models maintain the same robust construction as the HDDP, ensuring long-lasting durability even in challenging environments. The new High-Performance Container Dumper (HPDP) stands out with its up to 180-degree dump rotation, ensuring complete and efficient emptying of containers. Designed for continuous use, the HPDP can perform up to 22 cycles per hour across three shifts per day. Its robust design makes it suitable for high-demand environments, delivering exceptional performance without compromising on space. The new Ultra High-Performance Container Dumper (UHPDP) takes efficiency to the next level, combining the advanced features of the HPDP with enhanced control settings, including a unique shuffle mode for optimized operation. With the highest operational efficiency and the ability to handle the most rigorous tasks, the UHPDP is designed for industries requiring top-tier performance. Advance Lifts backs its products with some of the best warranties in the industry, reflecting its offerings’ superior durability and reliability. The standard warranty covers 1 year on electrical components, 250,000 cycles, and 10 years for structural components. The HPDP models include a 5-year, 500,000-cycle warranty, while the UHPDP models come with a 5-year, 1,000,000-cycle warranty.

What the Fed Interest Rate Cut may mean for Manufacturers

In a highly anticipated move, Federal Reserve Chair Jerome Powell announced the target rate would be cut 50 basis points, bringing the federal funds rate to a 4.75% to 5% target range. This move comes less than a week after the close of IMTS 2024, the largest manufacturing trade show in the Western Hemisphere. At this show, the technology needed to meet the consumer and business demands of tomorrow was on display and met with overwhelming enthusiasm by manufacturers. “Economic convention says this decrease will help spur additional consumer purchasing and business investment. Fulfilling this additional demand will require the parts and products that are made with the metalworking machinery AMT members provide,” said Christopher Chidzik, principal economist of AMT – The Association For Manufacturing Technology. “A gradual normalization of interest rates would have been a welcome signal the Fed has squeezed inflationary pressures from the economy without tipping it into recession. With this larger cut, Chair Powell has also recognized some growing risks of rising unemployment. While that may cause some to entrench their hesitation into future planning, the forward guidance shows unemployment deviating little from the longer-term trend. If consumers and businesses take those signals from the Fed and translate them into additional spending and investment in the remainder of 2024, demand for manufacturing technology will surely begin to increase for the rest of the year and remain elevated through 2025.”

NRF Foundation launches Customer Conflict De-escalation training for front-line workers

Today, the NRF Foundation launched a new Customer Conflict De-escalation training program for front-line retail employees. The latest offering is part of the RISE Up educational training program. It focuses on fostering a safe and positive environment for retail employees and the millions of customers they serve. “As the nation’s largest private-sector employer, retailers help millions of customers find the items they want and need on a daily basis,” NRF Foundation Executive Director Adam Lukoskie said. “The Customer Conflict De-escalation program provides customer-facing employees with the knowledge and training to identify situations of potential conflict, and, most importantly, abate them successfully and ensure an enjoyable shopping experience for all.” The NRF Foundation partnered with the Crisis Prevention Institute (CPI) to create a 30-minute online de-escalation training program. Explicitly developed for front-line, customer-facing, and distribution center employees, the course teaches associates how to identify and manage customer conflict within a retail environment. “At CPI, we understand that retail employees face unique challenges on the front lines every day. Our partnership with the NRF Foundation to develop the Customer Conflict De-escalation training ensures that these vital skills are accessible to those who need them most, fostering safer and more positive environments for both employees and customers,” said Susan Driscoll, president of Crisis Prevention Institute. In 2023, the NRF Foundation earned more than 58,000 RISE Up training credentials. For more information, visit here.

Diversified Fall Protection appoints Gabe Galvan as EBM Design Director West

Galvan to oversee West Coast expansion with SIT Licensure, including testing and inspecting suspended scaffolding and building safety equipment in California Diversified Fall Protection (DFP) has appointed Gabe Galvan as EBM Design Director. Galvan will play a key role in leveraging the company’s newly acquired California SIT (Scaffold Inspection and Testing) license. This license permits DFP to offer inspection, testing, and design services related Exterior Building Maintenance (EBM) and other equipment within the state of California. After helping DFP secure the license, his role will enhance the company’s adherence to California’s stringent regulations, and ensure the highest standards of compliance for workers in California. “Obtaining California SIT license #56 makes it possible for DFP to offer mandated services which, until now, had to be provided by others,” said Travis Nelson, CEO of DFP. “We are so fortunate to have someone of Gabe’s caliber and expertise leading our EBM offering. We’re now a one-stop-shop in California for all required fall protection and EBM systems and services. I remain steadfast in the belief that our people are the most important input to our success; we want the best people in our industry, and Gabe is one of them.” Galvan brings 31 years of earned expertise to DFP, primarily in California, with eight years as an SIT surveyor. He has worked in all facets of this industry, from upper management to working side-by-side with field techs. His position ensures that DFP can now efficiently manage several critical compliance aspects, including the creation of Operating Procedures Outline Sheets (OPOS). These detailed documents provide comprehensive information on roof layout, equipment to be serviced, existing fall protection systems, and safety protocols necessary for the compliant execution of work. The OPOS is required for any building taller than 36 feet in California. “I’m eager to apply my comprehensive career insight to this position,” said Galvan. “Given the specific regulations and requirements within the state of California, securing this SIT licensure for DFP is something that will only enhance the formidable lineup of services we already provide.” As the leader of DFP’s EBM offering, Galvan will also facilitate the issuance of Letters of Written Assurance for vendors using fall protection equipment, verifying that all equipment has been inspected, and that vendors are properly trained for safe rooftop access. These letters must be produced for each vendor using the equipment on a given building. Established in 1994, DFP currently employs 275 professionals across six U.S. locations, serving all 50 states. The company has experienced exponential growth, quadrupling in size since 2019, propelled in part by four strategic acquisitions between late 2019 and 2021 (PEAK Fall Protection, Fall Protection Systems, Rooftop Anchor, and Versatile Systems). Since 2021, DFP has achieved a remarkable 30% growth rate. Currently, DFP specializes in partnering with strategic clients as their trusted advisor, assessing fall protection concerns with their fully integrated model, and providing “Fall Protection Partnership for Life” through the design, engineering, installation, and servicing of permanent systems. DFP also fabricates and distributes a range of fall protection products under their SafePro brand.

