Machinery manufacturer Norwalt introduces tight tolerance, deep learning-enabled, 360-degree Bottle Inspection System

Sophisticated new machine was concepted, designed and engineered in Norwalt’s dedicated Vision Systems Lab Norwalt, a specialist in custom-built automation and line integration machinery for complex manufacturing applications, has engineered one of its most sophisticated bottle vision inspection systems to date. The company’s Vue Inspection System integrates standardized vision components with custom-made elements and deep learning tools. Norwalt’s new machine has one overarching, pioneering benefit: its ability to monitor gaging defects as miniscule at 10 thousandths of an inch on a translucent surface. It accomplishes this by using shape transformation on the sloped areas of bottles. The Vue Inspection System was concepted, designed, and engineered in Norwalt’s dedicated Vision Systems Lab. Outfitted to accommodate up to eight programmers simultaneously, the state-of-the-art facility incorporates next-gen visual inspection and deep learning tools, including emerging Artificial Intelligence (AI) vision innovations and 3D profiling. Norwalt also integrates advanced optical character recognition (OCR) and verification via optical character verification (OCV). With the Vision Systems Lab, Norwalt also designs machines that utilize closed-loop data for machine adjustments and continuous production improvements. The lab also provides gage repeatability and reproducibility (GR&R), and Type One studies when needed, as well as full evaluation of a project’s field oriented control (FOC). “Norwalt is increasingly committed to enhancing our vision capabilities, and as industry demand increases, we’re seeing an increasing number of requests for our advanced and more sophisticated systems,” said Keith Harman, Director of Business Development & Technical Sales for Norwalt.

Bobcat donates $250,000 to parks to promote sustainability and cultivate community

Five parks each receive $50,000 for park restoration, beautification or enhancement needs and a new Bobcat zero-turn mower Bobcat Company, a global compact equipment, innovation and worksite solutions brand, has extended five grants, each worth $50,000, to parks across the nation as part of its partnership with the National Recreation and Park Association (NRPA). In addition to the grant offering, every park and recreation department that applied for the grant—regardless of receiving the grant or not—will receive a new Bobcat zero-turn mower to help them accomplish more for their community spaces. The recipients of the $50,000 grants include City of Stonecrest in Stonecrest, Ga.; Davidson County Parks and Recreation in Lexington, N.C.; City of Buffalo Parks in Buffalo, N.Y.; San Antonio River Authority in San Antonio, Texas; and City of Auburn Parks, Arts & Recreation in Auburn, Wash. “Our commitment to positively impact communities is ingrained in all of us at Bobcat, and we are humbled to give back to these deserving communities in support of this mission,” said Mike Ballweber, president, Doosan Bobcat North America. “By supporting sustainability efforts today, we can offer a better tomorrow to the generations to come.” Through Bobcat and NRPA’s shared commitment to creating vibrant and sustainable community park and recreation areas, the grant dollars will support various restoration, sustainability, beautification or enhancement activities at these sites. The grant recipients’ plans include: City of Stonecrest in Stonecrest, Ga.: The City of Stonecrest, located east of Atlanta, plans to develop a walking trail at Everett Park. The new trail aims to encourage community residents to engage with the outdoors and attend the park and recreation department’s programs which include forest therapy programs, bird watching walks, summer camps, fishing and camping opportunities. The local park and recreation team will utilize the grant dollars, plus Bobcat equipment for forest mulching, grading and compacting to support development of this new ADA-compliant trail. Davidson County Parks and Recreation in Lexington, N.C.: A pollinator garden and bog garden is being developed at a newly created park called Yadkin River Park. The project is being led by the Davidson County Parks and Recreation Department in collaboration with the master gardeners of Davidson County, Catawba College Department of Environment and Sustainability, North Carolina state agencies, Town of Spencer and Friends of Rowan County. The gardens will demonstrate the resilience of the native bog plants in North Carolina, and it will also protect the surrounding community from adverse effects like water pollution and flooding. Educational signage will be on display for the public and local educators to use these spaces to teach children as they play at the nearby playgrounds. The agencies will work together to plant, mulch, maintain and teach people how these plants help the environment. City of Buffalo in Buffalo, N.Y.: The City of Buffalo Parks and Buffalo Niagara River Land Trust are partnering on a 22-acre conservation easement known as Houghton Park. What was once a dumping ground of large broken concrete slabs, bricks and stones, will become an open nature conservation area in a dense urban neighborhood overlooking the Buffalo River. The project team will leverage compact equipment from Bobcat to remove the heavy construction debris, while offering a light footprint on the sensitive landscape. The conservation area will reconstruct pedestrian trails and create access points from the area neighborhoods. San Antonio River Authority in San Antonio, Texas: The San Antonio River Authority plans to develop new trails, create two bioswales and plant native species at its 351-acre Trueheart Ranch Park which fronts the San Antonio River. These park initiatives aim to make the park more resistant to climate outcomes. After the completion of this project, the park plans to open these areas to the public and offer various programming opportunities such as fishing clinics, tent building and nature hikes. The team will utilize Bobcat equipment for use in constructing the trails. City of Auburn Parks, Arts & Recreation in Auburn, Wash.: Located south of Seattle, the City of Auburn Parks, Arts & Recreation will create a more inclusive environment for the community by creating new ADA-accessible gravel pathways at Auburndale Park. The project will reinvigorate two existing pathways to remove the outdated asphalt and replace it with crushed gravel. To complete the project, the team will use Bobcat equipment to demo the asphalt, then to install the gravel paths to proper grade. “We are so excited to help create more sustainable and resilient communities by extending grants to these deserving communities,” said Ayanna Williams, NRPA director of community and environmental resilience. “Park and recreation professionals are champions in addressing our most pressing environmental challenges and we are grateful to Bobcat for their support to improve, preserve and beautify these spaces.” Each park will begin its project this summer with varying stages of completion over the next several months.

