Episode 505: Celebrating heroes in transportation with Road Dog Coffee

Welcome to The New Warehouse Podcast! In this episode, we dive into the world of coffee with a mission. Our guest is Spencer Squier, CEO and founder of Road Dog Coffee, a unique company that serves truckers and logistics professionals. Spencer shares the journey of creating a coffee brand that delivers premium coffee and honors truckers’ vital role in our economy. Road Dog Coffee’s innovative approach stems from Spencer’s deep roots in the transportation industry and his passion for supporting the often-overlooked heroes of the highways. The Birth of Road Dog Coffee Road Dog Coffee was born from a profound respect for truckers and a love for coffee. Spencer, with a background in transportation, recognized the need to spotlight the importance of truckers, especially during the pandemic. “I’ve always loved coffee. I’ve always had a passion for coffee. I’m a big coffee drinker. And I love trucking, and I love our truckers and our logistics professionals because they all go hand in hand.” This vision led to creating a brand that provides premium coffee specifically for truckers and logistics heroes, ensuring they can access quality brews even on the road. Promoting the Contribution of Truckers Spencer shares the dual mission of Road Dog, “We have a kind of a two-pronged business model. We’ve got the educational and awareness side of things. And we have the accessibility side of things.” The brand educates the public about the critical role of truckers through various channels, including the informative content on their coffee bags. On the accessibility front, Road Dog Coffee ensures that truckers can access premium coffee, a rarity at typical truck stops, thus enhancing their daily experience. Expanding Impact and Future Plans The reception to Road Dog Coffee has been overwhelmingly positive, with truckers appreciating the tailored blends. Long Haul Blend: Medium roast coffee designed for all-day drinking. Expedite Blend: Dark roast coffee for late hours, known as “dark as night.” Black Dog Blend: High-caffeine, ultra-dark roast coffee inspired by an urban legend. Spencer shares, “It’s been perceived very well…our long haul blend is a medium roast. It’s designed to drink all day long.” Looking ahead, Road Dog Coffee aims to broaden its impact through initiatives like the RDCC fund, which will support industry-related charities. Spencer’s vision includes expanding product lines to cater to the younger generation and enhancing brand visibility in wholesale channels. Key Takeaways from Road Dog Coffee Road Dog Coffee provides high-quality coffee tailored to the needs of truckers and logistics professionals. The brand promotes the importance of truckers to the economy, aiming to change public perceptions. The unique blends and mission of Road Dog Coffee have been well-received within the trucking community. Plans include launching new products and establishing a charitable fund to support the trucking industry. The New Warehouse Podcast Episode 505: Celebrating Heroes in Transportation with Road Dog Coffee

Staffing employment rebounds after July 4th holiday

Week-to-Week: Staffing employment up five points, New starts up 30 points Staffing employment improved during the week of July 8–14, with the ASA Staffing Index increasing by 5.2% to reach a rounded value of 88. The Index the week before Independence Day the index was at a rounded value of 90. Staffing jobs were down 12.7% compared with the same week last year. Many staffing companies still listed the July 4th holiday as a barrier that prevented further growth. New starts increased dramatically in the 28th week of the year, leaping by 30.0% from the prior week. Six in 10 staffing companies (60%) reported gains in new assignments week-to-week, well above the average of 42% per week so far this year. The ASA Staffing Index four-week moving average decreased from the prior week. Still, it held a rounded value of 88, and temporary and contract staffing employment for the four weeks ending July 14 was 10.6% lower than in 2023. “A near-complete rebound in staffing employment after the July 4th dip affirms continued stabilization within the industry. In the short term, the index will likely coalesce around its previous annual average of 90 as staffing employment remains challenged by a tightening macroeconomic environment. In the long term, however, this value is likely a floor from which staffing employment can improve once these conditions ease,” said Noah Yosif, chief economist at ASA. This week, containing the 14th day of the month, will be used in the July monthly employment situation report, which the U.S. Bureau of Labor Statistics will issue on August 2. The ASA Staffing Index is reported nine days after each workweek, making it a near real-time measure of staffing employment trends. ASA Staffing Starts are the number of temporary and contract employees placed in new assignments during the reporting week. ASA research shows that staffing employment has historically been a coincident economic indicator.

NetLogistik announces Testing as a Service (TaaS)

Partnership with Cycle Labs helps clients elevate testing precision with high-quality, reliable automation NetLogistik, a provider of transformative services for supply chain digitalization, announces its “Testing as a Service” offering. Progress is often limited with manual testing, which is prone to errors, and is limited to eight hours per day, as well as the subject matter expertise of the tester. Testing-as-a-Service (TaaS), Netlogistik’s testing automation offering, can help companies overcome the challenges associated with manual testing while delivering accurate, reliable results. This is crucial in helping identify potential problems earlier in the technology deployment process, reducing risk before it costs precious time, money, and resources. “NetLogistik has a global presence with over 500 logistics and commerce experts to be the trusted partner for clients,” says Jagan Reddy, Managing Director US at NetLogistik. “We use Cycle Labs patented Cycle Continuous Test Automation Platform to help clients accelerate change with better, low-risk solutions for complex problems faster than ever before.” Netlogistik’s TaaS can eliminate the need to procure, install, and learn testing automation solutions and the dedicated staff required to manage them—which can dramatically reduce overhead costs while speeding time-to-market. Outsourcing the testing workload to testing automation experts can also give companies more freedom to focus on their core competencies and innovate within their supply chain process. Additional benefits TaaS provides include: Peace of Mind: The confidence of knowing testing processes and results are consistent and predictable. Proactive Changes: Test configuration changes before deploying them into production. Faster Adoption: Deploy the newest functionality sooner with a more streamlined release adoption strategy. Highest Quality Assurance: Improve quality by eliminating the factor of human error. Improved Customer Experience: Deliver consistent customer results on the latest user interfaces. Cost Efficiency: Automated testing can save time and money by running testing off-hours.

Lowenthal elected Port of Long Beach Harbor Commission President

Colonna was selected as vice president, and both have one-year terms Harbor Commissioner Bonnie Lowenthal was elected president of the Long Beach Board of Harbor Commissioners on Monday, the five-person board that oversees the Port of Long Beach. The board also selected Frank Colonna as Vice President and Steven Neal as Secretary. Commissioners select a President and two board officers each July to serve one-year terms. The Commission’s new officers will begin their terms on Aug. 5, when outgoing Commission President Bobby Olvera Jr. will hand the gavel to Lowenthal at the Board’s meeting that day. Lowenthal was President from 2019-20 and currently serves as Vice President. She has served Long Beach in a public role for decades, first as a Long Beach Unified School District Board member, then as a City Councilwoman and Vice Mayor, and as a state Assembly member. Before her elected service, she worked as a licensed family counselor and mental health consultant. “It is an honor to be elected and serve as president of the Long Beach Harbor Commission,” Lowenthal said. “I look forward to working with my fellow commissioners as we build a port to better serve the residents of Southern California in the decades to come and continue to pursue our trailblazing environmental programs, innovative capital improvements, and our ongoing investment in workforce development.” Under the City Charter, the Board sets policy for the Port. It directs the Port’s Chief Executive Officer, who leads about 550 employees in developing and promoting the Port of Long Beach. Members are appointed by the Mayor and confirmed by the City Council. They may serve up to two six-year terms.