Hyster hydrogen fuel cell-powered ReachStacker honored by three sustainability award programs

BIG Sustainability, Green GOOD DESIGN and Global Good award programs commend innovative zero-emission container handling solution Hyster has announced that its hydrogen fuel cell-powered ReachStacker has been recognized by three award programs, adding to the list of accolades the company has earned for its efforts to help operations decarbonize by making the shift to electric material handling equipment. The solution, which produces zero tailpipe emissions, is being tested and validated at the MSC terminal in Valencia, Spain, one of the largest container terminals in Europe. “Industries that have typically relied upon diesel-powered equipment, such as ports, are increasingly seeking electric alternatives that satisfy emissions regulations from governments and ambitious targets companies are setting themselves,” says Lucien Robroek, President, Technology Solutions Division, Hyster. “This ReachStacker, as well as the award-winning hydrogen fuel cell-powered top-pick container handler and recently announced electric terminal tractors, are proof positive that Hyster is committed to working closely with customers to develop clean power solutions that provide the productivity that these applications require.” The ReachStacker was named one of the year’s best sustainable products by the BIG Sustainability Awards. Judged by experts on environmental impact, the program honors products that are designed to be more eco-friendly than market alternatives. The container handler also won a Green GOOD DESIGN Award, identifying it as one of the year’s best sustainable transportation solutions. The program honors companies and products that are driving progress toward a healthier and more sustainable world. The solution is also a finalist for the Global Good Awards in the Game-Changing Innovation of the Year category, alongside Microsoft and other major companies. The Global Good Awards reward businesses, nongovernmental organizations, charities and social enterprises that are blazing the trail for purpose-driven sustainability and ethical leadership. The hydrogen fuel cell-powered ReachStacker uses Nuvera®Fuel Cell Engines to convert hydrogen into electricity. The hydrogen is stored on board in high-pressure tanks and can be refilled in 10-15 minutes. The onboard hydrogen fuel cell charges the batteries and powers the electric motors and hydraulic systems, enabling the ReachStacker to lift laden containers with performance similar to that of a diesel-powered alternative. The pilot program is supported by the H2Ports project. H2Ports is funded by the Fuel Cells and Hydrogen Joint Undertaking (FCH-JU), coordinated by the Fundación Valenciaport, and involves several partners from the port community, industry and academia.

Episode 522: Tackling labor challenges in the Warehouse with Geek+

In this episode of The New Warehouse Podcast, Kevin sits down with Nicole Allison, Regional Sales Manager at Geek+. They dive into the intricacies of warehouse automation, focusing on how Geek+ addresses some of the most pressing challenges in the industry today. Geek+ is a global leader in autonomous mobile robots (AMRs) and goods-to-person technology. Nicole shares insights on how their innovative solutions optimize operations and improve worker ergonomics and satisfaction in the ever-evolving warehouse environment. Leveraging Automation for Labor Challenges in the Warehouse One of the most significant hurdles in the warehouse industry is labor management—finding, retaining, and ensuring the safety of employees. As Nicole highlights, “Labor is the largest component of any customer’s business, accounting for about 70 percent of their total operating costs.” Consequently, Geek+ tackles this challenge head-on by creating solutions that reduce the physical demands on workers. Furthermore, automation helps make jobs more ergonomic and more appealing. Nicole adds, “Geek+ is fortunate to have the largest portfolio of goods-to-persons technology on the market.” These systems allow workers to remain stationary while products are brought to them, significantly boosting productivity and worker satisfaction. Comprehensive Solutions for Diverse Warehouse Needs Geek+ stands out in the market with its extensive portfolio of robots tailored to various warehouse tasks. From shelves-to-person to totes-to-person and pallets-to-person systems, Geek+ can automate a wide range of operations within a warehouse. Nicole emphasized, “We refer to ourselves as an end-to-end solution provider because we can handle multiple applications in the warehouse.” Consequently, this flexibility allows Geek+ to address labor challenges across different departments. They can streamline operations and maximize efficiency through a unified software platform that controls all their robots. The Next Chapter in Warehouse Automation As automation becomes more commonplace, Geek+ plans to expand its footprint in the Americas. Additionally, Nicole notes that their focus is also on enhancing downstream operations. This strategy ensures their solutions are fast and highly adaptable to the needs of their clients. “Our software continues to optimize based on several factors, such as correlation and weight, to ensure that warehouses are running at their best efficiency,” she explained. They also plan to launch an innovation center in Atlanta this fall. Key Takeaways Labor costs account for about 70% of warehouse operating expenses, making automation a critical solution. Geek+ provides end-to-end solutions that integrate seamlessly across various warehouse operations. Geek+ has the largest portfolio of goods-to-person technology on the market. The New Warehouse Podcast Episode 522: Tackling Labor Challenges in the Warehouse with Geek+

ASSP unveils new membership model and management system

Occupational safety and health professionals can now find even more value in being a member of the American Society of Safety Professionals (ASSP). The Society’s membership model has been restructured to add key benefits while a new association management system simplifies member engagements. “More than ever, an ASSP membership is a smart investment in the continued growth of safety and health professionals,” said ASSP President Pam Walaski, CSP, FASSP. “It’s also an important investment in helping to keep workplaces safer in all industries worldwide.” ASSP members can now join common interest group and practice specialty communities at no additional cost. This free enhancement is geared to enrich member experiences through a greater sharing of resources and best practices with colleagues on a global scale. ASSP offers four common interest groups and 18 practice specialties, such as construction, manufacturing, ergonomics and transportation. “Our vibrant communities advocate for our profession and help individuals grow personally and professionally through education and networking,” Walaski said. “There is tremendous value in being part of a community at any career stage. Our communities also reflect our commitment to a diverse, equitable and inclusive Society.” In 2023-24, ASSP communities delivered more than 80 online workplace safety webinars, and nearly half offered free continuing education units (CEUs) to help safety professionals maintain certifications. As ASSP expands the value of membership, a modest dues increase will be phased in over the next three years to ensure the Society’s sustainability in providing top-tier services and resources. ASSP membership dues have not kept pace with inflation and have not changed in more than five years. The current rollout of the new membership model is aligned with the launch of ASSP’s new association management system, which streamlines how members engage with the Society when renewing memberships, registering for events and courses, and making purchases. “All of these changes are research-based and designed to support member needs while helping ASSP remain strong in advancing the safety and health profession,” Walaski said. “We are thoughtful in everything we do.” ASSP members have convenient access to a global network of more than 35,000 safety professionals and receive monthly issues of the Society’s award-winning flagship journal, Professional Safety. Discounted member-only pricing is available on industry-leading conferences, continuing education, voluntary national consensus standards and technical publications.

