Raymond wins bronze for innovation in event marketing at Global Eventex awards 2023

The Raymond Corporation won a bronze Eventex Award for its 100th anniversary immersive exhibit. The Eventex Awards, founded in 2009 to celebrate creativity, innovation and effectiveness, is the ultimate symbol of excellence in the world of events and experience marketing. With 761 entries from 49 countries worldwide, the 2023 awards recognized outstanding achievements in the events industry. Raymond’s 100th anniversary celebration included an interactive exhibit that took visitors on an adventure through time, highlighting game-changing innovations that make today’s supply chain possible and telling the stories of the people behind them. History was brought to life through museum-style artifacts, physical displays, video and an interactive touch-screen interface. “Receiving this award is a moment of immense pride and accomplishment for Raymond,” said Brian Howard, vice president, marketing and product management, The Raymond Corporation. “This recognition highlights our commitment to pushing the boundaries of our industry. We are honored to be acknowledged among our fellow innovators and look forward to the next 100 years and beyond as we continue delivering groundbreaking experiences and solutions for our customers.” The exhibit traveled to various Raymond Solutions and Support Centers across the country, with a final celebration at the trade show ProMat in Chicago in March. View the complete list of Eventex Awards winners here.

Santana Equipment announces new location in Northwest Florida

Santana Equipment Trading Company, a provider in the used material handling equipment market, has announced the opening of a new retail/rental location to better serve the Southeast region of the United States. Santana Equipment started in Illinois in 1999. Over the years the company grew into a leader in the wholesale forklift market and the need to expand became more evident. In 2013, after moving into a larger complex in North Chicago, Santana’s second location opened in Arizona. Santana Equipment West quickly became one of the top sellers of used forklifts in the Phoenix market. With Chicago Headquarters covering the north, and the Arizona location out west, the need was recognized for another location to serve the Southeast region of the US. After years of preparation and market research a warehouse was purchased in Pensacola, FL. The focus for this new location will be to continue the Santana Equipment business model of buying, selling, and renting quality new and used forklifts. When asked about the new Florida office Alex Stuckey, Santana Equipment West’s Operating Manager, said “We are so excited to be opening this new location in Florida! We’ve wanted to expand to this area for some time and I’m so glad we have had this opportunity to do so.” Seth Worthey, the Operating Manager of the new location added, “When I was researching where to move next, I saw that Pensacola is perfectly situated to serve all the surrounding markets. We will be able to provide our equipment to customers in Florida, Alabama, Georgia, Louisiana, and every else in this region with ease.”

SUN Automation Group enters exclusive Strategic Partnership Agreement with AL-GAR

SUN to become exclusive distributor and service provider for AL-GAR in USA and Canada effective August 2023 SUN Automation Group (SUN), has announced it has entered into an exclusive strategic partnership agreement with AL-GAR. Effective August 2023, SUN will be the exclusive representative of all AL-GAR products and support throughout the United States and Canada. Based in Barcelona, Spain, AL-GAR offers advanced engineering solutions for corrugated manufacturing. The company provides expertise and resources to optimize manufacturing processes, with customizable solutions for design, control systems, retrofits, and maintenance. AL-GAR bolsters its comprehensive services with its top-of-line product offerings engineered to enhance corrugated, paper, and converting operations globally. “By partnering with AL-GAR, SUN continues to expand its capabilities and presence around the world,” said Greg Jones, Executive Vice President of SUN Automation Group. “On behalf of our board, senior leadership team and our employee-owners, we welcome AL-GAR to the SUN Family.” AL-GAR’s technology-enabled solutions allow corrugated manufacturers to see quick benefits, from increased productivity and efficiency to saving on materials and cost. With AL-GAR, companies can be assured that all processes are fine-tuned to maximize results. “The partnership with SUN Automation Group will fuel the growth of both companies,” said Silvia Alcazar, Managing Director at AL-GAR. “By combining SUN’s exceptional sales and service support with our engineering expertise and resources, we will build upon our strong position in the global marketplace.” SUN leadership views the partnership with AL-GAR as a perfect complement to SUN’s current offerings. By introducing AL-GAR’s extensive services, SUN further solidifies itself as a complete solutions provider for the corrugated industry. “We are honored to work with AL-GAR and excited to introduce the company’s forward-thinking solutions to our current customers in the United States and Canada,” said Jones. “We look forward to introducing AL-GAR’s innovative Automatic Load Tag Inserter during the What’s New presentation at TAPPI CorrExpo later this month. Customers can also stop by booth #101 to learn more and meet with AL-GAR representatives onsite.” The strategic partnership between SUN Automation Group and AL-GAR reinforces their mutual dedication to innovation, efficiency, and customer-centric solutions. By leveraging each other’s strengths, they are poised to redefine excellence in the corrugated industry, ensuring a future of growth and success.

Women In Trucking Foundation announces Spring 2023 Scholarship Recipients – Now accepting Fall 2023 applications

Empowering Women in Trucking: The Women In Trucking Foundation Scholarship Program During its Spring 2023 scholarship application cycle, the Women In Trucking (WIT) Foundation received over 100 applications and awarded 31 scholarships. This is up from 23 recipients in the previous, Fall 2022 cycle. Learn more about the recipients on the WIT Foundation website. Why it matters The WIT Foundation scholarship program changes lives. It breaks down barriers, facilitating opportunities for women in the male-dominated trucking industry. By offering financial support through its scholarship program, the WIT Foundation allows women to overcome financial barriers to access education and training programs, empowering them to pursue successful careers in trucking. Recipients also receive a one-year membership to the WIT Association, which comes with access to mentorship, networking and education resources. Scholarships are awarded in four categories: Leadership, Driving, Safety and Technician. The Foundation’s scholarship recipients, through their success and achievements, become trailblazers, inspiring future scholarship applicants to pursue their aspirations. Encouraging women to apply WIT Foundation Fall 2023 scholarship application cycle is currently open. The deadline to apply is September 30. Supporting the Women In Trucking Foundation The Women In Trucking Foundation is a 501(c)(3) organization that raises funds for scholarships, which are distributed in a way that supports women in the trucking industry. In turn, the trucking industry benefits from a diverse and well-trained workforce that has continuous opportunities for development. The WIT Foundation depends on the generosity of individuals, foundations and corporations to fund scholarship awards, whether it’s a gift of $10 or $25,000! The Foundation is grateful for its sponsors and donors, who truly are making its work possible! You, too, can support women in the trucking industry – All contributions are tax-deductible to the extent of current law and a receipt will be provided.