Caldwell hires Sarah Stitt for RUD Products

The Caldwell Group Inc. has named Sarah Stitt product manager of the Rockford, Illinois-based company’s RUD range. The below-the-hook and material-handling equipment manufacturer has a longstanding partnership with RUD to bring lifting points and other products to the U.S. and Canada. Stitt has joined the company’s marketing team and will spearhead the portfolio’s growth in these key regions. She will work closely with Jay Schroeder, regional sales manager of RUD West, and the technical sales, customer service, sales, and engineering teams to identify new product sales opportunities, analyze market trends, and drive revenue for the RUD line. Stitt will also work closely with RUD’s German sales and marketing teams to help identify and grow market segments and user groups. Tyson Philippi, chief operating officer, said: “At Caldwell, we are committed to delivering innovative lifting points that exceed customer expectations, increase safety, and improve the performance of riggers, crane operators, material handlers, and manufacturers. With Sarah’s appointment, we are poised to enhance brand awareness and adoption in the North American market.” Lisa Sympson, marketing manager, said: “Sarah has been part of the Caldwell marketing team for more than a year and is a great fit for the RUD product management role. Her knowledge of the industry, customers, and now the RUD product line will give this growing part of our business the focus and attention it deserves.” Stitt said: “As the newest member of this dynamic team, I look forward to fostering collaboration between RUD and Caldwell to provide our customers with the best solutions available. I am committed to using my knowledge to help bring RUD brand awareness and value to the U.S. and Canada.” The new-look Caldwell RUD team will continue to raise the profile of a range of rigging products already considered best-in-class in Europe and elsewhere in the world. Caldwell has forged a successful collaboration with the RUD Group to unite sales and marketing activities in North America for material handling and lifting devices within a common organization. The RUD portfolio includes slings and lifting points for the most complex tasks for integration into almost any application. Caldwell’s Schroeder added: “RUD is a high-quality, Germany-manufactured product, so it takes a certain type of company to be able to deliver it here in North America, keeping lead times short and stock levels high, close to the point of use. The timing is perfect to add Sarah to the team with continued emphasis on telling everyone we are here — and here to stay.”

Nucor reports 11% consolidated net sales decrease for the first six months compared to prior year

Nucor Corporation announced consolidated net earnings attributable to Nucor stockholders of $645.2 million, or $2.68 per diluted share, for the second quarter of 2024. By comparison, Nucor reported consolidated net earnings attributable to Nucor stockholders of $844.8 million, or $3.46 per diluted share, for the first quarter of 2024 and $1.46 billion, or $5.81 per diluted share, for the second quarter of 2023. In the first six months of 2024, Nucor reported consolidated net earnings attributable to Nucor stockholders of $1.49 billion, or $6.14 per diluted share, compared with consolidated net earnings attributable to Nucor stockholders of $2.60 billion, or $10.26 per diluted share, in the first six months of 2023. “While market conditions have softened compared to recent record-setting years, Nucor remains focused on its long-term growth strategy and has returned more than $1.7 billion to investors through June,” said Leon Topalian, Nucor’s Chair, President and Chief Executive Officer. “Nucor’s strategy to grow our core steelmaking operations and expand into steel-adjacent downstream markets positions the company to create attractive shareholder value and improve the company’s through-cycle earnings profile. I am incredibly proud of the 32,000 men and women of Nucor who are executing this growth plan while achieving the safest start to any year in Nucor’s history.” Financial Review Nucor’s consolidated net sales decreased 1% to $8.08 billion in the second quarter of 2024 compared with $8.14 billion in the first quarter of 2024 and decreased 15% compared with $9.52 billion in the second quarter of 2023. Average sales price per ton in the second quarter of 2024 decreased 2% compared with the first quarter of 2024 and decreased 11% compared with the second quarter of 2023. Approximately 6,289,000 tons were shipped to outside customers in the second quarter of 2024, a 1% increase compared with the first quarter of 2024 and a 5% decrease compared with the second quarter of 2023. Total steel mill shipments in the second quarter of 2024 were comparable to the first quarter of 2024 and decreased 2% compared to the second quarter of 2023. Steel mill shipments to internal customers represented 21% of total steel mill shipments in the second quarter of 2024, compared with 21% in the first quarter of 2024 and 20% in the second quarter of 2023. Downstream steel product shipments to outside customers in the second quarter of 2024 increased by 11% compared with the first quarter of 2024 and decreased by 10% compared with the second quarter of 2023. In the first six months of 2024, Nucor’s consolidated net sales of $16.21 billion decreased 11% compared with consolidated net sales of $18.23 billion reported in the first six months of 2023. Total tons shipped to outside customers in the first six months of 2024 were approximately 12,513,000 tons, a decrease of 4% compared with the first six months of 2023, and the average sales price per ton in the first six months of 2024 decreased 7% compared with the first six months of 2023. The average scrap and scrap substitute cost per gross ton used in the second quarter of 2024 was $396, a 6% decrease compared to $421 in the first quarter of 2024 and a 13% decrease compared to $455 in the second quarter of 2023. The average scrap and scrap substitute cost per gross ton used in the first six months of 2024 was $409, a 6% decrease compared to $435 in the first six months of 2023. Pre-operating and start-up costs related to the Company’s growth projects were approximately $137 million, or $0.43 per diluted share, in the second quarter of 2024, compared with approximately $125 million, or $0.39 per diluted share, in the first quarter of 2024 and approximately $90 million, or $0.27 per diluted share, in the second quarter of 2023. In the first six months of 2024, pre-operating and start-up costs related to the Company’s growth projects were approximately $262 million, or $0.82 per diluted share, compared with approximately $172 million, or $0.52 per diluted share, in the first six months of 2023. Overall, operating rates at the Company’s steel mills decreased to 75% in the second quarter of 2024, compared to 82% in the first quarter of 2024 and 84% in the second quarter of 2023. Operating rates in the first six months of 2024 decreased to 79%, compared to 82% in the first six months of 2023. Financial Strength At the end of the second quarter of 2024, we had $5.43 billion in cash and cash equivalents and short-term investments on hand. The Company’s $1.75 billion revolving credit facility remains undrawn and does not expire until November 2026. Nucor continues to have the strongest credit ratings in the North American steel sector (A-/A-/Baa1), with stable outlooks at Standard & Poor’s and Fitch Ratings and a positive outlook at Moody’s. Commitment to Returning Capital to Stockholders During the second quarter of 2024, Nucor repurchased approximately 2.9 million shares of its common stock at an average price of $170.70 per share (approximately 8.5 million shares during the first six months of 2024 at an average price of $177.30 per share). As of June 29, 2024, Nucor had approximately $1.82 billion remaining authorized and available for repurchases under its share repurchase program. This share repurchase authorization is discretionary and has no scheduled expiration date. On June 6, 2024, Nucor’s Board of Directors declared a cash dividend of $0.54 per share. This cash dividend is payable on August 9, 2024, to stockholders of record as of June 28, 2024, and is Nucor’s 205th consecutive quarterly cash dividend. Second Quarter of 2024 Analysis The largest driver of the decrease in earnings in the second quarter of 2024 as compared to the first quarter of 2024 was the decreased earnings of the steel mills segment, primarily due to lower average selling prices and, to a lesser extent, decreased volumes. The steel products segment had decreased earnings in the second quarter of 2024 as compared to the first quarter of 2024 due to lower average

