Brass Knuckle® Slingshot™ glasses repel fog

Proprietary BK-Anti-FOG+ is 40 times stronger than the strictest standard One of the simplest, most effective weapons used by early

Proprietary BK-Anti-FOG+ is 40 times stronger than the strictest standard One of the simplest, most effective weapons used by early

Fairlane Products, Inc. offers a complete line of both bearing mount and stud mount rollers. Rollers are designed to protect

Material handling equipment has always been required to be efficient, reliable, and safe. However, as industries evolve, the focus on

The offering gives warehouses and logistics businesses the flexibility to scale their operations to meet fluctuating demands during the peak

Felling Trailers, Inc. conducted its twelfth annual online auction of an FT-3 drop deck utility trailer to benefit a non-profit

Multiple lanes, multiple flavors. Wow. Multi-Conveyor recently built a series of stainless steel-constructed conveyors to transport cans or bottles to

Omnicon has expanded its U.S. presence by establishing operations across several states, allowing for closer client support in the region.

Motion Industries, Inc. signed a definitive purchase agreement to acquire the operating assets of Canadian-based Stoney Creek Hydraulics. The transaction

Tunable, Dimmable LED Linear Luminaires LEDtronics® has announced its latest line of LED Linear Low Bay Luminaires. These new luminaires

Integrated dryer package ensures consistent, dry, clean air in a compact, economical design PneuTech highlights the RK Rotary Screw Air Compressor

Hikvision, a world-leading manufacturer and supplier of security products and solutions that deliver the ideal combination of high performance and

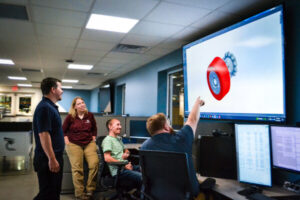

Caster Concepts has further expanded operations at their West Michigan Ave facility in Albion, Michigan to include a 3,000 square foot advanced

Rope and Sling Specialists Ltd. (RSS) will return as a lead sponsor and take a new exhibit to LiftEx 2024,

The firm will triple the size of its Chicago office in response to strong market demand, as it eyes continued

SUN Automation Group (SUN) has announced the introduction and application of the SUN625® HD Rotary Die Cutter. The first of

Versatile Appleton™ Glomaster™ LED fixtures streamline set-up with field selectable lumen output and CRT levels for safer, more productive work

Motion’s Market Expanding in Canada Motion Industries, Inc. signed a definitive purchase agreement to acquire the operating assets of Canadian-based

CL&D’s new South Carolina facility, its second in the state, positions the company to increase its flexographic production capabilities to

Innovative light, flexible, and ergonomic crane systems for safer and more productive workplaces, further expanding and enhancing Kito Crosby’s installed

NORD offers a wide selection of gear units, electric motors, and drive electronics that work in unison to deliver efficient,