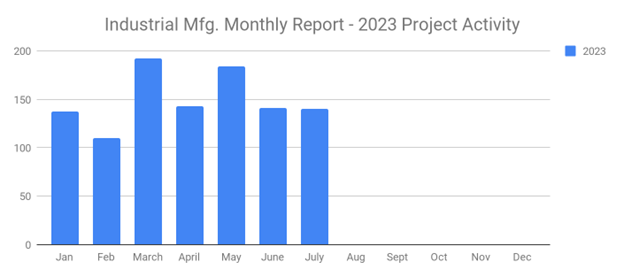

140 New Industrial Manufacturing Planned Projects for July remain steady for second month

SalesLeads announced today the July 2023 results for the new planned capital project spending report for the Industrial Manufacturing industry. The Firm tracks North American planned industrial capital project activity; including facility expansions, new plant construction and significant equipment modernization projects. Research confirms 140 new projects in July as compared to 141 in June, unchanged for the Industrial Sector. The following are selected highlights on new Industrial Manufacturing industry construction news. Industrial Manufacturing – By Project Type Manufacturing/Production Facilities – 129 New Projects Distribution and Industrial Warehouse – 82 New Projects Industrial Manufacturing – By Project Scope/Activity New Construction – 44 New Projects Expansion – 48 New Projects Renovations/Equipment Upgrades – 57 New Projects Plant Closings – 13 New Projects Industrial Manufacturing – By Project Location (Top 10 States) California – 10 New York – 9 Texas – 9 Indiana – 8 Ohio – 8 Michigan – 7 Georgia – 6 Minnesota – 6 Tennessee – 6 South Carolina – 5 Largest Planned Project During the month of July, our research team identified 16 new Industrial Manufacturing facility construction projects with an estimated value of $100 million or more. The largest project is owned by Formosa Plastics Corporation, who is planning to invest $12 billion for the construction of a processing facility in ST. JAMES, LA. They are currently seeking approval for the project. Construction is expected to start in Summer 2024. Top 10 Tracked Industrial Manufacturing Projects CALIFORNIA: Semiconductor MFR. is planning to invest $2 billion for the expansion, renovation, and equipment upgrades on their manufacturing facility at 7501 Foothills Blvd. in ROSEVILLE, CA. They are currently seeking approval for the project. Completion is slated for 2026. TENNESSEE: Automotive component mfr. is planning to invest $790 million for the construction of two manufacturing and warehouse facilities totaling 940,000 SF in STANTON, TN. The project includes the construction of a 400,000 SF manufacturing facility in LAWRENCEBURG, TN. Completion is slated for 2025. TEXAS: Tissue paper MFR. is planning to invest $400 million for the construction of a manufacturing and warehouse facility on Gene Campbell Rd. in NEW CANEY, TX. They are currently seeking approval for the project. They will relocate their operations upon completion. INDIANA: Plumbing equipment MFR. is expanding and planning to invest $300 million for the construction of a 300,000 sf manufacturing facility adjacent to their existing plant in WABASH, IN. Construction is expected to start in early Fall 2023. ARIZONA: Semiconductor equipment MFR. is planning to invest $270 million for the construction of a laboratory and manufacturing facility on the Arizona State University campus in TEMPE, AZ. They are currently seeking approval for the project. FLORIDA: Building materials MFR. is planning to invest $235 million for the expansion and equipment upgrades on their manufacturing facility in PALATKA, FL. They are currently seeking approval for the project. GEORGIA: Automobile MFR. is planning to invest $200 million for the renovation and equipment upgrades on their manufacturing facility in WEST POINT, GA. Completion is slated for Spring 2024. OHIO: Tissue paper MFR. is planning to invest $185 million for a 500,000 SF expansion of their manufacturing facility in CIRCLEVILLE, OH. They are currently seeking approval for the project. Completion is slated for 2025. SOUTH DAKOTA: Industrial supplies MFR. is planning to invest $158 million for a 200,000 sf expansion of their manufacturing and warehouse facility in BROOKINGS, SD. They are currently seeking approval for the project. KENTUCKY: Automotive components MFR. is planning to invest $153 million for a 752,000 SF expansion and equipment upgrades on their manufacturing facility in BEREA, KY. They are currently seeking approval for the project. About IMI SalesLeads, Inc. Since 1959, IMI SalesLeads, based in Jacksonville, FL is a leader in delivering industrial capital project intelligence and prospecting services for sales and marketing teams to ensure a predictable and scalable pipeline. Our Industrial Market Intelligence, IMI identifies timely insights on companies planning significant capital investments such as new construction, expansion, relocation, equipment modernization and plant closings in industrial facilities. The Outsourced Prospecting Services, an extension to your sales team, is designed to drive growth with qualified meetings and appointments for your internal sales team. Visit us at salesleadsinc.com.

