Choosing the right strapping materials for your product

When it comes to securing your products for shipment, selecting the right strapping materials is critical. This decision impacts not

When it comes to securing your products for shipment, selecting the right strapping materials is critical. This decision impacts not

Nano One® Materials Corp. has announced the allowance and/or issuance of 7 new patents to its portfolio, bringing its 2024

Bluewater Battery Logistics, a provider of battery lifecycle management, has announced an official partnership with HazMat Consulting. Bluewater is helping

Navigating the world of battery transportation can feel like trying to solve a puzzle with pieces that don’t seem to

Bluewater Battery Logistics has announced that Max Khabur has joined the team as the Director of Marketing. With extensive expertise

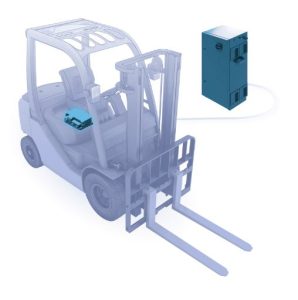

Green Cubes Technology announced the launch of its innovative Battery Retrofit Kit for OneCharge Batteries. This product offers a streamlined,

With 2024 now behind, ROYPOW is reflecting on a year of dedication and celebrating the progress and milestones achieved throughout

Founded in 2012, BSL New Energy Technology Co., Ltd. (“BSL Battery”) is an innovative lithium-ion battery manufacturer that designs and manufactures

In modern material handling, lithium-ion and lead-acid forklift batteries are popular choices for powering electric forklifts. When choosing the right

Material handling equipment has always been required to be efficient, reliable, and safe. However, as industries evolve, the focus on

Green Cubes Technology, a manufacturer of cutting-edge power solutions, announced the launch of its innovative Swappable Power Platform, designed for

BSL Battery Industrial announced that it had joined the ECOTEC (Micropower) Charger Compatibility List. This program qualifies California customers for

As logistics and supply chain management rapidly evolve, modern warehouses are being pushed to meet increasingly demanding requirements and challenges.

ZAPI GROUP, a global provider of electrification headquartered in Italy, aims to grow North American awareness of its brand’s solutions at

Universal Lithium Battery Supply (ULBS) opened its headquarters with a grand opening on September 26, 2024. Located in Brookshire, TX,

Battery Builders, a manufacturer of lead-acid batteries for the motive power industry, has announced Bobby Kehley’s appointment as the new

Green Cubes Technology has announced the launch of its Lithium SAFEFlex PLUS batteries based on UL recognized modules and the

BSL Battery – Industrial will exhibit its integrated and enhanced lithium portfolio at Logis-Tech Tokyo 2024, held at Aricke 135-oo63,

BSL New Energy Technology Co., Ltd. (Brand: BSLBATT® ), an innovative high-tech company that designs and manufactures smart lithium-ion batteries

Led by Fonds de Solidarité FTQ, the investment will accelerate the company’s growth, expand its global reach, and enhance its