Episode 422: ShipHero is ushering in a new era of efficiency for 3PLs

In a recent episode of The New Warehouse podcast, we had the opportunity to sit down with Aaron Rubin, the founder of ShipHero. ShipHero is a game-changing software platform that provides many services to shippers, brands, and 3PLs, including order management, inventory tracking, and warehouse management. With ShipHero, Aaron aims to simplify complex processes, help manage returns more efficiently, and ultimately create a better shipping experience for all parties involved. So whether you’re a brand owner, a logistics professional, or just interested in the fascinating world of warehousing, tune in to gain insights directly from an industry expert. How ShipHero is Improving Supply Chain Efficiency The e-commerce landscape is evolving rapidly, with it, consumers’ expectations. Gone are the days when customers were willing to wait extended periods for their packages to arrive. In this fast-paced world, supply chain efficiency has become a pivotal concern for businesses. As Aaron Rubin aptly puts it, “The landscape has shifted so dramatically that if you’re not leveraging technology at every step of the supply chain, you’re already behind.” ShipHero aims to be that technological leverage, offering solutions that bridge gaps in real-time tracking, order management, and even returns. The Returns Conundrum: A Sustainable Solution by ShipHero It’s not just about shipping products out; it’s also about managing the influx of returns sustainably. “Returns are not just a logistical problem; they’re an environmental concern too,” Rubin emphasizes. ShipHero goes beyond the traditional methods of handling returns. Their software intelligently determines the most appropriate action for each returned item: restocking, repairing, or recycling. This is good for business; it’s good for the planet. Social Media: The New Frontier for ShipHero The role of social media in influencing consumer behavior, especially regarding e-commerce. “TikTok isn’t just for dancing and memes; it’s turning into a significant sales channel,” says Rubin. ShipHero is well ahead of the curve, working on features integrating these new avenues directly into their platform. This flexibility allows warehouses to adapt rapidly to trending products, ensuring that the supply chain is as efficient and responsive as possible. Key Takeaways Leveraging technology in supply chains is no longer optional; it’s essential for staying competitive in today’s fast-paced market. A sustainable approach to returns management is becoming increasingly vital for the environment and a brand’s longevity and reputation. The rise of social media platforms as sales channels is a trend to watch, necessitating adjustments in how businesses manage e-commerce and fulfillment. The New Warehouse Podcast EP 422: ShipHero is Ushering in a New Era of Efficiency for 3PLs

AIT Worldwide Logistics joins Smart Freight Centre community

Membership in nonprofit organization to accelerate decarbonization journey in collaboration with fellow logistics, shipping companies As part of the company’s evolving sustainability commitments, global supply chain solutions leader, AIT Worldwide Logistics, recently became a Smart Freight Centre (SFC) member. SFC is an international nonprofit focused on reducing the emissions impacts of global freight transportation. The organization provides a forum for collaboration among top companies in the logistics industry. Members in the SFC community work together by consolidating existing knowledge and developing new approaches to foster emissions reductions throughout the global supply chain. According to AIT’s Chief Information Officer and Executive Vice President, Ray Fennelly, partnerships developed within the SFC will help strengthen efforts to achieve the company’s goal of net-zero emissions by 2035. “Sharing our existing knowledge and supporting the industry as a whole is an important aspect of our company’s sustainability strategy,” Fennelly said. “Joining the SFC community is a natural next step as the firm’s environmental initiatives continue to mature.” As a result of becoming an SFC member, AIT is now participating in the Global Logistics Emissions Council, Clean Cargo, and Clean Air Transport programs. In 2023, AIT expanded its supply chain solutions to help customers avoid emissions as efficiently and cost effectively as possible. For example, in its most recent sustainability report, the company included updates on pilot programs involving sustainable aviation fuel and electric delivery vehicles in multiple locations on three continents. AIT also became a signatory of The Climate Pledge in 2022, joining more than 400 other companies around the world in an agreement to measure and report greenhouse gas emissions, implement decarbonization strategies, and neutralize remaining emissions with credible offsets. Email AIT’s experts at sustainability@aitworldwide.com to discover how the team forms partnerships that help customers achieve their environmental goals.

New Floor Level Palletizer with compact footprint and high performance

Columbia Machine introduces the NEW FLD2500 Floor Level infeed conventional palletizer. This new model is the next step in the evolution of a new family of Floor Level infeed palletizers from Columbia Machine. The FLD palletizers are all capable of being equipped with a fully integrated stretch wrapper that allows for concurrent “stack and wrap” load building at much higher rates than previously achievable. The FLD2500 utilizes a dual hoist concept and an electric overhead Row Pusher. The dual hoist format, when combined with a roller style Layer Stripper Apron, allows the footprint to be reduced significantly (40%!) over Floor Level palletizers with similar throughput capacity. The movement and positioning of each hoist is numerically controlled using servo technology. This allows for faster and more accurate machine movements leading to greater throughput and easier set up and programmability. The FLD2500 is capable of palletizing virtually any package type including unwrapped trays, film only bundles, plastic totes, RPCs and many others too. Options include fully integrated stretch wrapping, Smart Diagnostics with video playback to assist maintenance personnel in identifying the cause of a machine stoppage and a servo actuated touchless turning infeed for gentle package handling, display ready case orienting or 4 way “labels out” layer forming (and several more options). Columbia is renowned for the industry-leading safety and guarding system that provides “next level protection”. On the FLD2500, this standard package includes Category 3, Performance Level D safety components and incorporates fully integrated guarding, full height light curtains, automatic hoist pins, case infeed tunnel and interlocked load building area access doors. This safety package keeps your employees safe while still being operationally “friendly” and meeting production demands by providing convenient and safe access when needed.

Construction commodities see increased traffic on US Great Lakes in August as Ports show ambitious activity