Value-added services can add an additional revenue stream to your dealership

Back in February’s edition of Wholesaler, I wrote about ‘forklift battery management’ to your dealership’s services offering as a one-stop shop solutions provider. Subsequently, the topic of optimizing forklift battery management as a value-added service to your end-customer while being an additional revenue stream for your dealership. I recently got the opportunity to catch up with Dustin Love, Business Development Manager, at Flight Systems Industrial Products, and he was able to provide some inspiration and content for this month’s article. So, with that, let’s dive into battery chargers, charging lead-acid vs charging lithium-ion batteries, and the intricacies of charging. As technology advances, the demand for batteries continues to grow, and with it comes the need for efficient charging solutions. Lead-acid and lithium-ion batteries have distinct charging requirements. Understanding these differences and offering specialized services, your dealership can increase service revenue while providing optimal charging solutions for your customers. Prolong Battery Life A battery’s performance is only as good as its charger. When paired correctly, a quality battery charger will prolong battery life and provide maximum run time. When selecting the right charger for your end-customer’s application, there are many variables to consider, such as: Vehicle type (for example, industrial vs golf car) Power Source Battery Type (Lead-Acid – Flooded, AGM, Gel or Lithium-Ion) Battery Size (Voltage & Amperage) Connectors and Accessories Charging time and specifications Charging Lead-Acid Unlike lithium-ion, there is no special communication technologies or internal battery monitoring systems (BMS) monitoring the cells and communicating with the charger. To charge a lead-acid battery you can simply supply current at the correct rate using the main battery’s positive and negative connections. Regular maintenance, such as equalization charging and periodic water level checks, testing, and monitoring healthy charging tendencies is crucial to ensure optimal performance and extend battery life. It is important to use a charger designed for lead-acid batteries. Lead-acid batteries can be charged using older technology from the 1950s–60s, which is very dependable, but they can also benefit from using a newer high-frequency switching charger. High frequency chargers typically require more maintenance, but they offer higher efficiency, healthier charging, and up-to-date technology with programmable charge curves. Charging Lithium-Ion Lithium-ion batteries also benefit from a charge rate based off its amp-hour capacity. Proper charging tendencies are not as crucial with lithium, so it can be charged faster and still be considered a healthy rate. It’s important to avoid overcharging or discharging the batteries excessively. Additionally, temperature monitoring during charging is crucial to prevent overheating. These batteries should be charged using chargers that are specifically designed for lithium-ion technology and set to the recommended voltage and current levels. Lithium-ion battery technology sometimes is marketed as being maintenance free, but those with experience know that is not the case, it’s just a different kind of maintenance needed. Instead of cycling and equalizing charging to ‘boil out’ lead-acid sulfation, the ‘maintenance’ aspect of it is more programming adjustments to the lithium charger and BMS technology on the battery, such as updates and troubleshooting. Setting Up the Battery Charger Follow the battery manufacturer’s guidelines and use chargers specifically designed for the battery chemistry when setting up a charge for both lithium-ion and lead-acid batteries. Following the recommended charging practices ensures optimal performance, maximizes battery life, and ensures safety during the charging process. A lead-acid charger will need to be set with the correct voltage, output current, and standard connector type. More advanced lead-acid operations will use a battery identification device (BID) on the charger that can program itself automatically for various kinds of lead-acid batteries and monitor its performance. A lithium charger’s set-up is determined by the battery manufacturer’s design. In the material handling industry, there is no standardization for chargers such as DC connectors, auxiliary connection pinouts, BMS protocol signals, etc. Setting up a charger for lithium entails working directly with the battery manufacturer to develop a working charger that communicates with their battery specifically. Safety In both battery types, you must incorporate safety considerations when setting up a battery charger. Charging lithium-ion batteries requires extra caution. Lithium-ion batteries are sensitive to temperature extremes and can be damaged or even become a safety hazard if charged improperly. Lithium batteries are equipped with an integrated battery management system (BMS) to optimize their performance and ensure safety. Acting as the control center for individual batteries, the BMS prevents overcharging and over-discharging, safeguards against potential hazards, monitors battery health, balances charge across cells, and promptly shuts down the battery if unsafe conditions are detected, protecting both the battery and the user. Lead-acid batteries are generally less sensitive to charging conditions, but proper ventilation and monitoring for hydrogen gas are still essential for safety. Also, be sure to check the battery manufacturer’s specifications for recommended charging voltage thresholds. As Dustin Love mentions, “Maintain to sustain! Properly maintaining your batteries is important for their longevity. A battery that is routinely serviced will significantly outlast a neglected battery. Knowing how to maintain your battery is the first step.” So, consider adding ‘forklift battery management’ to your dealership’s service offering to enhance the longevity of your customer’s electric forklift fleet’s batteries, reduce downtime, and ultimately boost their productivity. About the Author: Chris Aiello is the Business Development Manager at TVH Parts Co. He has been in the equipment business for 16-plus years as a service manager, quality assurance manager, and business development manager. Chris now manages a national outside sales team selling replacement parts and accessories in various equipment markets such as material handling, equipment rental, and construction/earthmoving dealerships.

People of Influence are successful. Are you one them?

Are you seeking more influence with your customers? With your boss? With your prospects? With your connections? With your associates and coworkers? Have you ever thought about what elements go into being an influential person? Below is the list, BUT don’t just read it – compare your skill levels to it, so that you can develop your understanding AND your status at the same time. This list contains elements of the IDEAL influencer. All people of influence do not have to have all these qualities, but the more they possess, the greater their power to influence. A power influencer is: Smart. A person who can reason and be reasonable. A person who can think in terms of answers, rather than fret over circumstances. Someone who sees the big picture, rather than the immediate urgency. Shrewd. Beyond smart, a shrewd person sees an answer and a game plan to implement it. And the implementation is seen in favor of the other, rather than in favor of themselves. It doesn’t mean that you give up your winnings (earning, commission, money), but it does mean that everyone wins, not just you. Knowledgeable. Beyond smart, a knowledgeable person knows what’s going on in detail. Product knowledge, service knowledge, and experience. Not just how to work it – but how to use it to profit and produce. Successful. A person who has completed tasks successfully and had successful outcomes. A person who lets their record speak for them. A Winner. A person whose history shows they know how to win, and they’ve won more often than they’ve lost. Full of Answers. Influencers do not always push. Often, they are called upon because an answer is needed, and the caller has confidence or faith that the influencer knows the right answer and the best answer. Someone with ideas that work. Ideas based on past experience, the best possible answer, and a firm understanding of the circumstance will create influence enough to be accepted and implemented. Creative. Creativity is the mother of ideas. A creative person has studied creativity and combined it with the brainpower to never be at a loss of thought in any situation. A thinker. Most people never spend time thinking. That’s why most people are not power influencers. Thinkers are also observers. They don’t just talk – they look, they think, they reason, and then they respond. Someone with a GREAT reputation. If you seek to become a person of influence, other people will have to corroborate your credentials and your credibility. You may think you’re a person of influence, but in the end, it’s not what you think, it’s what others think and what others say about you. Someone with great timing. Knows when to hold ’em. Knows when to fold ’em. Someone with a great attitude. I don’t think you can influence at the same time you’re whining and complaining. And maybe you should substitute the words power influence with the words positive influence. Well, that’s the end of part ONE. Yes, there are several more elements to being a “power influencer” and I’ll reveal them all next in a future issue. How are you doing so far? More complicated than you thought. Relax – you’re not alone. Rereading and rating yourself on each element will give you a realistic picture of your present power to influence. PLEASE NOTE WELL. There is nothing on this list about using sales tactics or closing techniques. No need to. Power influencers do not close sales; they create the desire for the customer to BUY. About the Author: Jeffrey Gitomer is the author of twelve best-selling books including The Sales Bible, The Little Red Book of Selling, and The Little Gold Book of Yes! Attitude. His real-world ideas and content are also available as online courses at www.GitomerLearningAcademy.com. For information about training and seminars visit www.Gitomer.com or email Jeffrey at salesman@gitomer.com or call him at 704 333-1112.

