Episode 345: eThium at MODEX 2022

In addition to being generous booth neighbors with snacks and coffee, eThium offers a wide range of lithium-ion technology solutions

In addition to being generous booth neighbors with snacks and coffee, eThium offers a wide range of lithium-ion technology solutions

The latest generation of the Battery Management System is built for reliability and service features Green Cubes, the leader in

EnerSys®, the global provider of stored energy solutions for industrial applications, has received the 2022 Industry Award from the Richmond

The New Warehouse Podcast welcomes Stephan Dumont and Jean-Francois Marchand from UgoWork. Based out of Canada, UgoWork manufactures lithium-ion batteries

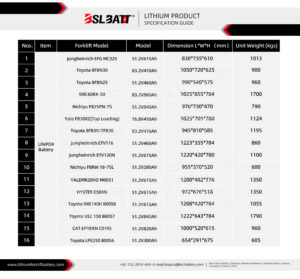

BSLBATT battery is a fast-paced, high-growth (200% YoY ) hi-tech company that is leading the adoption of lithium-ion technology solutions.

Following many decades of engineering evolution around the only power-source technology (the lead-acid battery), electric lift trucks and forklifts have

UgoWork™, a Canadian energy solutions provider specializing in the material handling industry, received a Companies-to-Watch award as part of the

UgoWork™, a provider of flexible Energy as a Service (EaaS) solutions for industrial vehicles, announced the closing of its all-equity

On this special episode of The New Warehouse Podcast, we get an education on Lithium 101 with Robin Schneider, Director

The Division provides the Plastic Injection Molded Battery Components and Terminals critical to the growth of U.S. Energy storage manufacturing

CALSTART has collaborated with the California Air Resources Board (CARB) on a market readiness and technological status assessment of zero-emission

Nano One® Materials Corp., a clean technology innovator in battery materials, has announced that, through a wholly owned subsidiary, it

FSIP’s (Flight Systems Industrial Products) exclusive ChargePlus Universal offboard charger line-up is getting a new addition: ChargePlus FLEX. This universal,

Mebane, NC expansion and investment marks another significant company milestone in the U.S. market $40 million investment to expand NC

UgoWork™, a Canadian energy solutions provider specializing in the material handling industry, just announced that its UL-listed lithium-ion battery line-up

EnerSys®, the global provider of stored energy solutions for industrial applications, has strengthened its Manufacturer Representative Agreement with Industrial Battery

UgoWork™, a Canadian energy solutions provider specializing in lithium-ion batteries and Energy as a Service (EaaS) solutions in the material

Sealed AGM, Gel, TPPL, and Lithium Ion batteries are often selected for use in golf cart fleets, pallet jacks, forklifts, scissor lifts,

The diversity in forklift lithium battery module design, chemistry composition, and form is what sets apart industrial lithium brands on

Flux Power Holdings, Inc., a developer of advanced lithium-ion energy storage solutions for the electrification of commercial and industrial equipment, today