Overall shipping activity for the US Great Lakes in 2023 continues in lockstep with the previous year, with approximately 19.9 million tonnes of total cargo traffic traveling the seaway system for the year to date. In 2022, the total traffic to the end of August was 19.8 million tonnes. While there has been year to year variation in the traffic of specific commodities, key construction commodities showed year over year gains in August. Almost 1.2 million tonnes of cement and clinkers having traveled the system this year (a year over year increase of 205,000 tonnes, or 20.65%). Stone also saw increased annual traffic, with 158,000 tonnes transiting the system (a year over year increase of 73,000 tonnes, or 86.43%.) “New construction, modernization and infrastructure activity remained strong throughout the first part of the year in U.S. & Canadian Great Lakes Markets,” said Kelly Curtis, SVP, Cement Sales and Logistics for VCNA/St Mary’s Cement. “The flexibility of our maritime operations played an essential role in our ability to respond and adapt to changing dynamics in our operating environment.” The movement of key commodities along the US Great Lakes is not only vital to supply chain strength, but also economic strength – a point made clear in a document recently released by a member port of the Chamber of Marine Commerce (CMC). In August, the Toledo-Lucas County Port Authority announced the results of an economic impact study documenting the many contributions made by the Port of Toledo and maritime shipping to the City of Toledo, Lucas County, State of Ohio and the Great Lakes region. The study reported that in 2022, the Port of Toledo supported 7,971 jobs and generated $906.2 million in economic activity. Maritime shipping in Toledo produced $183.2 million in federal, state and local tax revenue and supplied $708.6 million in personal income and local consumption expenditures. “The Toledo-Lucas County Port Authority had an excellent year in 2022,” said Thomas J. Winston, President and CEO of the Toledo-Lucas County Port Authority. “The results from this year’s study indicate an increase of 888 new jobs and more than $237 million in additional economic activity compared to data reported in the 2018 study. This increase can be mostly contributed to the addition of the Cleveland-Cliffs Toledo Direct Reduction Plant at Ironville in East Toledo.” Brisk maritime shipping activity during August brought port tonnage within 7% of the 2022 year-to-date total. With over 6.5 million short tons handled year to date, the Port of Toledo is well ahead of the 2020 and 2021 shipping seasons. In addition to announcing economic contributions, CMC member ports are also showing their commitment to the environment. On September 7, The Port of Cleveland refreshed its strategic vision, most notably to include a commitment to a Climate Action Plan, with the goal of achieving net-zero greenhouse gas emissions by 2050. This goal is in alignment with the Biden administration’s greenhouse gas reduction targets, and the goals of the City of Cleveland, Cuyahoga County, and the Northeast Ohio Areawide Coordinating Agency. The port’s goal was undertaken with the intention of becoming one of the most environmentally responsible ports in the nation. “While we acknowledge that reaching this ambitious goal demands close collaboration with our industry, community and government partners, the port has a proven track record of rising to challenges,” noted William D. Friedman, President and CEO of the Cleveland-Cuyahoga County Port Authority. “We wholeheartedly embrace this opportunity to lead the way toward a cleaner, greener future for our region, demonstrating our unwavering commitment to environmental sustainability and the well-being of our community.” The new commitment by the port builds on an already impressive list of environmental initiatives undertaken to date. They include sediment processing/management, stormwater filtration, and planning for electrification of port equipment, docks and terminals. Other goals in the organization’s new 2024-2028 Strategic Plan included creating new opportunities for business expansion and job growth; elevating the port’s commitment to diversity, equity and inclusion; and developing civic assets by solving community challenges. “Ports along the Great Lakes have become true leaders and standard-bearers when it comes to driving the economy while protecting and preserving the environment,” said Bruce Burrows, President and CEO of the Chamber of Marine Commerce. “They work closely with stakeholders in their regions, are responsive to the needs of businesses and consumers, keep supply chains moving in all circumstances, and do so while holding themselves to high standards with respect to sustainable practices. In doing so, they continue to build marine shipping’s reputation as the reliable, resilient, and green mode for shipping.”

AAR Rail Traffic for the week ending September 16, 2023

The Association of American Railroads (AAR) today reported U.S. rail traffic for the week ending September 16, 2023. For this week, total U.S. weekly rail traffic was 489,790 carloads and intermodal units, up 1.8 percent compared with the same week last year. Total carloads for the week ending September 16 were 232,723 carloads, up 0.2 percent compared with the same week in 2022, while U.S. weekly intermodal volume was 257,067 containers and trailers, up 3.3 percent compared to 2022. Six of the 10 carload commodity groups posted an increase compared with the same week in 2022. They included motor vehicles and parts, up 2,410 carloads, to 16,233; petroleum and petroleum products, up 1,498 carloads, to 10,393; and chemicals, up 1,072 carloads, to 32,758. Commodity groups that posted decreases compared with the same week in 2022 included coal, down 3,518 carloads, to 69,268; grain, down 1,581 carloads, to 16,294; and nonmetallic minerals, down 637 carloads, to 33,914. For the first 37 weeks of 2023, U.S. railroads reported cumulative volume of 8,303,938 carloads, up 0.1 percent from the same point last year; and 8,806,749 intermodal units, down 8.7 percent from last year. Total combined U.S. traffic for the first 37 weeks of 2023 was 17,110,687 carloads and intermodal units, a decrease of 4.6 percent compared to last year. North American rail volume for the week ending September 16, 2023, on 12 reporting U.S., Canadian and Mexican railroads totaled 341,118 carloads, down 0.6 percent compared with the same week last year, and 339,525 intermodal units, down 1.0 percent compared with last year. Total combined weekly rail traffic in North America was 680,643 carloads and intermodal units, down 0.8 percent. North American rail volume for the first 37 weeks of 2023 was 23,974,092 carloads and intermodal units, down 4.1 percent compared with 2022. Canadian railroads reported 92,110 carloads for the week, down 1.2 percent, and 71,440 intermodal units, down 12.8 percent compared with the same week in 2022. For the first 37 weeks of 2023, Canadian railroads reported cumulative rail traffic volume of 5,837,742 carloads, containers and trailers, down 3.5 percent. Mexican railroads reported 16,285 carloads for the week, down 7.4 percent compared with the same week last year, and 11,018 intermodal units, down 9.8 percent. Cumulative volume on Mexican railroads for the first 37 weeks of 2023 was 1,025,663 carloads and intermodal containers and trailers, up 3.2 percent from the same point last year. To review rail traffic charts, ckick here.

A Bright Future- MHEDA CEO Liz Richards retires after 28 years

As MHEDA CEO Liz Richards prepares to retire, a look at her 28 years of experience and what comes next for the association. In nearly three decades leading the Material Handling Equipment Dealers Association, (MHEDA), Liz Richards has helped the organization run smoothly and also steered it in new directions. The non-profit association is dedicated to serving all segments of the material handling business community, according to its website. “For over 65 years, MHEDA has provided material handling companies and their employees with business resources, leadership training, networking opportunities, benchmarking data, career development tools and insights on the latest industry trends,” the site said. Now, as Richards plans for retirement from her role as CEO of the association at the end of the calendar year, she took a few moments to reflect on her tenure with Material Handling Wholesaler. Below are some of her thoughts, which have been edited for a print format: Wholesaler – What is the timeline for the MHEDA leadership transition? Richards – “I’m working until the end of the year, Dec. 31,” she said, adding that MHEDA Interim CEO Jeannette Walker will then be taking over. “She started on July 10th and she’s amazing. She came from the industry, she’s been in it for over 20 years, and she’s familiar with the association. She hit the ground running.”Richards said a wealth of plans are in place for the association going forward. “I’m feeling great about it,” she said, of Walker’s future leadership and the association’s future. Wholesaler – How did you learn about MHEDA and end up in the role of CEO? Richards – “MHEDA used to be led by an executive vice president before the title changed to CEO,” she said, noting that in 1994 she received a call from then Executive Vice President Tony Colletti about taking a job as the association’s director of marketing. Richards, who at that time had just had a baby, was unfamiliar with the material handling industry, including the association. “I said that I didn’t even know what this is and so thanks but no thanks,” she said, who added that she also loved her current job. A few months later, Colletti called again. He was leaving the post as executive vice president and thought Richards had the perfect skill set. “He said, ‘Please meet with the search committee,’ which I did, and they offered me the position,” Richards said. She had to jump in and learn quickly, starting the job Jan. 3 of 1995 and her first ProMat following on Feb. 10. “I was walking around, thinking ‘Oh my gosh, what did I do?” she said. “In retrospect, the board of directors and the past presidents could not have been more gracious or more welcoming. Together, we all made it work.” Wholesaler – During your time at MHEDA, what were the organization’s greatest achievements? Richards – “Tony got the board much more engaged than they were previously. He did some organizational restructuring,” she said. And during Richards’ first year, Tim Hilton of Carolina Handling was in his first year on the board and introduced his strategic planning process. “We modified it and implemented it at MHEDA. Having that process in place helps us plan everything we do in the organization. It’s been our greatest success,” she said. Richards said the process includes identifying, through an annual in-depth environmental analysis, what MHEDA members are facing. This includes challenges, opportunities and trends and topics include everything from wages to labor to automation. The research then becomes “the basis for everything we do as an organization,” she said. “I call it our organizational engine.” It took a while to build out the strategic plan, according to Richards, who said each year the executive committee reviews the surveys, feedback and more to create a road map. “We put the process in place in the late 90s and continue to tweak it,” she said, of the strategic planning process. In addition, Richards is also pleased with how the organization interacts with board members to continually improve. This includes an involved nominee orientation meeting, including flying members to Chicago, all the way through exit interviews. “These are all little pieces of the process,” she said. Wholesaler – During your tenure you brought a lot of new programs like Women In Industry, MHEDA-NET and Networking Events. How has MHEDA programming changed during your years with the association? Richards – She pointed again to how the impact trends researched by the association have helped formulate the programming. “I realized that we need to dig into our organization, hence the Emerging Leaders Conference. We are also forming an Emerging Leaders Advisory Group,” Richards said. Women In Industry began as a breakfast at the convention and has grown and expanded from there. And the Automation Solutions Conference has also grown out of trends. The association’s networking events are of particular value, Richards added, offering the chance to “network with others, learn from mistakes and avoid failures.” MHEDA organizes peer groups, which set their own agendas, to talk about current challenges, as well. “That’s something that has been very popular,” Richards said. “And we have regional networking programs that we host at member locations.” Wholesaler – What are some areas that you did not have as much time to address during your tenure in need of attention that you would like to see focused on in the future? Richards – “One particular thing that we always struggle with is it’s really hard to come up with a stump speech about why MHEDA is so important,” she said. “There are so many different areas that somebody in the industry can develop from” through the association, she said. “I think sometimes non-members think, ‘Why would I get involved and share my secret sauce?” But Richards said when people join the association, they quickly appreciate the benefits. “When you join and find others are tackling the same issues that you are and people in the industry are so gracious and they’re willing to share,” she said. “It’s a relationship that’s hard to sometimes put into words. “I’ve heard from so many different members who come to

