E Tech Group names visionary sales leader Sean Smiley as First Chief Revenue Officer

As CRO, Smiley’s leadership will strengthen E Tech Group’s sales strategy and support continued expansion across key markets. E Tech Group

As CRO, Smiley’s leadership will strengthen E Tech Group’s sales strategy and support continued expansion across key markets. E Tech Group

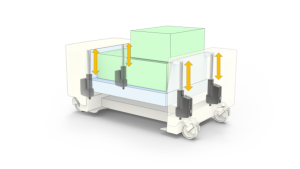

Thomson Industries, Inc. has announced the availability of an enhanced synchronization option for its Electrak® HD smart electric linear actuator. The

Tele Radio America LLC, a leading provider of wireless and radio remote controls, has expanded its product line to include

Distribution center technology provider, Lucas Systems, has announced its new software enhancements to help warehouses make quicker and more effective

Encryption solution safeguards against unapproved internal or external personnel accessing critical or proprietary information. Schreiner Group, Schreiner PrinTrust, and Schreiner

E Tech Group has received a 2025 System Integrator of the Year award from Control Engineering and Plant Engineering, part of WTWH Media. This

The offering gives warehouses and logistics businesses the flexibility to scale their operations to meet fluctuating demands during the peak

Patti Engineering CEO Sam Hoff will present “Utilizing Digital Tools for Commissioning and Life Cycle Management” at 10:00 a.m. on

EDC announces the ongoing certification achievements of its engineers in UL, Rockwell Automation, Siemens, Ignition, and other critical areas, highlighting

Cattron leverages advanced, hardened, technology to expand its offerings to various markets and demanding and specialized applications across North America.

Customizable Signal Fits a Range of Applications from Control Cabinets to Autonomous Vehicles Pfannenberg, a manufacturer of thermal management and

Signaling and indicator lights, switches, and buttons – elements that hardly any machine can do without. The new JW Winco

Continuing to expand its offerings of LED indicators for industrial, medical, and other controls and retrofit panel mount applications, LEDtronics®

H2 Clipper, Inc. (“H2C”), an aerospace and alternative energy company developing uniquely capable hydrogen-powered dirigibles, has announced that it was

Product bundle combines trailblazing Pick-by-Voice solution with best of breed wearable scanners ProGlove is joining forces with topsystem, a division

XR2 sets a new benchmark in RFID technology with unmatched speed, accuracy and affordability Janam Technologies, a provider of rugged

Electronic Drives and Controls expands its presence in the Midwest by appointing Dean Grosel as the new regional representative for

Ignition Gold Certified Integrator Patti Engineering’s Akash Agarwal has earned the Ignition Core Certification by Inductive Automation, providing certified expertise

The company’s flagship system is lauded by small municipalities and medium-sized cities that rely on the use of physical keys

Oklahoma resident brings nearly three decades of experience to his role Governors America Corp. (GAC) recently welcomed Jeff Little as