More ROYPOW Lithium-ion Forklift Battery models obtain UL2580 Certification

Recently, ROYPOW has announced that several of its lithium-ion forklift battery models that comply with the BCI battery standards, including 24V, 36V, 48V, and 80V voltage systems, have received the UL 2580 certification. This is another achievement following the last UL certification of several products. It shows ROYPOW’s constant pursuit of quality and safety assurances for reliable and high-performing lithium battery solutions. BCI (Battery Council International) is a North American battery industry trade association. It has introduced BCI Group Sizes that categorize batteries based on their physical dimensions, terminal placement, electrical characteristics, and any special features affecting the battery fit. Manufacturers build their batteries according to these specifications of BCI Group Size for each vehicle. Companies use BCI Group Sizes to streamline finding the perfect match for the vehicle’s power needs and ensure proper battery fitment and performance. By sizing its batteries to specific BCI Group sizes, ROYPOW eliminates the need for battery retrofitting, significantly shortening installation time and enhancing efficiency. The 24V 100Ah and 150Ah batteries use the 12-85-7 size, the 24V 560Ah batteries the 12-85-13 size, the 36V 690Ah batteries the 18-125-17 size, the 48V 420Ah batteries the 24-85-17 size, the 48V 560Ah and 690Ah batteries the 24-85-21 size, and the 80V 690Ah batteries the 40-125-11 size. Forklift businesses can choose ROYPOW batteries for true drop-in replacements for conventional lead-acid batteries. UL 2580, a crucial standard developed by Underwriters Laboratories (UL), sets forth comprehensive guidelines for testing, evaluating, and certifying the lithium-ion batteries used in electric vehicles and covers environment reliability tests, safety tests, and function safety tests, addressing potential hazards like short-circuit, fire, overheating and mechanical failure to ensure that the battery can withstand the demanding conditions of daily use. Certified to the UL 2580 standard indicates that manufacturers comply with regulatory requirements and industry standards and that their batteries have undergone comprehensive and rigorous testing to meet recognized industry safety and performance standards. This assures clients that the batteries installed in their electric vehicles are ultra-safe, reliable, and perform optimally. After testing, ROYPOW several lithium-ion forklift battery models that meet the BCI standards successfully pass the UL 2580 certification, a significant breakthrough for the performance and safety of ROYPOW products. “The Li-ion material handling battery industry is experiencing massive growth, making safety a crucial concern. We are very proud to achieve this listing, which is a key milestone, serving as a powerful testament to ROYPOW’s commitment to powering the industry toward a safer and more effective future,” said Michael Li, Vice President of ROYPOW. ROYPOW batteries offer a full range of capacities from 100Ah to 1120Ah and voltages from 24V to 350V, suitable for Class I, II, and III forklift trucks. Each battery features industry-leading automotive-grade designs with a lifespan of up to 10 years, minimizing the need for frequent maintenance and battery swapping. With fast and efficient opportunity charging, maximized uptime is ensured, allowing continuous operation through multiple work shifts. The built-in intelligent BMS and unique hot aerosol fire extinguisher design enhance safety performance, setting it apart from other forklift battery brands. ROYPOW has specially designed explosion-proof and cold-storage batteries to tackle performance challenges in more demanding environments. Featuring an IP67 waterproof rating and unique thermal insulation, ROYPOW cold storage forklift batteries deliver premium performance and safety even at temperatures as low as -40℃. With these safe and robust solutions, ROYPOW batteries have become the choice of the world’s top 20 forklift brands.

Intella Parts searches for the oldest Toyota forklift

For over 86 years, Toyota has built a reputation for reliability, innovation, and leadership in the automotive and industrial sectors. The iconic Toyota Corolla, with over 50 million units sold worldwide and the best-selling car in history, underscores the brand’s exceptional success in the automotive industry. Beyond its prominence in passenger vehicles, Toyota has also established itself as the leading forklift brand globally. With an estimated market share of 28.44%, businesses worldwide rely on Toyota forklifts for their robust performance, reliability, and efficiency. Toyota forklifts are crucial in enhancing operational efficiency and productivity from warehouses to distribution centers and manufacturing facilities. In daily operations, we often encounter remarkably old units that are still working well. Last year, Intella Parts held a contest to determine the oldest-running Hyster forklift. The winner was a 1945 Hyster model KD KarryKrane owned by Phillip DeLuna from Public Steel in Amarillo, TX. The question arises: What is the oldest Toyota forklift that is still operational? How to participate: Email Intella Parts your photos to oldestforklift@intellaparts.com, along with details about the forklift’s year, stories, and some interesting facts about the unit. If possible, include a picture of the plate. The winner will receive a $100 gift certificate for Intella Parts, a $100 Visa gift card, and bragging rights as the owner of the oldest Toyota forklift.

Wolter Inc. acquires Cincinnati Crane & Hoist

Wolter Inc.‘s first acquisition of a manufacturing company was Cincinnati Crane & Hoist (CC&H), a crane and hoist manufacturer based in Cincinnati, Ohio. This strategic acquisition significantly enhanced Wolter Inc.’s capabilities and expanded its product offerings in the crane industry. “We’re excited to welcome Cincinnati Crane & Hoist to Wolter Inc.,” said Jerry Weidmann, president of Wolter Inc. “This acquisition allows us to leverage our strengths and expand our offerings of crane and hoist solutions. CC&H’s innovation and expertise in custom crane systems perfectly align with our commitment to accelerating productivity. Together, we aim to set new industry standards, ensuring our customers receive unparalleled support—from initial design and installation to commissioning and ongoing service and maintenance.” With over 16 years of industry trust, CC&H is renowned for innovative designs, custom solutions, and turnkey project capabilities, including overhead cranes, gantry cranes, monorail systems, runway systems, hoists, custom crane systems, and tailored turnkey solutions. Under the Wolter Inc. name, customers will benefit from an expanded product line, custom-engineered capabilities, and enhanced installation, maintenance, and repair support coverage. Wolter Inc. is committed to maintaining the high standards of quality and service that Cincinnati Crane & Hoist customers expect, ensuring a seamless transition with a continued focus on accelerating productivity.

Episode 504: Leveraging QR Codes to Transform Supply Chain Efficiency

Today’s episode of The New Warehouse Podcast welcomes Sam Titus, the CTO of FreightPrint. FreightPrint is transforming supply chain management with innovative tracking solutions utilizing QR codes. This episode dives into the advantages of a QR code over traditional barcodes, the seamless integration of FreightPrint’s system, and the future of warehouse technology. Unifying Supply Chain Data with QR Codes FreightPrint’s core mission is to simplify and unify the tracking of goods through various supply chain stages. Sam explains, “Our software really allows them to bring this complex tracking metric into more of an easy-to-use platform.” By leveraging QR codes, FreightPrint enables seamless data flow across different supply chain entities, from shippers to warehouses to final-mile deliveries. This integration ensures accurate, real-time tracking and enhances operational efficiency. The Advantages of QR Codes Over Traditional Barcodes QR codes offer several benefits over traditional barcodes, including greater data capacity and ease of use. Sam notes, “The good thing about QR code is it can store a lot more data.” QR codes facilitate detailed tracking and authentication processes, allowing users to access shipment information by simply scanning with a smartphone. This innovation reduces the need for bulky, outdated scanners and enables more efficient inventory management and data entry. The Future of Warehouse Technology with QR Codes The future of warehouse technology lies in integrating advanced systems like QR codes with emerging technologies such as AI and drones. Sam envisions a future where manual scanning becomes obsolete and is replaced by automated processes: “Products are QR code friendly; you can just fly a drone through your warehouse and know within 10 minutes the exact cycle count.” This shift enhances accuracy and frees up human resources for more meaningful tasks, fostering a more efficient and worker-friendly environment. Key Takeaways A QR code can store significantly more data than traditional barcodes. Scannable by smartphones, reducing dependency on specialized scanners. Potential for AI and drone integration to automate inventory management. Implementing QR code technology can save up to 75% in time spent on data entry The New Warehouse Podcast EP 504: Leveraging QR Codes to Transform Supply Chain Efficiency