Nucor Promotes two warehousing leaders in anticipation of new initiatives

Nucor is pleased to announce the promotion of two esteemed teammates – Daniel Aguirre who is now Commercial Director and Keavon Anbardan who accepted the position of Construction and Installation Director. Both material-handling industry leaders have played a vital role in developing Nucor Data Systems (NDS) as the ultimate single-source provider of data center essentials. Daniel Aguirre’s career with Nucor began in 2014 at Hannibal Industries as an inside sales representative for its tubing products, where he held various responsibilities until his promotion to Distribution Sales Manager. In 2023, he was promoted to National Sales Manager of Nucor Warehouse Systems. As Commercial Director of Nucor Data Systems, Aguirre will lead the group’s commercial and design teams as it captures the explosive growth within AI and Cloud Computing infrastructures with Nucor Data Systems. In his new role as the Construction and Installation Director at Nucor Data Systems, Keavon Anbardan will lead the growing team of install technicians, project managers, construction engineers and sub-contractors. Anbardan was a key player in the rapid growth of Nucor Data Systems and will explore more growth opportunities for Nucor Fabricated Products in the construction and installation scope for data and warehousing. Previously, Anbardan was the Operations Manager for Southwest Data Products (SWDP), now Nucor Data Systems. “As we grow and expand with these exciting new data and warehouse market opportunities, we need strong leaders to help navigate our teams so that we can best serve our customers with our continuously evolving solutions,” said Dave Olmsted, VP and GM, Nucor Data Systems. “Daniel and Keavon are the best people for the job, with forward-thinking strategies that align with our unique position in the industry. They are going to help our team and customers build towards the future.”

Iowa vs. Minnesota Football rivalry Bobblehead unveiled to celebrate Saturday’s game

The National Bobblehead Hall of Fame and Museum unveiled a limited-edition Iowa Hawkeyes vs. Minnesota Golden Gophers Rivalry Bobblehead ahead of Saturday’s game between the two rivals in Minneapolis. The bobblehead features Iowa’s mascot Herky the Hawk and Minnesota’s mascot Goldy Gopher with a replica Floyd of Rosedale Trophy. The bobblehead commemorates the rivalry, which dates back to 1891. The special edition bobblehead, which will be released in conjunction with the 118th meeting between the Hawkeyes and Golden Gophers on Saturday, September 21st, at Huntington Bank Stadium in Minneapolis, Minnesota, is available exclusively from the National Bobblehead Hall of Fame and Museum, an official licensee of the University of Iowa and the University of Minnesota. “We’re excited to unveil this limited-edition Iowa vs. Minnesota Rivalry Bobblehead ahead of tomorrow’s game in Minneapolis,” National Bobblehead Hall of Fame and Museum co-founder and CEO Phil Sklar said. “This bobblehead will be the perfect way for Iowa and Minnesota fans, alumni, students, faculty, and staff to show off their school and state pride!” Each bobblehead is individually numbered to 2,024, and they are now available at this link in the National Bobblehead Hall of Fame and Museum’s Online Store. The bobbleheads, expected to ship in January, are $50 each plus a flat-rate shipping charge of $8 per order. The unique Floyd of Rosedale trophy, introduced in 1935 and awarded to the winner of the game, is a giant bronze pig commemorating its namesake. After the 1934 matchup was filled with controversy over the treatment of Iowa star running back Ozzie Simmons, the lead-up to the 1935 game was filled with back-and-forth barbs. To lighten the mood, Minnesota Governor Floyd Olson sent a telegram to Iowa Governor Clyde L. Herring on game-day morning, which read, “Minnesota folks are excited over your statement about Iowa crowds lynching the Minnesota football team. I have assured them you are law-abiding gentlemen who are only trying to get our goat. … I will bet you a Minnesota prize hog against an Iowa prize hog that Minnesota wins.” The Iowa governor accepted, and Minnesota won the incident-free game, 13-6. Governor Herring obtained an award-winning prize pig, which had been donated by Allen Loomis, the owner of Rosedale Farms. Dubbed Floyd after Minnesota Governor Olson, a few days later, Governor Herring collected “Floyd of Rosedale” and personally walked him into Governor Olson’s carpeted office. Floyd died of cholera just eight months after making headlines. Since the two schools could not continue wagering a live pig, Governor Olson commissioned Saint Paul sculptor Charles Brioschi to capture Floyd’s image. The result is a 98-pound bronze pig trophy, which is 21 inches long and 15 inches high. Tied for the fourth-longest rivalry in the Big Ten Conference, Iowa, and Minnesota have been squaring off on the football field since 1881. Minnesota leads the all-time series, 63-52-2, but the Hawkeyes have won eight of the last ten meetings and 15 of the last 20. The Golden Gophers snapped an eight-game losing streak to the Hawkeyes with a 12-10 upset victory last year in Iowa City. One of the most notable games in the rivalry was in 1960 when No. 1 Iowa and No. 3 Minnesota – both undefeated – played for the Big Ten championship, the 1961 Rose Bowl berth, and the No. 1 ranking. Minnesota won the game, 27-10.

Women In Trucking Association names new Membership Director

The Women In Trucking Association (WIT) recently named Alyssa Kirkman senior director of membership. In this newly created position, Kirkman is responsible for all aspects of membership, engagement, retention, and strategic recruitment initiatives for the association. In this critical role, Kirkman will also help to advance WIT’s mission to encourage the employment of women in the transportation industry, eliminate barriers they face, and promote their accomplishments. Kirkman has over 15 years of experience in membership, marketing, and education leadership with industry associations. Previously, she was a communications and marketing manager and a member of IFMA, the world’s largest international association for facility management professionals. She supported 24,000 members in more than 100 countries. Kirkman was also in membership and marketing leadership roles with CORFAC International, the National Glass Association, and the American Cleft Palate-Craniofacial Association. “We are thrilled to have a professional of Alyssa’s caliber leading WIT’s membership growth and retention initiatives,” said Jennifer Hedrick, CAE, president and chief executive officer of WIT. “As the first association to focus on gender diversity in the commercial freight transportation industry, the Women In Trucking Association is looking to enhance the strategies of WIT’s membership programs that will broaden our impact on the industry through more female talent.” Hedrick notes that WIT is today one of the larger trade associations in transportation with more than 8,000 members in 10 countries. “WIT has done an incredible job of growing organically over the last 17 years, and I look forward to leading membership initiatives to continue the membership trajectory of the association,” said Kirkman. “I’m excited to support the industry as a whole and to expand our reach so that more women are supported in their careers.”