Skyjack announces retirement of President Ken McDougall and appoints Charlie Patterson

Skyjack division announce the retirement of Skyjack President Ken McDougall, and subsequent appointment of Charlie Patterson as President, effective January 1, 2024. The two will be working together over the next several months to ensure a seamless transition for the organization. McDougall started his career at Skyjack parent company Linamar in 1987 as a tool designer, moving up into various key roles including Global Sales and Estimating Manager, and Vice President of Operations. Two-time Skyjack president McDougall’s tenure also saw the acquisition of two telehander lines from Carelift/Zoom Boom and Volvo, a crucial foundation for the company’s existing telehandler line up. More recently, McDougall led Skyjack’s immense global capacity increases. Taking the number of manufacturing plants from two in Canada to five globally, Skyjack’s potential global unit capacity is expected to increase 235% when compared to 2022. McDougall’s tenure also saw a number of successful Skyjack product launches including ELEVATE, updated boom and vertical mast lines. “It has been an honor to serve as Skyjack President during this period of immense growth and transformation. 2023 marks my 36th anniversary with Linamar and Skyjack, and over those years I have had the great pleasure of working for and with countless talented and dedicated individuals,” shared McDougall. “It has been an honor to lead the Skyjack team and I am confident that with his experience, knowledge and leadership skills Charlie Patterson will do an outstanding job in moving Skyjack forward.” Current Vice President of International Operations, Charlie Patterson started with Skyjack in 2000 as UK Sales Manager and went on to head the UK and European operations for the organization. Patterson oversaw the opening of Skyjack offices in the UK, Germany, France, Sweden and Australia and previously led sales in Asia-Pacific. “I am thrilled and honoured to take on the role as Skyjack President,” shared Patterson. “Ken has done an exceptional job moving Skyjack forward to date, and I look forward to continuing to build upon that momentum. As always Skyjack will be dedicated to being easy to do business with, while developing simple and reliable solutions for rental companies worldwide.” Patterson’s title as Skyjack President will be effective January 1, 2024 as he and McDougall work together for the remainder of 2023 to facilitate a smooth transition.

AIT Worldwide Logistics names Angela Mancuso chief human resources officer

Global supply chain solutions provider AIT Worldwide Logistics has elevated Angela Mancuso to serve as the company’s chief human resources officer. Mancuso joined AIT in 2018 as vice president of human resources and was promoted to executive vice president, global human resources in 2021. With this advancement, she becomes the sixth member of the company’s C-level team led by Chairman and CEO, Vaughn Moore. “During her tenure, Angela has allowed us to scale up the company tremendously, and I’m confident she will continue to successfully support our growth,” Moore said. “Her experience working with large organizations has been an enormous advantage for our business as we’ve expanded our footprint around the globe. The human resources structure and governance she established are critical components that contribute to the successful execution of AIT’s strategic growth plan.” In Mancuso’s five years with AIT, teammate count has tripled. Under her guidance, the human resources team has supported the organization’s growth by launching an annual core values index survey, revamping the new hire onboarding process, implementing manager training programs, introducing teammate recognition platforms, enhancing performance management procedures, integrating new team members from multiple acquisitions into the company culture, and more. “Collaborating with the executive team to recharge engagement by understanding teammate feedback, then responding with improvements to AIT’s culture is a fundamental component of my role,” Mancuso said. “It’s a great honor to help shape the company’s future by driving new processes and programs that develop talent – a key competitive differentiator.” “Our global human resources group has grown a great deal since 2018, and I could not do it without them,” she added. “I truly believe they are the best team in the industry.” Under Mancuso, AIT’s global human resources strategy in the coming years will focus on enhancing talent programs to support the organization’s expected growth around the world, including expanded use of people-data analytics to identify areas for improvement. The team will also continue to prioritize the social components of AIT’s sustainability efforts with plans to broaden diversity, equity and inclusion initiatives aimed at building a workforce that is reflective of the communities where the company operates. Prior to joining AIT, Mancuso served as chief people officer for Pampered Chef. She holds a master’s degree in human resources management from Roosevelt University as well as a bachelor’s degree in business administration from Northern Illinois University. She is an active member of the Society for Human Resources Management, and she has been a guest speaker for Argyle HR Forum, Chicago’s 101 Best and Brightest, FreightWaves’ What the Truck podcast, Glassdoor and Northwestern University’s MBA program.

Rennco debuts new Micro Vertical Cup Counter Loader (VCCL) at PACK EXPO 2023

A 30% footprint reduction without sacrificing throughput makes the Micro VCCL is a must-see Las Vegas attraction When it comes to packaging high volumes of paper cups with limited floor space – Rennco has the answer! Rennco, a ProMach brand, is debuting the new Micro VCCL (Vertical Cup Counter Loader), a solution that reduces footprint by 30% without sacrificing throughput, in booth C-3633 at PACK EXPO 2023, September 11-13, at the Las Vegas Convention Center, Las Vegas, Nevada. Rennco specializes in flexible, end-of-line packaging by providing vertical semi-automatic and automatic bagging solutions utilizing center-folded packaging material. The inception of the Micro VCCL is rooted in feedback from customers operating with limited floorspace but needing the same throughput and labor savings as achieved on Rennco’s traditional VCCL packaging systems. The solution is the Micro VCCL, a technologically advanced system that reduces footprint by 30% without sacrificing speed or reliability. At the heart of the Micro VCCL is a proprietary shuttle tower infeed that eliminates the need for the traditional staging area and belt infeed. This is where the reduction in footprint is achieved. The dual-lane tower design is capable of handling 330 cups per minute per lane. The machine also maintains cup reject and manual reload functionality for quality control. The Micro VCCL was designed in 2021 and then spent a year in beta testing with select customers with promising results. In head-to-head comparisons with larger, competitive machinery, the Micro VCCL held its own, delivering the same performance, speed, and control Rennco customers have come to expect. The machine can be integrated with upstream and downstream automation through its powerful Allen Bradley processor; customers have the option to attach a common case packer to the discharge area to increase returns in efficiency. Finally, the Micro VCCL can be configured and released to purchasing and manufacturing within hours of receiving a purchase order, a true example of Rennco’s commitment to reducing lead time through standardization. Add booth C-3633 to your PACK EXPO 2023 itinerary to see live demonstrations of the new Micro VCCL.

Defatte Equipment joins LiuGong North America Dealer Network

LiuGong North America has welcomed Defatte Equipment Inc. to its material handling dealer network. Located in the northern coastal area of Ukiah, California, Defatte has established itself for more than 20 years by growing its presence and customer following in the North Bay area, mainly Lake and Mendocino counties. Founded in 1999 as a used forklift dealer, today Defatte Supplies Sales, Rental, and Service throughout California’s Lake & Mendocino counties. The company supplies sales, service, rentals and parts to many industries within the community. It serves the construction, industrial and agriculture industries. “We’ve been growing as a heavy equipment rental and sales yard for the past 20-plus years and never taken on a line of material handling products,” said Joe Defatte, CEO, Defatte Equipment. Defatte described the key factors that led to joining the LiuGong dealer network. “We just felt that this was the next logical step in our growth,” he explained. “We chose LiuGong for their rare combination of quality and price point that we feel will fit into our market just right.” Jared Ward, Vice President, Material Handling, LiuGong North America, noted the Defatte company history and success while welcoming them on board. “The combination of Defatte Equipment’s industry knowledge and location in a great area make them an excellent addition to our growing dealer network,” Ward said. “They know how to move product and will help us continue our growth trajectory in material handling.”