Live from WERC 2024: Insights from Big Joe

This special episode comes to you from this year’s WERC Conference. This episode, sponsored by Big Joe Forklifts, dives into the latest trends and technologies in the material handling industry with Kevin being joined by Kurt Spyke, the Director of National Accounts at Big Joe Forklifts, to discuss the state of the industry, innovative solutions, and what lies ahead. The Big Joe Evolution Kurt provides an overview of Big Joe and how they’ve grown over the last 75 years, emphasizing their role as a solution provider in the material handling industry. He shares exciting news about their new 300,000-square-foot facility in Madison, Wisconsin, which will house both the Big Joe and EP brands. With a reputation for being the number one manufacturer of Class 3 products, Big Joe is also bringing innovative new lithium-ion Class 1 operating vehicles to their customers. Spyke explains that this strategic move to lithium-ion is driven by the industry’s increasing acceptance of this technology. “We’re investing heavily into the market through our dealer network and the National Account Channel,” says Spyke, as he outlines their commitment to providing energy-efficient and cost-effective solutions. Material Handling Trends and Technological Advances Kevin and Kurt dive into the current state of the material handling market, discussing the soft landing post-2022 and 2023. Spyke shares insights into how the market slowdown allows companies to refocus on research and development, particularly regarding lithium-ion technology. “It’s a time for education and exploration,” he notes, pointing out that the lower cost and improved safety of lithium-ion options are making them more attractive to companies traditionally using combustion or lead acid batteries. They discuss the influx of automation and robotics in the industry. Spyke introduces Big Joe’s semi-autonomous offerings which comes in the form of an Autonomous Mobile Robot (AMR) and provides an efficient and flexible solution without the need for extensive infrastructure. “We can have a situation up and running in under an hour,” he claims, highlighting the practicality and affordability of these solutions. He explains that companies are looking for ways to enhance efficiencies, particularly in repetitive tasks and by integrating semi-autonomous solutions, companies can significantly improve their operations without extensive overhauls or additional costs. Navigating the Future of Material Handling As the market dynamics change, Spyke emphasizes that decision-makers now have more power than ever. With inventories stabilizing, companies can be more selective about their purchases. “We are definitely in a buyer’s market,” he asserts, advising sales reps to listen closely to customer needs and provide tailored solutions. According to Spyke, the future of material handling involves a more consultative approach. Big Joe aims to educate customers and offer solutions that improve day-to-day operations without drastic changes. He believes in empowering companies to “make good great” by helping them find innovative, cost-effective solutions that fit their specific needs without having to pursue the large shiny objects. The New Warehouse Podcast Live from WERC 2024: Insights from Big Joe

Centralized Warehouse Orchestration: Revolutionizing efficiency for shippers

The distribution process is burdened with consumer expectations demanding faster deliveries, warehouse labor shortages, scarcity of physical storage space, and siloed supply chain data. Companies are taxed to improve distribution and warehouse processes to improve customer satisfaction, lower costs, and increase productivity. Artificial Intelligence (AI) and Machine Learning (ML) have emerged as transformative technologies within the supply chain, including in the warehouse. AI-powered solutions enhance warehouse operations and improve efficiencies. AI can sit on top of a warehouse management system (WMS) to dynamically orchestrate all activities within the warehouse to make the WMS more responsive. By integrating various aspects of warehouse operations through centralized warehouse orchestration, companies drive value by gaining efficiencies, reducing costs, and enhancing service levels. A centralized warehouse orchestration solution uses advanced technologies, such as artificial intelligence, analytics, and machine learning, to manage and optimize warehouse processes. In other words, it acts as the brain of warehouse operations, coordinating activities, optimizing processes, and ensuring seamless integration of all supply chain components. For multi-site operations, warehouse executives gain a bird’s eye view of what is happening at each site. A centralized warehouse orchestration system creates a comprehensive view of the entire distributed warehouse network, allowing executives to identify potential flow issues, which customers/shipments are at risk, and where action needs to be taken to avoid a service disruption. Benefits for Shippers A centralized warehouse orchestration platform enhances shippers’ operational capabilities, helping them gain a competitive edge. These benefits include: Increased Efficiency: Centralized orchestration streamlines warehouse operations, reducing manual labor and minimizing errors. This leads to faster and more accurate order fulfillment and better resource utilization. Cost Reduction: By optimizing inventory levels, automating processes, and making more efficient use of resources, shippers can reduce costs and waste. Improved Visibility and Control: Centralized warehouse orchestration systems give shippers real-time visibility into their warehouse network, allowing faster shipment tracking, proactive issue management, and more informed decision-making. Enhanced Customer Satisfaction: Customers get their orders at the right time and in the right amount by improving on-time, in-full fulfillment. This improves customer satisfaction, increasing customer loyalty and a competitive edge. Better Risk Management: Real-time data and analytics enable shippers to identify and mitigate risks more effectively. Managers can identify bottlenecks within the supply chain with a centralized view of the entire network of distribution centers and warehouses. Management can respond quickly to disruptions, such as delays or inventory shortages, minimizing the impact on their operations and customers. How a Centralized Warehouse Orchestration Solution Works A centralized warehouse orchestration solution works with existing systems, such as a WMS, Warehouse Execution Systems (WES), and Warehouse Control Systems (WCS). The tool integrates data from across supply chain systems, including inventory management, yard management, labor management, ERP, and warehouse systems, to create a centralized overview of information that facilitates decision-making. This integration ensures a seamless data flow and coordination across supply chain operations. It also allows for a single interface capable of managing the four critical pillars of warehouse orchestration: labor planning, inventory management, human-robotic interactions, and space optimization. Let’s look at each of these pillars and how a centralized warehouse orchestration solution benefits each function: Labor Planning – By monitoring the number of workers at each site, a centralized warehouse orchestration platform can compare how well a site works with a certain amount of labor versus others that use more or fewer workers. A centralized warehouse orchestration solution ensures that labor resources are utilized effectively, enhancing warehouse efficiency and productivity. It can also forecast labor demand based on historical data and predictive analytics, adjusting staff levels proactively or reducing overstaffing, which can save costs. Inventory Management—Provides a unified view of inventory levels across multiple warehouse locations to improve inventory management by enabling accurate tracking, forecasting, and stock replenishment. The solution leverages a real-time data-driven approach for proactive decision-making on warehouse performance, shipment statuses, and bottlenecks. This approach helps to optimize operations and improve efficiencies while allowing the business to quickly scale up or down based on seasonality and other activities. Space Optimization—A centralized warehouse orchestration platform facilitates space optimization by integrating various warehouse systems to maximize the efficient use of available space. With real-time data, the system can evaluate and adjust slotting arrangements to best use space. With a real-time view of inventory levels and locations, the system can enable better space management by ensuring that products are stored in the best locations. A centralized warehouse orchestration solution can facilitate cross-docking to minimize storage time and reduce space usage. Incoming goods are directed to outbound shipments without long-term storage. Smaller shipments can be consolidated into fewer, larger ones that take up less space. Human-Robotic Interactions—A centralized warehouse orchestration solution improves human-robotic interactions by coordinating the activities of human workers and robotic systems. The system provides a unified interface for real-time monitoring of human workers’ and robots’ activities and statuses. Information can be collected and analyzed from human and robotic activities to identify inefficiencies and performance bottlenecks. Managers gain insights from data analytics for continuous improvement of human-robotic workflows. Centralized warehouse orchestration is revolutionizing the supply chain industry by integrating and optimizing warehouse operations, giving managers a bird’s eye view and visibility into what is happening across the network to mitigate risks better and enhance customer satisfaction. About the Author: Michael Perdue is a Solutions Engineer at AutoScheduler.AI, an innovative Warehouse Orchestration Platform and WMS Accelerator. As a solutions engineer, Michael helps teams with strategies that deliver value to their supply chain operations. He worked for multiple SaaS companies before transitioning to the logistics world. He recently worked at a Third-Party Logistics company, gaining operational experience helping companies in the Food Industry, Cold Storage, Manufacturing, Retail, and CPG space. He has experience running teams in distribution centers and has gained tremendous insight into areas where optimization and improvements can occur in multiple warehouse settings.

