Herkules Equipment Corporation

Hayes Trading Company

Got-Rack.com

Global Material Handling

Frank H. Gill, Company

Loadsense Technologies

Arnold Machinery / Material Handling Equipment

TMI, LLC

Zorin Material Handling Company

Worthington Industries Company

Dynamic Systems, LLC

Dougherty Equipment Company

DISCOVERY SYSTEMS INC

A-SAFE TrailerKerb wins award

A-SAFE Inc. has been given a New Product of the Year award by Occupational Health & Safety (OH&S) magazine for TrailerKerb, a temporary barrier (or kerb) that provides resistance when forklift trucks get close to the edge of flatbed trailers during loading and unloading operations at the dock. A-SAFE, a manufacturer of protective guarding for warehouses, distribution centers, manufacturing facilities, and other workplace environments, launched TrailerKerb last year, since when it has been supplied directly to end-users and to the reseller/distributor marketplace. Like other products in the range, it is made from A-SAFE’s Memaplex material, the company’s patented blend of eight materials and rubber additives that, practically, absorbs impact without incurring damage. Paul Barlow, CEO at A-SAFE Inc., said: “This is a satisfying and significant moment for TrailerKerb, especially since this product was designed locally here in the U.S., specifically for the U.S. market. The award gives recognition of the efforts by the U.S. company to develop unique products for its local market, following the pioneering ethos of the business.” A-SAFE, which won in the Safety Barriers category, was among 26 companies that will be recognized with awards and covered in the November / December issue of the magazine; they are also featured on the website at ohsonline.com. The contest was judged by an independent panel of highly-qualified professionals that selected one winner in each category. Sydny Shepar, editor of OH&S magazine, said: “OH&S has been celebrating innovation and products optimized to keep workers safe for over 10 years. This year, safety products and services are being recognized on a global scale, bringing greater awareness to the important work completed by manufacturers in the industry. This year we are recognizing outstanding products in 26 award categories. Now more than ever, it is of the utmost importance to keep workers and employees safe from emerging and existing workplace hazards.” Filling a gap TrailerKerb filled a gap in the U.S. market for a product that enhances safety where loading of flatbed trailers is required from a dock. As Barlow explained, construction materials, for example, are commonly loaded from a dock, but as typical sites don’t have such docks, products must be shipped on flatbed trailers to facilitate unloading by telehandlers or other equipment. There are inherent hazards associated with operating forklifts on flatbed transportation without sides or means of protective guarding. A single section of TrailerKerb weighs just 22 lbs., measures 5 ft. 10 in. in length, and is rated at 3,000J. They will usually be supplied in sets of 12 with the option of a transport rack that can carry all pieces securely via wheels or lifted by a forklift. In a typical application, all 12 pieces will be installed from aboard the trailer then as the load is moved back, two pieces of the TrailerKerb are removed at a time. The process can be repeated in reverse if a flatbed is to be unloaded at a dock. TrailerKerb pieces are designed with two handles for ergonomic use in all instances. Barlow said: “There has been a lot of interest [in the product]; we’ve sold over 500 units now, including to roofing material manufacturers and small mobile plant equipment manufacturers. Obviously, the interest comes from companies that are loading flatbed trailers from a dock. We have now begun stocking the product locally in the warehouse to reduce lead-time. TrailerKerb is now on the second design iteration, with the addition of a rack for holding and transporting the product from the dock to dock available as well.” Judge Linda Sherrard, MS, CSP, safety consultant II at North Carolina Department of Public Safety, said: “Safety is all about the best. We train, we plan and we, as safety leadership, purchase the very best equipment, PPE, and related resources. This year’s award provides just that—thoughtful, timely products that will enhance your program and improve workplace safety, often at the fraction of the cost of one on-the-job injury. 2020 has an exceptional group of new products in many categories.” To be eligible for the 2020 awards, products must have been introduced to the market between July 2019 and July 2020.