Magni Telescopic Handlers adds Altorfer Rents to its dealer network

Magni Telescopic Handlers announced Altorfer Rents is now part of the Magni dealer network. Altorfer’s addition will bring Magni’s full line of telehandlers, including the rotating telehandler, heavy lift, and fixed boom telehandler models, to Altorfer’s rental customers in Illinois, eastern Missouri, Iowa, and Indiana. “We are delighted to welcome Altorfer to our esteemed dealer network,” said Joe Leinwol, chief sales officer, Magni America. “Altorfer’s reputation for outstanding service and expertise in the equipment industry makes them an ideal fit for Magni. Together we will continue to drive innovation and provide our customers with exceptional telehandler solutions.” “Altorfer Rents is excited to represent the Magni line of telehandlers as a great addition to our best-in-class fleet,” said sales manager Jon Hardy. “Our trained sales professionals are ready to show customers the benefits of lifting heavier loads to higher heights than traditional telehandlers, allowing them to complete jobs more safely, more efficiently and ahead of schedule.” With its extensive knowledge and expertise in the application, sales, parts, and service of Magni’s products, Altorfer is poised to deliver unparalleled value and support to its customers. “I am excited for Altorfer to become part of the Magni team and pair these exceptional machines with outstanding customer service in the heartland of the country,” said Jay Jude, regional sales manager, Magni America.

H&E Relocates Winston-Salem branch to Greensboro, N.C.

Effective July 17, 2023, H&E Equipment Services Inc. announces the relocation of its Winston-Salem branch to Greensboro, N.C. The new Greensboro location, just south of the airport, has easy access to I-40 and I-840 and enables H&E to serve both Greensboro and Winston-Salem more efficiently. “Our new Greensboro location is just south of the airport with easy access to I-40 and I-840,” said branch manager Hudson Essick. “Being on the west side of the city now puts us between Greensboro and Winston-Salem and allows us to serve both markets more efficiently. And with our Durham and Statesville branches within 70 miles east and southwest of Greensboro, we can quickly locate available fleet and provide faster response time to jobsites throughout the Piedmont Triad region.” The Greensboro branch specializes in the rental of aerial lifts, earthmoving equipment, telescopic forklifts, compaction equipment, generators, light towers, compressors, and more and represents Allmand, Atlas Copco, Bomag, Case, Club Car, Cushman, Doosan, Gehl, Generac Mobile, Genie, Hamm, Hilti, Husqvarna, JCB, JLG, John Deere, Kobelco, Kubota, LayMor, Ledwell, Lincoln Electric, Link-Belt Excavators, MEC, Miller, Multiquip, Polaris, Sany, Skyjack, SkyTrak, Sullair, Sullivan-Palatek, Tag, Towmaster, Unicarriers, Wacker Neuson, Yanmar, and others. Founded in 1961, H&E Equipment Services is one of the largest equipment rental companies in the nation, providing the higher standard in equipment rentals, sales, parts, and service. Branches are located throughout the Pacific Northwest, West Coast, Intermountain, Southwest, Gulf Coast, Southeast, Midwest, and Mid-Atlantic regions.

Big Joe releases new CB30 and CB35 Walkie Counterbalance Stackers

Big Joe’s new CB30/CB35 Walkie Stackers offer a next-gen alternative to sit-down forklifts Big Joe Forklifts has officially introduced the new CB30 and CB35 Walkie Counterbalance Stackers as a productive and safe alternative to traditional rider forklifts. Available in 3,000 lb. (CB30) and 3,500 lb. (CB35) capacities, these new walkie stackers are ideal for smaller facilities as a one truck solution or as a supplemental piece of equipment in larger facilities. The CB30/CB35 vehicles are an excellent choice when high speed travel is not required or where the use of rider forklifts may pose a threat to pedestrians. The Big Joe CB30/CB35 stackers offer advanced load handling capabilities and maneuverability due to their updated controls and compact chassis design, which features a cast counterweight. With 4.6 inches of maximum ground clearance, these machines can easily traverse dock transitions, streamlining the process for unloading or loading trailers. New users will find the CB30/CB35 to be extremely nimble and able to make tight turns easily via standard electric power steering and a 180-degree steer arc. These compact machines are an asset in any general material handling applications, including warehouse, manufacturing and retail deliveries from ground level when a dock or lift gate is unavailable. Big Joe’s well-known, easy-to-use designs carry into the new CB30/CB35 stackers with its intuitive and simple operation handle controls for forward and reverse travel. Additional features include proportional lift and lower levers for find load control, mass tilt, horn and a reversing switch for optimal safety. Standard features include a battery discharge indicator, key switch, hour meter and non-marking tires to protect facility floors. “Our new CB30/CB35 Walkie Stackers are a great solution to handle loads over short distances,” said Big Joe’s Chief Marketing Officer, Bill Pedriana. “We designed these machines to provide exceptional value and flexibility in smaller facilities as a one truck solution or to supplement traditional rider equipment in the biggest of operations. The new CB30/35 are a fantastic alternative to traditional forklifts, and in operations a great answer to the question we often pose, which is, ‘Why Ride When You Can Walk?’” The CB series stackers offer a two or three-stage configuration for low- or high-level handling, reaching up to a 157-inch lift height. These machines provide hydraulic tilt both forward and back for efficient handling of various load sizes. The CB30/CB35 have advanced power systems, giving your facility the option to use an AGM battery pack, industrial lead acid batteries, or a 205ah UL recognized lithium battery. When opting for Big Joe’s lithium batteries, the integrated battery management system supports opportunity charging and has no need for special infrastructure such as eyewash stations or battery watering, ultimately saving facility space, reducing complexity and increasing up time.