I’m satisfied with my current source. Well, maybe

The prospect is not waiting by the phone for your call. Most people have what you’re selling and are doing business with someone else. They have a source for what you do, and they think they are happy. Satisfied. Good News: Satisfied people are willing to do business with others. Your challenge is to get them to do business with you. For you statistic buffs, “I’m satisfied with my present source” ranks second on the all-time prospect objection list. “Price too high” is number one (and always will be). When the prospect says, “I’m satisfied,” they’re really saying: This is all I know now. I don’t want to bother with you. I’m doing business with someone I like (not necessarily the best). I’m not telling you the real reason. I’m satisfied it is a brush-off. It’s not all that bad. Your prospect is saying that their existing supplier is the best they’ve been able to find. You may have a better product, price, delivery availability, service, training, or warranty. The prospect is only telling you he’s satisfied from his perspective. He doesn’t really know about you or your company yet but don’t give him any reason to switch until you know why he’s satisfied. Knowing the reason(s) why the existing relationship is satisfactory will help you understand how to proceed. Knowing those reasons gives you a chance. Here are a few “interest-gainers” or challenges that may get you in the door: Good Response: Satisfied? Great! You’re going to love doing business with us! Our customers are ecstatic, so if you’re only satisfied, today is your lucky day. Better Response: Mr. Johnson, Many of our customers said that when they were prospects like you. I wish I had ten dollars for every prospect that said, “I’m satisfied with my present supplier,” who is now a customer. Let me share a few of their comments (show your testimonials that say, “I used to buy from (name the competitor you hate the most), now I’m a loyal (your company) customer. And I invite you to call me personally if you need further explanation.” WOW! Best Response: When you started with (their present supplier), you took some risk, didn’t you? I’m not asking for all your business, but I’d be interested in what caused you to take the risk back then, and I may ask you to take that small risk with me and let me earn the rest.” Here are a few dialog starters: “Most people initially feel that way, but our experience has shown…” “What do you like most about your supplier (his product/service)?” (agree with them) “That’s what lots of their former customers said.” “If your friend left the business but stayed in the industry, would you still do business with that company or go with your friend?” “What would you change about your present relationship?” “How did the relationship begin?” “When people say, “I’m satisfied” they usually mean…” Find a personal link (common ground) that can trigger a friendly conversation. If they like you, they will listen to you. (a bit more assertive) “Satisfied or complacent? When was the last time you really looked at the situation and did a comparison?” Sales Caution: If the prospect says, “I’m satisfied,” it’s open season on the competition. If the prospect says, “I’m loyal,” watch out. Loyal is 100 times more powerful than satisfied. Sales Reality: You will not convince everyone. But the more you practice, the more “luck” you will have. “I’m satisfied” is not an objection; it’s a stall. If you believe in the value of your product, you can get past it. Sales Tip of the Year: Record five customers who were satisfied with your competitors, switched, and are now ecstatic with your company. Get your customers to tell your story. It’s far more compelling (and believable). About the Author: Jeffrey Gitomer is the author of twelve best-selling books, including The Sales Bible, The Little Red Book of Selling, and The Little Gold Book of Yes! Attitude. His real-world ideas and content are also available as online courses at www.GitomerLearningAcademy.com. For information about training and seminars, visit www.Gitomer.com, email Jeffrey at salesman@gitomer.com, or call him at 704 333-1112.

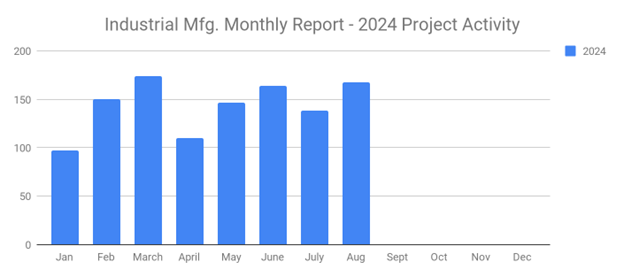

August 2024 bounces back with a 22% increase in new planned Capital Projects from the previous month

Industrial SalesLeads released the August 2024 results for the new planned capital project spending report for the Industrial Manufacturing industry. The Firm tracks North American planned industrial capital project activity, including facility expansions, new plant construction, and significant equipment modernization projects. Research confirms 168 new projects, compared to 138 projects the previous month. The following are selected highlights of the new Industrial Manufacturing industry construction news. Industrial Manufacturing – By Project Type Manufacturing/Production Facilities – 153 New Projects Distribution and Industrial Warehouse – 99 New Projects Industrial Manufacturing – By Project Scope/Activity New Construction – 43 New Projects Expansion – 56 New Projects Renovations/Equipment Upgrades – 68 New Projects Plant Closings – 18 New Projects Industrial Manufacturing – By Project Location (Top 10 States) New York – 15 Indiana – 14 Ohio – 13 Michigan – 12 Ontario – 11 Wisconsin – 11 North Carolina – 10 Pennsylvania – 6 Tennessee – 6 Arizona – 5 Largest Planned Project During August, our research team identified 11 new Industrial Manufacturing facility construction projects with an estimated value of $100 million or more. The largest project is owned by Natron Energy, which plans to invest $1.4 billion to construct a 1.2 million sf manufacturing facility in ROCKY MOUNT, NC. They are currently seeking approval for the project. Top 10 Tracked Industrial Manufacturing Projects QUEBEC: An aerospace company plans to invest $1.2 billion in the expansion of its manufacturing facility in MIRABEL, QC. They recently received approval for the project. NEW MEXICO: Solar Cell Manufacturing Company plans to invest $942 million in constructing an 834,000-square-foot manufacturing facility in Albuquerque, NM. They are currently seeking approval for the project, which is expected to start in late 2024. INDIANA: A steel company plans to invest $300 million in renovations and equipment upgrades at its manufacturing facility in Gary, IN. It is currently seeking approval for the project. MINNESOTA: A tissue paper manufacturer plans to invest $250 million in a 500,000 SF expansion, renovation, and equipment upgrades at a recently acquired manufacturing and warehouse facility in DULUTH, MN. They are currently seeking approval for the project. WEST VIRGINIA: A steel Mfr. plans to invest $150 million in constructing a manufacturing facility in WEIRTON, WV. They are seeking approval for the project, slated for completion in 2026. NORTH CAROLINA: A veterinary medical device manufacturer is planning to invest $147 million in the construction of a manufacturing facility in Wilson, NC, and is currently seeking approval for the project. KENTUCKY: Electric component MFR. is planning to invest $144 million to repurpose its manufacturing facility in MAYSVILLE, KY, and is seeking approval for the project. KANSAS: A pharmaceutical company plans to invest $130 million in the renovation, expansion, and equipment upgrades of its processing facility in ELWOOD, KS. It is currently seeking approval for the project. OHIO: A steel company plans to invest $100 million in expanding its manufacturing facility in Cantons, Ohio. It is currently seeking approval for the project. FLORIDA: A building materials manufacturing company plans to invest $78 million in constructing a 480,000-square-foot manufacturing and warehouse facility in ZEPHYRHILLS, FL. Construction is expected to start in late 2024. The company will consolidate its regional operations upon completion, which is slated for late 2025. About IMI SalesLeads, Inc. Since 1959, IMI SalesLeads, based in Jacksonville, FL, is a leader in delivering industrial capital project intelligence and prospecting services for sales and marketing teams to ensure a predictable and scalable pipeline. Our Industrial Market Intelligence, IMI identifies timely insights on companies planning significant capital investments such as new construction, expansion, relocation, equipment modernization, and plant closings in industrial facilities. The Outsourced Prospecting Services, an extension to your sales team, is designed to drive growth with qualified meetings and appointments for your internal sales team. Visit us at salesleadsinc.com.