Logistics Management announces the winners of the 40th Annual Quest for Quality Awards

The Quest for Quality Awards are the gold standard for customer satisfaction and performance excellence for carriers, ports, and logistics providers worldwide. Logistics Management’s (LM) Annual Quest for Quality Awards are the culmination of a six-month research project conducted by Peerless Research Group (PRG). For four decades, LM’s Quest for Quality Awards have been regarded in the transportation and logistics industry as the most important measure of customer satisfaction and performance excellence. Learn more. View the 2023 Winners “Now in its 40th year, the Quest for Quality Awards program continues to stand out in the industry for the simple fact that it’s not a popularity contest,” said Michael Levans, group editorial director of Peerless Media’s Supply Chain Group. “Instead, this annual survey of LM readers is by invitation only, ensuring that all participants are qualified shippers that use the services of these carriers and service providers on a regular basis around the clock and around the world.” “Indeed, here in 2023, we’re seeing some of the well-publicized supply chain congestion ease,” added Levans. “However, as our latest Quest for Quality results show, the improved collaboration between shippers and their carrier and services partners over the past year have only helped them to prepare for whatever supply chain disruption may be around the bend—an indication that more resilient logistics operations have been created to meet future challenges.” About the Quest for Quality Awards To determine the “best of the best,” LM readers—logistics, transportation, and supply chain decision makers—rate carriers, third-party logistics (3PL) service providers and U.S. port operators strictly on the basis of service quality. One of the most notable elements about the Quest for Quality Awards is that it calls these shippers to vote in the genre of services in which they are customers; therefore, they vote for the providers that they believe have best delivered on quality service in specific niches. This year, LM had 3,512 ballots cast from logistics and supply chain decision makers resulting in 142 transportation and logistics services providers that earned Quest for Quality gold.

Signode to highlight industry-leading Automation and Support Solutions at CorrExpo 2023

Signode, a global manufacturer of a broad range of automated transit packaging equipment, tools, consumables, and warehouse automation and support solutions, is highlighting industry-first technologies at CorrExpo in Cleveland. Held at the Huntington Convention Center of Cleveland August 28-30, Signode will present a selection of its innovative corrugated packaging advancements in booth 335. “We’ve seen tremendous growth in corrugated over the last several years,” says Jonathan Lust, Corrugated Segment Manager at Signode. “Our portfolio of solutions is designed to help corrugated plants keep up with these increasing demands. From easily integrated end-of-line automation options to ongoing equipment support via our Packaging Plus® Reliability Services Team, we aim to protect our customers’ corrugated automation investments while prioritizing optimal outcomes.” Corrugated solutions to be showcased at CorrExpo include: SIG-VCS Signode’s SIG-VCS automatic squaring bundler is our premier solution for customers seeking high-speed bundling capabilities. With bundling capacity of up to 32 bundles per minute, box converters are empowered to meet demanding deadlines and optimize throughput. The SIG-VCS is equipped with XL strap coils, quick-change strapping dispensers, and auto-refeed technology, all designed to minimize downtime with continuous strapping. The production versatility of the machine enables effortless changes in production requirements, giving box converters peace of mind to meet varying customer needs. The SIG-VCS has standard built-in features to keep production downtime to a minimum, and the auto-bundle teach option reduces set-up time to one minute or less. The patented easy-access strap guides require no tools for normal maintenance. SIG-CORR Another one of Signode’s automatic squaring and strapping bundlers, the SIG-CORR, will be on display at CorrExpo to demonstrate high-speed bundling capabilities for specialty-glued items, including crash-lock boxes, corrugated trays and lids, and straight-line cartons. Up to 50% faster in some specialty folder gluer applications, the SIG-CORR is manufactured with intuitive features such as signal lights to indicate low strap and end-of-strap monitoring with auto bundle ejection promotes continuous strapping and maximum uptime. Additionally, the SIG-CORR features easy-access strap guides for simplified maintenance. The SIG-CORR can accommodate production changes quickly and easily with storage of up to 5,000 bundle program configurations. BXT3 Battery Powered Strapping Tool Signode’s line of BXT3 battery powered hand tools offers a modern alternative to pneumatic and manual equipment by showcasing reliability, ease of use, and speed – essentially giving any operator highly consistent results not possible with manual tools. This battery powered strapping method is user-friendly, reduces operator fatigue, and saves time and money. The BXT3 is specifically designed for strapping applications using Signode Tenax® polyester and Signode Dylastic® polypropylene strapping. It accommodates 13mm to 32mm plastic strapping and is capable of variable tensioning speeds of up to 11’ per second. With a lightweight, ergonomic design, intuitive user interface and up to 800 cycles per charge, this tool is designed to increase customer uptime. Signode’s comprehensive suite of corrugated solutions is underscored by the Packaging Plus® Reliability Services Team, featuring more than 500 field service engineers and technicians around the world. These highly trained specialists are equipped with the latest technology, tools, and training and provide proactive maintenance, full line efficiency audits, and emergency repairs to keep customers’ packaging equipment operating at peak performance. The Reliability Services Team engages with customers to develop preventive, protective, and comprehensive care using a specially designed Performance Assessment Reporting.

SUN Automation Group highlights latest innovations and key partnerships at CorrExpo 2023

