August 2024 U.S. cutting tool orders total $209.3 million

Shipments of cutting tools, measured by the Cutting Tool Market Report compiled in a collaboration between AMT and USCTI, totaled $209.3 million in August 2024. Orders increased 9.1% from July 2024 but were down 4.5% from August 2023. Shipments of cutting tools, measured by the Cutting Tool Market Report compiled in a collaboration between AMT – The Association For Manufacturing Technology and the U.S. Cutting Tool Institute (USCTI), totaled $209.3 million in August 2024. Orders increased 9.1% from July 2024 but were down 4.5% from August 2023. Year-to-date shipments totaled $1.67 billion, up 1.5% from shipments made in the first eight months of 2023. The year-to-date growth rate has declined every month since April 2024. “U.S. cutting tool orders have hit significant headwinds as we move into the fourth quarter of 2024,” said Steve Boyer, president of USCTI. “We saw drop-offs in orders for two of the last three months of the third quarter of this year compared to last year. Challenges continue with work stoppages in the aerospace sector. Instability in world events is also significantly impairing market confidence as we finish out 2024. Defense spending continues to be strong, while other markets have shown some stagnation. Early expectations for continued growth in 2025 originally showed promise, but a lackluster 2025 is probably more realistic with so many factors in flux.” Bret Tayne, president of Everede Tool Company, said: “Sales of industrial metal cutting tools seems to have plateaued. We can look past some of the ‘noise’ by focusing on the 12-month moving average, and that is flat. This conclusion seems to be consistent with what we read about the broader economy. We are at an inflection point. Some macro data points to a recession and other data indicates we may avoid it. From the perspective of our industry, it will be interesting to see if we achieve any sustainable momentum from IMTS, which took place in September.” IMTS – The International Manufacturing Technology Show was held Sept. 9-14 in Chicago. A biennial event produced by AMT, IMTS is the largest manufacturing trade show in the Western Hemisphere and regularly provides a boost to manufacturing technology and machine tool orders across all sectors. The Cutting Tool Market Report is jointly compiled by AMT and USCTI, two trade associations representing the development, production, and distribution of cutting tool technology and products. It provides a monthly statement on U.S. manufacturers’ consumption of the primary consumable in the manufacturing process, the cutting tool. Analysis of cutting tool consumption is a leading indicator of both upturns and downturns in U.S. manufacturing activity, as it is a true measure of actual production levels.

H&E opens New Kansas City South Branch

Effective October 21, 2024, H&E Rentals has announced the opening of its Kansas City South branch, the company’s fourth location in the state of Missouri and its second in the Show-Me State in a year. H&E operates in 32 states and opened 16 branches across the country in 2024. The facility is located at 1100 SE Hamblen Road, Lee’s Summit, MO 64081-2938, phone 816-370-8200. It includes a fully fenced yard area, offices, and a repair shop and carries a variety of construction and general industrial equipment. “Our fourth location in the Show-Me State now makes it even more convenient for customers in the areas south of KC and on both sides of the Kansas and Missouri border. We can more quickly reach customers in Lee’s Summit, Independence, Overland Park, Olathe, Warrensburg, Ottawa, Harrisonville, Nevada, and all points in between,” says Branch Manager Kriss Mills. “Our position between our existing Kansas City, Columbia and Springfield facilities gives us the advantage of working together to source the equipment customers need from an expanded local fleet. We’re directly off Hwy 50 near highway 291 and I-470, so we can efficiently move equipment to job sites to better serve the market.” The Kansas City South branch specializes in the rental of aerial lifts, earthmoving equipment, forklifts, telehandlers, compaction equipment, generators, light towers, compressors, and more. The fleet represents the following manufacturers: Allmand, Atlas Copco, Blue Diamond Attachments, BOMAG, Case, Club Car, Connect Work Tools, Cushman, Gehl, Generac Mobile, Genie, Hamm, Haulotte, Husqvarna, JCB, JLG, John Deere, Kobelco, Kubota, LayMor, Ledwell, Lincoln Electric, Link-Belt Excavators, Manitou, MEC, Miller, Multiquip, Okada, Polaris, Sany, Skyjack, SkyTrak, Sullair, Sullivan-Palatek, Tag, Towmaster, UniCarriers, Vacuworx, Virnig, Wacker Neuson, Yanmar, and others.

Norwalt Automation Group launches new corporate umbrella company

New divisions strategically align company to better suit target markets in the automation space. Norwalt has announced the launch of its new corporate umbrella company, the Norwalt Automation Group. This strategic move brings together four specialized divisions under one unified brand to better serve the diverse needs of key industries. The new divisions include the Norwalt Automation Division, Norwalt Life Sciences Division, Norwalt Food & Beverage Division, and Norwalt Digital Division. Under the leadership of Chairman Mike Seitel, Norwalt Automation Group aims to deliver tailored, cutting-edge solutions to its partners across various sectors. This expansion reflects Norwalt’s commitment to innovation and growth, ensuring that the company remains at the forefront of automation technology. Each new division will be led by a collective team of divisional managers and senior company directors, and function under the leadership of the larger groups’ experienced leadership and executive team featuring industry leaders: Keith Harman, Executive Director of Business Development, Herbie Hoos, Executive Director of Manufacturing, and Donna Collura, Executive Director of Finance. “I’m thrilled to announce the formation of our newly structured divisions under the Norwalt Automation Group umbrella company,” said Mike Seitel, Chairman of Norwalt Automation Group. “These expanded divisions allow us to align more closely with the specific needs of our target industries, ensuring that we deliver tailored, cutting-edge solutions to our partners. This expansion reflects our unwavering commitment to innovation and growth.” The new divisions within Norwalt Automation Group include: – Norwalt Automation Division: Focused on advanced automation systems for a wide range of industries. – Norwalt Life Sciences Division: Dedicated to providing specialized automation solutions for the life sciences sector. – Norwalt Food & Beverage Division: Tailored to meet the unique needs of the food and beverage industry, offering innovative processing and packaging automation. – Norwalt Digital Division: A future-focused division specializing in digital printing and automation, integrating AI, vision/inspection equipment, data collection/security, Industry 4.0, and Digital Twin technologies.

Demand for Industry specific AI drives increasing adoption of IFS.ai

IFS has boosted its offering in the six hardcore industries it serves to 60+ in-depth Industrial AI scenarios, which are available in the IFS Cloud 24R2 release. More than 300 additional scenarios are in the process of MVP (minimum viable product) validation. Despite the noise around generic co-pilots and consumer-focused AI, IFS is driving change and adoption of arguably the most impactful application of AI: Industrial AI. IFS.ai is Industrial AI, with customers already using and able to immediately implement IFS.ai without the need for expensive investments in toolkits or additional implementation resource. The Industrial AI scenarios available today with IFS.ai fit within the following Classes, and span both Generative AI and Predictive AI: Generative AI Content generation (personalized training; autogenerated project reporting) Recommendation (configuration to improve production quality; sourcing and supplier decision support) Contextual knowledge (assembly instruction and real-time guidance; unstructured data knowledge retrieve) Predictive AI Event forecasting (automated risk and mitigation; simulate product and asset behaviors) Optimization (optimize task sequencing; optimize vs. resources vs. capacity) Anomaly detection (proactive quality control and monitoring) Customers already using IFS.ai are reporting rapid returns. Ependion has turned to IFS.ai to improve efficiencies in the Manufacturing space. CIO, Joakim Stolt said: “IFS.ai Manufacturing Scheduling and Optimization (MSO) will help us increase productivity by automating our production planning process. We can quickly respond to changes based on external factors with AI-driven optimization designed to maintain high utilization of our critical resources to better meet customer demand. Ultimately, we are able to deliver optimal outcomes to our customers and product planners.” Noble Corporation, a world-class offshore drilling company, is using IFS.ai to boost productivity and efficiency. Kristian Mortensen, Manager, Maintenance Process & Solutions, said: “Ideally we only want to service or replace a component when it is within 80% of its predicted failure time or lifetime. IFS.ai promises to help us get a lot closer to that more efficient maintenance scenario. It also promises to make our systems perform better because we know what it is that we need to do – the critical failure point – from the legacy and analytics projections. If we want to change the maintenance interval, IFS.ai will help us to justify decisions to authorities and OEMs based on the historic data and insight available within the system.” IFS.ai is the backbone of IFS’s ERP, Asset Management (EAM), and Service Management (FSM and ITSM) solutions. When applied to the industries IFS serves, the impact is profound: 8 out of 10 of the leading U.S. energy companies use IFS.ai to deliver power to American homes 200 million + Americans connect every day using cell phone networks maintained with IFS.ai 200 billion packages a year are sustainably produced and distributed across the world thanks to IFS.ai 2 billion people keep moving on elevators and walkways maintained and services with IFS.ai every day 105 million U.S. households have utilities powered by IFS.ai 9 billion sq ft of construction projects globally are managed with IFS.ai 310 million passengers a year fly safely thanks to aircraft maintained by IFS.ai “Industrial AI is at the very core the solutions we are powering for customers. They are pushing us for ready-to-use AI that they can adopt quickly to solve real industrial challenges like labor shortages, supply chain disruption, stagnated productivity,” said IFS Chief Customer Officer, Cathie Hall. “IFS is the pioneer of Industrial AI, and we are committed to further extending our global leadership position, making more real-world AI use cases available for customers in our hardcore industries. The IFS mission is to accelerate the pace of AI development and adoption throughout our organization and into the products and services we deliver to customers. Our commitment to continued investment in IFS.ai has never been stronger.” “IFS has strength in the breadth of service capabilities that incorporate AI, machine learning, and IoT,” said Aly Pinder, Research Vice President – Worldwide Aftermarket Services Strategies at IDC said. “IFS is helping organizations address the technology opportunities of a rapidly evolving market that is benefiting from advanced tools to insights, collaboration, and action. IFS has been able to incorporate these tools into an Industrial AI offering that drives improved service operations and outcomes.”

