Nucor Executive Vice President to retire

Nucor Corporation has announced that Chad Utermark, Executive Vice President of New Markets and Innovation, plans to retire effective June

Nucor Corporation has announced that Chad Utermark, Executive Vice President of New Markets and Innovation, plans to retire effective June

SeaCube Containers has introduced the SeaCube cold solution, a portable cold storage option designed to meet the food industry’s storage

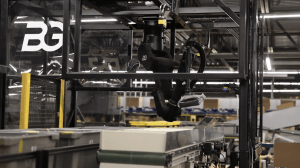

AutoStore has just announced CarouselAI™, an AI-powered robotic piece-picking solution designed explicitly for AutoStore that brings the latest advancements in

Versatile portable cooling unit revolutionizes temperature-controlled storage for warehousing needs Amerikooler, a commercial refrigeration solution, has announced the launch of

Hapman, a custom bulk material handling equipment, has highlighted our Vacuum Conveyors, designed for efficient material movement across various industries.

William Hackett, a supplier of safety-critical lifting, rigging and chain solutions, has strengthened its customer offering through a new acquisition.

New for Spring ‘25, the men’s Gibson offers a low profile that fits as well on the job site as

TVH Americas has been awarded the MVS (Most Valuable Supplier) Award for its outstanding achievements in 2024 by their industry trade

Motion Industries, Inc., has announced its forthcoming acquisition of Thompson Industrial Supply, Inc. Thompson Industrial Supply, a family-owned and operated

Tele Radio America LLC, a leading provider of wireless and radio remote controls, has expanded its product line to include

iWAREHOUSE® ObjectSense Detection & Notification System optimizes equipment, labor and data for greater warehouse productivity and operator training reinforcement Reinforcing a

ProGlove, a company that specializes in smart scanning, has partnered with BlueStar, a global distributor of B2B electronics devices. This

Kerney to lead SupplyOne’s sustainability initiatives SupplyOne, Inc. announced the appointment of Katherine Kerney as its new Director of Sustainability.

The 660,000-square-foot plant provides additional capacity ORBIS® Corporation has announced the opening of its new manufacturing plant in Greenville, Texas. The

Unirope Limited, a Canada-based specialist in wire rope and rigging products, has opened a new training center at its Mississauga

MasterMover will be making another return to ProMat 2025 in Chicago from March 17th – 20th. The electric tugger manufacturer

Hapman has announced its Vacuum Conveyors, designed for efficient material movement across various industries. This line of conveyors showcases Hapman’s

The Plastics Industry Association (PLASTICS) has announced a series of promotions, effective at the start of 2025, in addition to its announcement

The Plastics Industry Association (PLASTICS) has announced a series of new hires and promotions within its Executive Leadership Team, effective January 1,

Motion Industries, Inc. signed a definitive purchase agreement to acquire the operating assets of M.B. McKee Company, Inc. The transaction is