Free technical report helps employers protect temporary workers

Many businesses are increasingly using temporary workers during the holiday season and throughout the year, making it challenging to provide safe environments without proper planning and guidance. The American Society of Safety Professionals (ASSP) has published a free technical report that can help employers in all industries better protect workers who are hired on a short-term basis. The digital report is titled “ASSP TR-Z590.9-2023 Technical Report: Protecting Temporary Workers: Best Practices for Host Employers.” The document was originally published by the National Institute for Occupational Safety and Health (NIOSH), but ASSP has turned it into an ANSI-registered technical report to bring the guidance to a wider group of occupational safety and health professionals. “When a workforce involves temporary and short-term work arrangements, the likelihood of an injury or fatality can increase,” said ASSP President Jim Thornton, CSP, CIH, FASSP, FAIHA. “It’s important for businesses to implement safeguards in non-standard circumstances to ensure the safety and health of all workers.” The technical report enables organizations to integrate best practices into their safety and health management systems, going beyond regulatory compliance to achieve safer working conditions and a competitive advantage. The content in the document is organized into three sections: 1) Evaluation and contracting, 2) Training for temporary workers and their work site supervisors, and 3) Injury and illness reporting, response and recordkeeping. The technical report is focused on temporary or contract workers located in the same facility. That includes a construction site, which often involves multiple subcontractors. “Single work sites may include workers who are employed by different companies, so the supervising employer needs to manage the safety of everyone,” Thornton said. “That includes warehouses during the holiday season where temp agencies will help place a number of workers.” A related resource for businesses that use short-term workers is ASSP’s recently published book, “Safety Management Systems in a Joint-Employer Environment.” The book explains the escalation of risk in a joint-employer setting and describes how the traditional approach to managing hazards has not kept pace with the speed of today’s changing world of work.

Episode 421: Solving customer returns with Kyle Bertin of Two Boxes

In our latest episode of The New Warehouse Podcast, we are excited to have Kyle Bertin, Co-Founder of Two Boxes, on the show. Two Boxes aims to revolutionize the warehousing industry by tackling inefficiencies in the returns process—a problem we all want solved. If your returns area is an eyesore and you keep throwing more labor at the problem, this episode is for you. There is an easier way, so tune in and learn how Two Boxes makes reverse logistics a competitive advantage for 3PLs and warehouses. The Problem with Customer Returns Kyle Bertin was looking for a problem to solve and found one in customer returns. He points out, “Last year, customers in the U.S. returned 20% of their purchases,” and e-commerce heavy merchants are seeing up to 40%, illustrating the scale of the returns dilemma that 3PLs and warehouses must deal with. “Every time I went into a fulfillment center, there was a section of the warehouse that looked pretty nasty, to say the least, and every time I asked about it, it was the returns area.” According to Bertin, there are several challenges that 3PLs and other players in the space are grappling with. High-Volume Strain – “Some of our 3PL customers might receive a thousand, 2000, or 5000 units of returns in a given day.” The sheer quantity of returned items is overwhelming and demands a smarter allocation of labor and resources. SOP Complexity – Keeping up-to-date Standard Operating Procedures for returns is challenging due to the constant updates and multiple brand-specific requirements. Lack of Metrics – There’s a noticeable gap in tracking and billing mechanisms for the returns process. Missed Business Opportunities – Some 3PLs avoid certain types of business because managing their returns is too tricky. Sustainability – Additional packaging and transportation associated with reverse logistics contribute to logistics being responsible for 60% of the world’s carbon emissions. These points emphasize the need for technology and system improvements in managing the complex warehousing returns landscape. Efficiently Managing Customer Returns in Warehouses and 3PLs Two Boxes provides software designed to address the complexities of managing customer returns in warehouses. The platform aims to act as a centralized system of record, integrating with existing front-end systems to offer a unified return process across multiple brands. It also focuses on automating Standard Operating Procedures (SOPs) and guiding warehouse staff through the return process via step-by-step instructions. This feature not only aims to simplify training but also seeks to ensure more accurate inventory reconciliation. Another aspect of the software is its emphasis on data tracking and analysis. Two Boxes fills a gap in key performance indicators (KPIs) designed explicitly for the returns section, offering better oversight and actionable insights for warehouse operators and merchants alike. The software can aid in making billing, pricing, and value-added services more scalable, thus potentially transforming returns from a logistical headache into an asset. Creating a Better Worker Experience Kyle believes that technology elevates efficiency and improves the worker’s day-to-day experience. “At the end of the day, we make the actual worker’s experience better, too,” Kyle says. He insists this human-centric approach has a ripple effect, improving everything from brand value to end-consumer satisfaction. He adds, “We are rolling out new technology that enables us to triage returns upon receipt so that a 3PL can put their labor on the returns that will be most impactful to their merchants.” Three Key Takeaways: Returns are challenging and can be a competitive advantage with the right processes and technology. 3PLs need to overcome their hesitance to adopt new technologies for the sake of long-term efficiency and growth. A better worker experience can lead to overall improvements in operational performance and customer satisfaction. The New Warehouse Podcast EP 421: Solving Customer Returns with Kyle Bertin of Two Boxes