Advancing with automation and AI

In today’s material handling environment, warehouses are driven by the need for speed and accuracy. At the same time, finding the right labor force remains challenging for some operations. Some are looking for automation and artificial intelligence (AI) advancements to fill those gaps and meet expectations. Increased demand for automation Brett Webster, director of product management at Dematic, noted that AI has already been transformative in many settings, including automation. “The industry continues to face challenges, such as ongoing labor shortages and disruptions caused by global events,” Webster said. “In an era where supply chain resilience is no longer ‘nice to have’ but a requirement for success, increased visibility and connection are paramount,” Webster said. According to the company website, Dematic is a “global leader in innovative, integrated supply chain automation technologies, software, and services. ” Leaders at Dematic anticipate supply chains will continue to become more autonomous, aided in part by the growth of AI. Webster noted a recent report by MHI and Deloitte finding that 87 percent of companies believe autonomous, connected intelligent supply chains will be standard by 2027. “As a result, companies are increasingly investing in AI technology,” Webster said. Currently, Webster said AI’s largest impact is on enhancing algorithms for decision-making software and optimizing operations. “However, as AI continues to grow over the coming years, access to and proper use of data will become critical. Real-time data analysis allows AI systems to identify inefficiencies, streamline operations, and automate tasks, helping the cost of and need for labor amongst industry-wide shortages,” Webster said. AI can also ensure algorithms reduce travel times and increase output by optimizing inventory placement, and help provide predictions and adjustments for fluctuations in customer demand, according to Webster. “We believe building a holistic ecosystem of solutions, software, and data, powered by AI, will drive the development of autonomous supply chains the industry has long anticipated,” Webster said. Solutions for e-commerce According to Mike Oren, SVP of sales for the Americas for Dematic, the demand for automation has increased in the years following COVID. He said the demand is driven by “evolving consumer expectations, ranging from same or next-day delivery, to sustainable business practices to omnichannel shopping.” “This shift is further fueled by ongoing labor shortages and the rapid growth of e-commerce, putting significant pressure on businesses to improve efficiency,” Oren said. The drive is resulting in a turn to automated solutions like Automated Guided Vehicles, Autonomous Mobile Robots, mixed-case fulfillment, and goods-to-person picking, according to Oren. “Fluctuations in demand have become the norm, and flexible automation can be scaled to help our customers adapt to their shifting needs,” he said, adding that software is the brains behind all of the technological solutions. “Software provides the data and visibility necessary to make insightful decisions while maximizing performance and speeding up fulfillment,” Oren said. He added that the companies best positioned to be competitive in the coming years will be those providing comprehensive hardware, software, and services. According to Kevin Heath, director of global robotics, Dematic provides up-to-date solutions for the world of automation through the work of its Modernizations & Upgrades team. Heath said the team helps customers improve the effectiveness of their operations by identifying and incorporating new automation, controls, and software that optimizes performance. “We also identify the best solutions for our customers to address those changes,” he said, noting that while Autonomous Mobile Robots have been in the market for some time, Bin-to-Picker AMRs in particular are “ideally suited” for the growth of e-commerce. Heath noted that when 3PL provider Radial outgrew its manual distribution center in the Netherlands due to increased e-commerce demand, Dematic helped with the automation of a new facility. “This included adding almost 300 AMRs to their operations, including 10 Bin-to-Picker stations. Since the facility opened in 2023, picking and packing performance has improved significantly, and the error rate is vastly reduced,” Heath said. He added that for companies with scarce resources, Bin-to-Picker AMRs can operate without human intervention and with little to no fixed automation. “Bin-to-Picker AMRs are cost-efficient, easily scalable, and equipped with software to improve efficiency and reduce order fulfillment times,” said Heath, who said Dematic customers utilizing Bin-to-Picker AMRs report more than 99 percent order accuracy and an ROI in as few as 1.5 years. Dematic automated systems can also be adapted to different warehouse environments, which Heath said makes them “an ideal solution” for industries ranging from retail to third-party logistics. “Our automation systems are modular, meaning they can be upgraded and expanded as new technologies emerge or business needs evolve,” Heath added. Meeting automation needs Some companies are building advanced solutions via new collaborations. In September, Kivnon announced the formation of a strategic partnership with Macrovey. According to a press release, Kivnon is a leading producer of mobile robots, including automated guided vehicles and autonomous mobile robots. Kivnon specializes in solutions that optimize logistics and internal transport processes across industries. The statement said Macrovey is an industry leader in industrial equipment, performing electrical installations of complex motor and process controls for a variety of material handling systems. The new collaboration, which is now in effect, will “enhance both companies’ market presence and operational capabilities across North America,” the release said. “With this partnership, Kivnon aims to streamline the sales and installation processes for its mobile robots,” the release said. “At the same time, Macrovey will gain access to Kivnon’s innovative product line, allowing them to expand their offerings.” Jaume Martinez, managing director of Kivnon USA, said the partnership will ensure that customers receive top-tier service and support. “Together, we will set new standards in the automation industry, delivering tailored solutions that meet the specific needs of our clients,” said Martinez in a statement. In an email to Material Handling Wholesaler, Martinez said Kivnon’s automated guided vehicles and autonomous mobile robots help automate material handling tasks and integrate seamlessly with higher-level systems. “One of our key strengths is the ability to connect our robots to external fleet management systems, enabling businesses

