BEHRINGER Saws, Inc. highlights the HBE511A Dynamic

Revolutionizing horizontal bandsawing in the material handling industry. Automatic bandsaw delivers cost-effective cutting for diverse material handling applications. BEHRINGER Saws,

Revolutionizing horizontal bandsawing in the material handling industry. Automatic bandsaw delivers cost-effective cutting for diverse material handling applications. BEHRINGER Saws,

YOKE Industrial Corp. has combined with global channel partners to stock more Grade 100 Eye Self-Locking Hooks at the point

The Caldwell Group Inc. has expanded its RUD In-Stock range with popular products, including the ACP-Turnado Automatic Center Lifting Point

Enhancing customer service through advanced belting solutions Motion Industries, Inc. has announced the opening of its first Canadian Motion Conveyance

Residential construction is a key market for plastics, which are essential for the production of products like pipes, insulation, siding,

Marking eight decades of excellence and growth in bulk material handling Hapman is celebrating its 80th anniversary. Founded in 1945

A new era of strength, efficiency & reliability Nordock has introduced the ELEMENT™ Mechanical Dock Leveler (Model NMF)—a robust, high-performance

MARTINS has announced the strategic acquisition of Safety Seal, a recognized leader in high-quality tire repair tools and solutions. This

Comprehensive, ready-to-use solutions for efficient and reliable load securing PAC Strapping Products highlights its full range of strapping kits designed

The Plastics Industry Association (PLASTICS) has announced two new additions to its Public Affairs team, reinforcing the association’s ongoing commitment

Datalogic has announced the launch of the PowerScan 9600 RFID, a revolutionary addition to its best-selling range of handheld industrial

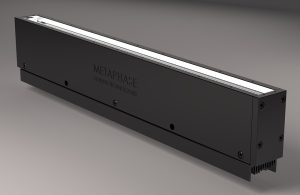

The TX ISO bar light delivers uniform, high-intensity illumination in form factors of 10 feet or more for machine vision

The UB-LL ultra-bright LED line light delivers 2.5 million lux and uniform illumination for demanding machine vision applications. Metaphase Lighting

AIT Worldwide Logistics acquires Miami-based forwarder, GSDMIA, Inc. Global supply chain solutions leader AIT Worldwide Logistics has finalized an agreement

Visit Booth 3641 to learn how Raymond’s innovative solutions can help you optimize, connect and automate your operation to enhance

The new KEEN Utility Speedworks work sneaker blends sneaker-like agility with jobsite-ready protection to deliver enhanced safety and performance. The

When it comes to securing your products for shipment, selecting the right strapping materials is critical. This decision impacts not

Kollmorgen’s new SFD-M (Smart Feedback Device, Multi-Turn) provides machine builders with high-resolution multi-turn feedback and absolute positioning information at system

Hapman highlights our Vacuum Conveyors, which are designed for efficient material movement across various industries. This line of conveyors showcases

Forklifts Group has announced it will expand its business operations to the West Coast with seven dealership locations. This will enable