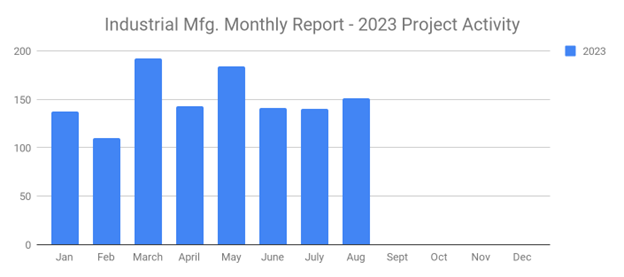

Summer 2023 ends with an increase with 151 new Industrial Manufacturing Planned Projects for August 2023

SalesLeads has announced the August 2023 results for the new planned capital project spending report for the Industrial Manufacturing industry. The Firm tracks North American planned industrial capital project activity; including facility expansions, new plant construction and significant equipment modernization projects. Research confirms 151 new projects in August as compared to 140 in July, an increase in the Industrial Manufacturing sector. The following are selected highlights on new Industrial Manufacturing industry construction news. Industrial Manufacturing – By Project Type Manufacturing/Production Facilities – 135 New Projects Distribution and Industrial Warehouse – 74 New Projects Industrial Manufacturing – By Project Scope/Activity New Construction – 57 New Projects Expansion – 34 New Projects Renovations/Equipment Upgrades – 53 New Projects Plant Closings – 20 New Projects Industrial Manufacturing – By Project Location (Top 10 States) Michigan – 10 New York – 10 Indiana – 8 North Carolina – 8 Ohio – 8 Arizona – 7 Tennessee – 7 Florida – 6 Georgia – 6 Texas – 6 Largest Planned Project During the month of August, our research team identified 20 new Industrial Manufacturing facility construction projects with an estimated value of $100 million or more. The largest project is owned by Gotion, Inc., who is planning to invest $2 billion for the construction of an EV battery manufacturing facility in MANTENO, IL. They are currently seeking approval for the project. Top 10 Tracked Industrial Manufacturing Projects LOUISIANA: Solar panel mfr. is planning to invest $1 billion for the construction of a manufacturing and warehouse facility at Acadiana Regional Airport in NEW IBERIA, LA. They have recently received approval for the project. Completion is slated for Spring 2026. MANITOBA: Biotechnology company is planning to invest $1 billion for the construction of a processing facility in MANITOBA. They are currently seeking approval for the project. NEW MEXICO: Solar panel MFR. is planning to invest $1 billion for the construction of a 2-million sf manufacturing, warehouse. and office complex in ALBUQUERQUE, NM. Construction is expected to start in early 2024. FLORIDA: Defense contractor is planning to invest $294 million for a 198,000 SF expansion and equipment upgrades on their manufacturing facility at 2400 Palm Bay Rd. NE in PALM BAY, FL. They are currently seeking approval for the project. PENNSYLVANIA: Biotechnology company is planning to invest $260 million for the construction of an 80,000 sf processing, laboratory, and office campus in PHILADELPHIA, PA. The project includes the construction of a 150,000 SF co-working biotechnology and office facility at the site. They are currently seeking approval for the project. MISSISSIPPI: Wood pellet MFR. is planning to invest $250 million for the construction of a manufacturing facility in BOND, MS. They have recently received approval for the project. Completion is slated for Fall 2025. TENNESSEE: Automotive component MFR. is planning to invest $170 million for the renovation and equipment upgrades on a manufacturing facility in LOUDON, TN. They are currently seeking approval for the project. MICHIGAN: Automotive parts mfr. is planning to invest $170 million for the renovation and equipment upgrades on a recently pre-leased 200,000 SF manufacturing facility in GRAND BLANC, MI. The project includes establishing a 50,000 SF testing and research facility and they are currently seeking a site in the FLINT, MI area. MINNESOTA: Medical device MFR. is planning to invest $170 million for the construction of a 400,000 sf laboratory, processing, training, and office campus on 73rd Place in MAPLE GROVE, MN. They are currently seeking approval for the project. The site will allow for a future 150,000 SF expansion. KENTUCKY: Automotive parts mfr. is planning to invest $131 million for a 320,000 sf expansion and equipment upgrades on their manufacturing facility in BARDSTOWN, KY. They have recently received approval for the project. Completion is slated for early Fall 2024. About IMI SalesLeads, Inc. Since 1959, IMI SalesLeads, based in Jacksonville, FL is a leader in delivering industrial capital project intelligence and prospecting services for sales and marketing teams to ensure a predictable and scalable pipeline. Our Industrial Market Intelligence, IMI identifies timely insights on companies planning significant capital investments such as new construction, expansion, relocation, equipment modernization and plant closings in industrial facilities. The Outsourced Prospecting Services, an extension to your sales team, is designed to drive growth with qualified meetings and appointments for your internal sales team. Visit us at salesleadsinc.com.

Distribution headwinds

Improve productivity and reduce costs. Those are the deliverables promised my just about 100% of the ads you read regarding both warehouse space and manufacturing floors. The scary part is that these rewards result from robotics, a lower headcount, and a specific claim to reduce equipment Cap X by $200000 to $400000. Great results for the distribution centers and manufacturers, but not so great for the material handling dealers since those references to Cap-X spend probably represent what you are selling and renting, selling parts for and providing maintenance on. If the distribution technology potential improvements are not enough to deal with, you now have the national retail entities offering distribution and delivery services for goods they did not sell. I had to study this for a bit, but it does make sense if a distributor wants to expand their warehouse locations to be closer to their customers, or just looking for a way to simplify their product delivery. Amazon and Walmart are two of the national companies that move products to just about every city in the country. So why not add other goods to their delivery trucks to stock a local warehouse or deliver the product to the end user. As of today, Amazon is just providing this service for companies selling products via Amazon. It is expected they will expand to non-sellers if this initial venture proves to be profitable. Walmart will provide the service for any vendor where it makes sense to do so. When you think about it these programs make sense if the seller’s goal is to improve logistics problems, allowing faster delivery times for less cost. A win-win. Again, I would like to consider the impact of this type of program on the material handling business. And again, I arrive at potential negative impact. Inventories currently stored, in a facility you now provide equipment and support to, may now be moved out of your territory or placed into a facility you do not do business with Inventories may be relocated to various locations across the country where you do not do business. New business coming into your territory may be under an Amazon or Walmart contract where they provide the material handling services. I can see this type of service expanding at the expense of your bottom line. Let’s face it, manufacturers and distributors want to sell and deliver faster, and will use methods to achieve those goals because when compared to their current process it costs less and adds to customer satisfaction. The point here is the demand for material handling services in your territory could decline because the robots are moving and counting the inventory, or building product in a robotic production line, or because there is less inventory to work with because it has been moved out of the territory. So how does Material Handling Management deal with this situation? Be a source for the technological improvements distributors and manufacturers need. Be a resource to maintain the new systems being installed. Partner up with independent professionals who can help prepare a plan of action and system selection. Educate customers about potential changes needed to remain competitive. Outsource to get what you need to put this plan into place. Let’s assume these changes will take place. What else do you need to remain profitable and competitive? Prepare a budget reflecting slower unit sales and adjustments for parts and service. Add new revenue sources once you have a plan in place to offer new services. Find and implement technology to reduce headcount and reduce costs. Further tune the budget to where GP margin can cover expenses, interest and taxes. Use these new metrics to become more competitive in your region. Add new business. Make customers want to work with YOU! I have this type of conversation with dealers and rental companies on a regular basis. Most of the time the discussion revolves around exit planning, be it current or five- years off. What I tell them is do it NOW if they are a current seller, before the —- hits the fan and you have a 10-year window before values improve to where they are today. If they want to stay another five years, I suggest they will have to make the improvements mentioned above to keep the value up, and if they can’t stomach the aggravation and cost, to execute the exit as soon as possible, because the alternative is the risk of lower values even though the technology improvements were made to stay competitive. Maybe there is something in between where you can get some money off the table and remain on board to help the company move forward. None of this is easy to deal with. But industries go through cycles, with a need to make major adjustments to generate adequate free cash flow that covers the nut. But to try and push these changes through just working with your current personnel is very questionable. This is why I suggest outsourcing to determine the changes required, the solutions available and the time and cost to make conversions. About the Columnist: Garry Bartecki is a CPA MBA with GB Financial Services LLC and a Wholesaler columnist since August 1993. E-mail editorial@mhwmag.com to contact Garry.