SUN Automation Group (SUN), a global industry provider of innovative corrugated solutions for feeding, printing, and converting, welcomes customers to CorrExpo in Booth 101 at the Huntington Convention Center in Cleveland, Ohio from August 28-30. Visitors can learn more about the SUN625® Rotary Die Cutter, SUN’s next-level solution for corrugated manufacturing. With comprehensive feeding, printing, and converting capabilities, the fixed-frame system offers more production volume than two traditional RDC machines, while also producing superior container quality. “We’re incredibly excited to share SUN625® at CorrExpo,” said Gokul Gopakumar, Vice President of Technology and Business Development. “The technology embodies our commitment to innovation and productivity and offers unprecedented cost savings to our customers. It sets new standards in efficiency and versatility, and we look forward to engaging in discussions about its transformative capabilities in August.” SUN will also be highlighting Helios, the company’s machine learning and IIoT platform. The SaaS solution quantifies and analyzes key elements of the corrugated manufacturing process. With this data, box plant leaders are empowered to make more efficient and informed decisions around when to schedule downtime and order parts to prevent machine failure. “Helios saves box plants time and money by enabling their equipment to work smarter, not harder,” said Gopakumar. “Its machine learning capabilities enable predictive maintenance, and its real-time remote monitoring allows for quick identification and resolution of issues. Helios is the 21st-century solution for optimizing the manufacturing process.” In addition, SUN will feature their breadth of strategic global partnerships at CorrExpo. By combining the experience, equipment, service, and technology of experts worldwide, SUN is able to provide the right solution for any operation and accommodate even the most unique needs. “Our strategic partnerships allow us to stake our claim as a total solutions provider for the corrugated industry,” said Greg Jones, Executive Vice President. “We are able to capitalize on our all-encompassing resources to provide individualized solutions for our customers. We look forward to demonstrating how our expanded knowledge, experience, and global presence can serve the corrugated community.” SUN is proud to maintain key partnerships to provide solutions for increasing production, efficiency, and profitability. When CorrExpo attendees visit SUN’s booth this year, they will also have the opportunity to meet and learn more about these strategic partners. Latitude Machinery Group (LMC) Since August 2019, SUN Automation Group has been the exclusive representative for Latitude Machinery Corp. (LMC) in North and Central America. As a world-class manufacturer of Rotary Die Cutters and Flexo Folder Gluers and with over 100 machine installations in North America, LMC has an outstanding reputation for reliability and throughput. PARA Srl Machinery and Material Handling for Corrugated Board As a globally integrated Italian material handling company and partner to SUN since 2021, PARA boasts a vast variety of material handling solutions for the corrugated industry, with over 15,000 products installed world-wide. PARA’s extensive product range includes pre-feeders, palletizers, RDC stackers, bundle breakers, pallet inserters, vertical storage solutions, paper mill roll transports, and unit conveyor systems. Al-Gar Al-Gar, SUN’s newest partner, is a global leader offering corrugated engineering solutions. Based in Barcelona, Spain, the company provides expertise and resources to optimize manufacturing processes, with customizable solutions for design, control systems, retrofits, and maintenance. Al-Gar bolsters its comprehensive services with its top-of-line product offerings engineered to enhance corrugated, paper, and converting operations. eProductivity Software Packaging (ePS) SUN’s strategic partnership with ePS works to provide the most comprehensive software solutions for the corrugated and packaging industries. Headquartered in Pittsburgh, PA, ePS offers a robust portfolio of highly flexible, modular packaging software solutions built to enable revenue growth, improve operational efficiency, and reduce manufacturing costs. ePS software is seamlessly integrated with SUN’s Helios platform, empowering customers to not only unlock intricate insights into machine settings and patterns but also to transform their operations into a more proactive, efficient, and evolved system. Highcon SUN and Highcon have been cultivating a growing relationship since 2021. Highcon represents the digital arm of corrugated converting solutions, bringing a patented digital cutting and creasing process for post print processes in the folding carton and corrugated carton industries. SUN is committed to delivering excellence to the corrugated industry. To learn more about how your operations will benefit from SUN’s well-rounded suite of corrugated support and solutions, visit booth 101 at CorrExpo.

Trew® named 2023 Top Workplaces Award winner by employees

The award recognizes top companies in the Greater Cincinnati region based on employee feedback Trew, LLC has been recognized by Enquirer Media as a 2023 Top Workplaces award winner. Trew’s team includes a wide range of roles including solutions development, project management, software, engineering, manufacturing, installation, sales, marketing, and other general corporate services, and is proud to be recognized by its employees as a top workplace. “I am incredibly proud of our teammates for making this award possible,” said Alfred Rebello, Trew President and COO. “We put a lot of effort into building an environment where people make big things happen and win together by creating value for our customers. The Top Workplaces Award is confirmation that the people who make Trew great share a passion for excellence.” The Top Workplace Award is based entirely on employee feedback gathered by a third-party survey administered by Energage, LLC. The confidential survey uniquely measures 15 culture drivers that are critical to success of any organization such as alignment, execution, and connection. “Earning a Top Workplace award is a badge of honor for companies, especially because it comes authentically from their employees,” said Eric Rubino, Energage CEO. “That’s something to be proud of. In today’s market, leaders must ensure they’re allowing employees to have a voice and be heard.” Trew was formed in January 2019 by warehouse automation veterans and has quickly become a solutions leader in the industry. The company is anchored in Cincinnati, with a diverse hybrid workforce and additional facilities in Milwaukee, Wisconsin and the greater Toronto, Canada area.

Hodge Company CEO announces retirement with successors selected

A Dubuque, IA-based company announced its longtime CEO’s retirement on Thursday, as well as plans for co-CEOs to take over the company. Hodge Company. announced in a press release that Tim Hodge will retire September 11. Hodge has worked at the company for 44 years, serving as CEO for two decades. “Since its establishment in 1958, HODGE has evolved from a public warehousing company with a handful of employees into a thriving enterprise, employing over 1,200 team members across three states,” the release states. “Behind this growth is CEO Tim Hodge. … HODGE extends its deepest gratitude to Tim Hodge for his invaluable contributions to the business and community throughout his tenure as CEO.” Zach Hodge and Jordan Fullan — Tim Hodge’s son and daughter, respectively — will take on co-CEO roles following their father’s retirement. They will be the fourth generation in their family to lead the company. Zach Hodge currently serves as the company’s president, and Fullan currently serves as executive vice president of human resources and safety. “The seamless collaboration between Zach and Jordan, honed over the past seven years as executive leaders within HODGE, sets the stage for a successful transition into fourth-generation ownership,” the release states. “While each co-CEO will have their defined areas of responsibility, their shared commitment to excellence and their aligned vision for the company’s future will ensure unity in propelling HODGE forward.”

BSLBATT Battery joins SPE Elettronica Industriale Charger Compatibility Program

BSL Battery just announced that it has joined the Compatibility Program of SPE Industrial Electronics Charger Manufacturer in Crevalcore, Bologna, Italy, with the help of Flight Systems Industrial Products (FSIP), the exclusive SPE agent in Pennsylvania, USA. The program provides BSLBATT Battery with the tools to pursue new opportunities with Original Equipment Manufacturers (OEMs). “As part of the compatibility program for SPE charger manufacturers, BSLBATT can present its integration with SPE Elettronica Industriale in a curated network of tested and compatible batteries and charging solutions”. said Dustin Love, Executive Business Development Manager, Flight Systems Industrial Products. FSIP is excited to have developed chargers for BSL Battery, three-phase and single-phase. “We had a battery in-house for a couple of weeks to fine tune their firmware files, and I will say that these batteries are the real deal. Thank you BSL Battery – Industrial for the opportunity” added Love. How Does This Benefit You? The program Charged by SPE Elettronica Industriale is a great fit for us and we are excited to be part of this effort with SPE. We are eager to continue growing with SPE and are eager for the opportunity to provide outstanding solutions to industries that work with the SPE product line. BSLBATT will receive a “SPE Elettronica Industriale” logo for use on its products and marketing materials. This logo signifies to OEMs that BSLBATT’s battery was iteratively tested and validated by SPE’s team of engineers. It also offers BSLBATT the opportunity to target electric vehicle and industrial equipment and machine industries that SPE Elettronica Industriale currently operates in. “SPE Elettronica Industriale offers a unique way for battery and BMS partners like BSBATT Battery to generate more business by signaling a level of quality and compatibility that OEMs can rely on. Currently, there is no other resource available that offers OEMs a one-stop-shop with this level of curated solutions,” said SPE Managing Director presso Alessandro Poletti. To learn more about the BSLBATT solution offered at SPE Elettronica Industriale, visit https://www.lithiumforkliftbattery.com/charger/charged-by-spe-elettronica-industriale.html.