DBCI delivers greater reliability, security for Roll-up Doors with introduction of Advanced, Slim-Profile Motors

The cutting-edge, easy-to-install motors pair with any DBCI commercial light- and a heavy-duty roll-up door, providing enhanced convenience and security. “Choosing and installing one of these new motors changes the daily operation of a site such as a warehouse or storage facility that is constantly opening and closing the roll-up doors. It’s about reliability, security, and hassle-free operation,” said Ashley Harper, product manager, DBCI. “The EasyRoller and ShedMaster models offer the latest in automatic motor technology and serve as the optimal solution for effortless operation and peace of mind for our customers.” EasyRoller features a slim profile and comes equipped with the latest intelligent safety system (ISS). The motor is compatible with ATA’s Auto-Ki Smart Phone Control Kit and features wireless safety beams for added user protection. Suitable for doors up to 16.5m2, EasyRoller has 100 watts of motor power combined with a soft start/stop function that reduces stress on the door and the opener. ShedMaster features a rugged, IP24 rated weather-resistant housing and is designed for exposed, all-weather climates such as open carports or perimeter doors. A built-in lockout system helps prevent unauthorized entry, and the operator also features wired safety beams and ISS. ShedMaster runs on a 550N DC motor and is compatible with DCBI doors of up to 15m2. EasyRoller and ShedMaster are the latest additions the DBCI’s roster of motor operators, all designed for ease of use, enhanced security, and added convenience for day-to-day operations.

Engineered Lifting Systems of Canada acquired by Gorbel® Affiliate

Gorbel Inc. announces that one of its new affiliate businesses has acquired Engineered Lifting Systems (ELS) & Equipment Inc. of Elmira, Ontario. ELS is a manufacturer, designer, and distributor of a wide portfolio of material handling products used in environments ranging from distribution centers to heavy manufacturing. Primary products produced in Elmira include Destuff-IT™/Restuff-IT™ ergonomic conveyor systems for loading and unloading containers, overhead crane systems, transfer carts, and below-the-hook lifting attachments. The integration of the two companies will begin immediately and is expected to last throughout 2021. “The acquisition of ELS allows Gorbel® to build upon our mission to Improve People’s Lives beyond our traditional overhead lifting solutions”, says Brian Reh, Gorbel® CEO. “In particular, the Destuff-IT™ and Restuff-IT™ products that protect and assist employees in distribution centers to enable Gorbel to effectively enter a market where we have had a minimal presence in the past. Additionally, we intend to add many of ELS’s other products to our overhead lifting offering thus better serving our traditional markets.” In addition to growing the manufacturing team and capacity in Elmira, Ontario, Gorbel® is expanding its footprint in the Rochester, New York area in order to meet the anticipated needs that will result from the acquisition. The increased demand for production is expected to create as many as 90 new jobs in the Rochester area during the next year.