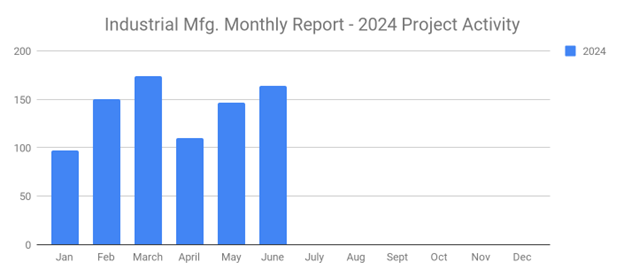

New Industrial Manufacturing projects third month in a row of growth with 164 new projects for June 2024

Industrial SalesLeads announced the June 2024 results for the new planned capital project spending report for the Industrial Manufacturing industry. The Firm tracks North American planned industrial capital project activity, including facility expansions, new plant construction, and significant equipment modernization projects. Research confirms 164 new projects compared to 147 in May and 110 in April. The following are selected highlights of the new Industrial Manufacturing industry construction news. Industrial Manufacturing – By Project Type Manufacturing/Production Facilities – 148 New Projects Distribution and Industrial Warehouse – 98 New Projects Industrial Manufacturing – By Project Scope/Activity New Construction – 45 New Projects Expansion – 58 New Projects Renovations/Equipment Upgrades – 67 New Projects Plant Closings – 17 New Projects Industrial Manufacturing – By Project Location (Top 10 States) Indiana – 13 Ohio – 11 Tennessee – 10 North Carolina – 9 Ontario – 8 Florida – 7 California – 6 Georgia – 6 Illinois – 6 Texas – 5 Largest Planned Project In June, our research team identified 11 new industrial manufacturing facility construction projects with an estimated $100 million or more value. The largest project is owned by Eli Lilly & Company, which plans to invest $5 billion to expand its processing facility in LEBANON, IN. They are currently seeking approval for the project. Completion is slated for 2028. Top 10 Tracked Industrial Manufacturing Projects MISSISSIPPI: EV battery MFR. is planning to invest $2 billion in constructing a manufacturing facility in MARSHALL COUNTY, MS. They have recently received approval for the project. Completion is slated for 2027. NORTH CAROLINA: A pharmaceutical company is planning to invest $1.5 billion in expanding its processing facility in CLAYTON, NC, and is currently seeking approval for the project. ALABAMA: Automotive MFR. plans to invest $282 million to expand its manufacturing facility in Huntsville, AL, and is seeking approval for the project. QUEBEC: Trailer MFR. plans to invest $170 million in its manufacturing facility’s expansion, renovation, and equipment upgrades in SAINT-GEORGES, QC. The company is currently seeking approval for the project. FLORIDA: Aircraft Manufacturing Company plans to invest $135 million in constructing a laboratory, manufacturing, and testing facility in Jacksonville, FL. They are currently seeking approval for the project. TEXAS: A steel company is planning to invest $110 million in renovations and equipment upgrades at its manufacturing facility in BAYTOWN, TX, and is seeking approval for the project. NEW YORK: A pharmaceutical company plans to invest $106 million in a 43,000 SF expansion, renovations, and equipment upgrades at its processing and warehouse facility in Rochester, NY. It is currently seeking approval for the project. KENTUCKY: An aluminum product manufacturer plans to invest $85 million to expand its manufacturing facility in HENDERSON, KY, by 80,000 SF. They recently received approval for the project, slated for completion in 2026. WISCONSIN: A biotechnology company plans to invest $75 million in a 50,000 SF expansion and equipment upgrades at its processing facility in MILWAUKEE, WI. The company is currently seeking approval for the project. Construction is expected to start in Summer 2024 and be completed in Summer 2026. MISSISSIPPI: A defense technology company plans to invest $75 million to expand its manufacturing facility in MCHENRY, MS. They have recently received approval for the project. About Industrial SalesLeads, Inc. Since 1959, Industrial SalesLeads, based in Jacksonville, FL, is a leader in delivering industrial capital project intelligence and prospecting services for sales and marketing teams to ensure a predictable and scalable pipeline. Our Industrial Market Intelligence, IMI, identifies timely insights on companies planning significant capital investments such as new construction, expansion, relocation, equipment modernization, and plant closings in industrial facilities. The Outsourced Prospecting Services, an extension to your sales team, is designed to drive growth with qualified meetings and appointments for your internal sales team. Visit us at salesleadsinc.com.

Future proof your supply chain: Embracing automation and AI

Supply chain leaders are turning to automation and AI to enhance operational efficiency, reduce costs, and elevate the customer experience Automation in both process and physical forms has been around dating back as far as the Industrial Revolution. However, it wasn’t until the 1980s that automation began to emerge in supply chains. Back then, warehouse automation—such as automated storage and retrieval systems (ASRS), sortation systems, and conveyors—involved expensive physical infrastructure and millions of dollars in capital. What’s more, as business models evolved or companies created new models, these approaches struggled to be responsive. Fast forward to today. With advances in technology that include AI/machine learning and RPA in the form of software robotics, modern automation such as AMRs and other automated systems are much more conducive for pilots with small investments—providing the ability to prove value before a larger commitment is made. This benefit is just one of several reasons supply chain leaders need to embrace the enormous potential for advances in automation and AI technologies, which will continue to gain momentum for years to come. Additional benefits include: A solution to labor shortages: Finding enough workers with the right skill sets has opened the door for the adoption of warehouse automation, including the use of automated sorting systems, picking and packing automation, robotic automation, and autonomous vehicles. In addition to reducing dependence on human labor, these solutions can increase efficiency by operating 24/7 without fatigue. This translates into reduced costs and higher productivity levels, helping warehouses meet customer demands even during peak periods. Additionally, automation systems can minimize the risk of injuries to human workers by performing hazardous tasks. Enhanced customer experience: Brands and retailers are investing heavily in automation and AI to meet consumer demands for fast and reliable delivery. For example, AI helps companies optimize routes and provide accurate delivery estimates. Additionally, AI-driven chatbots can track orders, handle routine inquiries, and offer product recommendations—enabling companies to minimize response times and allow human customer service representatives to focus on complex issues. Improved accuracy/reduced errors: Precision is one of the most significant advantages of warehouse automation. The implementation of automated systems can drastically reduce human errors, which can lead to more accurate order fulfillment and inventory management. This can go a long way in maintaining customer satisfaction while reducing waste. Enhanced demand forecasting: AI technology excels at forecasting demand by extracting insights from extensive repositories of data, including numerous sources such as past sales records, customer transactions, social media mentions, and prevailing economic indicators—helping supply chain and logistics organizations maintain the delicate balance between consumer demand and supply. Additionally, AI projection tools can help facilitate better collaboration between supply chain partners by allowing demand forecast data to be shared with suppliers. This helps businesses optimize inventory levels and minimize stockouts while creating a harmonized supply chain system. Real-time visibility: Today’s businesses need to have complete, real-time supply chain visibility. AI-powered systems provide this level of visibility by integrating data from various sources such as suppliers, manufacturers, logistics providers, and retailers. This helps businesses track inventory levels, monitor shipments, identify bottlenecks, and respond quickly to disruptions or changes in demand—which enhances overall supply chain agility. Take the First Step—Consult with a Supply Chain and Logistics Expert Before investing in automation and AI, supply chain leaders need to understand the complex nature of these technologies as well as the current and future state of the market. This can be effectively accomplished by leveraging the expertise of a supply chain logistics and implementation partner—one that can help you deliver a customer experience that will build brand loyalty and accelerate growth. About the Author: Recognized for industry thought leadership and customer value creation, Jagan Reddy brings 25 years of experience in building and delivering supply chain and logistics solutions to his position as Managing Partner of Netlogistik US.