Saluting Women in Material Handling: Champions of Industry Innovation and Excellence

As the material handling industry evolves and grows, so do the ranks of professionals within the business. This month, Material Handling Wholesaler spotlights some women’s work in the material handling industry. Those who participated in the article talked about their history in the business, shared thoughts on where the industry is today, and discussed changes they envision in the near future. Jeannette Walker Walker, currently the CEO of MHEDA got her start in material handling in 2001 thanks to a conveniently located business. Intrupa manufactured parts for forklifts and was just a mile from her home in suburban Chicago. After passing the operation on a longer commute, Walker decided to apply. When she was offered a job as an assistant to the CEO, Walker decided to go for it. “I took it and worked my way up,” she said. TVH acquired the business in 2006, and Walker stepped in to implement marketing during the acquisition and grew into other roles from there. Following her experience in leadership at TVH, Walker took on the role with MHEDA. She worked with former CEO Liz Richards for six months before taking the reins in July. “She did anything and everything she could,” said Walker of Richards’ help with the leadership transition. According to its website, MHEDA is the Material Handling Equipment Distributors Association, a non-profit trade association dedicated to serving all segments of the material handling business community. As to the current economy, Walker said the feeling for 2025 is “cautiously optimistic.” At a recent meeting of MHEDA’s board of directors, Walker identified several impactful trends. “The economy is number one,” she said, adding that the market is normalizing, although situations vary by region. “We talked a lot about consolidation in the market and what that means,” said Walker of the leadership discussion. Automation and AI continue to be among top-of-mind for MHEDA members, particularly with a universal talent gap in the industry, according to Walker, who said technology is helping fill the need in some spaces. She reflected that career paths for women in material handling vary. Still, the industry seems to be filled with professionals who are open to sharing information and through that, helping others succeed. According to Walker, there continues to be a growing number of women taking up leadership roles in the material handling industry. “I think it’s evolving very rapidly,” she said. MHEDA will also host a “Women in Industry” conference this fall. The event will be held November 6 and 7 in Rosemont, Ill., and registration is still open, according to Walker. Walker says the session will include topics important to women in the business. “There is also a leadership focus,” she said. Registration information can be found online at www.mheda.org. Candi N. Powers As a teenager, Candi Powers aspired to become a doctor. In pursuit of that dream, she traveled to Nashville, TN, enrolled in medical courses, and became an intern. In the meantime, her father, Henry M. Powers, and wife, Darlene Powers, were busy building a business. That business, focusing on developing and manufacturing new products for the materials handling industry, led him to develop a vertical lift that would propel his company’s success in the industry. To grow his new business into the innovative powerhouse now known as Custom Industrial Products (CIP), Henry Powers surrounded himself with the people he trusted most…his family. Candi Powers began her career with CIP advancing the materials handling cart division where she managed clients in hospitality, a critical industry that was the first to apply vertical lifts for improving operational efficiency and safety. She worked long and hard, eventually earning the crucial position of Material Control Manager. As Ms. Power’s responsibilities grew, so did her passion for solving unmet needs in materials handling. Besides the hospitality industry, CIP vertical lift systems began to make a difference in warehousing and distribution, government, automotive, retail, education, aerospace, and more. There were so many applications that CIP’s line of vertical lifts expanded to accommodate and adapt to a variety of space requirements, load and weight needs, height restrictions, safety concerns, workflow integrations, and environmental considerations. “I am one of the lucky ones who found a place where I could thrive and help others,” states Ms. Powers. “So instead of helping patients with their health, I’m helping people with the health of their business and with their workers’ safety.” Candi Powers became President of CIP in 2021 after helping the company weather the pandemic. In 2023, Henry Powers passed away, leaving a legacy of innovation and excellence in industrial duty manufacturing as well as a corporate headquarters in Melbourne, FL, with 50 employees and 126,000 square feet of space for fabrication, welding, powder coating, engineering, administrative, and storage. Candi Powers took the reins as CEO to continue and expand her father’s legacy. Henry Powers was a masterful mentor. In addition to the deep work values and ethics he instilled in Candi Powers as a child, he worked side by side with her at CIP, teaching Ms. Powers manufacturing insights, design and engineering, sales and marketing, and managing people. As Ms. Powers sees it, people are the most important part. “Dad really cared for all those around him,” recalls Candi Powers. “He was accessible and everyone’s go-to person for help. His example inspired me to listen and lead.” Today, Candi Powers works side-by-side with CIP President (and brother) Chris Powers to usher in the next generation of CIP products and solutions. In 2024, they launched CIP Lifts as Custom Industrial Products’ flagship product line with new vertical lifts that are expanding the envelope and applications of what a VRC or materials handling lift can do. “We are continuously improving every aspect of our operation from customer service and design to production turnaround and quality superiority,” states Ms. Powers. “The minute a call comes in, our multi-interdisciplinary team is assessing and addressing customer needs before customizing a solution that only CIP can provide…faster…smarter…better.” Megan Brune Brune got her start in material handling