Logitrans celebrates 80th anniversary–a look from Gitte Kirkegaard

On August 4th – 80 years ago, my grandparents established Nisap Maskinfabrik, which today is known as Logitrans A/S. Looking back at the long and exciting story, created by my parents and grandparents, I am touched and proud. Courageous, persistent, foresighted and present There is no doubt that my grandparents were courageous, persistent, foresighted, and present. They believed in their idea, and my grandfather took pride in developing and producing quality products for customers, while my grandmother honored to be present and take care of both family and employees. Their work, which was a combination of development and presence, has undoubtedly created the DNA, being the base of our company today. When my grandparents bought the bankrupt smithy in Farup 80 years ago, I am sure they could not imagine the development of our company, growing from a small smithy in Farup to a global company with a huge dealer network and production in China and sales office in the USA. From chalk lines on the floor to high-tech machines and robots. From agricultural machinery and hydraulic solutions to unique handling solutions. Many people ask: “How has this been possible?” There is no better way to tell about the first five years of the company’s existence than my grandmother´s flashback from 1998. She was 83 years old and made the following flashback. The flashback about the first five years, by the wife of Nis A. Pedersen, Ingrid Marie Pedersen (written in 1998): “Today, when I look back on the company, growing so very big, I would like to tell, how we ended up in Farup. I had a dressmaker´s workroom in Esbjerg, and Nis worked as a smith in Tarp. Nis lost his job and did not receive any financial support. He had to find a new job very quickly. Looking in the newspaper, he saw that the smithy in Farup was for sale. The smithy had gone bankrupt, and the bank had taken over the smithy and the residence buildings. After a lot of talking and some hesitation, we agreed to risk our savings, and we managed to provide the payment. On May 1, 1940, we were to take over the smithy, and on April 9, 1940, Nis went to Ribe to sign the deed. This became a day rich of memories – Nis had to accompany the German Wehrmacht back to Esbjerg – the German Wehrmacht occupying Denmark. I stayed in Esbjerg during the summer to earn money, so that electricity could be put in the residence buildings. Esbjerg was not a nice town to live in any longer – soldiers all over and the blackout time – I was pleased to leave the town on November 1. It was the coldest winter, I can remember – and we had only a little fuel. As a wedding gift, we got two loads of peat from the parents of Nis, but the peat did not last long. During spring we had to use branches from the cemetery trees – we were allowed to take the brushwood from the pruned trees. We did not have much money the first time, and right before Christmas, Nis lost his purse, containing all our money. He had to go to the municipality in Ribe and ask for pre-payment of some work in progress. This was the first and last time, we lent money for private use. And this although all the money we could make was used in the smithy. Sometimes it was hard, but I guess it helped that we could not buy anything anywhere. We learned how to remake our clothes, and many strange things were mixed so that we had something to wear. However, we also had a good and positive time. We had good neighbors, and when the streets started smelling of burned rye, we knew that we would soon gather for a cup of substitute coffee and barley meal bread. We learned to appreciate the good people, living around us, in a time when the world was out of order. We did not see the Germans very much during the first time, but one night the war was right above us. We woke up, hearing the bullets from machine guns hit the zinc roof. It was an English plane, followed by the Germans. One day the Germans suddenly arrived in Farup. Nis had soldiers around in the workshop; they were to shoe their horses. According to the German soldiers, four of them were to live in our home. I don´t remember how long they lived in our house, but suddenly they went to the frontline in Russia. We could feel that they were not fond of going there. All the time, Nis worked very hard in the workshop. We had enough to do, but there was a lack of materials and spare parts. However, nothing goes on and on, and after five long years, the war ended on 5 May 1945. We will never forget this day, nor the sight of the proud German Wehrmacht. They shuffled through Farup – no glory was left in their eyes. They were bringing old barrows, bikes and whatever might roll. They were transporting their belongings, and what they had bought for their last Danish money. Arriving at the borderline, everything was taken away from them, and they could continue empty-handed through the German country, being shot to pieces. And this was our first five years in Farup.” Today vs back then Back then, they were not separated from socializing with each other, as we are right now during the Corona crisis. However, they experienced just as many problems with the supply chain, as we are experiencing in these times. When the war was over, my grandfather saw a need from the farmers for machines that could help them grow crops and clean the stables. He developed, among other things, rubber vehicles, mowing machines, wheelbarrow, beet harvester, fertilizer spreader, and a manure removal system. The manure removal system was controlled by