Getting started with AI-Powered Chatbots

You’ve heard the buzz around Generative AI-powered chatbots like ChatGPT, Claude, and Gemini. But are they worth the hype? Absolutely. The key to success is learning how to use these tools effectively. With the correct instruction, chatbots can produce detailed, relevant, and tailored results to your specific requirements. No technology expertise is required to become a pro – just a curiosity for exploration. It would be best to learn how to “prompt,” which means providing good instructions to the chatbot, so you get more valuable responses and output. Start with basic experimentation to understand where AI works well (and not well). From there, you can explore how to integrate AI into your workflows to tackle more complex needs. This article will explore using chatbots and provide tips for effective prompting. Where should you start? Many robust use cases are simple and require no prior experience or specific expertise. Start by asking your chatbot the same questions you’d ask a search engine – in many cases, you’ll find the responses more useful. Chatbots can provide personalized, context-aware answers tailored to your criteria. Plus, follow-up questions help refine responses to get exactly what you need. For instance, chatbots can quickly propose a customized travel itinerary, saving you the hassle of researching online. Try out this prompt: I’m flying from [home city] to [destination city] from [start date] to [end date] and want to stay near [insert landmark or area]. I prefer a direct flight and to stay in [insert hotel preference, e.g., preferred hotel chain], but I’m open to alternatives if the price difference is more than [$XX] for the flight or [$XX]/night for the hotel. Please recommend an itinerary, including the best flight times. More prompt ideas are provided at the end of this article. Tips for prompting Chatbots Chatbots respond to “prompts”—instructions or questions you provide. Here are a few tips for writing effective prompts: Speak naturally Ask questions as if you’re talking to a person. This makes it easier for the chatbot to understand and respond accurately. And don’t worry overly about spelling; it will figure it out. Be clear and specific Treat the chatbot like a new employee who needs clear instructions. The more specific you are, the better the response. Example: Instead of “Plan a meeting,” try to “Create an agenda for a 30-minute meeting to discuss quarterly sales targets.” Utilize follow-ups Think of chatbot interaction as a conversation. If the first response isn’t quite right, refine it with follow-up prompts or ask it to try again. Example: “Incorporate a 10-minute Q&A session at the end of the meeting” or “Your response is not to my liking; try again.” Set context To get better responses, tell the chatbot what kind of role, tone, or personality you want it to have. Example: Instead of “Create a marketing campaign,” say, “You are a senior marketing director. Create a professional B2B marketing campaign for warehousing and logistics.” Specify the desired output Let the chatbot know how you want the information presented. It can provide summaries, bullet points, tables, or even images. Example: Instead of “Tell me about the project,” try “Give me a bullet-point summary of the project timeline.” Attach relevant documents Quickly and effectively analyze files, especially documents and PDFs, by attaching them to your prompt. Example: Instead of manually analyzing a customer or vendor contract, attach it to the chatbot and use this prompt: “Summarize the key terms, pricing, and product details in the attached contracts, and provide the output in a bullet form.” Experiment with your scenarios and prompts; the more you try different ways, the better you will get. A reminder While chatbots are powerful, be cautious with data confidentiality. Unless you implement the enterprise version of these chatbots, your data and chat history may be used to train AI models. Final thoughts AI-powered tools, like chatbots, have the potential to deliver efficiency, personalization, and insights at an unprecedented scale. However, success with AI isn’t just about the tools themselves. It starts with understanding how to apply these technologies effectively. Focus on small, practical use cases as you begin experimenting with AI. These could include simple communication, generating content, or automating routine tasks. Over time, this knowledge will open the door to more complex applications, such as predictive analytics or customer service automation. Your business will thrive in the new AI-driven landscape by starting small, experimenting thoughtfully, and staying informed about AI’s evolving capabilities. If you have any questions or need help getting started, please contact me at ai_automation@connorgp.com. You can also connect with me on LinkedIn for the latest trends and insights in AI and automation. Useful prompting tool ChatGPT Prompting Guide (Ruben Hassid, LinkedIn) Example prompts To get started, here are some example prompts you can try today. Update the wording in [brackets] according to your needs and enter them into your chatbot of choice: Writing an Email “Write an email as a [job title] to [name], informing them of [topic]. Use a [desired tone].” Completed Example: “Write an email to John as an Account Manager, informing them about the XAR32, a new forklift that your company is offering, and to offer an on-site demo at their warehouse. Use a warm yet professional tone.” Prepare a “How-To” Guide “You are an experienced [job title]. Give me best practices and a detailed how-to guide on [insert topic]. The guide should cover [insert desired sections].” Example: “You are an experienced Warehouse Manager. Give me best practices and a detailed how-to guide on warehouse layout optimization for perishable food products. The guide should cover safety protocols and tips for energy efficiency.” Contract Review Prompt Attach the contract you’d like to review for a thorough contract analysis. Specify the key terms and clauses you want highlighted. The chatbot can also point out any unusual or non-standard terms for this type of agreement. “Review the attached [contract type] contract and highlight key terms such as [insert specific terms, e.g., payment terms, liability clauses]. Additionally, identify any clauses

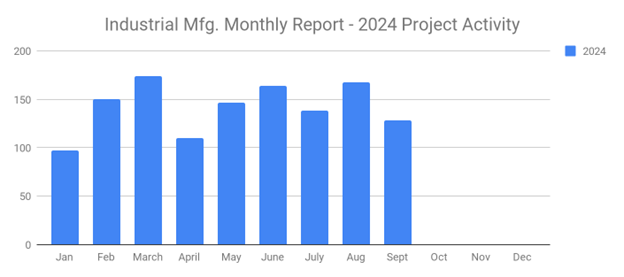

128 promising Industrial Projects on the horizon for September 2024

Industrial SalesLeads released its latest MiR Report for September 2024 results for the Industrial Manufacturing industry’s planned capital project spending. This comprehensive report tracks North American industrial capital project activities, encompassing facility expansions, new plant constructions, and significant equipment modernization projects. The data within the report serves as a valuable resource for businesses seeking insights into industrial investment trends and strategic decision-making. Research confirms 128 new projects, a notable decline from August, which reported 168 projects in the Industrial Manufacturing sector. The following are selected highlights of the new Industrial Manufacturing industry construction news. Industrial Manufacturing – By Project Type Manufacturing/Production Facilities – 100 New Projects Distribution and Industrial Warehouse – 75 New Projects Industrial Manufacturing – By Project Scope/Activity New Construction – 35 New Projects Expansion – 36 New Projects Renovations/Equipment Upgrades – 54 New Projects Plant Closings – 15 New Projects Industrial Manufacturing – By Project Location (Top 10 States) Indiana – 11 Michigan – 9 Ohio – 9 Texas – 8 Tennessee – 7 Ontario – 6 Pennsylvania – 6 Virginia – 6 Louisiana – 5 New York – 5 Largest Planned Project In September, our research team identified 16 new industrial manufacturing facility construction projects with an estimated value of $100 million or more. Highland Materials, Inc., which owns the largest project, plans to invest $1.4 billion in constructing a 1.2 million-square-foot manufacturing facility in Rocky Mount, NC. The company is currently seeking approval for the project. Top 10 Tracked Industrial Manufacturing Projects TENNESSEE: Specialty silicon product manufacturer plans to invest $1 billion in constructing a 1.2 million-square-foot manufacturing facility in SURGOINSVILLE, TN. They are seeking approval for the project, which is expected to start in 2026. NORTH CAROLINA: A titanium manufacturer plans to invest $868 million in constructing a 500,000-square-foot manufacturing facility at 557 Bethune Dr. in FAYETTEVILLE, NC. They are seeking approval for the project, which is slated for completion in 2027. KENTUCKY: Battery Manufacturing Company is seeking approval for a $712 million project to construct a manufacturing facility in SHELBYVILLE, KY. INDIANA: Solar panel manufacturer is planning to invest $500 million in the renovation and equipment upgrades of a 781,000-SF—manufacturing and warehouse facility at 5880 W. Indiana 28 in TIPTON, IN. Construction is expected to start early in 2025, with completion slated for fall 2026. MICHIGAN: Automotive manufacturers plan to invest $400 million in renovations and equipment upgrades at their manufacturing facilities in STERLING HEIGHTS, MI, WARREN, MI, and DUNDEE, MI. It is currently seeking approval for the project. PENNSYLVANIA: A plastic recycling service provider is seeking approval for a $183 million project to construct a warehouse and processing facility in ERIE, PA. MICHIGAN: An EV battery manufacturer is planning to invest $175 million in constructing a manufacturing facility in Flint, MI, and is seeking approval for the project. WEST VIRGINIA: A battery technology company plans to invest $150 million in expanding its manufacturing facility in WEIRTON, WV. It is currently seeking approval for the project. ILLINOIS: A pharmaceutical company plans to invest $146 million to expand its manufacturing, processing, and distribution campus in ROCKFORD, IL, by 545,000 SF. Completion is slated for Fall 2025. MICHIGAN: Battery materials manufacturing company plans to invest $125 million in constructing a manufacturing facility at 4925 Evanston Ave. in EGELSTON TOWNSHIP, MI. They are currently seeking approval for the project, which is expected to start in early 2026. About Industrial SalesLeads, Inc. Since 1959, Industrial SalesLeads, based in Jacksonville, FL, has been a leader in delivering industrial capital project intelligence and prospecting services for sales and marketing teams to ensure a predictable and scalable pipeline. Our Industrial Market Intelligence, IMI, identifies timely insights on companies planning significant capital investments such as new construction, expansion, relocation, equipment modernization, and plant closings in industrial facilities. The Outsourced Prospecting Services, an extension to your sales team, is designed to drive growth with qualified meetings and appointments for your internal sales team. Visit us at salesleadsinc.com. Each month, our team provides hundreds of industrial reports within a variety of industries.