Must read: Dealers, we have an opportunity for you

Another year-end is approaching. But I’m not sure what to expect for next year. Before we do anything further, I wanted to review the AI program we have made available to you. Some of you must be thinking, WHAT IS BARTECKI UP TO NOW? Well, let me tell you. The goal is to produce a dealer standard for investigating AI, to determine if your system and data can provide meaningful data to assist customers and improve internal processes and knowledge to do more with less, to determine how long it will take to implement a workable program, and finally, how much investment is required over what period, along with an estimated ROI to expect from this investment. Can you see the benefit here? What you do with Connor Corp will become an industry-specific dealer program where you will find industry-specific answers and suggestions about using AI in a dealership. Since this is a no-cost program until you decide to move forward, you can contact Connor, and they will compile a file based on what they hear from dealers and address it in their monthly column in MHW. And don’t worry; no specific dealer will be identified in the column or during conversations with dealers. I suppose dealers representing a particular brand could assemble an AI group to discuss how their group could benefit from AI and, if so, have the OEM participate in the AI planning. All participants in the process are on the same page. So please take advantage of this benefit for two reasons: 1. It will benefit your operation internally and externally when dealing with customers. 2. Going through this process will provide you with a path to assist customers who are going through the same process. In short, this would be a value-added benefit on your part. So please give this a shot if you are investigating AI or have decided to move ahead based on your work to date. In either case, industry-specific findings will help reduce the cost of implementing AI and the time it takes to install it. I hope readers will provide input into the process so that other readers can benefit from their conclusions and findings. To me, having a process to help me through this type of expenditure geared to my kind of business would be at the top of my list. I want nothing better than to be able to compare notes with other dealers to avoid costly mistakes. So please use Connor Corp, and let’s get the program going because it will make your life a lot easier regarding AI decisions. On to another subject. How about we review where we stand regarding inflation and deflation? Inflation is moving downward for certain products and services but is still above the 2% rate the Fed is looking for. In terms of inflation, James Altucher states we are suffering from a case of EconCovid because 40% of all money printed in the history of the US was printed in the six months after COVID-19 started in March 2020. Now you know where the inflation originated from. To contain and lower inflation, the Fed increased interest rates to reduce the funds and move them into banks to earn interest while slowing down borrowing to keep borrowed funds out of the money supply. Let me say that again: BORROWED MONEY CAN CAUSE INFLATION. I HOPE OUR RESIDENTS IN DC UNDERSTAND THAT. Deflation is also something to consider because if we have a slowdown that causes increases in inventory levels, prices will fall, and margins will take a hit. These deflation hits will have to be offset with payroll reductions and general cost-cutting to try and make ends meet. However, another cause of deflation could pop up even if we avoid a recession. This deflation will result from new forms of technology that will produce INNOVATION, BETTER PRODUCTION, AND AUTOMATION that will lower costs and thus pricing while maintaining margins. How about that…. a good deflation. With all that is happening, you can expect to deal with many variables in 2025 when planning for CAP-X, which contains technology, AI, and general production spending, no matter what industry you are in. My brother was in the machine tool manufacturing business until they opened the gates to China. You can guess the rest. In any event, he always told me that YOUR COMPETITOR IS YOUR BEST ENGINEER. FIND OUT WHAT THEY ARE DOING AND DO IT BETTER. In other words, who is considered to have a better operation than yours? Then, do your homework to find out why customers feel that way, and “poof,” you have a list of issues to work with to catch up and overtake them in your market. One last thing. I just finished reading Masters of the Air by Donald L.Miller. It covers the air war in WW2. This is an outstanding piece of writing, about 500 pages, that will personally impact you. It will make you cry, lose sleep, and maybe even come up with a nightmare or two. What we put those kids through is unbelievable. And they were kids…. flying B-17s. Give it a try….you will not forget it. About the Columnist: Garry Bartecki is a CPA MBA with GB Financial Services LLC and a Wholesaler columnist since August 1993. E-mail editorial@mhwmag.com to contact Garry.

Dealers Embrace Sustainability: Managing Resources & Environmental concerns

In the past few years, the material handling industry has seen a significant shift toward sustainability, driven by the need to better manage resources and address environmental concerns. The concept of the circular economy is driving this shift for dealerships. This mindset emphasizes maximizing the use of equipment and its parts, reducing waste, and establishing processes that ensure equipment and components stay in service for as long as possible. As we enter Q4 of 2024, it’s clear that circular economy practices aren’t just a passing trend. They’ve become a key part of the evolving material handling industry. Companies increasingly adopt these practices to meet regulations and customer expectations, reduce costs, enhance sustainability, and foster innovation. Circular Economy Defined The circular economy is a system that aims to keep resources in use and get the most value out of them, unlike the traditional “take-make-dispose” approach. In a linear economy, products are made from raw materials, used, and then thrown away. Conversely, the circular economy aims to keep resources in use for as long as possible, get the maximum value from them, and then recover and regenerate materials at the end of their life. Key strategies of the circular economy involve designing products and components for durability, ensuring they last longer, are easy to repair, and can be upgraded. Another important approach is remanufacturing and refurbishing, which focuses on restoring used products and components to a like-new condition. Additionally, recycling and material recovery play a crucial role by reclaiming raw materials from used products and reintegrating them into the manufacturing process. Circular Economy in the Material Handling Industry The material handling industry is well-positioned to benefit from circular economy practices. Forklifts, conveyors, and automated systems combine heavy use with long lifespans, making them perfect candidates for strategies like remanufacturing, refurbishing, and recycling. Remanufacturing and refurbishing are becoming more common in the material handling industry. Companies are offering refurbished forklifts, pallet jacks, and other equipment as cost-effective and environmentally friendly alternatives to buying new ones. These refurbished machines are restored to a high standard and often come with warranties similar to those of new equipment, giving customers reliable and affordable options. Recycling is another vital part of the circular economy in material handling. Companies are finding innovative ways to recover valuable materials from equipment that has reached the end of its life. Metals, plastics, and other materials are extracted and recycled, reducing the need for new raw materials. This lessens the environmental impact and lowers costs tied to getting new materials. Some manufacturers are even developing programs to take back used products from customers, ensuring that valuable materials are recovered and reused in the production process. This approach helps reduce the industry’s overall carbon footprint and supports a more sustainable supply chain. Circular Economy for Forklift Replacement Parts Remanufactured forklift parts offer several key advantages that can drive sales, boost your dealership’s profitability, and enhance customer satisfaction. Cost savings are a primary driver. Remanufactured parts typically cost 30-50% less than new OEM parts, offering a more affordable option for your customers, particularly those with budget constraints. This price advantage can lead to increased sales volume. Because the cost of refurbishing used parts is generally lower than manufacturing new ones, your dealership can enjoy higher profit margins on these parts. Quality assurance is crucial for your customer’s confidence. High-quality remanufactured parts are rebuilt to meet or exceed original OEM specifications, ensuring reliability and performance comparable to new parts. Offering warranties on these parts gives your customers peace of mind, reducing perceived risk and making them more likely to purchase. Another significant benefit is availability and lead times. Remanufactured parts can often be sourced more quickly than new parts, especially for older or discontinued models, reducing customer equipment downtime. Faster lead times also help dealerships respond to urgent customer needs, improving service levels and satisfaction. Promoting the sustainability of remanufactured parts can appeal to your environmentally conscious customers. These parts reduce waste and lower energy consumption, contributing to a circular economy. Highlighting your dealership’s commitment to sustainability by promoting remanufactured parts can enhance your company’s image and attract loyal customers. Offering reliable, cost-effective solutions like remanufactured parts enhances customer trust and relationship building. Educating your customers on the benefits, including their performance and value, helps overcome hesitations, leading to repeat business and referrals. Additionally, remanufactured parts can extend the life of older forklift models, allowing your customers to maximize their investment in their existing equipment, another great selling point for remanufactured parts. When it comes to remanufactured replacement parts for forklifts, you can incorporate these elements into your dealership’s strategy, not only to increase parts sales and profitability but also to position your dealership as a trusted partner in maintaining and extending the life of your customers’ forklift fleets, ultimately enhancing their satisfaction. Looking Ahead As the material handling industry evolves, adopting circular economy practices will likely accelerate. Regulatory pressures, customer demand for sustainable solutions, and the need to reduce costs will drive further innovation and integration of these practices. Companies that embrace the circular economy will be well-positioned to lead the industry into a more sustainable and prosperous future. The rise of circular economy practices in the material handling industry represents a significant shift towards more sustainable and efficient operations. By focusing on these strategies, companies can reduce their environmental impact and unlock new opportunities for growth and customer engagement. About the Author: Chris Aiello is the Business Development Manager at TVH Parts Co. He has been in the equipment business for 17-plus years as a service manager, quality assurance manager, and business development manager. Chris now manages a national outside sales team selling replacement parts and accessories in various equipment markets such as material handling, equipment rental, and construction/earthmoving dealerships.

