Do you want to be a distributor of BSL lithium batteries?

BSLBATT battery is a fast-paced, high-growth (200% YoY), a hi-tech company that is leading the adoption of lithium-ion technology solutions.

BSLBATT battery is a fast-paced, high-growth (200% YoY), a hi-tech company that is leading the adoption of lithium-ion technology solutions.

The National Association for Business Resources (NABR) announced Flow-Rite Controls‘ (FRC) inclusion in its prestigious West Michigan’s Best and Brightest

Port Sustainability: Delivering Clean Energy and Performance to Ports In port and terminal operations, having trucks to ensure that cargo

CLARK Material Handling Company, a top-ten global manufacturer of forklift trucks and spare parts, has partnered with Sunlight Group to

After ten years of activity, Flight Systems Industrial Products (FSIP) has redesigned and relaunched its Material Handling Technical Forum. The new look makes navigating,

David Suarez joins me this week from the booth at MODEX 2022. David Suarez is the VP of Business Development

Yale Materials Handling Corporation extends its range of electric lift trucks with the introduction of 4,000-pound capacity integrated lithium-ion powered

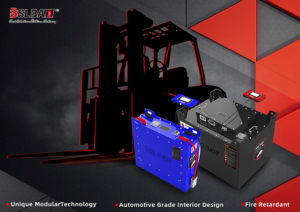

BSLBATT Battery – Industrial, is a fast-paced, high-growth (200% YoY) hi-tech company leading the adoption of lithium-ion technology solutions. BSLBATT

The event marks the expansion of the Company’s industrial supply chain footprint EnerSys®, the global provider of stored energy solutions

Forklifts are an invaluable part of a paper manufacturer’s production process and for good reason. A typical paper roll may

Joining me on this episode of The New Warehouse Podcast is Harold Vanasse from EnerSys®. Enersys is the world’s largest

Sunlight Group’s ambitions to improve lithium-ion and lead-acid battery capacity for the international market will be supported by €275m funding from

BSLBATT Battery is one of the largest lithium-ion forklift battery suppliers in China, and their partner-customer recently completed the assembly

Nano One® Materials Corp. (“Nano One” or the “Company”), a clean technology company with patented processes for the low-cost, low-environmental

The last thing you need in a warehouse is unplanned downtime due to battery failure. At BSLBATT®, they are committed

Nano One® Materials Corp. (“Nano One” or the “Company”), a clean technology innovator in battery materials, has announced the appointment

The California Air Resources Board (CARB) is planning to ban sales of all new forklifts that aren’t zero-emission by 2026.

EnerSys®, the global provider of stored energy solutions for industrial applications, joins the Industrial Truck Association (ITA) in support of

Definitive Agreement to acquire 100% of the shares of Johnson Matthey Battery Materials Ltd. a Canadian entity located in Candiac,

BSLBATT, a China Forklift battery manufacturer specializing in the material handling industry, will be exhibiting at LogiMAT 2022, from May