Tune up time

It is time once again to figure out how you did compared to last year, against budget, against cash flow budgets, and against your peers. We review the overall results and then dive into each department. Finally, you review personnel in each department in terms of “sales per employee,” gross profit per employee, and then sales and gross profits per employee for each department. Good for you if you find yourself in the top 25 % of the peer group. If you did not, there is a ton of $ available waiting for you and your team to harvest them. And really, there is no excuse not to make strides every year to close the gap between the Top 25 and your results. Get the SEC documents from the public companies in your SIC code to make this study even more interesting. They make it interesting reading when they explain market fluctuations, supply chain issues, changes in customer demands and expectations, and the sales per employee stats that most of them provide. Your internal review and a public company financial report would be great topics for your 2025 strategic planning meeting. Many companies also have their “ANNUAL” meeting around this time to discuss the current year against the planned expectations and to approve the plan for the following year. The Board typically approves cap-X costs and related financing decisions at this meeting. A critical topic for the remainder of this year and next year will be inflation and how the fed rate reduction affected inflation going forward. The essential points are as follows: REDUCING INFLATION DOES NOT MEAN PRICES DECLINE. IT MEANS THE ANNUAL INCREASE WAS REDUCED. AND THERE STILL IS INFLATION BECAUSE THE GOAL WAS TO REDUCE IT TO 2% PER YEAR. SO, YOU STILL HAVE INFLATED COSTS, BUT THEY ARE NOT INCREASING AS THEY HAVE IN THE LAST FOUR YEARS. THE COST OF PRODUCTS COULD DECREASE BECAUSE OF DEMAND AND SUPPLY ISSUES. LET’S ASSUME YOU AND YOUR OEM ARE STUCK WITH UNITS THAT COST OUT AT THE HIGH END OF THE RANGE. IF YOU NEED TO TAKE A HIT ON THESE UNITS TO MOVE THEM, THEN THERE WILL BE A PRICE REDUCTION UNTIL THE MARKET IS IN BALANCE ONCE AGAIN. BUT THIS DOES NOT MEAN THE PRICES WILL FALL BY ANY SUBSTANTIAL AMOUNT AND STAY THAT WAY. PRICE REDUCTIONS, TO ANY GREAT EXTENT, WILL CAUSE DEFLATION, WHERE PRICES WILL, IN FACT, DECREASE UNTIL THE DEMAND EQUATION IS IN BALANCE AGAIN. DEFLATION IS USUALLY CAUSED BY RECESSIONS OR DEPRESSIONS, WHICH PRODUCES A WHOLE OTHER SET OF ISSUES TO DEAL WITH. IN THIS DAY AND AGE, AN OEM OR DEALER CAN PRODUCE DEFLATION AND, AS A RESULT, BE MORE COMPETITIVE IN THEIR MARKETS. YOU CAN ACHIEVE THIS GOAL BY DEVELOPING A PROGRAM COMPRISED OF INNOVATION-PRODUCTIVITY IMPROVEMENT- AND AUTOMATION. BY REDUCING COSTS AND SPEEDING UP PROCESSING A COMPANY CAN OFFER MORE EFFECTIVE PRICES AND CREATE THEIR OWN DEFLATION, WHICH FLOATS DOWN TO CUSTOMERS. One last point on inflation: It contains two indices: one for products and services and one for payroll. The payroll results may not decrease as much because of a shortage of help in most industries. Keep this in mind when planning for 2025. The experts are expecting payroll increases in the 3.5-4.0% range. Another reason to do more with less is to keep costs in check. Your financial arrangements also need review. Bank terms and rates to see if you can renegotiate your loans to reduce interest costs or to spread out payments in some way to reduce cash outflow. I would not hesitate to shop my loan package to reduce my rate and/or to push out the payment schedule. And what about customer financing? Customers would also like to reduce their rates and spread out the payments. Can you or your OEM do anything to reduce their cash flow burden? Insurance has also been costly. Shop your program with at least three carriers. Work with an experienced broker who can read and suggest upgrades or changes needed in the policy. Please pay special attention to cyber coverage because it will require internal upgrades on your part before it begins. I would ask my IT folks to review the Cyber policy to ascertain that you can provide the IT coverage required to support and protect your systems and information. And how can any tune-up not discuss local, state, and Federal taxes? I suggest you take advantage of the current tax programs before year end because many of the current breaks are set to expire in 25. And it goes without saying that customers should consider doing the same if it fits into their current financial plan. Have your tax folks make your sales department knowledgeable about these opportunities. There is, of course, a possibility that the current tax breaks will be extended, but that will depend on who wins in November. You have heard a lot about FREE CASH FLOW, which is next month’s topic. I would like to know if any of you have had the opportunity to discuss AI, etc., with Connor Group. If so, please let me know how it went. HAPPY PLANNING! About the Columnist: Garry Bartecki is a CPA MBA with GB Financial Services LLC and a Wholesaler columnist since August 1993. E-mail editorial@mhwmag.com to contact Garry.

Backorder management is more than just keeping parts flowing

I recently attended MHEDA’s Parts and Service Management Conference, and as is often the case with these industry events, I came away inspired with content for this month’s edition. One of the presenters was an industry colleague who gave an insightful presentation on backorder management and building processes for unforeseen delays. As she noted, a phrase that is all too common for parts and service managers is, “We’re just waiting on parts…” Let’s take a closer look at this topic and explore how you can strategically minimize the negative impacts of backorders. Your customers have grown accustomed to same-day delivery and rapid fulfillment, and the pressure to meet high expectations is greater than ever. Backorders are not a matter of if but when, and when they occur, they can create significant disruption throughout the supply chain. The key to handling these challenges effectively is preparation — building processes and teams that can respond proactively rather than reactively. When a backorder occurs, it affects more than just inventory levels. The impact ripples through your entire organization. A low parts fill rate can cause service work-in-progress (WIP) to back up, technicians may become idle, and customer satisfaction can suffer. Uptime is crucial to your customer’s operation, so even minor delays can lead to significant financial loss for your customers, resulting in frustration and potentially damaged relationships. Strategies to reduce the impact of backorders The first step in managing backorders effectively is to have strategies in place that minimize their impact on daily operations and customer experience. Several key approaches to consider are prioritizing communication, optimizing inventory, being flexible in sourcing, and leveraging technology. Clear communication with suppliers and customers is essential. Build strong relationships with your suppliers and maintain open communication to anticipate delays and adjust as needed. Be transparent about delays and expected timelines to maintain customer trust and loyalty. Optimizing inventory is also crucial. Analyze historical data to identify back ordered parts and adjust stock levels accordingly frequently. Use predictive analytics to forecast demand and implement a dynamic safety stock strategy that adjusts based on lead times and demand variability, ensuring sufficient inventory without overstocking. Diversify your supplier base to reduce dependency on a single source. Establish multiple supplier relationships or alternative sources to create backup options and increase flexibility during supply chain disruptions with primary suppliers. Invest in technology that enhances supply chain visibility. Real-time data analytics can help identify potential issues before they escalate, while automated ordering systems keep you informed about orders and priorities. Discuss API services with your ERP provider and suppliers to enable real-time access to pricing, availability, order submissions, and shipment notifications. Developing adaptable team members Beyond strategy and technology, the people managing the backorder process in your organization are critical to its success. A well-prepared team can make all the difference in minimizing the negative effects of backorders. Regular training sessions can empower your team members to handle backorder situations with confidence and agility. Equip your staff with the knowledge and tools they need to make quick decisions, understand alternative options, and find creative solutions to supply chain issues. Cross-training is equally essential. When team members understand multiple roles, they can step in where needed, maintaining workflow continuity. For instance, a parts manager should understand service scheduling well, and a service coordinator should be familiar with the parts ordering process. This flexibility ensures that operations run smoothly, even when key personnel are unavailable. Create an environment where collaboration is encouraged and problem-solving is celebrated. Regular team meetings to discuss backorder challenges and share ideas can foster a culture of continuous improvement. Recognize and reward innovative solutions that improve backorder management processes, reinforcing a proactive approach. When team members feel empowered to contribute ideas and solve problems, they are more likely to take ownership of the issues at hand, leading to quicker and more effective resolutions. Standardizing backorder processes Consistency is key in any operational process, and backorder management is no exception. Standardized processes help ensure that every team member understands their role in managing backorders, which leads to more predictable outcomes and better customer satisfaction. Start by developing and documenting clear procedures for managing backorders. These procedures should cover every process step, from identifying a potential delay to communicating with the customer. Standardized workflows help reduce confusion, minimize errors, and provide a framework for continuous improvement. As mentioned earlier, technology can play a significant role in standardizing processes. Use software tools that provide real-time updates on inventory levels, track supplier performance, and automatically generate alerts for potential delays. Automated communication tools can streamline the process of informing customers about backorders, providing consistent and accurate information without the need for manual intervention. Establish key performance indicators (KPIs) that track important metrics such as backorder duration, parts fill rate, customer satisfaction scores, and service WIP levels to ensure your backorder management processes are effective. Regularly review these KPIs to identify areas for improvement and adjust your strategies accordingly. Creating stability for your customers Backorder management is about more than just keeping parts flowing; it’s about creating a sense of reliability and stability for your customers. When customers trust that you manage unforeseen delays professionally and transparently, they are more likely to remain loyal, even when challenges arise. Focus on building a reputation for dependability. By implementing effective backorder strategies, developing adaptable team members, and standardizing processes, you create an environment where backorders become less of a disruption and more of an opportunity to demonstrate your commitment to customer satisfaction. Remember, backorders are inevitable, but with the right strategies and processes in place, you can ensure they are just a temporary bump in the road, not a detour. About the Author: Chris Aiello is the Business Development Manager at TVH Parts Co. He has been in the equipment business for 17-plus years as a service manager, quality assurance manager, and business development manager. Chris now manages a national outside sales team that sells replacement parts and accessories in various equipment markets, such as material handling, equipment