Relational capital

I recently attended a leadership conference in Boston. While my plans during my stay in Boston included seeing a Red Sox game in the evening at Fenway Park, enjoying a pint of beer at an Irish pub, and eating clam chowder and lobster, I was also looking forward to the lineup of speakers and workshops at this conference. One speaker in particular was Ed Wallace and his workshop on relational capital. Ed Wallace is President and Chief Relationship Officer of The Relational Capital Group; he is critically acclaimed as the foremost authority on business relationships and their impact on performance. There were many takeaways from his workshop, and I knew this topic would be a good one for my monthly aftermarket column here. The success of your dealership is often attributed to a combination of factors, including innovative products, effective marketing strategies, and efficient operations. However, one essential but often underestimated factor plays a pivotal role in shaping your organization: relational capital. This intangible asset encompasses the network of relationships you build with your customers, partners, and employees. Let’s look at the significance of relational capital and explore how it can be a game-changer for your business. Relational Capital Defined The relationships with your customers, suppliers, partners, and employees should be considered a core asset of your business, known as relational capital. Relational capital can be understood as the collective value derived from your business’s relationships with various parties. It extends beyond financial transactions and encapsulates the trust, goodwill, and mutual understanding fostered between your business and its stakeholders. These stakeholders include customers, suppliers, investors, employees, and even competitors. At the heart of relational capital lies trust. Establishing trust with your customers and partners can lead to long-lasting relationships that are built on honesty and integrity. Trust fosters loyalty, and loyal customers are not only more likely to stick with your brand, products and services, but also become advocates, spreading positive word-of-mouth and attracting new customers. After-sale service at a lift truck dealership encompasses maintenance, repairs, parts replacement, and technical support. Relational capital in this context revolves around the intangible value generated from trust, customer loyalty, and the quality of interactions between your dealership and your customers in all aspects of the after-sale service. Customers In the age of information and social media, customers have more power than ever before. They can easily share their experiences and opinions about your business with a global audience. A strong focus on building positive customer relationships can help you manage your brand’s reputation and ensure customer satisfaction. Happy customers are more likely to provide repeat business and recommend your products or services to others. Running a lift truck dealership entails more than just selling equipment; it involves cultivating enduring relationships with your customers. The post-sale service phase presents a valuable opportunity to establish and nurture these relationships through relational capital. Suppliers Relational capital is not limited to customer relationships. Partnerships with suppliers, distributors, and even competitors can drive innovation and open up new avenues for growth. Having a good relationship with suppliers is vital, especially where critical components and complementary offerings are concerned. Successful companies understand that trust is an important distinction between a business transaction and a true relationship. They invest tremendous energy in developing ways to institutionalize trust in their procurement processes. For example, many successful businesses tend to develop long-term relationships with their vendors and suppliers rather than simply buying from the lowest-cost provider. They prioritize quality first, followed by service and cost. Building a good working relationship with suppliers helps develop their reputation and attract additional business. It is important to conduct regular strategic business reviews to assess the relationship and discuss performance, improvements, and new product development. It is also important to foster relationships with suppliers that share the same values as your organization. Focus on developing trust-based, mutually beneficial, and long-term relationships with your suppliers. Employees A business’s most valuable asset is its employees. Building strong relationships with your team members can result in higher employee satisfaction, improved morale, and increased productivity. As I stated in a previous column, the competition for service technicians, parts professionals, sales staff, office personnel, and management continues to be fierce. When employees feel valued and connected to your company’s mission, they are more likely to go the extra mile and contribute positively to your organization’s success. Strategies to Deploy Communication: Regularly engage with your stakeholders through various channels. This could include personalized interactions, newsletters, social media, and more. Specific to service, regularly communicate with your customers to remind them of upcoming service intervals, provide maintenance tips, and address any concerns they may have. Deliver Value: Continuously deliver value to your customers, partners, and employees. Show that you are invested in their success. Networking: Collaborating with other businesses can lead to the exchange of ideas, resources, and expertise, ultimately enhancing your own products or services. Attending industry events, conferences, and seminars to expand your network and connect with potential collaborators. Empathy: Understand the needs and concerns of your stakeholders. Showing empathy helps forge deeper connections. Personalized Maintenance Plans: Develop customized maintenance schedules based on each customer’s usage patterns and needs. This proactive approach demonstrates your commitment to their specific requirements. Transparency: Be open about your business’s operations, values, and challenges. Transparency builds trust and demonstrates authenticity. Additionally, offer clear and transparent cost estimates for repairs and parts replacements. Customers appreciate honesty and are more likely to return when they trust your pricing. Expert Technical Support: Provide accessible and knowledgeable technical support for troubleshooting and assistance. Prompt and effective support builds customer confidence. Warranty and Service Guarantees: Offer warranties on repairs and services, showcasing your confidence in your team’s expertise. Such guarantees bolster customer trust in your dealership. Customer Training: Organize workshops such as forklift operator training. This educational approach enhances customer empowerment and loyalty. Feedback Integration: Encourage your customers to share feedback after each service interaction. Act on their suggestions to continually improve your services. The benefits of these strategies include customer