Post-it note your way to achievement

People are not afraid of achieving success, they just don’t know how. Here’s one element that will put you on the path. You have several goals you want to achieve, but they are not written down. They just pop up in your head every once in a while, only to be buried in a black hole of procrastination, excuses, and guilt. Take heart, I found a way to beat the system. Post-it Notes. Want to achieve your goals? Here’s a tested and proven method. You already have all the tools necessary to achieve success: Post-it Notes Bathroom mirror Bedroom mirror Felt tip pen Write down big onesOn 3×3 yellow Post-it notes write down your three prime goals in short words. (Get funding for business; new car Toyota; New Client Bank in Milwaukee) Write down small onesUse three more notes and write down your three secondary goals in short words. (Read a book from Dale Carnegie; Organize desk; Build new closet) Put them upPost them on your bathroom mirror. Where you can see them twice a dayYou are forced to look at them every morning and evening. Keep looking until you actYou will look at them until you are sick of looking at them and begin to accomplish them. Seeing the note there every day makes you think about acting on it every day.Once you start acting, the note triggers a “What do I have to do today to keep the achievement on target?” The note forces you to act. To achieve your goal. Revisit your success every day.After the goal is achieved post it on the bedroom mirror so you can see your success every time you look in that mirror. The program is simple. The program works. The results will change your attitude. The results will change your life. The results will change your outlook about your capability of success achievement. You will look at those Post-it Notes until you are sick of looking at them and begin to accomplish them. To Achieve Goals You Must Do the Following… Make a decision as to which goals you specifically want to achieve. Make a personal commitment to yourself to do whatever is necessary to achieve your goals. Be relentless. Don’t quit in the pursuit of your achievement. Do a little toward your goal every day. Write down how much (or how little) you must do each day in order to achieve. Harness your personal power. Discipline yourself, and focus on your commitment. Enlist the help of others who will support you. Give up goal (smoke, drink, eat) Share with and seek the support of everyone you know. (Family, friends, coworkers). Go up goal (Better on the job, best salesman) Share only with family and friends to avoid on-the-job jealousies. You must get the support of others to achieve your goals. It’s easy to getsupport all you have to do is give Don’t be vulnerable to the negative influence of other people. Work on two of your goals every day, even if only for a short time. Visualize yourself doing the steps necessary to achieve your goal. Visualize yourself actually achieving your goal. Don’t let other people tell you…”You can’t.” Tell them how you will and ask for their support! By posting the goal in the bathroom you are consciously reminded of your goals several times a day. From there, your subconscious gets into the act – gnawing away at your soul until you are driven to take positive action. Achievement actions. At last, you can say the magic words. Scream them I DID IT! (Screaming positive things always feels wonderful.) Here comes the best part. Take the Post-it Note off the bathroom mirror and triumphantly post it on your bedroom mirror. Now, every day you get to look at your success. WOW. Not only does it feel great, but you can set the tone for a successful day, every day, first thing in the morning by looking at success, remembering how good it felt, and thinking about what it took to do it. Plus, it gets you motivated to keep achieving more. By the time you have your bedroom mirror full of achieved Post-it note goals, you’ll have enough money to go out and buy a bigger mirror and the house to put it in. Post-it. Post haste. About the Author: Jeffrey Gitomer is the author of twelve best-selling books including The Sales Bible, The Little Red Book of Selling, and The Little Gold Book of Yes! Attitude. His real-world ideas and content are also available as online courses at www.GitomerLearningAcademy.com. For information about training and seminars visit www.Gitomer.com or email Jeffrey at salesman@gitomer.com or call him at 704 333-1112.

Higher performance & lower TCO: Embrace Lithium Battery Technologies to empower future material handling

Forklifts are the workhorses of many industries for material handling, revolutionizing the movement of goods across manufacturing, warehousing, distribution, retail, construction, and more. As we enter a new era in material handling, the future of forklifts is marked by key advancements—lithium battery technologies. These technologies promise enhanced performance, efficiency, sustainability, and cost-effectiveness. Battery Type: Choose Lithium over Lead Acid For years, lead-acid batteries have been a capable solution for electric forklifts and dominated the market. With the ever-growing demands of global supply chains, most industries for material handling must optimize operations, reduce costs, and ensure timely deliveries, all while being environmentally conscious. Compared with traditional lead-acid battery solutions, lithium forklift batteries are up to the challenges of these requirements. Their advantages include: Higher energy density: Store more energy without increasing the size, making lithium-powered forklifts more agile in operations requiring tight maneuvers. Fast and opportunity charging: No memory effect and can be charged during breaks and between shifts. Increase equipment availability and maximize uptime for industries operating multiple shifts a day. More stable performance: Stable voltage at all levels of discharge for consistent performance without sudden power sag. No dangerous substances: Safe and environmentally friendly. Frees up construction of specific battery rooms and purchase of HVAC & ventilation equipment. Virtually zero maintenance: No regular water top-ups and daily checks. No need to remove the battery from the forklift for recharging. Reduce battery swapping needs, battery maintenance frequency, and labor costs. Longer service life: With a longer cycle life, one battery lasts for many years for reliable power. Enhanced safety: Intelligent Battery Management System (BMS) supports real-time monitoring and multiple safety protections. Advancements and Innovations of Lithium Technologies To enhance battery performance and safety as well as business profits, companies are investing heavily in the R&D of lithium technologies. For instance, ROYPOW develops anti-freeze forklift batteries for cold storage. With unique internal and external designs, these batteries are well-protected from water and condensation while maintaining optimal temperatures for stable discharge. This significantly enhances forklifts’ performance and safety, ultimately ensuring operational efficiency and productivity. Some manufacturers are also exploring next-gen battery technologies such as faster charging rates, high energy density options, advanced BMS, and more that could redefine the market. Moreover, as market demand continues to skyrocket, achieving productivity goals becomes more challenging, making the automation of forklift equipment a growing trend in modern warehousing. Therefore, developing lithium battery systems for automated forklifts becomes increasingly critical. In addition to product innovations and excellence, lithium forklift battery manufacturers also leverage various strategies to constantly navigate the dynamic environment. For instance, companies like ROYPOW are expanding their production capacities through modular production and shortening delivery times by stocking up in advance in overseas warehouses and establishing localized services. Moreover, some companies are trying to enhance the customer experience by offering training sessions for optimal battery use. All of these strategies contribute to improving efficiency and reducing total costs of ownership. Final Thoughts To conclude, though high upfront costs and variability in return on investment might be a hindrance in the short term for businesses to make the switch, lithium-ion technology is the future for material handling, offering competitive strengths in performance and total cost of ownership. With the continuous innovations and growth of lithium technologies, we can expect even greater improvements that reshape the future of the material handling market. By embracing these technologies, businesses can benefit from increased efficiency, enhanced safety, greater sustainability, and higher profits, positioning themselves at the forefront of the evolving material handling industry. About the Author: Recognized for industry thought leadership and customer value creation, Jodie Miller brings 15 years of experience in material handling and lithium energy storage system solutions to her position as Managing Partner of ROYPOW.