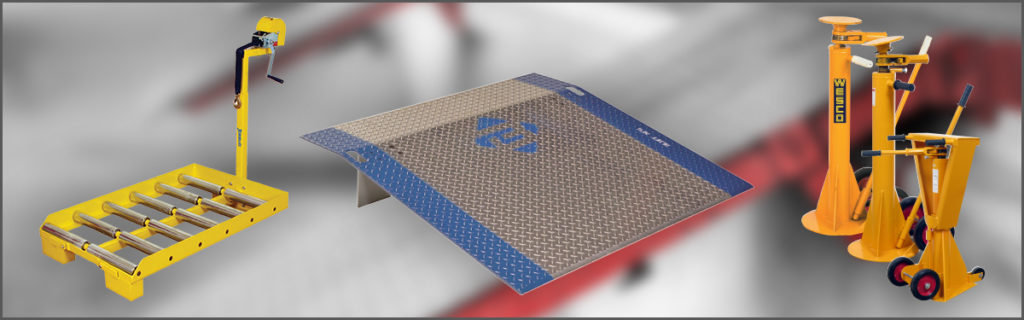

TVH ramps up product offering

TVH in the Americas (TVH), a global provider of quality replacement parts and accessories for the material handling and industrial equipment industries, is ramping up their product offering. Everyone knows that an efficient workplace is a productive workplace. They have recently added some new products from Bluff Manufacturing and WESCO Industrial Products such as dock ramps and plates, battery carts, stands, and more to help improve the overall efficiency of your worksite. Dock plates and boards can make moving large loads on and off of trucks quicker. While a plate is ideal for manual traffic only such as hand trucks or pallet jacks, the dock boards can handle the weight of a vehicle such as a forklift. The battery cart is simple and easy for one person to use, freeing up another employee for a different task. For more information on the dock plates or boards, battery carts, portable yard ramps, stands, and more, please contact one of their sales representatives. TVH has grown to become one of the most respected names in the material handling and industrial equipment industries. Our commitment to service, knowledge, and product availability has made TVH the One-Stop-Shop for our customers. We offer more than 42 million products from 16 locations in the Americas and 72 locations globally.

Episode 79 – Locix at MODEX

In this episode, I got to catch up with Matt Davidson who is the VP of Product and Marketing for Locix. He came by the booth at MODEX so we could discuss what Locix has been up to since the last time I spoke to him at ProMat. Interestingly enough, this conversation was recorded just as the COVID-19 pandemic was starting and in the weeks following Locix was able to pivot their technology to help assist in different ways which you can hear about on Episode 78 featuring Locix’s CEO Vik Pavate. Key Takeaways Locix focuses on spatial intelligence technology which can be utilized for many different purposes. For our industry, their technology can be utilized to give greater visibility at the dock which is what we primarily discussed at ProMat last year but they have expanded into visibility within the entire facility as well. SmartLPS is their solution for expanded visibility within the warehouse. As Matt explains, this takes your visibility a step beyond your WMS to give you a true idea of where your assets, like forklifts, are as well as where your associates are. This helps you to increase your efficiency and make necessary task assignments in real-time. It also tracks the historic data which can now give you tools to help make process improvements. One example is utilizing a heat map to see where there are heavily trafficked areas. By pointing these areas out you can tell if there are products in wrong slotting positions and then move them closer to your shipping area for less travel time on picking. The advantage of capturing this kind of data in real-time is that you can now make changes but immediately see the impact of your changes as well. Matt makes a really interesting point about how changing one thing may improve a certain process but then down the line make a different process worse. Utilizing the SmartLPS technology you are able to see much more quickly the negative and positive impacts of process improvements. This gives you a lot of flexibility and opportunity to improve without being so worried about a negative outcome not being identified until much later. Implementation has always been one of the biggest pain points when it comes to making improvements or upgrades in an operation. With Locix’s technology being able to identify awareness of where things are happening, it helps to identify where automation should be implemented. By doing this, it makes implementation easier because you do not end up automating beyond your needs and you also automate in the most efficient way possible. Listen and watch the episode below. EP 79: Locix at MODEX 2020 In this episode, host Kevin Lawton talks to Matt Davidson of Locix about their spatial intelligence technology. They also discuss how the increased visibility from their solutions helps to make better process improvements in your operation. For more information about Locix find their website here. To connect with Matt find him on LinkedIn here.

Gaylord Tilter loads conveyors and sorters quickly and easily

A new Gaylord Tilter from Southworth Products Corp is the fast, efficient way to get parcels and other items from gaylords and other large containers on to conveyors and automated sortation systems. The Model GTU-500 tilts loads up to 110˚ to provide controlled emptying of container contents. It features a unique pan-style platform that sits essentially flush with the floor when lowered, allowing gaylords to be placed and retrieved by a hand pallet truck – no forklift necessary. A steel retention bar prevents gaylords from falling even when the unit is tilted to the full 110˚. Unloading container contents with a tilt device like the GTU-500 makes work faster, safer and easier which translates into higher productivity and reduced workers strain and injury. The GTU-500 has a 500 lb. capacity when fully tilted. The 50” x 50” platform easily accommodates gaylords on 48” x 48” pallets. The tilt angle is operator adjustable via a foot control switch. A 1 HP power unit operates on 115/1/60 power. Compact size, just 62 1/2” x 66”, allows it to be used in confined spaces. Southworth employs the industry’s largest, most experienced engineering staff. When standard tipper products are not appropriate, they work closely with systems integrators to custom tailor unloading solutions specifically for application requirements including capacity, container dimensions, dumping speed, electrical controls, facility restrictions (ceiling height, etc.), and much more.