I’m satisfied with my present source. Well, maybe

The prospect is not waiting by the phone for your call. Most people have what you’re selling and are doing business with someone else. They have a source for what you do, and they think they are happy. Satisfied. Good News: Satisfied people are willing to do business with others. Your challenge is can you get them to do business with you? For you statistic buffs, “I’m satisfied with my present source,” ranks second on the all-time prospect objection list. “Price too high,” is number one (and always will be). When the prospect says, “I’m satisfied” they’re really saying: This is all I know, now. I don’t want to bother with you. I’m doing business with someone I like (not necessarily the best). I’m not telling you the real reason. I’m satisfied is a brush off. It’s not all that bad. Your prospect is saying that their existing supplier is the best they’ve been able to find. You may have a better product, price, availability for delivery, service, training, or warranty. The prospect is only telling you he’s satisfied from his perspective. He doesn’t really know about you or your company yet, BUT don’t give him any reasons to switch until you know why he’s satisfied. Knowing the reason(s) why the existing relationship is satisfactory will help you understand how to proceed. Knowing those reasons gives you a chance. Here are a few “interest-gainers” or challenges that may get you in the door: Good Response: Satisfied? Great! You’re going to love doing business with us! Our customers are ecstatic so if you’re only satisfied, today is your lucky day. Better Response: Mr. Johnson, Many of our customers said that when they were prospects like you. I wish I had ten dollars for every prospect that said, “I’m satisfied with my present supplier,” that is now a customer. Let me share a few of their comments (show your testimonials that say, “I used to buy from (name the competitor you hate the most), now I’m a loyal (your company) customer. And I invite you to call me personally if you need further explanation.” WOW! Best Response: When you started with (their present supplier) you took some risk, didn’t you? I’m not asking for all your business, but I’d be interested what caused you to take the risk back then, and I may ask you to take that same small risk with me and let me earn the rest.” Here are a few dialog starters: “Most people feel that way at first, but our experience has shown…” “What do you like most about your supplier (his product/service)?” (Agree with them) “That’s what lots of their former customers said.” “If your friend left the business, but stayed in the industry would you still do business with that company or go with your friend?” “What would you change about your present relationship?” “How did the relationship begin?” “When people say, “I’m satisfied” they usually mean…” Find a personal link (common ground) that can trigger a friendly conversation. If they like you, they will listen to you. (a bit more assertive) “Satisfied or complacent? When is the last time you really looked at the situation and did a comparison?” Sales Caution: If the prospect says, “I’m satisfied,” it’s open season on the competition. If the prospect says, “I’m loyal,” watch out. Loyal is 100 times more powerful than satisfied. Sales Reality: You will not convince everyone. But the more you practice, the more “luck” you will have. “I’m satisfied” is not an objection, it’s a stall. If you believe in the value of your product, you can get past it. Sales Tip of the Year: Record five customers that were satisfied with your competitors, switched, and are now ecstatic with your company. Get your customers to tell your story. It’s far more compelling (and believable). About the Author: Jeffrey Gitomer is the author of twelve best-selling books including The Sales Bible, The Little Red Book of Selling, and The Little Gold Book of Yes! Attitude. His real-world ideas and content are also available as online courses at www.GitomerLearningAcademy.com. For information about training and seminars visit www.Gitomer.com or email Jeffrey at salesman@gitomer.com or call him at 704 333-1112.

NAW and Applico announce EquipmentShare’s Jabbok Schlacks and BRINGG’s Guy Bloch as Keynote Speakers at 2023 Innovators Summit

The National Association of Wholesaler-Distributors (NAW), the voice of the $8.2 trillion wholesale distribution industry that employs over 6 million U.S. workers, along with Applico, an advisor to billion-dollar distributors and manager of the wholesale distribution industry’s first dedicated venture capital fund, announced that Jabbok Schlacks, CEO/Co-Founder of EquipmentShare will be the Marketplace keynote speaker for the 2023 NAW Innovators Summit, powered by Applico; and Guy Bloch, CEO at BRINGG, will be the keynote Supply Chain Technology speaker at #IS2023. Taking place Tuesday, November 14, 2023, from 3 p.m. CT – Thursday, November 16, 2023, at 1 p.m. Austin, Texas, at the Omni Austin Hotel Downtown, the NAW Innovators Summit powered by Applico, has been hailed as the industry’s top matchmaking event between distributors, leading B2B tech companies and investors. “We cannot wait to welcome Jabbok Schlacks and Guy Bloch as keynote speakers to the Innovators Summit stage,”said NAW CEO Eric Hoplin. “In 2023, the Innovators Summit seeks to showcase everything unique about the inaugural technology conference from 2022 while also expanding the types of technology companies present and inviting the investor community to further participate and share their unique perspective and insights. Schlacks and Bloch are an invaluable addition to the program, and we look forward to hearing their insights relating to marketplaces and supply chain technology,” Hoplin concluded. “The Innovators Summit is truly a one-of-a-kind experience to hear the real story behind innovation in B2B,” said Applico Founder and CEO Alex Moazed, “Jabbok and Guy will provide attendees with powerful insights and innovative solutions to problems facing distributors in the areas of marketplaces and supply chain technology,” Moazed concluded. The NAW Innovators Summit powered by Applico welcomes leading industry executives across North America to meet the founders of the most exciting B2B distribution-focused technology startups in closed-door presentations. Attendees get the ‘inside scoop’ – and if distributors like what they hear, they can book private, one-on-one time with founders to discuss opportunities in more detail. The technology tracks will include marketplace technology, sales and operations technology, supply chain technology and “AI in action” – pragmatic examples of AI for wholesale distributors. Jabbok Schlacks is the CEO/Co-Founder at EquipmentShare, whose digital solutions gather data in a central location to give contractors a single place to analyze and understand their business operations data. By providing contractors and fleet managers with digital and electronic ways to record, gather and monitor fleet utilization data, EquipmentShare saves them hours typically spent manually collecting the same information, digesting it, and applying it to business decisions. Guy Bloch is CEO at BRINGG, whose open SaaS platform simplifies the last mile experience, enabling organizations to turn delivery into a competitive advantage by leveraging innovative technology to manage their own fleets, or tapping into a global network of 200+ integrated carriers including parcel, same day, and LTL. By providing a scalable, data-driven solution to dynamically manage fleets, increase delivery options and automate processes, Bringg is able to create a seamless experience for drivers, dispatchers, and customers while reducing last mile costs. Applico is the trusted advisor to billion-dollar distributors on strategic partnerships with tech startups. Applico Capital is the wholesale distribution industry’s first dedicated venture capital firm. With backing from more than 5 billion-dollar distributors, Applico Capital’s B2B Distribution Fund I invests in technology that will help distributors modernize and digitize their core business.

Lithium forklift batteries make a good business case for rental dealers and renters