The secret formula for personal achievement is YOURS

“Going for the gold” is wrong. Being the best you can be in order to earn the gold, or get the gold is a surer path to success. What path are you on? Are you the best at what you do? Everyone wants success, but very few achieve the success they dream about. I’m on my journey just like you. While studying, I realized the importance of personal achievement. Last week and this, I’m sharing a personal achievement (secret) formula I accidentally uncovered. Discovering the formula was an accident, but very few people are accidentally fulfilled. Success, achievement, and fulfillment are on purpose. The principles successful people execute and live by are the basis (foundation) for their success. I’m presenting the elements I discovered so that you may compare them to the ones you execute on your own journey. It’s most interesting to me that people who have “big money” as their ultimate goal rarely attain it. Those who have “being the best at what they do” or “love what they do” almost always attain financial security. Why? They execute the elements of personal achievement. The six elements are: Vision Love Best Attitude Personal Student Last week, I discussed having a personal vision, loving what you do, and striving to be your best, but then I ran out of room. Striving to be the best was revealed as the most powerful element, but unless you couple it with a personal vision to see the big picture and a love of what you do, you will never achieve your best. The rest of the elements are: Many people cheat themselves out of achievement and success by having the wrong attitude (element four). Have you ever heard anyone say, “They don’t pay me enough to…” Have you ever thought about it or said it yourself? Those are six words that will keep you mediocre. Don’t make the mistake of failing to be your best or do your best because someone isn’t paying you. Who are you cheating? Achievement is not about money; achievement is about the best. Ask yourself what you’re worth if you don’t think they pay you enough. Having the right attitude about money will make it happen faster than wanting lots of it. So much has been written about goals that it has caused those dedicated to personal achievement to moan at the thought of another seminar on “Goal Setting and Achievement.” It’s not a matter of goals or no goals. Goals are a prerequisite for success. The question is, what kind of goals? The secret of goals is to make them personal (element five), not material. Make goals about you, not about it. Which is a more powerful driving force to make your monthly quota or be the best at sales? The quota will automatically be achieved if you aim to be the best. The other aspect of personal is athletic based. Athletes are always striving to achieve their personal best. Not to beat everyone else (although that’s a great accomplishment), just to beat their previous personal best. That keeps them going. It can keep you going, too. I got a clear vision from a Jim Rohn seminar. He said, “Whatever you want, study it first. If you want to be a doctor, study medicine, if you want to be a success, hang around successful people and study success.” Rohn says, “Be a student (element six) first. And always be a student. Not just a father but a student father. Not a teacher, a student teacher.” Wow, what a powerful piece of advice. From the day I learned my first sales technique (January 1972), I wanted to be the best at sales. I’ve been studying sales for 25 years. That’s why it’s working for me. I’m not saying that’s how it works. I am saying that’s how it works for me. Follow the advice of Jim Rohn to be a student first. With all my heart, that’s how I believe it will work for you. In my seminars, the best audience comment I get is, “Jeffrey loves what he does, and it shows.” If you love what you do, people will say it’s in your blood. And that blood of toil begins to manifest itself in your bank account. Last week, I watched the musician Kenny G. being interviewed on CNN. They asked him what drove him to his phenomenal success. He said, “I never wished for fame and fortune. When I found out I liked to play the saxophone, I just wanted to be the best. The rest just showed up.” Cool. And the real cool part is, if you think that being your best and doing your best is just a bunch of baloney, don’t worry. This information doesn’t apply to you. It only applies to those who will pass you. About the Author: Jeffrey Gitomer is the author of twelve best-selling books, including The Sales Bible, The Little Red Book of Selling, and The Little Gold Book of Yes! Attitude. His real-world ideas and content are also available as online courses at www.GitomerLearningAcademy.com. For information about training and seminars, visit www.Gitomer.com , email Jeffrey at salesman@gitomer.com, or call him at 704 333-1112.