Elevating your Business with AI

I’m thrilled to join Material Handling Wholesaler as their newest columnist. I jumped at the opportunity when Garry Bartecki suggested I help address readers’ AI-related questions. As a Partner at Connor Group, I’ve led many business transformations, technology strategies, and automation efforts, enabling companies of various sizes to grow, drive profitability, and improve cash flow. This experience has given me firsthand exposure to the transformative power of Artificial Intelligence (AI) and automation. As a guest columnist, I’m excited to share how even the simplest forms of AI can be transformative, making our organizations more efficient and resilient. Current Trends in AI Artificial Intelligence (AI) technology allows computers to perform tasks that traditionally require human intelligence, such as reading, writing, pattern recognition, problem-solving, and decision-making. Additionally, the AI ecosystem is broad, encompassing a variety of technologies with different capabilities. Here are a few important technologies to be aware of: Generative AI (GenAI) can create new content, such as text, images, or music, by analyzing and mimicking patterns from existing data. It “generates” new outputs based on the information it has learned. Machine Learning (ML) is a method of teaching computers to learn from past data to make predictions or decisions without being explicitly programmed. For example, ML can analyze past sales data to forecast future sales. Large Language Models (LLMs) are advanced AI models trained on vast amounts of text data. It can understand and generate human-like text, making it useful for tasks like answering questions, writing essays, reading documents, or summarizing information. Although AI technology might seem complex and unapproachable, it’s already embedded in many applications we use daily. For instance, Netflix employs ML to recommend shows based on your watch history, and Amazon uses GenAI to summarize product reviews. These AI-enabled functions contribute to a seamless and user-friendly experience. However, it’s not only tech consumers who benefit from AI; numerous organizations are also reaping its rewards. A recent Connor Group survey found that 78% of respondents plan to adopt AI, highlighting that this technology is here to stay. Practical Applications of AI A common misconception is that large IT departments and expensive resources are required to implement AI in your organization. This does not have to be the case—there are several tools that are relatively inexpensive, easy to deploy, and can significantly increase efficiency and productivity. Here are some practical uses for AI in your daily operations: Simpler uses: ChatGPT and other LLM-powered Chatbots can be leveraged for the following tasks: Document & Content Creation: Generate detailed policies, standard operating procedures, marketing materials, emails, etc. Document Summarization & Data Extraction: Transform lengthy contracts into digestible summaries, highlighting key terms and pull data points (e.g., prices, products) with ease. How-to Guide: Are you struggling to figure something out? Ask your AI—it can recommend step-by-step technical guides, ways to solve system issues, etc. Meeting Assistant: Use AI capabilities within communication tools like Zoom and Teams, for automated summaries and action lists. More complex uses for AI: Accounts Payable Automation: Automate vendor invoice processing and matching to purchase orders. Predictive Analytics: Examine past data and predict future outcomes such as customer upsell, potential machine issues, product returns, etc. Recommendations: Optimize warehouse operations and recommend on-hand inventory and/or buying levels. Customer service management: Support your agents with quicker access to large volumes of technical documents or facilitate direct customer interactions for support or sales. These are just a few examples and there are countless ways organizations can start utilizing AI to realize meaningful gains. Which Tools Should You Start With? To embark on your AI journey, start by exploring accessible AI tools with straightforward use cases. Here are several options to consider as you explore AI technologies: Chatbots like ChatGPT, Google Gemini, Edge Chat (included in your Microsoft Edge browser), and Claude – most of these are available in free, premium, and enterprise versions. Microsoft Copilot provides AI across all Microsoft Office products (Excel, PowerPoint, Outlook, etc.). It is available for individuals or company accounts with a qualifying Microsoft 365 plan. Purpose-built tools help with specific tasks such as document management or customer service applications. An example is VIVI from KSG, which can help organizations (typically $50M+ in annual revenue) with sales, support, customer services, etc. AI in your existing system. Most modern technologies are rapidly adding AI capabilities, so I recommend reaching out to your software providers. You might get some exciting features for free! A Few Words of Caution The top two concerns surrounding AI are the AI making mistakes and data confidentiality. Firstly, if you are using Generative AI, you will find that most of the time, it provides accurate information. However, at times, it can hallucinate, providing inaccurate or entirely made-up information. You must always ensure there is a human-in-the-loop – someone to review the AI-generated outputs to ensure they are accurate, especially for business-critical decisions. Secondly, many of these AI technologies can gather, save, and use the data you provide, which could include sensitive or proprietary information. Enterprise versions, purpose-built tools, and applications from Microsoft tend to be more secure. Ensure you understand how any data you input is being used, and be extra careful with any private or highly confidential information. There are very secure AI options – make sure you know how your AI tools operate. Future Trends and Best Practices In summary, AI is a practical tool that offers many benefits that are accessible to businesses of all sizes. Looking ahead, AI integration in daily operations will become increasingly sophisticated, with advancements in predictive analytics, AI assistants, and robotics. Staying informed is the key to staying ahead—invest some time each week to explore AI developments on LinkedIn (feel free to follow me), read my upcoming articles, and subscribe to AI newsletters. If you have any questions, contact me at ai_automation@connorgp.com. I would be happy to answer them. About the Author: Jason Pikoos is a Managing Partner and leads Connor Group’s Technology and Innovation, including AI-driven solutions. He brings over 20 years of accounting, operational,