JLG® ClearSky Smart Fleet™ Turns Connectivity into Interactivity

JLG Industries, Inc. now offers standard ClearSky Smart Fleet™ connectively on most new JLG® equipment. This breakthrough IoT (Internet of Things) technology launches with 25 unique features, including analyzers, telematics and productivity applications, into a single connectivity beacon on JLG machines for seamless back-and-forth interaction through a comprehensive ClearSky mobile app, a user-friendly web portal or an advanced API. Equipment owners and operators can send a prompt to the beacon to identify a machine’s status or perform diagnostics wirelessly through the mobile app. “ClearSky Smart Fleet is a bold, new frontier in fleet connectivity,” says Ara Eckel, director of product management for JLG’s connected solutions. “It’s a true, two-way fleet management and communication platform that turns yesterday’s one-way data transmission into two-way interactivity that gets JLG equipment fleets talking like never before.” According to Eckel, ClearSky Smart Fleet is more than yet another singular piece of software. It is built as a robust, constantly evolving IoT platform capable of delivering new functionality, new insights and new ways to run more efficient, cost-effective operations. Comprehensive Mobile App Developed from the ground up, the all-new ClearSky Smart Fleet app provides a modern mobile experience to manage data and machine interaction, even when cellular data and Wi-Fi are not available. For example, key features of the mobile app include: FIND MY MACHINE — This feature activates audible and visual cues from the machine to make equipment identification and location effortless. “With ClearSky Smart Fleet, equipment owners and operators can light a specific machine’s beacon or honk its horn with the tap of a screen,” says Eckel. MACHINE STATUS INDICATION — Visual cues from the machine allow equipment owners and operators to wirelessly identify a machine’s status, such as active diagnostic trouble codes (DTC)s, battery or fuel level, ignition and more “…simply by looking at the color of the beacon,” says Eckel. DIGITAL ANALYZER — Perform diagnostics wirelessly with the built-in analyzer functionality that replaces the JLG wired handheld analyzer. DIGITIZED INFORMATION — Access to targeted information, such as parts and technical manuals, to help solve service issues without moving a step. COMING SOON: DIGITAL ANALYZER READER — A one-page summary shows a machine’s set-up, personalities, diagnostics and fault log data, which can be downloaded and shared. User-Friendly Web Portal The ClearSky Smart Fleet web portal delivers clear, efficient navigation and powerful features for immediate visibility into a fleet’s health and performance data. To help digitize daily processes, the web portal features include: DYNAMIC DASHBOARD — Display as much data as needed through a dynamic, action-oriented dashboard. “Whether a fleet view or individual model view is wanted, powerful filters and tailored customization, including drag-and-drop window widgets,” says Eckel, “allow any role to prioritize the actionable insights necessary to maximize productivity and ROI (return on investment).” MACHINE LEVEL DATA — Access to specific serial number and asset ID data, such as interactive schematics, knowledge articles, technical manuals and parts information, can be done in seconds. EXPORT — Generate reports and export the overview dashboard as a PDF or Excel file. UNIFIED LOGIN — ClearSky Smart Fleet is now part of Online Express, allowing for single sign-on and access using Online Express credentials. “By integrating ClearSky Smart Fleet into JLG’s Online Express service, equipment owners and operators can manage a fleet, troubleshoot machine issues and order parts — everything they need to keep a fleet in top shape — with a single login,” says Eckel. COMING SOON: AUTOMATIC SITE NETWORKS — Receive notifications when a machine arrives at or leaves a job site using the site network feature. “Site Networks act like automated geofences,” says Eckel, “when two or more machines are within range of a local connection, a site network is formed automatically, simplifying equipment tracking and reporting.” Advanced API Equipment owners and operators can effortlessly combine actionable, JLG-rich, ClearSky Smart Fleet data into a current telematics solution to manage an entire mixed fleet from a single screen, no matter where they are. “Our next-generation IoT platform offers an integrated, enhanced data feed to combine actionable, JLG-rich data into our customers’ in-house solution to manage their entire mixed fleet from a single screen, maximizing efficiencies and improving ROI,” finishes Eckel. ClearSky Smart Fleet is being introduced as a phased global rollout, starting July 2023. Customers with existing JLG products can continue to use the legacy ClearSky program for their connected needs. Both platforms are integrated into Online Express, JLG’s 24/7 e-Commerce site.

Brenton names Lanel Menezes as Vice President of Sales

Lanel Menezes has been named Vice President of Sales for Brenton, a role in which he will be promoting the brand’s products and services, developing strategic plans for growth, forging customer relationships, leading sales teams, and organizing and maintaining sales operations. Brenton his a global provider in designing and manufacturing integrated end-of-line systems and machines, specializing in case packing and palletizing using both robotics and other automation. Menezes brings a wealth of industry experience to Brenton. For the past 15 years, he held various technical and commercial positions with Mettler-Toledo, a leading global manufacturer of precision technology and services used across a customer’s entire value chain. “I am excited to become the next Vice President of Sales at Brenton. I am grateful to be joining an organization respected throughout the industry and cannot wait to start this new adventure working alongside an amazing team,” Menezes said. “Joining the ProMach family is an absolute privilege, honor, and a blessing. I am looking forward making a positive difference by bringing Brenton’s proven solutions to new and existing customers.” In 2019, Menezes earned an Executive MBA in International Business from the University of South Florida. He also holds a Master’s Degree in Engineering Management, and a Bachelor of Science in Software Engineering from Robert Morris University. Menezes can be reached at Lanel.menezes@promachbuilt.com.

