New product features patented design; offers more than twice the wear life of the leading sintered bushing chain on the market

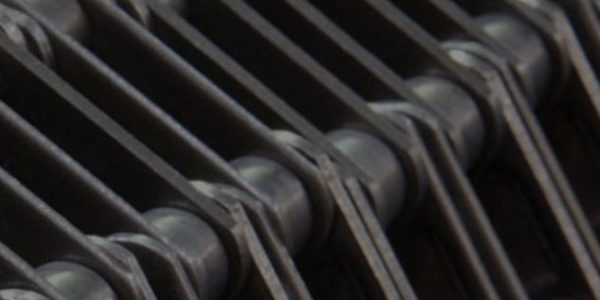

The Timken Company, a world provider in engineered bearings and power transmission products, has announced the release of Drives Element™ roller chain—a maintenance-free, sintered bushing chain designed specifically for applications where regular lubrication is not possible or practical. With more than 2.5 times the wear performance of the current industry-leading sintered bushing roller chain, Drives Element is an ideal choice for packaging, food and beverage or general applications where traditional lubrication and lubrication systems are not an option.

The name “Element” reflects the combination of three essential roller chain performance elements into a single patented design:

- Integrated Lubrication – Drives Element utilizes a premium H1 food grade lubricant with a proprietary bushing that maximizes the lubricant available to the pin, thus eliminating the need for traditional in-application lubrication and reducing the opportunity for product contamination.

- Superior Wear Performance – Extended Life CHP® chrome-hardened pins offer a smooth, hard pin surface that works in concert with the lubricant and bushing to minimize wear, thereby reducing chain elongation and providing greater than 2.5 times the wear performance of the industry-leading sintered bushing product.

- Corrosion Resistance – Element chain also features Silver Shield CR®coating on exposed surfaces, providing three times the corrosion protection of nickel-plated chain and making it suitable for high-humidity applications.

“We designed the Drives Element roller chain to be a versatile product that outperforms all other sintered bushing chains on the market,” explained Rich Neuhengen, product manager, Drives®. “The H1 food-grade lubricant allows the chain to be used in incidental contact food processing applications, while delivering outstanding wear performance for both food and industrial applications. Testing shows that the patented combination of lubrication, bushing and chrome-hardened pins delivers greater than 2.5 times the wear performance of the industry-leading sintered bushing chain, with substantial life still left on the Drives Element chain. The addition of Silver Shield allows the chain to be used in high-humidity environments where rusting may be a concern. While packaging and food and beverage applications will be common users of Drives Element, it offers a compelling value proposition for many general-purpose applications where traditional lubrication isn’t a viable option.”

The Drives Element roller chain is designed to operate at a maximum speed of 160 feet per minute and at temperatures ranging from 14ºF/-10ºC to 302ºF/150ºC. It is available in single-strand ANSI 40, 50, 60 and 80 sizes as well as double-pitch C2040, C2050, C2060H and C2080H.

Drives, a leading manufacturer of chain products, offers a broad line of superior quality precision roller chain, attachment chain and engineered conveyor chain for the world’s toughest applications. Providing the most comprehensive line of quality chain products, Drives delivers cutting-edge solutions with nearly 60 years of advanced engineering knowledge and experience.