Lithium-ion batteries are powering the intelligent future of warehousing

As logistics and supply chain management rapidly evolve, modern warehouses are being pushed to meet increasingly demanding requirements and challenges. Efficient handling of goods, faster turnaround times, and the ability to adapt to fluctuating market needs have made operational efficiency of warehousing the top priority. The Importance of Warehouse Automation Warehouse automation is one of the most important technological innovations that revolutionize warehousing efficiency, especially automated material handling technologies. The adoption of automated material handling systems such as Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) offers numerous advantages that significantly enhance operational efficiency and provide a competitive edge, including: Increased efficiency and productivity: Automated material handling streamlines repetitive and time-consuming tasks such as sorting, picking, and transporting materials. Businesses can achieve a continuous flow of operations, minimizing downtime, enhancing overall efficiency, and allowing for higher throughput. Improved accuracy and reduced human error: Automated material handling equipment is designed to handle tasks with high accuracy and consistency for order fulfillment and inventory management. Compared with labor work, errors and mistakes are minimized. Enhanced safety and working conditions: Automated material handling takes over physically demanding or hazardous tasks. This reduces the risk of injuries related to wrong operation or fatigue, improving employee well-being and creating a safer, more productive work environment. Labor shortage pressure alleviated: Automated material handling systems help address the skilled labor shortage issue by reducing dependence on manual labor. Moreover, it allows businesses to redirect their existing workforce towards more strategic and value-added tasks. Cost savings and ROI: Despite the costly initial investment, automated material handling equipment delivers substantial long-term savings through reduced labor costs, decreased downtime, and optimized resource use. The durability and longevity of these systems further enhance the Return on Investment (ROI). Warehouse Automation Powered by Lithium-ion Batteries Lithium-ion batteries have become the preferred power source at the heart of automated material-handling equipment, including AGVs, AMRs, and industrial robots. Traditionally, lead-acid batteries have been used for power storage in AGVs and AMRs. While they work well for their usage and charging strategies, lithium-ion technology’s emergence presents significant warehouse automation advantages. Lithium-ion solutions offer higher energy density for longer run times, faster charging (2 hours vs. 8 to 10 hours) during breaks to minimize downtime, and a longer lifespan (over 3,000 times vs. about 1,000 times) that reduces replacement costs. Besides, their lightweight design enhances agility in tight spaces while minimal maintenance requirements eliminate regular water top-ups, lowering operational costs. Additionally, built-in Battery Management Systems (BMS) provide real-time monitoring and safety protections. This shift to lithium-ion technology positions companies to optimize efficiency and remain competitive in warehouse automation. Many battery manufacturers are focusing on the R&D of lithium-ion battery technologies to empower automated material handling equipment with higher efficiency. For instance, ROYPOW aims to enhance automated operation safety to minimize unexpected automated equipment downtime and unavailability through five unique safety features. These include comprehensive safety certifications such as UL 2580, self-developed chargers with multiple safety protections, intelligent BMS, built-in hot aerosol fire extinguisher, and UL 94-V0 rated fire-proof materials. This offers long-term operational efficiency, cost savings, and safety benefits, ultimately leading to more resilient and agile warehouse operations. Additionally, some battery manufacturers are devoted to optimizing lithium-ion batteries’ energy density and charging capabilities to enhance performance in automated material handling equipment further. Innovations such as faster charging cycles and opportunity charging during operational breaks enable equipment to remain active for extended periods, boosting overall productivity. Moreover, developing modular battery systems allows for more effortless scalability, enabling businesses to adapt quickly to changing demands without overhauling their existing infrastructure. Join the Warehouse Revolution with Lithium-ion Batteries Automation powered by lithium-ion batteries is at the forefront of this transformation to embrace warehouse efficiency. This will allow businesses to stay competitive, agile, and prepared for the future of material handling. About the Author: Recognized for industry thought leadership and customer value creation, Jodie Miller brings 15 years of experience in material handling and lithium energy storage system solutions to her position as Managing Partner of ROYPOW. For further information and inquiry, please visit www.roypowtech.com or contact marketing@roypow.com.

The Four Pillars of Warehouse Orchestration: Why you need more than just “Better”

Every warehouse is on a mission to improve, trying to be a little better every year. But let’s be honest—the warehousing landscape has changed so drastically that “being better” just doesn’t cut it anymore. With rising complexities, tighter margins, and growing customer demands, it’s no longer about tweaking what you already do. Now, you have to be different. Warehouses today are more complex than ever. You’ve got robotic systems, human workers, fluctuating inventories, and rapid demand shifts—balancing these moving parts has become necessary to maximize throughput and ensure the operation doesn’t grind to a halt. Add to this the fact that warehousing is in the middle of a leadership shift—10 years ago, site leaders had 15 years of experience running a smooth operation. Today, they have less than four years on average. It’s no wonder things can feel like they’re spinning out of control. Enter orchestration is about finding new ways to optimize your warehouse operations. Warehouse orchestration is no longer a luxury; it’s a necessity. It’s about ensuring everything flows smoothly. It can be summarized as advanced optimization that helps you manage a site by focusing on four critical pillars: Labor Planning, Inventory Flow Management, Human/Robotic Task Handoffs, and Space and Constraint Optimization. Labor Planning: Putting the Right People in the Right Places Labor planning is the backbone of any efficient warehouse. You can’t just throw workers at a problem and hope for the best—across all of the complex processes in a facility, you need to place people where they’re needed strategically. One minute, it’s all about bulk orders; the next, it’s a flood of e-commerce pick requests. Without the right labor plan, your team either stands around or scrambles to catch up. Orchestration platforms keep you ahead of the curve. By planning out optimal workflows across multiple shifts and adjusting labor accordingly, these platforms ensure you have the right number of workers at the right time in the right areas. You’re not overstaffed when things slow down, and you’re not scrambling when the rush hits. The result? A warehouse that runs smoothly, where employees are productive, and throughput is maximized. Inventory Flow Management: Keeping Goods on the Move Efficient inventory flow is like having a highway system with no traffic jams. When inventory constantly moves to the right place at the right time, your operation runs like clockwork. But too often, warehouses resemble a parking lot at rush hour, with goods not being brought in on time to meet outbound demand, creating delays and forcing workers to waste time on unnecessary movements. This is extremely costly to warehouses, where even a .1-.2% increase in “controllable cuts” can result in $500K – $1M in lost business PER MONTH. Orchestration changes the game by ensuring that inventory flows smoothly. It automatically prioritizes when items flow through the facility to ensure that throughput is delivered and trailers leave on. It even balances how the trade of shipping more product versus being late (for example, if you have an inbound arriving in an hour that has ten pallets that are needed on an outbound, it might make sense to delay the outbound for 1 hour to cross dock those ten and achieve a better fill rate). Human/Robotic Task Handoffs: Maximizing Efficiency Through Collaboration In a warehouse, humans and robots can be the perfect team if they don’t step on each other’s toes. Having the latest technology is one thing, but if your human and robotic workers are often not coordinated, robotic initiatives fail to realize their expected value. Orchestration ensures that tasks are handed off seamlessly between humans and robots by understanding their capacities and planning out which work they will execute at what times. When a robot finishes moving a pallet, a human worker will pick up the next task. Conversely, if a human is prepping an order, robots are ready to take over when it’s time to transport or load. This smooth collaboration reduces delays, maximizes output, and keeps human and robotic workers operating at peak efficiency. Space and Constraint Optimization: Understanding Bottlenecks In a Facility Space is a finite resource in any warehouse, and using it wisely is critical. With narrow aisles, towering shelves, and complex product layouts, making everything fit while maintaining easy access is no simple task. Poor space management leads to slowdowns, with workers spending extra time navigating the floor or searching for misplaced items. Orchestration takes a methodical approach to space optimization, considering the physical layout and the operational constraints that come with it. It factors in product sizes, aisle widths, and even the number of doors available relative to order times to ensure that every square foot is used efficiently. As work is planned, constraints like space, equipment, and product flow are managed to ensure that no one component stops the operation. If potential issues are on the horizon, they are called out well ahead of time, and the orchestration platform will create alerts for management to review. This gives every site a balanced operation that has the potential to maximize throughput, with every action taken now done so in confidence that the site is not compromising the future state of the facility. Conclusion: Why Orchestration Is Essential Today’s warehouse operations are more complex and demanding than ever before. It’s no longer enough to “be better.” It would be best if you were different, innovative, and smart in handling every moving part of your operation. Tools like AutoScheduler.AI bring orchestration to the forefront, helping you streamline labor, keep inventory moving efficiently, and optimize space in ways that directly impact your bottom line. With the four pillars of Labor Planning, Inventory Flow Management, Human/Robotic Task Handoffs, and Space and Constraint Optimization, you can ensure your warehouse doesn’t just survive the demands of today’s environment—it thrives. About the Author: Keith Moore is the CEO of AutoScheduler.AI, which orchestrates warehouse activities directly on top of a WMS, optimizing operations for peak performance. Developed alongside industry leaders like P&G and successfully deployed at prominent companies such as