Help is on the way

According to a PwC Pulse Survey ….40% of Executives plan to implement significant reorganization, including layoffs. That is up from 23% a year ago. The changes will focus on productivity boosts and top-line growth, with technological changes leading the way to achieve the goals planned. It appears that margin compression is the key driver of the reorganization. If you cannot pass on costs to customers and remain competitive, actions need to be taken to reduce costs and find ways to increase revenue. Of course, artificial intelligence (AI) will be part of this program. A. McKinsey from McKinsey & Company has also reported that its latest Global Survey reflected that 65% of the respondents are using Gen AI regularly, double the percentage from their last survey ten months ago. WOW! And 75% of the respondents predicted that gen AI would significantly change their industries in the years ahead. The benefits of AI use relate to both cost decreases and revenue increases in the business units adopting AI technology. Many are using AI in multiple functions, meaning their analysis indicated that it would work in this function and provide a positive ROI. This is all valuable information, but we must consider that these McKinsey respondents are large companies with IT departments and managers who can spend to get the “learning” they need to make decisions about AI. Can smaller companies do the same thing? Not so sure they can, but if they do not, they will find the larger companies nipping at their heels in terms of supplying services to customers. It is no secret that large company reps attend conventions and shows to learn how to steal gross profits from smaller companies. Does anybody know Amazon? I have probably read about 100 AI-related articles to figure out what I would do if I were sitting in your office and decided that the company needs to take AI seriously or find ways to offset threats from competitors. So, what did I do next? I read another twenty-five articles and made fifteen phone calls to find a source to help me with my problem. One call I made was to my granddaughter, who happens to work in the system installation world, and told me why we can do this now. when I asked her for a referral, she responded, “Hell, we do that and are very good at it.” She works for a CPA firm that specializes in high-end financial management and, along those lines, has an IT department with a particular unit that helps companies of all sizes with AI implementation. The firm is Connor Group. I asked my granddaughter to send me the section from their website regarding AI, and after going through every page of the website material and related articles, I said to myself, “Self, this is what you have been looking for.” I say that because any small to medium-sized company could use this material to get a very good understanding of what is available, what choices need to be made, how to go about implementing the system, and how to measure the results from the standpoint of return on your investment (ROI). Not only did I send Dean a copy of this material to make it available to you, but I also called the managing partner of Connor Group and asked him if he would be willing to set up contact with our readers to address questions about how to set up AI, provide a range of the cost to do that and help you determine if your data can give the “answers” you are looking in terms of decreasing costs or increasing sales. Dean jumped on board and suggested we make this a part of the monthly Wholesaler publication you receive. This way, we could answer readers’ questions and share the information with our print and electronic readers. Only the questions would appear; the sender’s name, rank, and serial numbers would not appear. In short, MHW is taking an active role in making your company more efficient and profitable and assisting you with your AI effort so you get it done right the first time. In addition, I could see this work for twenty groups or work for OEMs who need to keep their dealers competitive. I could see dealers helping customers relate to AI. If you helped a customer become more profitable, do you think you would lose the business any time soon? In the end, we wind up with systems designed for equipment dealers. And you may want to inform your OEM that this opportunity is available. They may even want to work out a deal geared to their brand. What is in it for Connor Group? Fees, of course, if you use them to assist you. The goal is to learn the industry and get to the point where they have the expertise to where dealers would go to them first before calling another vendor. I think you will like their AI materials and see what I mean by saying they are presented in an understandable format using the right sequence of events. What do you think? What else can I do for you? Let us hear from you. Send your comments to Dean. His email address is editorial@MHWmag.com. I made a deal with him to only forward the nice ones and toss the others. On another front, I sent Dean the last issue of John Mauldin’s Thoughts from the Front Lines, dated June 15, 2024. It will give you an understanding of what we are in for and who it will hurt. There is more reason to shoot for the moon regarding AI to keep your financial position in the top 20% of the market. About the Columnist: Garry Bartecki is a CPA MBA with GB Financial Services LLC and a Wholesaler columnist since August 1993. E-mail editorial@mhwmag.com to contact Garry.

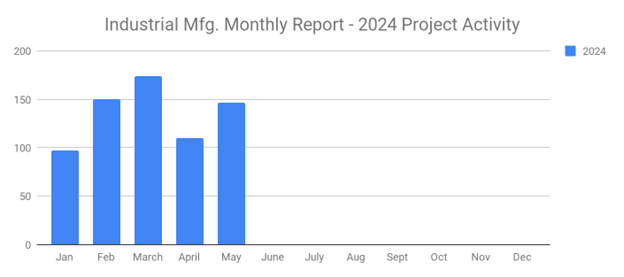

May 2024 makes a comeback with 147 new Industrial Manufacturing Projects

Industrial SalesLeads has announced the May 2024 results for the new planned capital project spending report for the Industrial Manufacturing industry. The Firm tracks North American planned industrial capital project activity, including facility expansions, new plant construction, and significant equipment modernization projects. Research confirms 147 new projects compared to 110 in April and 174 in March. The following are selected highlights on new Industrial Manufacturing industry construction news. Industrial Manufacturing – By Project Type Manufacturing/Production Facilities – 129 new projects Distribution and Industrial Warehouse – 73 new projects Industrial Manufacturing – By Project Scope/Activity New Construction – 42 new projects Expansion – 52 new projects Renovations/Equipment Upgrades – 66 new projects Plant Closings – 14 new projects Industrial Manufacturing – By Project Location (Top 10 States) Indiana – 10 Ohio – 10 Texas – 9 Michigan – 8 New York – 8 California – 7 Pennsylvania – 7 South Carolina – 7 North Carolina – 6 Quebec – 5 Largest Planned Project During May, our research team identified 22 new Industrial Manufacturing facility construction projects with an estimated $100 million or more value. The largest project is owned by Honda Canada Inc., planning to invest $15 billion to construct an EV battery manufacturing complex in ALLISTON, ON. They are currently seeking approval for the project. Completion is slated for 2028. Top 10 Tracked Industrial Manufacturing Projects ILLINOIS: EV MFR. plans to invest $1.5 billion in their manufacturing facility’s expansion and equipment upgrades in NORMAL, IL. They are currently seeking approval for the project. INDIANA: Automotive MFR. plans to invest $1.4 billion in its manufacturing facility’s expansion, renovation, and equipment upgrades in PRINCETON, IN. Construction is expected to start in Fall 2024, with completion slated for late 2026. QUEBEC: A global technology company plans to invest $730 million in the expansion and equipment upgrades on their manufacturing facility in BROMONT, QC. They are currently seeking approval for the project. TEXAS: Automotive MFR. plans to invest $531 million to expand its 1 Lone Star Pass manufacturing facility in SAN ANTONIO, TX by 500,000 SF. They are currently seeking approval for the project. MINNESOTA: Semiconductor MFR. plans to invest $525 million for their manufacturing facility’s expansion and equipment upgrades in BLOOMINGTON, MN. They are currently seeking approval for the project. GEORGIA: Hygiene products MFR. plans to invest $418 million for the expansion and equipment upgrades on their manufacturing, warehouse, and office facility in MACON, GA. They are currently seeking approval for the project. KANSAS: Automotive MFR. plans to invest $390 million for the renovation and equipment upgrades on their manufacturing facility at 3201 Fairfax Trafficway in KANSAS CITY, KS. They are currently seeking approval for the project. NORTH CAROLINA: Solar panel MFR. plans to invest $300 million for the construction of a 1-million SF manufacturing facility in GREENVILLE, NC. They have recently received approval for the project. NEVADA: Recycled paper product MFR. plans to invest $272 million in the construction of a recycling facility in WINNEMUCCA, NV. They have recently received approval for the project. WASHINGTON: The aerospace company is planning to invest $200 million for a 70,000 SF expansion and equipment upgrades on their manufacturing facility in SPOKANE, WA. They are currently seeking approval for the project. About IMI SalesLeads, Inc. Since 1959, IMI SalesLeads, based in Jacksonville, FL is a provider in delivering industrial capital project intelligence and prospecting services for sales and marketing teams to ensure a predictable and scalable pipeline. Our Industrial Market Intelligence, IMI identifies timely insights on companies planning significant capital investments such as new construction, expansion, relocation, equipment modernization, and plant closings in industrial facilities. The Outsourced Prospecting Services, an extension to your sales team, is designed to drive growth with qualified meetings and appointments for your internal sales team. Visit us at salesleadsinc.com.