Buy-Lease-Rent Financing status: You better sit down for this

At this time in our economic lives this topic has a lot of pros and cons to consider before deciding what dealers need to do, what customers want to do and how dealers need to assist customers meet their goals using proper financial options. When we consider the three variables involved (buy-rent-lease)…. the pandemic equipment pricing for both new and used equipment…..interest rates along with new bank loan agreements and covenants……the inability of customers to handle the monthly nut now required if a unit is purchased or part of a long-term rental program. And then there is the collateral risk associated with lease residuals as well as book values four or five years out where the book value or residual will not even be close to reasonable once the new and used markets get back to a “normal” status where new unit pricing has decreased and there is adequate supply of used units available causing used sales to return to a “normal” as some percentage of recent new unit cost. Let’s face it folks, someone must pay for these crazy new and used costs and still make a buck doing it. Check out the auto industry to see how this is working out for them. There are dealers taking new and used cars to auction to try to get rid of them, and they are not hitting the reserves to make a deal. Banks are doing the same thing with repos. What I saw today watching CNBC is that CarMax is doing better because the glut of used cars for sale is causing pricing to soften to the point where they are improving their bottom line. The commentator also noted that more car customers are keeping their rides longer and buying used cars because they cannot afford a new one. If this same scenario repeats itself for other types of financial assets, the players will wind up in the same situation be that an OEM, Dealer, Customer or Bank. And if you think this situation is going away any time soon, think again. The supply and demand situation may continue to lower the cost to build new units, but it may be accompanied by a recession as well as continued high interest rates. In other words, this scenario of tighter money with less financing availability will take years to play out a delay out causing the value of used units (including rental units) to decrease to where you are upside down on the residual and/or book value which converts to taking losses on units purchased at pandemic rates. Is there money available for purchasing or leasing a unit. Yes, there is, but at a cost customers may not want to deal with. Interest rates could be somewhere between 8-13% depending on the FICO score, years in business and the ability to establish that you are running a profitable business. To give you some perspective on this issue I found in the June 17th issue of John Mauldin’s THOUGHTS FROM THE FRONT LINE, specifically a comment by Peter Boockvar which is as follows: “The credit crunch is here, and this will take not quarters, but years to play out if the cost of capital remains high. Understand too that many small and medium businesses have to pay an interest rate on a loan that is above 10% if they can even get one. Things in the private economy worked ok at 3-4% interest rates, not so much at 10% as were on a whole new economic playing field that I don’t think is being fully appreciated.” To which John Mauldin added. “Read that quote two or three times. An entire generation of investors and business leaders has never known a capital-constrained economy. Can they adjust? Probably, but not easily or instantly.” Let’s assume that I am one of those younger folks going through this type of economy for the first time. I have a company to run and need to have my material handling equipment operating properly to keep my efficiency levels where they need to be generating a proper Gross Profit that converts to budgeted profit and cash flow. Keeping that GP % means keeping costs where they are at because I don’t have the ability to pass on cost increases to my customers. Let’s further assume that I stay up to date on economic matters and thus expect higher costs for materials, services and especially equipment, which are big ticket items. What will my thought process be under these circumstances? Do I need new units? Can I find a used unit if I need it? Do I have anything to trade-in at these aggressive values? What will it cost to finance a new or used unit? Can I afford it? Wonder what it would cost to refurb the units I have? Maybe I should lease them? But if I am leasing new units won’t the lease cost also rise due to the cost of the units? I wonder if I can get the OEM or Dealer to buy down the interest rate. Would an RPO work for me in this situation? Can I gain enough newfound efficiency to cover the higher cost of the units? I do not want to get stuck with a residual value or book value I can’t recover. How do I avoid this? Can I just do a rent-to-rent deal for the months in the year when I need more units? How will a purchase impact my loan covenants? For that matter how will a lease impact my loan covenants? Being that I have worked primarily in two equipment industries …. material handling and construction equipment, I am comfortable calculating what a rental rate should be to cover the cost with a “standard” level of usage over a five-year period, and what to expect the residual value to be assuming proper maintenance has been incurred. Having this knowledge would also cover budgeting for the purchase of new or

Herc Holdings acquires Houston-based Champion Rentals

Herc Holdings Inc., a North American equipment rental supplier operating as Herc Rentals Inc., announced that it has acquired substantially all the assets of Houston-based Champion Rentals, Inc. (Champion). Terms were not disclosed. Champion is a full-service general equipment rental company comprising approximately 100 employees and four locations serving contractors and industrial, manufacturing and government customers in the Houston metropolitan area. The addition of Champion expands Herc Rentals’ Houston-area presence to 12 physical locations, which collectively provide general and specialty equipment rental solutions and related services. “I am pleased to welcome Champion’s team members to Herc Rentals,” said Larry Silber, president and chief executive officer. “Champion has served the Houston market since 1982 and has a strong reputation for excellent customer service and premium equipment. Our combined team and resources position Herc Rentals to be a preeminent equipment rental partner for the Houston market’s diverse mix of construction, industrial and government customers. “This acquisition supports our long-term strategy to achieve greater density and scale in select urban markets across North America to better serve both our local and national customers. In addition, Champion’s locations will facilitate the expansion of our Centers of Excellence concept for vital categories of equipment to support critical projects and essential operations throughout Houston and across the nearby Gulf region.” The transaction represents Herc Rentals’ first multi-location acquisition since it became an independent, publicly traded company in 2016. The company expects the acquisition to be accretive to its earnings in the first year. “Our disciplined capital management has contributed to a solid balance sheet, strong free cash flow and a net leverage ratio comfortably within our stated target range of 2.5x to 3.5x,” added Silber. “We are well positioned to pursue growth across a variety of fronts, including expansion of select equipment categories, greenfield and acquired locations, and niche opportunities, while remaining committed to a sound financial footing.”

AAR reports rail traffic for the week ending August 12, 2023

The Association of American Railroads (AAR) has reported U.S. rail traffic for the week ending August 12, 2023. For this week, total U.S. weekly rail traffic was 472,498 carloads and intermodal units, down 4.2 percent compared with the same week last year. Total carloads for the week ending August 12 were 224,412 carloads, down 3 percent compared with the same week in 2022, while U.S. weekly intermodal volume was 248,086 containers and trailers, down 5.3 percent compared to 2022. Three of the 10 carload commodity groups posted an increase compared with the same week in 2022. They were motor vehicles and parts, up 1,534 carloads, to 14,945; petroleum and petroleum products, up 1,419 carloads, to 9,952; and miscellaneous carloads, up 695 carloads, to 9,281. Commodity groups that posted decreases compared with the same week in 2022 included grain, down 5,695 carloads, to 14,533; chemicals, down 1,869 carloads, to 29,957; and forest products, down 1,321 carloads, to 7,415. For the first 32 weeks of 2023, U.S. railroads reported cumulative volume of 7,166,006 carloads, up 0.2 percent from the same point last year; and 7,578,973 intermodal units, down 9.4 percent from last year. Total combined U.S. traffic for the first 32 weeks of 2023 was 14,744,979 carloads and intermodal units, a decrease of 4.9 percent compared to last year. North American rail volume for the week ending August 12, 2023, on 12 reporting U.S., Canadian and Mexican railroads totaled 329,821 carloads, down 0.7 percent compared with the same week last year, and 329,158 intermodal units, down 7.5 percent compared with last year. Total combined weekly rail traffic in North America was 658,979 carloads and intermodal units, down 4.2 percent. North American rail volume for the first 32 weeks of 2023 was 20,689,575 carloads and intermodal units, down 4.1 percent compared with 2022. Canadian railroads reported 87,490 carloads for the week, up 1.9 percent, and 70,907 intermodal units, down 14.7 percent compared with the same week in 2022. For the first 32 weeks of 2023, Canadian railroads reported cumulative rail traffic volume of 5,043,304 carloads, containers and trailers, down 3 percent. Mexican railroads reported 17,919 carloads for the week, up 19.8 percent compared with the same week last year, and 10,165 intermodal units, down 3.6 percent. Cumulative volume on Mexican railroads for the first 32 weeks of 2023 was 901,292 carloads and intermodal containers and trailers, up 5 percent from the same point last year. To view weekly rail traffic, click here

