CES 2020 opens with innovation that will change the World

CES® 2020 opens today unveiling the next generation of innovation that will redefine industries, create jobs and solve many of society’s

CES® 2020 opens today unveiling the next generation of innovation that will redefine industries, create jobs and solve many of society’s

Forte Data VR Glove lets you “Touch” & “Feel” textures and surfaces and move digital objects as they exist in

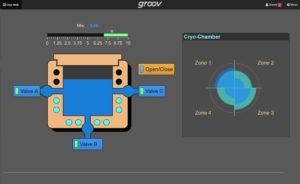

New groov View gadgets and functions come to groov EPIC along with external HDMI touchscreen management and USB file access

JLT Mobile Computers, a supplier of reliable computers for demanding environments, announces the launch of its upgraded VERSO™ Series vehicle-mount

The 2020 Equipment Leasing and Finance U.S. Economic has been released. This comprehensive report analyzes global and domestic trends impacting

Seeq’s advanced analytics solution now available as SaaS application in the AWS Marketplace Seeq Corporation, advanced analytics applications for process

U.S. manufacturing technology orders totaled $376 million in October 2019 according to the latest U.S. Manufacturing Technology Orders (USMTO) Report

Smartrac Technology Group, a global provider in RFID technology and IoT solutions, has announced that it has reached a definitive

Columbus McKinnon Corporation, a designer and manufacturer of motion control products, technologies, and services for material handling, has announced the

U.S. manufacturing technology orders fell 1 percent from the previous month to a total of $361.5 million in September 2019

Advanced feature set expands upon Latitude WMS’s existing wire cutting management capabilities and provides valuable solution to control remnants PathGuide

Smartrac Technology Group, a global provider in RFID technology and IoT solutions, and SensThys Inc., a technology company that seamlessly integrates sensors

Cutting edge telematics provider adds automated PM scheduling capabilities to its hour meter collector product, Vital. Making simple asset management

SAM, LLC, (Surveying And Mapping, LLC) a provider in providing geospatial data solutions, will be the first company in North

The new IPS 400i from Leuze electronic is the smallest camera-based positioning sensor on the market for double-depth compartment fine

Image Recognition, Weather Analysis and Green Initiatives Improve Workflows Today at Procore Groundbreak, EarthCam, the leading provider of construction camera technology, announced

Companies are now turning to robotics and other automated technologies to meet customer demands. Updating facilities with new equipment used to

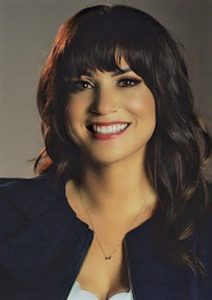

Leading Document Management Publication Selects Lujan for Her Positive Industry Impact Toshiba America Business Solutions is proud to announce that Maegan

The international technology group Körber strengthens its Business Area Logistics Systems by acquiring a majority stake in Cohesio Group Ltd.

Toshiba’s New Thermal Barcode Printers and Automated Shipping System Collaboration Ensure Shipping Speed, Accuracy and Customer Satisfaction Toshiba America Business