U.S. Rail Traffic Report for the week ending October 12, 2024

The Association of American Railroads (AAR) has reported U.S. rail traffic for the week ending October 12, 2024. For this week, total U.S. weekly rail traffic was 505,033 carloads and intermodal units, up 2.6 percent compared with the same week last year. Total carloads for the week ending October 12 were 222,003 carloads, down 1.3 percent compared with the same week in 2023, while U.S. weekly intermodal volume was 283,030 containers and trailers, up 5.9 percent compared to 2023. Seven of the 10 carload commodity groups posted an increase compared with the same week in 2023. They included grain, up 1,346 carloads, to 23,523; metallic ores and metals, up 1,164 carloads, to 19,277; and farm products excl. grain, and food, up 891 carloads, to 17,894. Commodity groups that posted decreases compared with the same week in 2023 were coal, down 3,412 carloads, to 58,233; nonmetallic minerals, down 2,473 carloads, to 30,465; and motor vehicles and parts, down 1,301 carloads, to 14,412. For the first 41 weeks of 2024, U.S. railroads reported a cumulative volume of 8,919,323 carloads, down 3.2 percent from the same point last year; and 10,755,542 intermodal units, up 9.1 percent from last year. Total combined U.S. traffic for the first 41 weeks of 2024 was 19,674,865 carloads and intermodal units, an increase of 3.1 percent compared to last year. North American rail volume for the week ending October 12, 2024, on 9 reporting U.S., Canadian and Mexican railroads totaled 332,200 carloads, down 1.2 percent compared with the same week last year, and 364,671 intermodal units, up 4.5 percent compared with last year. Total combined weekly rail traffic in North America was 696,871 carloads and intermodal units, up 1.7 percent. North American rail volume for the first 41 weeks of 2024 was 27,375,648 carloads and intermodal units, up 2.4 percent compared with 2023. Canadian railroads reported 98,096 carloads for the week, up 3.5 percent, and 70,155 intermodal units, up 1.6 percent compared with the same week in 2023. For the first 41 weeks of 2024, Canadian railroads reported cumulative rail traffic volume of 6,514,669 carloads, containers and trailers, up 0.1 percent. Mexican railroads reported 12,101 carloads for the week, down 27.2 percent compared with the same week last year, and 11,486 intermodal units, down 9.2 percent. Cumulative volume on Mexican railroads for the first 41 weeks of 2024 was 1,186,114 carloads and intermodal containers and trailers, up 3.0 percent from the same point last year.

Big Lift adds CMO and VP of Sales to its management team

Today, Big Lift, LLC announced the appointment of Martin Boyd as Chief Marketing Officer and Jason Dunigan as Vice President of Sales for its Big Joe and EP North America brands. Dunigan started this week, and Boyd will begin in January 2025. These executive positions will support the company in its many objectives, including a strong focus on expanding its leadership in lift truck electrification. “Big Lift has a clear focus on where our products will best serve our customers moving into 2025 and beyond, and the addition of both Martin and Jason to our team will help us be better positioned for success,” said Dan Rosskamm, President of Big Lift. “As the industry shifts to modernize warehouse equipment, these most recent executive appointments will help us continue to provide cleaner, more efficient technology that makes today’s supply chain run smoothly. We welcome them to the Big Lift brands and look forward to working together for the success of our company.” With more than 30 years in the material handling industry, Boyd will lead all marketing functions for both brands. Before Big Lift, he worked with major OEMs such as Hyster-Yale Group, Cascade Corporation, and Toyota Material Handling, holding leadership positions in engineering, technical service, product management, and marketing. As Big Lift’s newest addition to the senior executive team, Boyd will utilize his experience to strengthen the Big Joe and EP brands in the North American market. His customer-centric passion will ensure the company’s resources are focused on delivering the right solutions based on market trends. As Vice President of Sales for Big Lift, Dunigan will lead both brands’ national account and dealer development teams. He comes to Big Lift with more than 25 years of sales management experience, more than 20 of which focused on the industrial forklift industry. Dunigan is a US Army Veteran who most recently worked with KION North America, where he was instrumental in increasing Linde’s market share in North America by transforming the Key Account Department and developing partnerships with distribution channel partners.

Port of Long Beach sees strongest September on record

Demand for holiday-related goods nudged the Port of Long Beach to its most active September and busiest quarter on record. Shippers continued to move goods ahead of a labor contract deadline for seaports on the East and Gulf coasts, which resulted in a three-day strike at the start of October. Dockworkers and terminal operators moved 829,499 twenty-foot equivalent units last month, up just 70 TEUs from the previous record set in September 2023. September also marked the Port’s fourth consecutive monthly year-over-year cargo increase. Imports increased 2% to 416,999 TEUs, exports declined 12.8% to 88,289 TEUs, and empty containers moving through the Port rose 1.5% to 324,211 TEUs. “We have plenty of room across our terminals as the peak shipping season drives a record amount of cargo through this critical gateway for trans-Pacific trade,” said Port of Long Beach CEO Mario Cordero. “We are anticipating continued growth through the rest of the year as retailers stock the shelves for the winter holidays.” “Our ability to work with industry and workforce partners allows us to move large volumes of cargo reliably, quickly, and sustainably,” said Long Beach Harbor Commission President Bonnie Lowenthal. “Additionally, we continue to deliver strong customer service to meet the needs of consumers and the national supply chain.” The Port moved 6,917,373 TEUs during the first nine months of 2024, up 18.8% from last year. It was also the Port’s busiest quarter overall, with 2,625,747 TEUs moved between July 1 and Sept. 30, breaking the previous record set during the second quarter of 2022 by 78,628 TEUs. For complete cargo numbers, visit polb.com/statistics.

TAPPI/AICC’s 2024 Box Manufacturing Olympics winners

Arvco Container Corp awarded the Attendees’ Choice Award by SuperCorrExpo® attendees The winners of the second TAPPI/AICC Box Manufacturing Olympics (BMO) were announced at the recent SuperCorrExpo® in Orlando. Winners of the first, second and third place awards, as well as honorable mentions for each category, were announced on Monday, September 9. The Best of the Industry for both the Structure and Printing categories, as well as the Attendees’ Choice Award winner, were announced prior to the final Keynote Address by NFL Hall of Famer Cris Carter on Thursday morning. Arvco Container Corp. won this year’s Attendees’ Choice Award for its custom food tray entries, including one that was shaped like a football stadium. Their entry also earned the judges’ first place award in the Corrugated Structure, Innovative Structural Design – Consumer Focus category. Vanguard Companies won the Best of Industry – Corrugated Printing prize for a PopSockets Grip & Go Target endcap display. The display also won the judges’ first place in the category. Peachtree Packaging & Display won the Best of Industry – Corrugated Structure prize for their BODYARMOR Stadium. The entry also earned first place in the Corrugated Structure, Floor Displays & Standees – No Product category. First held at SuperCorrExpo® in 2021, BMO is a combination of TAPPI’s CorrPak Competition and AICC’s Design Competition. The panel of judges evaluated entries on a number of levels, including design, quality, graphic excellence, technical difficulty and innovative application, among others. Nineteen companies and one packaging school participated in this year’s BMO for a total of 66 entries across all 41 categories. Royal Containers Ltd. and Peachtree Packaging & Display both earned five medals in the competition. The competition was open to all TAPPI and AICC members from around the globe who produce corrugated, rigid box and folding cartons, as well as their suppliers. Packaging schools and universities were also invited to participate in the competition. The competition was judged by a panel of 15 industry experts representing the diverse fields and industries of corrugated, folding carton and rigid box. The judges, led by the Box Manufacturing Olympics Chairman Colten Freeze, Bennett Packaging, had a combined 537 years of industry experience and most had previously judged other industry competitions. Freeze was assisted by outgoing Chairman Cordes Porcher, retired, who oversaw the 2021 BMO and had served as TAPPI’s CorrPack Chair for many competitions.

NOBLELIFT® opens a new facility in Korea

NOBLELIFT Opens New Facility in Korea and has a Grand Opening Ceremony. On September 25th, NOBLELIFT celebrated the official opening of its Korean subsidiary in Gyeonggi-do, marking a significant milestone in its international expansion. The ceremony was attended by COO Mr. Andy Liu and CEO of the Korean subsidiary, Mr. Kay Kang. In his opening remarks, Mr. Liu acknowledged the invaluable support from partners and customers, announcing the construction of NOBLELIFT’s fifth factory and the Shanghai International Headquarters in China. This investment underscores the company’s commitment to enhancing its brand through collaboration and innovation. Mr. Kay Kang confidently assured attendees that the new subsidiary, backed by NOBLELIFT’s headquarters, is well-positioned to meet and exceed customer expectations with a robust, locally tailored service support system. NOBLELIFT’s entry into Korea introduces MEWPs and forklifts, along with its technology in AGVs and automated warehousing solutions. Dedicated to innovation, quality, and customer service, NOBLELIFT continues to offer advanced material handling solutions aimed at enhancing global logistics efficiency.