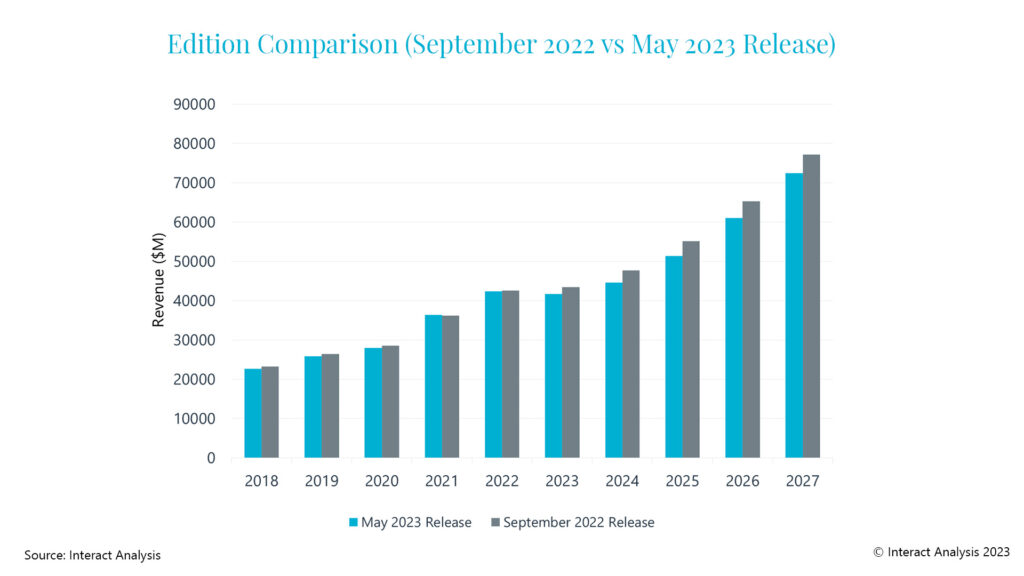

Warehouse construction declines by 25% in 2023

Demand for mobile robots has increased, while demand for end-to-end fixed automation slowed in 2022. The COVID-19 pandemic had a significant impact on e-commerce, fueling demand for warehouse automation. Total market size for warehouse automation will be 6% lower in 2027 than initially forecast, owing to a negative adjustment to our fixed automation forecast. While demand for mobile robots has increased this year, the number of new warehouses being built in North America and Europe has declined during 2023, according to new research from Interact Analysis. The market intelligence specialist reveals in the latest update to its warehouse automation premium market research report that the fall in warehouse building is having a knock-on effect on demand for end-to-end automation projects. Compared with 2022, there has been a 25% slowdown in the number of new warehouses being built in the US and Europe in 2023, and, as a result of this, demand for end-to-end automation decreased. However, the slowdown is expected to be short lived and warehouse construction is predicted to pick up again by 2025. The APAC region has been less affected by the current macroeconomic volatility; however, Interact Analysis does expects a slight slowdown in growth for this region in 2023. The mobile robot market has enjoyed exponential growth in recent years and will continue to do so over the next 5 years. Interact Analysis has increased its forecast projection for this segment of the market despite forecasting a slight downward trend for fixed automation demand. The reason for the adjustment to our forecast is mainly driven by the automated forklift segment and slower price erosions. The slowdown in e-commerce growth has had a direct impact on the demand for automation from the grocery, apparel and general merchandise segments. Traditionally, these have been the fastest growing segments, while vertical markets upstream in the supply chain, such as manufacturing, have experienced slightly slower growth. However, in 2022 demand for automation from grocery, apparel, and general merchandise slowed down as a result of the decline in e-commerce, while upstream vertical markets like durable manufacturing and food & beverage have experienced strong growth, driven by near-shoring.

Carolina Handling hosting Patriotic Forklift Auction for charity

On National Hire a Veteran Day on July 25, Carolina Handling will launch an online auction to raise funds for two veteran organizations, Folds of Honor and Upstate Warrior Solution, with the sale of a custom painted patriotic forklift. The Raymond 7000-Series Single Reach Truck features large images of Old Glory and Lady Liberty, white stars along the mast and operator cabin, and red forks. Painted by a Carolina Handling renewed shop technician, who also serves in the South Carolina National Guard, the colorful piece of material handling equipment was a photo op stop during the recent BMW Charity Pro-Am in Greenville, South Carolina, where the truck was on display outside the Carolina Handling Military & First Responders Skybox. Ideal for high rack applications, the Raymond Reach Truck is forward stance with a collapsed height of 107″ and extended height of 241″. It weighs 7,757 lbs and can lift up to 3,500 lbs. “Whether an inspirational workhorse for your warehouse or a novelty piece for your place of business, this patriotic reach truck is the perfect display of pride and patriotism,” said Carolina Handling President & CEO Brent Hillabrand. “The winning bidder also will support two nonprofit organizations doing incredible work for military veterans and their families.” All auction proceeds will benefit Folds of Honor Palmetto State Chapter and Upstate Warrior Solution. Founded in 2007, Folds of Honor awards scholarships to the spouses and children of America’s fallen and disabled service members. Upstate Warrior Solution assists veterans and their family members with housing, employment, healthcare, education and family support. The Carolina Handling Patriotic Reach Truck online auction will begin at 8 a.m. on Tuesday, July 25, 2023 and conclude at 8 p.m. on Thursday, August 17, 2023, which is National Nonprofit Day. For more information and bidding, visit 32auctions.com/CarolinaHandling.

Alta Equipment Group Inc. announces pricing of upsized Secondary Offering of Common Stock

Alta Equipment Group Inc. (NYSE: ALTG) (“Alta” or the “Company”), a provider of premium material handling, construction and environmental processing equipment and related services, today announced the pricing of an upsized underwritten secondary offering of 2,200,000 shares of its common stock, par value $0.0001 per share (the “Common Stock”) by an affiliate of B. Riley Financial, Inc. (the “Selling Stockholder”) at a price to the public of $16.25 per share. The underwriters have been granted a 30-day option to purchase up to an additional 330,000 shares of Common Stock from the Selling Stockholder. The offering is expected to close on July 25, 2023, subject to the satisfaction of customary closing conditions. Alta is not offering any shares of Common Stock in this offering and will not receive any proceeds from the sale of shares by the Selling Stockholder and will bear certain costs associated with the sale of such shares, but not underwriting discounts and commissions. D.A. Davidson & Co. and B. Riley Securities are acting as joint book-running managers and representatives of the underwriters for the offering. Northland Capital Markets is serving as a co-manager for the offering. The offering of these securities is being made pursuant to a resale shelf registration statement, which was filed with the U.S. Securities and Exchange Commission (the “SEC”) on March 25, 2020 and initially declared effective on April 3, 2020, as amended by Post-Effective Amendment No. 1, filed with the SEC on July 1, 2021 and declared effective on July 12, 2021. The offering is being made only by means of a prospectus supplement and an accompanying prospectus. A copy of the prospectus and prospectus supplement relating to the offering may be obtained, when available, by visiting the SEC’s website at www.sec.gov. Alternatively, copies of the prospectus and prospectus supplement relating to the offering may be obtained by contacting: D.A. Davidson & Co., Attention: Equity Syndicate, 8 Third Street North, Great Falls, MT 59401, (800) 332-5915, prospectusrequest@dadco.com or B. Riley Securities, Inc., Attention: Prospectus Department, 1300 17th Street North, Suite 1300, Arlington, Virginia 22209, Phone: (703) 312-9580, Email: prospectuses@brileyfin.com.