The electric forklift rental business model benefits greatly from switching the equipment to lithium batteries from widespread lead-acid batteries. Lithium batteries have longer lifespans, are more economical and durable, and require less maintenance, resulting in improved profitability for forklift dealers and helping customers achieve their sustainability objectives. As forklifts become increasingly electrified and rental fleets expand, lithium batteries are a wise investment for both dealers and renters. Long-term rental of forklifts When renting forklifts for extended periods, the switch to Li-ion batteries provides similar advantages as leasing or buying own equipment. These benefits can be summarized as follows: Reduction in labor costs for maintenance (no need for daily watering and synchronization charges), resulting in 20-40% savings on the total cost of ownership of material handling equipment. Lower electricity use, leading to lower carbon emissions during operations, due to higher efficiency of energy conversion of lithium batteries. Improved overall efficiency in operations with less downtime and better forklift performance. A cleaner and safer workplace when compared to using flooded lead-acid battery packs. Companies may choose to buy new or select used electric forklifts in online classifieds and get all these benefits of lithium technology. But what about those operations that opt for short-term rental of their forklifts? Short-term rental of forklifts When it comes to renting forklifts for shorter periods of time, dealers face unique challenges. Renters have no incentive to invest in the proper maintenance of the batteries, often neglecting to water them regularly or synchronize their charge, returning them “dry” at the end of the lease term. The renter is required to run the tests and discuss the potential reimbursement for the damage and service labor, which no one likes to do. Here is how Eddie Burke, President and owner at Combilift Depot in Houston, TX, describes the problem: “We rent equipment all over the country, and can’t send technicians for daily watering. Most machines are rented out monthly, and when they come back, we inspect the battery, if it is damaged it is hard to determine whose fault it is… You can’t prove (if it is the customer’s fault), and I don’t want to argue with the customer over the damage to the battery. We are switching to li-ion, so the conversation is more like – “Is there a hole (in the battery)? No? We are good!” It’s just so much easier to do the testing (of a lithium battery) and make the judgment call.” Combilift Depot spends 4-6 hours of technician labor per lead-acid battery for diagnostics and service each time it is rented out and returned. Taking into account the much longer cycle life of a lithium battery, the savings are impressive. Eddie Burke continues: “In a perfect world a well-maintained lead-acid (battery) lasts 5-6 years, in rental conditions, it is great if it gets to 2-3 years when you start replacing cells. With OneCharge Li-ion (battery) we expect 10 years (of cycle life), it is a no-brainer”. A dealer would typically sell used equipment after 5 years, and the value of a lead-acid battery by this time is zero. With an advanced forklift battery, such as OneCharge, a buyer gets a full picture of the cycles left in a battery and can calculate how many years it can be expected to power the truck he buys. Rental contracts can be irregular, and if left idle for even a few weeks, a lead-acid battery can lose its charge and suffer permanent loss of capacity if not cared for properly. The worst thing that can happen to a lithium battery is if an operator forgets to charge the battery pack. Compared to lead-acid batteries, lithium-ion batteries are much more energy-dense and do not lose voltage with discharge. This means that a lithium battery with a lower Ah capacity can still cover most needs of a diverse pool of forklift renters, significantly reducing the cost of purchasing batteries for dealers. Additionally, lithium battery chargers are much smaller and lighter, which makes them easy to install or wall-mount around the facility. Growing popularity of equipment rentals In a recent article published by Forkliftaction, Rod Dayrit – the Business Development Director at Delta-Q Chargers – highlights the increase in equipment rental growth. He explained that forklift buyers see very long lead times for new equipment, and dealers are facing challenges in meeting demand due to economic factors such as high inflation rates and supply chain disruptions. Due to the rising costs and low availability of the new equipment, more and more end users are opting to rent instead. This helps them have fixed costs, and avoid potentially depreciation costs related to the unstable economic situation. Eddie Burke says the growth of the rental business started before COVID, but has accelerated in 2020: “We’ve seen a steady increase over the last 5 years. The current economic uncertainty with a war starting in one country and a government overthrown in another, with the US presidential election next year, pushes customers towards the rental model”. According to the American Rental Association (ARA), equipment rental revenue in the United States is expected to continue growing. In their 2023 update, the ARA projected a 7.6% increase, which would amount to $60.4 billion in revenue for construction and general tool rentals. Conclusions Lithium forklift batteries offer unique benefits for the burgeoning market segment of forklift fleet rentals by completely eliminating the pain of irregular service and maintenance. Lower required capacity, long cycle life, and significant savings on the total cost of ownership help accelerate the electrification of equipment and improve dealers’ bottom line while helping their customers achieve their sustainability and safety goals. Eddie again: “For the renters, the change to lithium (technology) means no maintenance, no obligations to watering, which is always a big mess, lower electricity use, and no damages discussions. And – safety guys do not like lead-acid batteries!” About the Author: Tim Karimov, President of OneCharge Lithium Batteries

Doosan Bobcat employees and leaders volunteer time and talents for community engagement initiatives

Efforts further Bobcat’s commitment to community, sustainability and its Environmental, Social and Governance strategy In recognition of its commitment to communities and sustainability across the globe, Doosan Bobcat (Bobcat) employees and members of its leadership team are celebrating its support of nearly 100 different volunteer projects to benefit the places where Bobcat employees live and work. In 2023 so far, more than 1,000 employees across Bobcat’s global footprint participated in company-organized projects, volunteering thousands of combined hours this year alone. “As an organization, we aim to create positive social impact to enhance the communities where we live and work, as well as benefit our neighbors,” said Scott Park, Doosan Bobcat CEO and vice chairman. “Our community engagement initiatives are a company tradition, and over the years, we have supported hundreds of organizations with thousands of volunteer hours all with the goal of creating a better tomorrow.” Bobcat employees just completed a week of volunteer events across 12 different countries. Volunteers carried out various activities such as environmental clean-up projects in the Czech Republic, South Africa, China and the UK; donating blood in France; supporting schools and medical facilities in India; and conducting renovations and upkeep for playgrounds, parks and non-profit facilities across the U.S. In applicable projects, volunteers used a fleet of Bobcat equipment—such as compact loaders, excavators, compact tractors, mowers and more—to make tough jobs easier, while increasing efficiency and productivity. Bobcat employees from around the world participated, which included North America, Europe, Middle East, Africa, Asia, Latin America and Oceania regions. The global effort supports Bobcat’s Environmental, Social and Governance (ESG) commitments to community engagement, sustainability and responsible growth as an organization. Teams from across the company partnered around these common goals to advance the organization’s efforts to build a better, more sustainable future. Bobcat is committed to investing time and resources in the communities where its employees live and work. The organization has a long history of volunteer efforts – providing time, resources and charitable contributions to help create a stronger tomorrow. Learn more about Bobcat’s community partnership at bobcat.com.

Mezzanine Safeti-Gates hires Jerry O’Neill to head its sales team

Mezzanine Safeti-Gates, Inc., an innovator in the design and manufacturing of pallet drop safety gates that provide fall protection in distribution centers, warehouses, manufacturing and material handling facilities, has announced the hire of Jerry O’Neill to head the sales team. The material handling sales veteran will lead the efforts in North America, including focus on systems integrators, distributors and consultants. Jerry joins the Mezzanine Safeti-Gates team from InCord, where he worked for over 13 years as a custom safety netting representative serving the Eastern United States and Canadian territories. At InCord, he proved to be an integral team member, helping to spur the company’s rapid growth. “We’ve always emphasized working with material handling distributors to promote pallet drop safety,” said Aaron Conway, president of Mezzanine Safeti-Gates, Inc. “Jerry will be a great addition to our team as we continue to expand our safety gate product line and custom-engineered solutions.” Prior to joining the material handling industry, Jerry spent over 20 years in the printing industry, sharpening his service-oriented problem solving skills. A graduate of Kutztown University, Jerry resides in the Philadelphia area with his family. Used in thousands of locations throughout the world, pallet drop safety gate systems offered by Mezzanine Safeti-Gates are available in single and double wide pallet widths, rack supported configurations, and can be customized to accommodate specific pallet widths, depths and heights. Safety gates can be purchased with manual or power operation, and fully comply with OSHA’s Walking Working Surface Fall Protection Standard, ANSI fall protection guidelines and IBC standards. All models, including safety gates for the loading dock and lifts, are available in powder coated mild steel or electro-polished stainless steel.

The ARA Foundation and Toro partner to build sensory riding path for therapeutic equestrian center

The American Rental Association (ARA) Foundation, in partnership with The Toro Company Foundation, completed a community impact project in Langley, British Columbia, Canada to benefit Pacific Riding for Developing Abilities (PRDA). PRDA is a not-for-profit, therapeutic equestrian riding center dedicated to enhancing the quality of life for individuals with a wide range of abilities. On September 6 and September 7, volunteers from all three organizations worked together to improve two indoor riding arenas, create a sensory riding path — a key new component to the therapy program, and trench in the paddock area to provide an electrical conduit so the electrical cords are underground, improving safety for staff and volunteers. “It was wonderful to see rental members donating equipment and their time to improve the facilities at PRDA. Each project had a significant impact on enhancing the quality of the experience for the individuals served and gave ARA members networking opportunities and a chance to gain new skills while giving back to the community,” said Judson McNeil, ARA Foundation director of programs and fundraising. To complete the work at PRDA, more than 30 volunteers from ARA, The Toro Company Foundation and PRDA staff moved 1,800 pounds of arena footing material and resurfaced the two riding areas, over a two-day period. Others painted the extensive baseboards and created the sensory path. All projects required the use of different equipment provided by local rental stores. “We are beyond grateful for the generous support from ARA and The Toro Company Foundation for the significant impact they have made in support of PRDA riders,” said Erin Julihn, PRDA director of operations. “Each of the completed projects significantly supports the therapeutic riding experience of PRDA riders, empowering the PRDA staff and volunteers to best serve each one’s individual needs.” The PRDA project is the second Community Impact project the ARA Foundation has completed in partnership with The Toro Company Foundation in 2023. The next project is planned for September 27 in Bigfork, Montana.

