Yale Reliant solution helps reinforce lift truck operating best practices by controlling performance based on real-time information and site-specific rules

Yale Materials Handling Corporation announces an industry-first suite of operator assistance technologies that warehouses can use to help reinforce lift truck operating best practices. The Yale Reliant™ solution automatically adjusts lift truck performance based on proximity to pedestrians and obstacles, load weight, equipment status, and location-specific rules. The technology is the product of more than 29,000 hours of research and development invested by Yale’s parent company, Hyster-Yale Group.

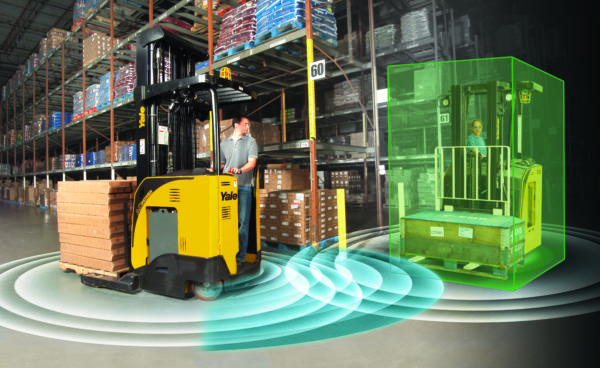

Yale Reliant is a tool for supporting operator awareness and adherence to best practices. The solution triggers audible and visual alerts to inform operators of proper operating protocols and initiates lift truck performance reduction based on facility-specific rules while leaving the operator in ultimate control of the equipment.

“Advanced dynamic stability is the core technology of Yale Reliant. It applies performance limitations to equipment without introducing a ‘jerk’ event that can upset stability – but that’s not all,” says Kevin Paramore, Emerging Technology Commercialization Manager, Yale Materials Handling Corporation. “Rather than controlling performance based solely on equipment and load status, it scales beyond that, acting based on proximity and location information to account for the complexity of warehouse environments.”

In practice, this suite of technologies enables a broad range of functionality. For example, warehouses can set the desired following distance between equipment, and Yale Reliant can automatically limit the speed to maintain proper distance. Operations can implement location-based rules to limit travel speed at the end of aisles, exclude equipment from pedestrian-heavy zones, and much more. Yale Reliant also can apply performance controls in a variety of scenarios based on truck sensors and inputs, such as restricting travel and lift functions if a load exceeds the weight limit and reducing cornering speed to avoid upsetting stability.

The Yale Reliant solution leverages three key technologies to control truck performance based on real-time information. It provides proximity detection through either local or real-time location technologies that use tags on equipment, pedestrians, and infrastructure to provide truck-to-truck, truck-to-pedestrian, and truck-to-beacon detection. For further awareness, including objects not connected to proximity tags, lidar-based technology detects obstacles in the path of travel. Advanced dynamic stability uses information from lidar and proximity detection, together with equipment-level sensors and inputs, to provide advanced traction, hydraulic, and overload control to support lift truck stability.

The Yale Reliant solution leverages three key technologies to control truck performance based on real-time information. It provides proximity detection through either local or real-time location technologies that use tags on equipment, pedestrians, and infrastructure to provide truck-to-truck, truck-to-pedestrian, and truck-to-beacon detection. For further awareness, including objects not connected to proximity tags, lidar-based technology detects obstacles in the path of travel. Advanced dynamic stability uses information from lidar and proximity detection, together with equipment-level sensors and inputs, to provide advanced traction, hydraulic, and overload control to support lift truck stability.

Yale Reliant is currently deployed on five common warehouse models and available on a select range of the company’s lift trucks.