High Torques thanks to compact bevel Gear Boxes and Worm Gear Reducers

JW Winco has expanded its product range with two compact and robust angular gear boxes that translate rotational movements by 90 degrees and transmit high torques with or without a gear ratio. They are suitable for applications such as handling systems, packaging machines, and conveyor technology. The bevel gear box GN 3971 is available in seven sizes with housing lengths between 1.26 and 2.36 in (32 and 60 mm) and widths between 0.71 and 1.38 in (18 and 35 mm). The gear ratio between the gear box shafts is always 1. The direction of rotation can be selected as desired. The gear shafts can receive axial and radial forces of 13.9 lbf (60 newtons) on the smallest model and 124 lbf (550 newtons) on the largest. The special tooth geometry of the bevel gears of case-hardened steel allows for particularly high torques relative to the size. This can be as high as 10 newton meters, depending on the operating speed. Thanks to small center distances, the worm gear reducer GN 3975 measures only 2.36 in (60 mm) on the sides and only 1.38 in (35 mm) in width. An internal hardened steel screw moves a worm gear made of special brass. Seven versions provide gear ratios between 1:13 and 1:65. The maximum radial and axial force ranges between 44.96 and 112 lbf (200 and 500 newtons) on the input side and is always 112 lbf (500 newtons) on the output side. Starting with a gear ratio of 1:18, a static self-locking mechanism prevents the rotation of the worm gear from the output side, offering improved safety in many applications. The encapsulated housings of anodized aluminum make both angular gears light and corrosion resistant. They also effectively dissipate the resulting frictional heat. Numerous fastening holes make it possible to mount the gear boxes in many positions. The shafts can be rotated in both directions and feature a threaded bore and parallel keys for a positive connection to the hub. The bevel gear boxes, and worm gear reducers have lifetime lubrication and therefore require no maintenance. The two gear boxes can also be combined, such as with the elastomer jaw coupling GN 2240.

Wholesale Distribution industry opposes Teamsters strike against UPS

The strike against UPS threatens the US supply chain, impacts American families and businesses, and causes turmoil and unrest during economic uncertainty, severely wounding the already turbulent US economy The National Association of Wholesaler-Distributors (NAW), the voice of the $8.2 trillion wholesale distribution industry, that employs over 6 million U.S. workers, and is essential to our nation’s economic health and the flow of goods and services, released the following statement in opposition to the UPS Driver Strike: “Distributors and our supply chain partners are closely watching the outcomes of this negotiation,” said NAW President and CEO Eric Hoplin. “Once again, America’s supply chain and economy are being held hostage by labor unions and their plans to strike. Union Bosses are threatening our supply chain, the economy, and American families and businesses based on lofty whims and political agendas. A strike by UPS drivers affects every American household and stops the US supply chain in its tracks. Blocking millions of dollars of essential products from families, companies, and institutions that need them to live, work, build, heal, educate, transport, and protect this great nation. Without partners like our carriers, access to essential products and materials stall, putting life on hold for everyone who depends on them. Family-owned distributors make up the bulk of our industry, and many rely heavily on UPS for inbound and outbound deliveries of products to their customers, and will feel the pain acutely, with massive delays, price increases, and reduced inventory of vital goods and services. While America relies on distributors and their unique ability to get products to their destination, should talks stall, the impact and magnitude of this strike will feel similar to the disruptions seen during the global pandemic,” concluded Hoplin.

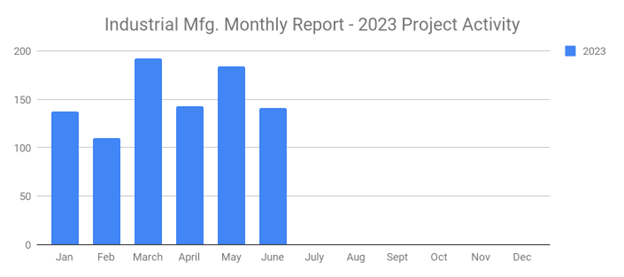

June 2023 shows 141 new Industrial Manufacturing planned project with renovations & equipment upgrades remaining constant

IMI SalesLeads announced today the June 2023 results for the new planned capital project spending report for the Industrial Manufacturing industry. The Firm tracks North American planned industrial capital project activity; including facility expansions, new plant construction and significant equipment modernization projects. Research confirms 141 new projects in June as compared to 184 in May the Industrial Manufacturing sector. The following are selected highlights on new Industrial Manufacturing industry construction news. Industrial Manufacturing – By Project Type Manufacturing/Production Facilities – 132 New Projects Distribution and Industrial Warehouse – 61 New Projects Industrial Manufacturing – By Project Scope/Activity New Construction – 38 New Projects Expansion – 46 New Projects Renovations/Equipment Upgrades – 59 New Projects Plant Closings – 17 New Projects Industrial Manufacturing – By Project Location (Top 10 States) Texas – 12 Michigan – 11 New York – 10 North Carolina – 9 Georgia – 7 Illinois – 6 Ohio – 6 Alabama – 5 Kentucky – 5 Pennsylvania – 5 Largest Planned Project During the month of June, our research team identified 18 new Industrial Manufacturing facility construction projects with an estimated value of $100 million or more. The largest project is owned by Nexen Tire America Inc., who is planning to invest $3 billion for the construction of an EV battery manufacturing facility in NEW CARLISLE, IN. Construction is expected to start in 2025, with completion slated for 2026. Top 10 Tracked Industrial Manufacturing Projects GEORGIA: Tire MFR. is considering investing $1 billion for the construction of a manufacturing facility and currently seeking a site in GEORGIA. MICHIGAN: Automotive MFR. is planning to invest $1 billion for the renovation and equipment upgrades on two of their manufacturing facilities in FLINT, MI. They are currently seeking approval for the project. ALBERTA: Fiberboard mfr. is planning to invest $790 million for the construction of a manufacturing facility in STETTLER, AB. They are currently seeking approval for the project. INDIANA: Automotive MFR. is planning to invest $632 million for the renovation and equipment upgrades on their manufacturing facility in ROANOKE, IN. They are currently seeking approval for the project. KENTUCKY: Automotive mfr. is planning to invest $591 million for the renovation and equipment upgrades on their manufacturing facility in GEORGETOWN, KY. They are currently seeking approval for the project. Completion is slated for 2025. NORTH CAROLINA: Pharmaceutical company is expanding and planning to invest $500 million for the construction of a manufacturing, processing, and office facility at 67 TW Alexander Drive in DURHAM, NC. They are currently seeking approval for the project. Construction is expected to start in early 2024, with completion slated for early 2026. TEXAS: Automotive MFR. is planning to invest $500 million for the renovation and equipment upgrades on their manufacturing facility at 2525 E. Abram St. in ARLINGTON, TX. They are currently seeking approval for the project. NORTH CAROLINA: Biotechnology company is planning to invest $458 million for the renovation and equipment upgrades on a 210,000 SF processing facility in GREENSBORO, NC. They are currently seeking approval for the project. MISSISSIPPI: Specialty building products mfr. is planning to invest $418 million for the construction of a manufacturing facility in SHUQUALAK, MS. They are currently seeking approval for the project. ALABAMA: Wood panel product mfr. is planning to invest $350 million for the construction of a manufacturing facility in OXFORD, AL. They are currently seeking approval for the project. Construction is expected to start in Fall 2023. About IMI SalesLeads, Inc. Since 1959, IMI SalesLeads, based in Jacksonville, FL is a provider in delivering industrial capital project intelligence and prospecting services for sales and marketing teams to ensure a predictable and scalable pipeline. Our Industrial Market Intelligence, IMI identifies timely insights on companies planning significant capital investments such as new construction, expansion, relocation, equipment modernization and plant closings in industrial facilities. The Outsourced Prospecting Services, an extension to your sales team, is designed to drive growth with qualified meetings and appointments for your internal sales team. Visit us at salesleadsinc.com.