Episode 411: Data in Warehousing – Dexory is transforming operations with real-time insights and autonomous robots

In this exciting episode of The New Warehouse podcast, we sit down with Andrei Danescu, the visionary co-founder and CEO of Dexory, a trailblazing company at the forefront of transforming warehousing through real-time data and autonomous robotics. Andrei Danescu’s journey from a background in Formula One racing to co-founding Dexory is a testament to his passion for pushing the boundaries of technology. Armed with expertise in data engineering and a zeal for robotics, Andrei is leading Dexory’s charge to reshape the warehousing industry with data-driven insights and cutting-edge automation. Dexory is revolutionizing how warehouses operate by harnessing the power of real-time data and autonomous robots. By seamlessly combining these elements, Dexory provides warehouses an unparalleled advantage in streamlining operations, optimizing resource utilization, and driving efficiency. Real-Time Data in Warehousing: The Heartbeat of a Modern Warehouse A pivotal shift from traditional manual processes has emerged in an era defined by the digital transformation of warehousing. Andrei underscores this shift: “We are transitioning from pen-and-paper operations to a digital twin environment.” Dexory’s technology facilitates this transition by offering real-time data insights that empower informed decision-making, streamlined workflows, and adaptive strategies. He adds, “The entire company has access to the data, and everyone can discuss specific challenges within various warehouses, all from a single source of truth.” Unlocking Efficiency through Digital Twin and AI Dexory’s digital twin platform, augmented by AI algorithms, stands as a game-changer in the quest for operational excellence. Warehouses can now create virtual replicas of their facilities, enabling them to simulate various layouts and scenarios. This AI-driven approach empowers warehouses to forecast capacity, analyze demand, and make proactive decisions for optimal efficiency. “With Dexory’s AI copilot, you can visualize different warehouse layouts, optimize resources, and ensure efficient operations. It’s like having a virtual assistant guiding your every move.” Driving Innovation through Strategic Partnerships Andrei succinctly captures the essence of this partnership: “Our collaboration with Maersk showcases the transformative impact of real-time insights and data-driven decision-making on warehousing operations, setting the stage for a more efficient future.” This collaborative venture stands as a vivid embodiment of Dexory’s groundbreaking technology, dynamically reforming accuracy, efficiency, and scalability within the industry. The path to the ‘warehouse of the future’ is being paved right before us. Key Takeaways: The shift from manual to digital operations with real-time data is shaping the future of warehousing, enhancing decision-making and efficiency. Dexory’s integration of autonomous robots, advanced sensors, and AI algorithms enables warehouses to optimize operations and resource management. Dexory’s strategic collaboration with industry leaders like Maersk highlights the tangible benefits of real-time insights in driving warehousing accuracy, scalability, and operational excellence. The New Warehouse Podcast EP 411: Data in Warehousing – Dexory is Transforming Operations with Real-Time Insights and Autonomous Robots

Cornerstone Equipment joins LiuGong North America Dealer Network

LiuGong North America has added Cornerstone Equipment to its dealer network. The Dry Ridge, Kentucky-based operation sells both construction equipment and material handling products. The business started in 2009 as an industrial equipment solutions provider. It serves the agriculture, outdoor power, construction and material handling equipment industries, and its three branches help to cover the tristate area of Kentucky, Ohio and Indiana. Devin Ponder, CEO, Cornerstone Equipment, has drawn upon his family’s roots and success with the business over the last 15 years. His parents, Bryan and Kathy Ponder, founded the business in 2009 after his dad worked for the region’s largest material handling dealership. He took over day-to-day operations at Cornerstone in 2020. While its roots were in forklifts, the company pivoted to its current line during the pandemic from 2020 to 2022 and expanded its operations in both Ohio and Indiana. The company is now blending its industrial equipment background with recent retail success to expand further, adding construction and material handling equipment. Ponder hailed the relationship already established with LiuGong team members during the recruitment process as Cornerstone Equipment joins the dealer network. “The vision of Cornerstone Equipment’s future and the LiuGong future in North America align perfectly,” he said. “Our team is uniquely qualified to be the market leaders in construction and material handling equipment sales, service and rental operations in the tristate area. “The broad product line offered from LiuGong covering both construction and material handling equipment fits our target customer base perfectly. The value of bringing machines with industry-leading components to market at an extraordinarily competitive price and lead time is exciting.” Andrew Ryan, President, LiuGong North America, expanded on the relationship they’ve developed and what Cornerstone Equipment can add to the dealer network. “There is a strong family history that Cornerstone Equipment has established, along with a pursuit of excellence and strong vision for what they want to achieve,” Ryan said. “It’s a great addition to our LiuGong dealer network across both construction and material handling equipment.” Jared Ward, Vice President, Material Handling, LiuGong North America, added the background they have within the material handling field will only strengthen the material handling dealer network. “The Cornerstone Equipment group has shown strong interest and dedication to serving material handling customers,” Ward said. “We look forward to growing with them in this space and we welcome their family to the LiuGong family of dealers.” Ponder closed by emphasizing the connection he has developed thus far. “The mission of LiuGong to be dealers’ preferred choice resonates with our team, and its organizational structure in North America supports that mission,” Ponder said. “Every LiuGong team member we met in Katy, Texas was truly professional; that’s something required for us to deliver the best customer experiences possible. “Lastly, LiuGong offers us the ability and opportunity to scale and expand our business on a regional level going forward and deliver excellent customer experiences for years to come.”