Are your parts and service managers “Long-term relationship builders”?

It is hard to believe we’re already well past the first half of 2024! Time is flying, and I hope everyone is hitting their sales, customer experience, and satisfaction goals. As we progress into the latter part of the year, it’s important to take a moment to reflect on our accomplishments, reassess our strategies, and gear up for the challenges ahead. This month’s edition let’s explore the topic of managing customer expectations and how you can enhance your service delivery to stay ahead of your competition. Parts and Service Managers at your dealership are at the forefront of customer interactions and play a critical role in maintaining the efficiency and reliability of your customer’s lift truck operations. One of the key challenges they face is managing your customer’s expectations, particularly when it comes to parts, service, and other aftermarket activities. Getting this right not only ensures customer satisfaction but also strengthens your dealership’s reputation and builds long-term loyalty. In June’s edition of Material Handling Wholesaler, I discussed how the success of your dealership hinges not only on the quality of products and services you sell but also on the seamless collaboration between the different departments within your dealership. Also, siloed departments within your dealership can impede efficiency, communication, and ultimately, customer satisfaction; breaking down these silos is essential for thriving in today’s landscape within our industry. Fundamentally, the quality of the relationship you have with your customer, your grasp of their needs, and the effectiveness of your communication is vital. How your various departments interact with your customers must be perceived as genuine, dependable, and credible. Failure or reluctance to communicate to your customer, especially when for example there are delays in parts or service delivery, or there are additional costs that were not initially anticipated, can cause customer dissatisfaction and failure to meet their expectations. Here are some ways we can effectively manage these expectations. Clear Communication is Key Communication is the foundation of managing expectations. From the moment a customer contacts your dealership, they need clear, transparent information about the services and parts you offer, costs, and expected timelines. Miscommunication can certainly damage your credibility. Effective communication is essential for managing customer expectations. This begins with providing detailed quotes that are comprehensive and include all potential costs—labor, parts, and any additional fees. Transparency in quotes prevents surprises and builds trust with your customers. Additionally, drafting clear service agreements that outline the scope of work, timelines, and service levels is crucial. Ensuring your customers understand these terms before starting any work sets a solid foundation for mutual expectations. Finally, keeping your customers informed about the status of their service requests through regular updates is vital. This consistent communication helps manage expectations, especially if there are delays or additional work required. Set Realistic Expectations Setting realistic expectations is crucial. Honesty about what your team can achieve and within what timeframe will always work in your favor. Before committing to a job, assess the situation thoroughly and advise your customers on what can realistically be done, including evaluating part availability and repair timeframes. Be upfront about potential limitations or delays; if a part is backordered, inform the customer of the expected delivery time and any available alternatives. Additionally, help your customers prioritize their needs based on urgency and impact, as not all requests are equally critical. Managing this can help set realistic expectations about response times and service delivery. Building Long-Term Relationships I came across an industry colleague’s profile the other day on LinkedIn. His job title was: Long Term Relationship Builder! How clever is that! But it speaks to exactly the point here, managing customer expectations is about more than just the immediate service interaction. It’s about building long-term relationships based on trust and reliability. Satisfied customers are more likely to return and recommend your products and services to others. After completing a service job, follow up with your customers to ensure they are satisfied, demonstrating your commitment to quality and customer care. Additionally, you could implement loyalty programs that reward your repeat customers with discounts on future services or priority scheduling for urgent repairs. Finally, understand the unique needs of each customer and tailor your services accordingly, as personalized service can significantly enhance customer satisfaction and loyalty. Leverage Technology Implement customer portals that can be accessed through your company’s website where your customers can track the status of their service requests, view service history, and communicate with your team. Additionally, integrate feedback systems to gather customer input on their service experience, using this feedback to make continuous improvements and show customers that their opinions are valued. For Parts and Service Managers at your dealership, managing customer expectations is a crucial part of their role. By focusing on clear communication, setting realistic expectations, providing consistent quality, leveraging technology, and building long-term relationships, you will not only meet but exceed your customer expectations. This approach fosters trust, loyalty, and long-term success for your dealership. About the Author: Chris Aiello is the Business Development Manager at TVH Parts Co. He has been in the equipment business for 17-plus years as a service manager, quality assurance manager, and business development manager. Chris now manages a national outside sales team selling replacement parts and accessories in various equipment markets such as material handling, equipment rental, and construction/earthmoving dealerships.

Safety 2024 in Denver features session with OSHA’s Parker

The American Society of Safety Professionals (ASSP) will welcome Doug Parker, assistant secretary of labor for occupational safety and health, at next month’s Safety 2024 in Denver. Parker will discuss the latest Occupational Safety and Health Administration (OSHA) activities before taking questions from attendees and media members. The special session at ASSP’s professional development conference and exposition will start at 10:30 a.m. MT on Friday, Aug. 9, in front of thousands of workplace safety and health professionals in the Mile High Ballroom at the Colorado Convention Center. Parker will present “An OSHA Update” with insights on regulatory priorities, enforcement actions, and outreach initiatives. The 60-minute session will include an interactive Q&A with questions submitted via text by audience members. Afterward, Parker will meet with members of the press at 11:45 a.m. MT in Room 505. “It’s always an honor to welcome Mr. Parker to our signature event where safety and health professionals appreciate hearing from him directly about important workplace safety developments,” said ASSP President Pam Walaski, CSP, FASSP, who will moderate the live Q&A on stage. Parker became the 13th assistant secretary of labor for Occupational Safety and Health on Nov. 3, 2021. He has participated in similar ASSP sessions at Safety 2022 in Chicago and Safety 2023 in San Antonio. The OSHA session is a dynamic three-day program to inform and inspire occupational safety and health professionals. Safety 2024 is the 63rd annual conference of the world’s oldest professional safety organization. ASSP is headquartered in the Chicago suburb of Park Ridge. Safety 2024 attendees can register online, with groups of eight or more from the same company qualifying for a discount.