Increase service department sales by training topics

I recently met with a customer discussing their service technician opportunities and while we were talking about this, we also touched on service technician training topics to help drive additional parts and service revenue. They were specifically looking into ways for their service technicians to quote and upsell additional service and parts opportunities when on a service call or routine PM service. Since it was June and National Forklift Safety Day had just passed, they specifically discussed quoting and selling more tires on these service calls. With this, let’s talk about forklift tires for this month’s article. A forklift’s tires will wear down faster than other parts on a forklift. The weight of the forklift and its load causes a lot of wear and tear on the tires. Worn out tires can be dangerous for the forklift operator. Part of the OSHA pre-operation inspection for the operator is to check the tire condition and pressure including looking for cuts and gouges. Sometimes these items get overlooked, so tires are certainly a service and parts sale that your technicians can be looking to quote to your customers. As with a pre-operation inspection performed by a forklift operator, technicians can look for the following in regard to forklift tires: Visible damage such as chunking, tearing, splitting, and cracking of the rubber. Chunking is usually a result of running a forklift in an outside application, or running over objects, or on rough terrain. As you are familiar with checking the wear on your car tires, solid rubber tires can be checked similarly. If tread distance from the manufacturer’s nameplate on the tire falls below an inch or reaches the band on the wall of the tire, or tread is no longer visible, it’s time for replacement. If a tire is flat and patching the leak or hole does not fix the tire, it will need to be replaced. Additionally, tires with visible flat spots, due to uneven alignment or sudden stops by the operator, should also be replaced. With any of these conditions found on your customer’s forklift tires, it is important to convey to them that the condition of their forklift’s tires is critical to safety and regulatory compliance. They will not want to wait until an accident occurs when tires should have been replaced. Additionally, worn tires also put stress on the rest of the lift truck’s parts and fuel efficiency. For example, as forklift tires wear down so does their ability to absorb shock. Excessive shock on a lift truck can loosen parts, cause leaks in fluid lines, and even damage electrical components. Many dealerships will offer mobile tire service with a dedicated tire service department, sometimes with specially equipped mobile units for on-site tire pressing. While other dealerships may sub-out this service to a dedicated tire service company. The process is similar to when you have your tires on your car replaced, except with the pressing and mounting of the forklift tires. Nonetheless, if your service department is servicing the truck for regular repairs and maintenance, your service technicians should not be overlooking the opportunity for a tire replacement service and parts opportunity. Forklift Tire Basics Considering how the truck will be used and the environment it operates in will go a long way to helping you quote and sell the correct tire for your customer. Rubber or Polyurethane? In general, rubber tires are used on internal combustion trucks while polyurethane (poly) tires are more common on electric lift trucks. Here are some additional factors to consider when quoting tires for your customer’s forklift: Rolling Resistance – Poly tires offer less resistance than rubber. Because they are battery-powered, electrics trucks should use poly tires to conserve energy during operation and reduce downtime for recharging. Cushioning – The higher a tire’s durometer number, the harder the tire. A softer tire absorbs more impact and provides more cushioning. Because rubber tires have a lower durometer, they should be used if a softer ride is desired. Traction – Rubber tires offer a broader footprint over poly, thus giving them better traction. If you are still inclined to use a poly tire, modern versions now offer siping, or an engraved tread pattern, that lends them greater traction. Load Capacity – Because of their higher tensile strength, poly tires are more resistant to splitting, tearing, or chunking out under load than rubber tires are. Resistance to Cutting, Tearing, and Abrasions – As a general rule, poly tires will outlast a rubber tire by about four times. This is because poly tires are harder and less susceptible to cuts, tearing, and abrasions from sharp objects. Items that might cut a rubber tire will be deflected or become embedded in the much harder poly tire. High-Speed Operation – Polyurethane tires are more likely to fail due to heat buildup than rubber tires. This is because rubber tires can dissipate the heat better. For faster-moving trucks (propane and internal combustion) that see a higher buildup of heat, rubber tires are the way to go. Floor Marking – If marks on the floor (or a lack of) are a concern to you, then selecting a non-marking tire is an important consideration. While poly tires are naturally non-marking, black rubber tires will leave marks on the floor. You can get around this with special non-marking rubber tires. Response on Wet Floors – A smooth poly tire will have significantly less traction on wet floors than a rubber tire. If your operating environment requires a poly tire, consider one that has been siped to provide better traction. Chemical Resistance – Both poly and rubber tires are susceptible to chemicals in their environment. Knowing what type of chemicals your tires will come in contact with can help you choose between rubber and poly. It is best to use the right tire to match your needs to prevent costly failures. To sum up, rubber tires are often used indoors or outdoors where a softer ride or better traction is desired. Poly