Cast your vote in the Bobcat Park and Rec Makeover Contest

Five finalists are vying to win the Bobcat Park and Rec Makeover Contest worth $100,000, and public voting is now open to help determine the winner. Bobcat Company launched the contest in mid-July by teaming up with brand ambassador and renovation expert Chip Gaines for a baseball field makeover in Waco, Texas. The company aims to inspire communities to look for the potential in their hometowns. Hundreds of nominations were submitted from parks across 44 states. Finalists were selected in partnership with the National Recreation and Park Association (NRPA) based on several criteria, including demonstrated need, sustainability impact, and long-term community benefit. The finalists include: Aaron Perry Park in Pontiac, Michigan: Traditionally used for baseball and soccer, the park’s baseball fields have fallen into disrepair and are now unusable. The two baseball fields at the park require full restoration, with the goal of the Pontiac Youth Recreation Program using the space for its Youth Baseball Program. Chestnut Street Park in Henderson, North Carolina: Currently used for basketball games and community gatherings, the park lacks running water and permanent restrooms. The basketball court requires significant repairs due to large cracks. If selected, the park will be enhanced to accommodate family gatherings and community picnics better, continuing its role as a vital community space. City of Purcell in Purcell, Oklahoma: The tennis courts at the Purcell Multi-Purpose Center require significant repairs, including resurfacing and upgrading the outdated, maintenance-intensive lighting system. The city aims to revitalize the area with new surfaces, modern lighting, and additional amenities to ensure a safe and accessible space for the community. Plans also include expanding the courts to accommodate Pickleball. Ivan K. Hill Park in Winfield, Alabama: This multi-use park, featuring ballfields, playgrounds, and a senior center, requires updates to improve safety and accessibility. Plans include replacing the original 1960s fencing and backstop and enhancing access to the fields and restrooms. The renovations aim to ensure long-term accessibility for both players and spectators. Jones Park in Galveston, Texas: Jones Park has long been neglected. It lacks shade trees and experiences frequent flooding, rendering it unusable for extended periods. The proposed overhaul includes a new basketball court, benches, sidewalks, and trees or shade structures, creating a safe and revitalized space for the community. “We are moved by the incredible stories from communities nationwide, which highlight the need for park improvements to create safe and accessible gathering spaces,” said Laura Ness Owens, Bobcat vice president of global brand and marketing. “Through this contest, we hope it inspires others to recognize opportunities within their own neighborhoods and find ways to give back.” Voting is open through Oct. 3 at bobcat.com. Individuals can vote once per 24-hour period during the voting period. The winner will be announced in late October 2024. The contest runner-up will receive a new Bobcat zero-turn mower. To learn more about how Bobcat is giving back to communities, please visit bobcat.com.

ProMach has announced its Wine & Spirits Solutions Group

ProMach has announced the launch of their Wine & Spirits Solutions group that will provide a complete portfolio of process, equipment, and systems integration solutions for the wine and spirits industry. ProMach has been a strategic partner for many of the world’s best-known spirits companies for years. The creation of this solutions-based team will allow ProMach to gain even greater insight, offer a broader solutions portfolio, and continue to be a trusted advisor that helps optimize operations. Supported by industry experts from more than a dozen ProMach product brands worldwide, the Wine & Spirits solutions team is strategically positioned to solve the unique challenges of processing and packaging traditional bottled products, small format bottles, and ready-to-drink (RTD) products in both cans and single-serve bottles. From standalone systems to fully integrated packaging lines, ProMach’s Wine & Spirits Solutions group provides process, filling, capping, corking, canning, cooking, sterilizing, coding, tamper-evident applicators, labeling, case packing, cartoning, conveyance, and palletizing for virtually any type of wine or spirits packaging formats. This direction also bolsters ProMach’s position as a worldwide leader in filling, closing, labeling, and coding systems, with a portfolio of solutions that includes Fogg, Zalkin, P.E. Labellers, WLS, and ID Technology. With the recent acquisition of Italy-based MBF, ProMach is now one of the world’s premiere providers of wine filling solutions. “ProMach’s strategic investments in specific markets is an ongoing effort to deliver our customers with more complete and comprehensive solutions,” says Scott Smith, SVP – Strategic Marketing & Business Development. “Our support of these markets are a mix of new and innovative solutions, as well as acquisitions that fill gaps in our product portfolio. The wine and spirits industry is a key targeted market segment, and the formation of a dedicated team that is focused on this industry will allow us to better understand this ever-changing market and better serve our current and future customers.” Complimenting these solutions, the ProMach Systems Group provides integrated packaging lines, conveyors, and engineering services to many of the world’s largest wine and spirits companies. Featuring product brands Zarpac, ProMach Integrated Solutions, ZPI, Statera, and Sentry, these global teams of technical and application experts provide integrated solutions from line design to end-of-line systems. ProMach launched the Wine & Spirits Solutions team in conjunction with its annual Global Sales Leader meeting last week in Louisville, KY. “Given our strong position in the US bourbon market, Louisville was a great place to announce this team, and we were able to do it with customers in attendance to reinforce our position and dedication to them,” added Smith. “And with our upcoming presence at Pack Expo International in Chicago this November, attendees will be able to see the full range of our processing and packaging solutions in action.”

Patti Engineering’s Sam Hoff to present at MiA 2024

Patti Engineering CEO Sam Hoff will present “Utilizing Digital Tools for Commissioning and Life Cycle Management” at 10:00 a.m. on Wednesday, September 25 in Suite Pantry Lobby 4 during the Manufacturing in America 2024 event co-hosted by Siemens and Electro-Matic Products at Ford Field, in Detroit, MI. The Patti Engineering team will be exhibiting at booth #402 at this same event. Patti Engineering, Inc. has announced its multi-faceted participation in the upcoming Manufacturing in America (MiA) 2024 event, hosted by Siemens and Electro-Matic Products. The event takes place on Wednesday, September 25, 2024 at Ford Field in Detroit, MI. Patti Engineering Founder and CEO Sam Hoff will present a seminar titled “Utilizing Digital Tools for Commissioning and Life Cycle Management” at 10:00 a.m. in Suite Pantry Lobby 4. In addition, engineers from Patti Engineering will meet with attendees at exhibit #402 to discuss control system integration and Industry 4.0 digitalization strategies. “The Manufacturing in America conference has always been a great way for us to both learn from others in the manufacturing community as well as share our own depth of knowledge on topics such as robotics, legacy controls upgrades, countless strategies for OEE improvement, edge/cloud computing, digital twins, data analytics, vision system integration, and other advanced Industry 4.0 technologies,” said Hoff. “It’s an exciting event and we always look forward to it.” Hoff’s presentation will discuss how various tools including FANUC’s ROBOGUIDE robot simulation software, Siemens’ Tecnomatix Process Simulate, Siemens’ Tecnomatix Plant Simulate and Siemens’ virtual PLC software, PLCSim Advanced can be used to virtually commission a system in a visualized environment, therefore speeding up and reducing the costs of the physical commissioning process. In addition, Hoff will discuss how the same tools can be continually updated post-commissioning based on the actual system’s real-world parameters so that it behaves in the same way as the real system – popularly called a digital twin. Finally, Hoff will address how a mature digital twin can be used to guide the process of continuous improvement of OEE parameters throughout the system’s entire lifecycle. MiA 2024 brings together thousands of professionals from the manufacturing community to share and explore the latest advancements in manufacturing technology, discuss current best practices, and guide the future of this dynamic industry. Attendees can participate in dozens of technical seminars and exhibits dedicated to automation, digitalization, controls, drive technologies, smart manufacturing for automotive OEMs, artificial intelligence in manufacturing, AGV/AMR logistics systems, IT/OT integration, and aerospace automation.