Railroads leverage Emergency Dispatching Services to dramatically increase AskRail access

In another major stride toward enhancing rail emergency response, AAR, working with member company Norfolk Southern, integrated AskRail® into the Columbiana County, OH and Beaver County, PA emergency management agencies (EMAs) dispatching services. This initiative underscores the rail industry’s unwavering commitment to ensure that first responders can quickly access the right information to plan a safe response to any rail-related emergency. “Serving nearly every community across the nation, railroads are dedicated to preventing an accident before it happens and also bear the responsibility of equipping first responders with the right tools and training to manage a rail emergency safely and effectively,” emphasized AAR President and CEO Ian Jefferies. “Following the East Palestine incident, railroads pledged to dramatically increase the availability of AskRail and today are providing more than 2.3 million first responders with streamlined and reliable access to this critical tool.” Launched in 2014, the AskRail app was developed in partnership with the emergency response community to provide accurate, timely data about the hazardous materials transported in rail cars. This information empowers first responders to make informed decisions swiftly during a rail emergency. Following East Palestine, AAR and the rail industry conducted a thorough risk assessment of AskRail to identify areas for improvement. The industry has put in years of effort to provide individual responders access to the AskRail app and is now committed to greatly expanding access through a more centralized, universally accessible approach. Today, railroads’ AskRail objectives have been threefold: Increase continuity of coverage and information. Ensure reliability of communications streams. Streamline communications to create a more efficient response. To further enhance accessibility, AskRail has been integrated into CHEMTREC and CANUTEC’s 24/7 call centers in the U.S. and Canada, respectively. Through existing hazmat certification programs, first responders are trained to utilize these call centers for assistance in managing a chemical emergency response. This integration ensures that AskRail is now universally available to first responders in these two countries. However, railroads recognize that most volunteer fire departments, which make up nearly 82% of all U.S. fire departments and protect almost 30% of the U.S. population, according to the National Fire Protection Association, may be unfamiliar with CHEMTREC. Instead, when volunteer responders are called to the scene of an emergency, they are trained to utilize their county’s EMA or Emergency Communications Centers (ECC), more commonly known as dispatch, as their primary line of communication. By integrating AskRail into ECCs, railroads ensure those forces have access to vital information via established, streamlined and reliable communications channels. ECCs are mandated to always have backup power generation, redundant radio communications to first responders in the field and around-the-clock staffing. By leveraging these centers, AskRail data becomes an integral part of the standard communication protocols for all first responders – whether paid or volunteer – for handling potential emergencies within a community. In July, the Pipeline and Hazardous Materials Safety Administration (PHMSA) issued a safety advisory notice that noted, “Maintaining multiple access points to the emergency response information via both the emergency responders at the scene, as well as via 9-1-1 call centers, provides redundancy and helps ensure access to necessary information in the event of cellular data outage due to inclement weather, power failure, or lack of coverage at the accident site.” Expanding this access in Columbiana and Beaver counties today is just one more step the railroads are taking to support first responders and protect the communities they serve. Officials from PHMSA were present for the trainings in Columbiana and Beaver Counties today. The ultimate goal of the AAR and its members is integrating AskRail into the nation’s ECCs. As outreach to local ECCs is ongoing, emergency managers can proactively download the Windows Desktop Application version of AskRail to their dispatch center computer system and begin the approval process at AskRail.us. To access AskRail Technical Support, contact 1-877-724-5462 or send an email directly to support@askrail.us.

Rocrich AGV Solutions: Mitsubishi Logisnext Americas and Jungheinrich joint venture now in operation

German intralogistics pioneer Jungheinrich and Mitsubishi Logisnext Americas (Logisnext), a North American provider and manufacturer of material handling and innovative automation and fleet solutions, announced the successful launch of Rocrich AGV Solutions (Rocrich). Marking a significant milestone following the initial joint venture plans announced in June, this collaborative effort strengthens and expands on Jungheinrich’s and Mitsubishi Logisnext Americas’ existing partnership with over 570 Logisnext dealer locations across North America. Rocrich offers proven mobile automation solutions for warehouses, production facilities and the industry’s best service promise with leading local and regional coverage. Through Rocrich, customers and industry partners now have access to a comprehensive suite of mobile automation and robotics solutions – spanning all major customer use cases from standard to special purpose AGVs and automated forklifts. This strategic offering within the North American market further builds upon Rocrich’s ability to harness Rocla’s and Jungheinrich’s global industry-leading knowledge and expertise in automation – with a continuous stream of innovative products expected in the future. “Today marks an exciting achievement as our strategic vision becomes a reality, launching Rocrich into its operational journey,” said Brian Spradlin, President of Rocrich. “This moment highlights our dedication and drive to reshape the material handling industry through innovative mobile automation solutions.” In line with Mitsubishi Logisnext Americas’ and Jungheinrich’s commitment to drive next-generation logistics solutions, Rocrich will ramp-up operations starting this month. Rocrich anticipates adding significant increases in employees across sales, commissioning, installation and aftersales to further enhance the workforce and meet the growing demands of operation. Rocrich will be located at Mitsubishi Logisnext Americas’ headquarters in Houston, TX, with a dedicated team of professionals based in Marengo, IL, to ensure efficient and effective operations. Rocrich’s operations are also supported by Mitsubishi Logisnext Americas’ established dealer network throughout the U.S., Canada and Mexico.

Rail Safety Week: Together we can stop track tragedies

While rail remains the safest way to move goods over land, this Rail Safety Week, railroads and other safety advocates are intensifying their efforts to enhance public safety near railroad tracks — the single largest, most persistent rail safety challenge. According to Federal Railroad Administration data, more than ninety-five percent of all rail-related deaths involve drivers going through a grade crossing or a person on the tracks. Overwhelmingly, these tragedies are preventable AAR President and CEO Ian Jefferies emphasized the urgency of the situation, “Every three hours in the U.S., a person or vehicle is hit by a train. Rail Safety Week is a call to action, rallying the public to understand these avoidable risks. Stopping track tragedies demands collective effort. There is more work to do, and each one of us has a role to play.” Rail Safety Week, running September 18-24, aims to save lives through increasing public awareness about how to stay safe around railroad tracks. Protect yourself and your loved ones by following these top six rail safety tips: Cross tracks only at designated pedestrian or roadway crossings and obey all signs, warning lights and gates. Never try to beat a train, as trains are quieter and faster than you think. Recognize it can take a mile or more to stop a train because of its size and weight. Always expect a train on any track, in any direction and avoid distractions when you approach a crossing. Be aware that trains can extend three feet or more beyond the steel rail, so maintain a safe distance from the platform or track’s edge. Remember that rail property is private property, and walking on the tracks is illegal and dangerous. All week, Operation Lifesaver — the nation’s leader in rail safety education — will host programming and events nationwide to equip the public with the knowledge to make smart decisions near trains and tracks.