Internal audit

Back in the good old days I used to spend a lot of my professional life auditing equipment dealers and construction companies. Also did a lot of franchise work, which kind of ties in with the OEM-Dealer relationships. I was always fascinated with the full-service equipment dealers because of all the departments they had to manage to make the dealership work, keep the OEM and banks happy while also keeping the customer’s coming back. I was also lucky enough to get first-hand experience with the long-term lease (rental) with maintenance programs, which kind of locked in a relationship for 60 months or so. It was kind of pushing down the dealer management requirements down to the individual lease contracts because you were selling or renting equipment, buying and using parts, providing service, and hopefully in the end wind up with a rental unit for short-term purposes or part of the used equipment units held for sale. And in some ways the rental contracts could become even more complicated than the dealer management because of all the types of rental contracts offered. I just loved the entire program from start to finish. Though the dealer CEOs were exceptional business folks and still believe that to be true. So, I started thinking of how we used to audit these dealerships in order to complete a year end audit and give them a clean bill of health. Because of the nature of the dealer business the audit planning required some thought so that the end results were supported by the audit work performed and the documented audit results on file. Considering that we were dealing with both accounting and tax issues, planning could be more complex than expected. Listed below are the basic steps we took to audit your company. They are a bit different when compared to today’s digital techniques. We would review the prior year audit files, especially looking for the problem area for that period so we could see that the faulty issues were corrected and expected produce the correct data and conclusions in the year under audit. We would then prepare tests to determine that internal controls were working as planned, revenue and expenses are being reported in the right period and for the proper amounts, asset and related asset values are properly reported on the Balance Sheet. Bank loans and other financial contracts would all be reviewed to determine compliance with the documents. One big area was the accounting and value of fixed assets, which was primarily the fleet. What is the orderly liquidation value and what is it on the books for. This test covered both new units (and how long they have been sitting as part of the floor plan) used units and what they were on the books for compared to what they would sell for. The same questions applied to the rental units as well. IN TODAY’S ENVIRONMENT THIS WOULD BE ONE OF THE KEY TESTS GENERATED. There was also the question surrounding the maintenance contracts and how you record the maintenance revenues as part of the rental payments. I think we can all agree that recording the collection of the maintenance revenue on a straight- line basis is probably not the correct process to follow. Another questionable accounting practice was not backing out the inter-department profits, which generated higher than actual sales numbers. You are not supposed to do that, but I cannot remember more than 3-4 companies that followed this required accounting rule. And finally, the required practice of reporting current assets and current liabilities to be able to calculate working capital sometimes does not work for companies with large rental fleets. Large rental fleet assets are recorded as long-term assets, but when the current portion of the note payments are in the current liability section, you wind up with poor working capital position when in fact it may not be. This is why rental companies prepare unclassified balance sheets without the current assets and liabilities broken out. We also spent a lot of time analyzing financing agreements and bank loans, along with the required covenant calculations. Having the bankers question the accounting for their covenant calculations was to be avoided at all costs. And supporting the inventory (new and use) and rental unit values was a big part of this annual exercise. In the end our work was to determine that all the debits and credits were basically correct and recorded in the right accounting period. We also had to determine that adequate cash flows are being generated to cover debt service and other obligations. In short, that your company is a “going concern” and will not default in the near term or next 12 months. The auditors would then prepare a Management Letter spelling out suggestions for improvement and where a weakness in a control needs further review. The Department Heads were never happy with the Management Letter. Sometimes the banks weren’t either. I believe that the prior audit procedures pushed down the problems, discussions, and solutions to all levels of management to a greater degree compared to the current digital audits. Considering that all department heads had goals to meet to ensure operating results that meet the financial plan, the more they became aware of a problem along with the processes of devising solutions to mitigate the problem as well as implementing the solutions, the more chance there is to correct the problem, keep them from reappearing, and reaching the profit and cash flow goals planned for. As far as the important parts of the audit report are concerned, I find the Cash Flow report is the first page I look at. If the cash flow is adequate and there are no known potential stumbling blocks on the horizon, I am much more comfortable with the rest of the report. I guess my point this month is that there may be an opportunity available for dealers not required to provide a full audited set of financials to pick

More sales are made with friendship than salesmanship

Your mom said it best. As a child, when you were fighting or arguing with a sibling or friend, your mom would say, “Billy, you know better than that! Now you make friends with Johnny.” Your mother never told you to use the alternative of choice close or the sharp angle close on Johnny. She just said make friends. That may have been one of the most powerful sales lessons you ever got. It is estimated that more than 50% of sales are made because of friendship. In the south, it’s called “The good-old-boy network,” in the north, they say it’s “Who you know,” but it’s really just friendship selling. If you think you’re going to get the sale because you have the best product, best service or best price, dream on, Buddy. You’re not even half right. If 50% of sales are made on a friendly basis, and you haven’t made friends with the prospect (or customer) you’re missing 50% of your market. Friends don’t need to sell friends using sales techniques. Think about it. You don’t need sales techniques when you ask a friend out or ask for a favor. You just ask. You don’t need sales techniques; you need more friends. This does not eliminate your need to be a master salesman. You must know sales techniques to get the other half of the market, and sometimes even your friends need to be sold. Now think about your best customers. How did they get that way? Don’t you have a great relationship with them? If you’re friends with your best customer, it will often eliminate the need for price checking, price negotiating, and delivery time demands. You can even occasionally give bad service and still keep the customer. There’s another huge bonus to being friends. Competition is virtually eliminated. Your best competitor couldn’t blast you away from a customer who is also a friend. Most salespeople think that unless they are calling a customer to sell something, that it’s a wasted call. Nothing could be further from the truth. How do you start? Slowly. It takes time to develop a relationship; it takes time to build a friendship. (If you are reading this and thinking, “I don’t have time for this relationship stuff, I’m too busy making sales,” find a new profession, this one won’t last long.) Here are a few places to meet or take your customer. A different venue than the office will begin building friendships and relationships: a ball game the theater a concert a gallery crawl a Chamber after hours event a community help project a breakfast, a lunch, a dinner a seminar given by your company. If your customer has kids, get a few tickets to the Omnimax theater at Discovery Place and go on the weekend. Talk about solidifying a relationship. The Omnimax theater is the most fun in Charlotte, and it ain’t just for kids. Join a business association and get involved. The Metrolina Business Council is a shining example. MBC is a 14-year-old group of business owners and managers whose main objective is to do business with one another and help members get business. But MBC is not just about business, it’s about relationships and friendships ask any member. Having moved from the north to the south has helped me understand the value of business friends. They are much easier to establish in the south. I’m often in conversations where someone is lamenting the fact they can’t get into or around the so-called, “Good-old-boy” network. That is the biggest bunch of baloney, and lamest sales excuse I’ve heard. All the salesperson is saying is that he has failed to establish a relationship or make a friend AND SOMEONE ELSE HAS. You can only earn a commission using a sales technique. You can earn a fortune building friendships and relationships. ~Jeffrey Gitomer About the Author: Jeffrey Gitomer is the author of twelve best-selling books including The Sales Bible, The Little Red Book of Selling, and The Little Gold Book of Yes! Attitude. His real-world ideas and content are also available as online courses at www.GitomerLearningAcademy.com. For information about training and seminars visit www.Gitomer.com or email Jeffrey at salesman@gitomer.com or call him at 704 333-1112.