Episode 529: GEODIS’ strategic approach to warehouse innovation

Welcome to this episode of The New Warehouse Podcast, where our guest is Andy Johnston, Senior Director of Innovation at GEODIS, a global leader in end-to-end supply chain solutions. Andy shares his insights on the company’s disciplined approach to warehouse innovation, a key topic for those navigating today’s fast-evolving supply chain landscape. As one of the fastest-growing 3PL companies, GEODIS leverages cutting-edge technologies to address the most pressing challenges in warehousing, from labor shortages to automation. Tune in to discover how GEODIS is pushing productivity and operational efficiency boundaries. GEODIS’ Journey to Innovation Leadership GEODIS has always been at the forefront of warehouse innovation, with Andy Johnston playing a pivotal role in shaping their strategy. Reflecting on his 12-year journey with the company, Johnston highlights how the rise of e-commerce catalyzed the need for innovation. “E-commerce was the big catalyst,” Johnston recalls. “We went from picking cases and pallets to picking individual items, and orders multiplied significantly.” This shift demanded a new approach, and GEODIS has partnered with leaders in automation to tackle these challenges head-on. The Role of Automation in Modern Warehousing Automation has become indispensable in the warehousing industry. GEODIS has consistently invested in automation to enhance efficiency and meet the growing demands of e-commerce. As Johnston explains, “We’ve partnered with robotics companies like Locus and Vecna to streamline processes and improve productivity.” One significant advantage of automation is reducing training times. “We’ve cut training from weeks to days, especially during peak periods, which is a game-changer for our customers,” he adds. This focus on operational speed ensures GEODIS can fulfill orders faster, keeping up with consumer expectations. Addressing Labor Challenges Through Technology Labor availability remains a significant challenge for the industry, but GEODIS has found ways to address it through technology. Johnston explains that by incorporating cutting-edge robotics, GEODIS enhances productivity and makes jobs more engaging and sustainable. “By allowing our teammates to work with technology, we’re making their jobs easier and more fulfilling,” he notes. This human-centric approach helps retain valuable talent and ensures GEODIS meets its operational goals while fostering a better workplace environment. Key Takeaways E-commerce as a Catalyst: The transition from case-picking to individual items has fundamentally changed how warehouses operate, driving the need for warehouse innovation. Automation’s Impact: By leveraging advanced robotics, GEODIS has significantly cut training times and boosted productivity, helping the company keep pace with increasing consumer demand. Labor Strategy: GEODIS’ human-centered approach to technology addresses labor shortages and improves job satisfaction and retention. The New Warehouse Podcast Episode 529: GEODIS’ Strategic approach to warehouse innovation

Raymond West now selling DriveMod Tuggers

Cyngn announced the expansion of its dealer network to include Raymond West. A leading distributor and integrator of intralogistics solutions, Raymond West will begin selling Cyngn’s autonomous DriveMod Tugger. The autonomous tugger integrates Cyngn’s AV technology with Motrec’s MT-160. Cyngn Inc. has announced the expansion of its dealer network to include Raymond West. Raymond West will begin selling Cyngn’s autonomous DriveMod Tugger. The autonomous tugger integrates Cyngn’s AV technology with Motrec’s MT-160. “With 21 branches across the West Coast, Raymond West is an impressive company. It boasts more than $800 million in annual revenue — and we are excited to be able to add Cyngn’s autonomous vehicles to their catalog,” said Lior Tal, CEO of Cyngn. “Motrec’s industrial vehicles are known for high towing capacity and reliability. We are excited to equip Raymond West with the tools and training needed to offer our self-driving industrial vehicles to their customers. Their success is integral to our success.” Raymond West’s decision to join Cyngn’s Dealer Network came after a successful summit hosted at Cyngn’s Menlo Park headquarters, where key decision-makers experienced the company’s autonomous mobile robots (AMRs) firsthand. “We’ve identified several customers who stand to gain immensely from the DriveMod Tugger,” stated Marc Breton, Vice President of Sales at Motrec. “Autonomous industrial vehicle technology is revolutionizing manufacturing and logistics facilities, and the positive feedback from our sales channels confirms that automating a high-tow capacity vehicle like the MT-160, renowned for its quality, is a game-changer.”

Women In Trucking Association announces finalists for 2024 Influential Woman in Trucking Award

Today, the Women In Trucking Association (WIT) announced three finalists for the 2024 Influential Woman in Trucking award, sponsored by Daimler Truck North America (DTNA), a manufacturer of Class 6-8 commercial vehicles in North America. This award was developed in 2010 to recognize female leaders and to attract and advance women in the trucking industry. The award highlights the achievements of female role models and trailblazers in the trucking industry. The 2024 Influential Woman in Trucking Award finalists are: Lisa Gonnerman, Vice President of Enterprise Services, TA Dedicated Sheri Aaberg, Chief Operating Officer, Transport Enterprise Leasing Tracy Rushing, Executive Director of Safety, RE Garrison Trucking, Inc. Lisa Gonnerman is a seasoned professional with over 32 years of experience in trucking, leading safety and operations and playing an instrumental role in shaping safety practices and policies nationwide. Currently serving as Vice President of Enterprise Services with TA Dedicated, Gonnerman excels in safety leadership and mentorship. She has held influential positions throughout her career, including serving as the National Chair of the American Trucking Association (ATA) Safety Management Council from 2019 to 2021 and being named ATA National Safety Director of the Year in 2016. Beyond ATA, Gonnerman is the current chair of the Minnesota Safety Council leadership team and past safety conference chair. Her participation in key industry bodies, like the Commercial Vehicle Safety Alliance (CVSA) and the FMCSA’s CSA subcommittee, further emphasizes her leadership. Gonnerman advocates for a culture of safety and is passionate about mentoring future leaders, especially women in trucking. An active member of Women in Trucking, she continues to inspire others while positively impacting her community through her involvement with organizations like Make-A-Wish. Sheri Aaberg excels at creating organizations where people matter, where they are challenged, and where they have the opportunity to grow. The culture Aaberg has created while leading companies in the trucking industry for the past 24 years is one of excellence in performance, customer service, and team development. As the Chief Operating Officer of Transport Enterprise Leasing, LLC (“TEL”), Aaberg and her vision have been instrumental in the company’s growth and operating excellence since she joined TEL in 2014. She has overseen the development of processes and organizational structures that have been key to the firm’s success. Under her guidance, TEL’s lease portfolio has grown from 1,200 truck and trailer assets on lease to more than 9,300 vehicles. Employee headcount has grown exponentially, and TEL has expanded from its Chattanooga headquarters to a second location, an equipment reconditioning and remarketing facility in Indianapolis, Indiana. Aaberg has served on the board of the Used Truck Association and is a Heavy Truck Blue Book Advisory Committee member. Her speaking presentations have included engagements with the Truckload Carriers Association, Used Truck Association Conventions, TruckPaper forums, and Blue Book seminars. Through her leadership and executive sponsorship, Transport Enterprise Leasing has joined and become active in national and state-level trucking associations. Tracy Rushing began her career nearly 30 years ago in Forest, Mississippi, weighing trucks and calculating driver timesheets. Since then, she has advanced through various roles in the transportation industry, learning safety management, FMCSA Regulations, and driver relations. In 2022, she joined RE Garrison Trucking as the Executive Director of Safety, overseeing the safety, recruiting, and orientation teams. Rushing is an active member of the Society of Human Resources Management (SHRM), Truckload Carriers Associations (TCA) and the Safety & Maintenance Management Council of the Alabama Trucking Association (SMMC). She serves on the Risk Management Advisory Committee of the ATA Comp Fund (RMAC), the Women in Trucking Membership Committee (WIT) and as the chair of the Truckload Carriers Association’s (TCA) Safety, Recruiting and Retention Committee. Rushing has earned certifications from the North American Transportation Management Institute (NATMI) as a Certified Director of Safety (CDS) and as a NATMI Instructor. In 2023, she was honored as the Alabama Safety Director of the Year Runner-Up. Faith and family have been her strength and motivation throughout her career. She is enthusiastic about mentoring and supporting women in trucking, believing strongly in their contributions to this vital industry. The award finalists will participate in a panel discussion at the WIT Accelerate! Conference & Expo held in Dallas, Texas, November 10 – 13, 2024. The winner will give a HERstory speech following the panel discussion.