AAR reports weekly rail traffic for the week ending July 15, 2023

The Association of American Railroads (AAR) has reported U.S. rail traffic for the week ending July 15, 2023. For this week, total U.S. weekly rail traffic was 478,153 carloads and intermodal units, down 2.4 percent compared with the same week last year. Total carloads for the week ending July 15 were 225,609 carloads, up 0.9 percent compared with the same week in 2022, while U.S. weekly intermodal volume was 252,544 containers and trailers, down 5.3 percent compared to 2022. Seven of the 10 carload commodity groups posted an increase compared with the same week in 2022. They included motor vehicles and parts, up 1,828 carloads, to 14,678; nonmetallic minerals, up 1,441 carloads, to 34,008; and petroleum and petroleum products, up 581 carloads, to 9,857. Commodity groups that posted decreases compared with the same week in 2022 were grain, down 1,926 carloads, to 16,032; forest products, down 677 carloads, to 7,977; and coal, down 3 carloads, to 65,631. For the first 28 weeks of 2023, U.S. railroads reported cumulative volume of 6,266,430 carloads, up 0.5 percent from the same point last year; and 6,576,896 intermodal units, down 10.0 percent from last year. Total combined U.S. traffic for the first 28 weeks of 2023 was 12,843,326 carloads and intermodal units, a decrease of 5.2 percent compared to last year. North American rail volume for the week ending July 15, 2023, on 12 reporting U.S., Canadian and Mexican railroads totaled 329,965 carloads, up 0.9 percent compared with the same week last year, and 313,660 intermodal units, down 12.0 percent compared with last year. Total combined weekly rail traffic in North America was 643,625 carloads and intermodal units, down 5.8 percent. North American rail volume for the first 28 weeks of 2023 was 18,028,356 carloads and intermodal units, down 4.2 percent compared with 2022. Canadian railroads reported 87,054 carloads for the week, up 1.2 percent, and 49,682 intermodal units, down 36.3 percent compared with the same week in 2022. For the first 28 weeks of 2023, Canadian railroads reported cumulative rail traffic volume of 4,408,662 carloads, containers and trailers, down 2.7 percent. Mexican railroads reported 17,302 carloads for the week, up 0.0 percent compared with the same week last year, and 11,434 intermodal units, down 4.6 percent. Cumulative volume on Mexican railroads for the first 28 weeks of 2023 was 776,368 carloads and intermodal containers and trailers, up 3.8 percent from the same point last year. To view the weekly rail traffic charts, click here

Episode 403: Electric trailers from Range Energy: A unique solution to decarbonize logistics

In this episode of The New Warehouse Podcast, Kevin sits down with Ali Javidan, the CEO and Founder of Range Energy. Range Energy is taking a unique approach to electrifying fleets by focusing on electrifying the trailer rather than the truck itself. Ali Javidan has an extensive background in the automotive industry, starting with his experience in Motorsport and later joining Tesla Motors in its early days. With his deep knowledge of electric vehicles and robotics, Ali recognized the potential in electrifying trailers, leading him to found Range Energy. Be sure to tune in to hear all about how this innovative concept is decarbonizing logistics. Electrifying the Trailer vs. Electrifying the Truck One of the key topics discussed in the podcast episode is the difference between electrifying the trailer and the truck. Ali explains that Range Energy’s approach involves equipping the trailer with a fully activated electric axle, a battery pack, and a kingpin sensor system. The trailer operates independently and does not rely on a data connection with the truck. This innovative design integrates the trailer’s electric system with the truck’s propulsion system. Ali emphasizes that their system can work with current diesel tractors and upcoming electric or hydrogen-powered vehicles, showcasing its flexibility and compatibility. He also emphasizes the potential for significant fuel economy gains, estimating a 40% increase compared to current diesel tractors. “The energy consumption profile was much worse for an electric vehicle towing a trailer than a diesel or gasoline vehicle. We realized the big opportunity for decarbonization and making a real impact was to go after the class eight dry van space in the United States. Our system requires no information from the tow vehicle and can operate seamlessly using physics. We estimate a 40% increase in fuel economy from today’s diesel tractors, making it a game-changer for decarbonization efforts in the industry.” Ali Javidan Benefits of Electrified Trailers from Range Energy Another significant topic discussed in the podcast is the multitude of benefits Range Energy’s electrified trailers offer. Ali explains that Range Energy’s trailers provide a fuel economy comparable to bobtailing, allowing for substantial savings in fuel costs. The system also offers regenerative braking capabilities, enabling energy recovery during downhill descents. The trailers’ modular design and telematics capabilities allow seamless integration with existing infrastructure, such as charging stations and power gateways. The flexibility and adaptability of Range Energy’s solution make it an attractive option for companies looking to decarbonize their fleets and enhance operational efficiency. “Our system helps transition the industry into decarbonization without forcing it. It provides significant fuel economy gains, eliminates range anxiety, and enhances the towing experience for drivers. Our electrified trailers can be seamlessly integrated with existing infrastructure, and we have designed them to be compatible with future technologies, ensuring long-term viability and adaptability.” Ali Javidan Future Implications and Outlook for Electrified Trailers Looking ahead to the future, Ali shares his perspective on the potential advancements in the industry. While fully autonomous trailers may become a reality in the distant future, Ali believes that the role of drivers will remain essential for the next decade or more. He emphasizes the importance of driver safety and the need to ensure the reliability and stability of autonomous systems before removing the driver from an 80,000-pound vehicle. The ability of trailers to power other equipment, such as reefer units or lift gates, is highlighted as an example of the flexibility and future possibilities of Range Energy’s electrified trailers. “While fully autonomous trailers might be far off, yard automation is a more feasible and near-term possibility. We are building our system with a strong foundation of functional safety and compatibility to allow for future integrations and adaptations. The industry is evolving, and we want to be at the forefront of decarbonization efforts, providing innovative solutions that enhance operations and reduce environmental impact.” Ali Javidan Key Takeaways from Range Energy Electrifying the Trailer: Range Energy’s approach focuses on electrifying the trailer rather than the truck, allowing for significant fuel economy gains and decarbonization in the warehousing industry. Benefits of Electrified Trailers: Range Energy’s electrified trailers offer increased fuel efficiency, reduced emissions, regenerative braking capabilities, and improved driver experience. Their modular design and telematics capabilities provide flexibility and seamless integration with existing infrastructure. Future Outlook: While fully autonomous trailers may be a possibility in the distant future, the role of drivers will remain essential for the next decade or more. However, yard automation expects to advance more rapidly than roadway automation, offering new possibilities for efficiency and operational improvements. The New Warehouse Podcast EP 403: Electric Trailers from Range Energy: A Unique Solution to Decarbonize Logistics