HYMO Limited

Zorin Material Handling Company

West Bend Division of Bushman Equipment, Inc.

Optimal Handling Solutions

Veshai Handling Equipment Co. Ltd.

US Cargotools

Florida Forklift, Inc

Fermetco, Inc.

DISCOVERY SYSTEMS INC

Southworth promotes heavy-duty Lifts for Air Cargo Containers and Unit Load Devices

Air Cargo Lifts from Southworth Products Corp are high-capacity, heavy-duty scissor lifts designed to speed and simplify the transfer of loads to and from transport vehicles to cargo terminals and off-site warehouse and distribution center facilities. The standard lift platform is equipped with inverted casters placed in a uniform grid pattern that allows cargo containers and Unit Load Devices (ULDs) to be maneuvered or moved easily across the deck in any direction. A platform deck without the caster array can also be provided. The platform deck is coated with a durable grit slip-resistant finish to provide workers with sure footing as loads are moved across it. A bolt-on side platform allows workers to stand on the side of the caster deck and can be mounted to either the left or right side. Standard lifts have a load capacity of 15,000 lbs. with higher capacities available based on application requirements. Standard platform sizes are 10’ x 13’ or 13’ x 13’; custom sizes also available. The maximum raised height is 68” to accommodate any dock height. Power is provided by a 7.5 HP 460/3/60 externally mounted power unit. Control voltage is 115/1/60. Air Cargo Lifts can be equipped with a wide range of options including truck bumpers, bellows skirting, oil heaters for cold weather climates, redundant power units, manual lowering valves, custom paint colors, etc. Units are covered by a two-year parts and labor warranty.

Blue Giant Equipment acquires Verti-Lift Inc.

Blue Giant Equipment Corporation has announced the acquisition of Verti-Lift, Inc., October 9, 2020. Verti-Lift manufactures a complete line of scissor lift tables and ergonomic material handling equipment. Located in Louisville, Kentucky, Verti-Lift has been producing lift tables, tilters, upenders, work positioners, and turntables for the North American market for over 10 years. “Verti-Lift’s product offering and years of experience are a great complement to Blue Giant,” said Bill Kostenko, Chairman, Blue Giant Equipment. “Our shared core values such as innovation, quality manufacturing, and customer service further enhance our ability to provide a full in-plant product solution.” “Verti-Lift is excited to join the Blue Giant team,” said Wayne Dodge, Verti-Lift, President. “Blue Giant’s proven investment in leading-edge technology and infrastructure will allow us to be an industry leader in the lift table product category.”

LiftWise® introduces LiftMaster 4000 Lift Table

Designed for maximum convenience and versatility, the new LiftMaster 4000 lift table from LiftWise® has a fully lowered height of only 8.5 inches. It can be used to lift and lower a wide variety of parts into the ideal position for maintenance, service and other needs. Featuring a low profile and compact design, the LiftMaster 4000 is a valuable addition to any heavy equipment shop, repair facility or other service operation. The LiftMaster 4000 has a maximum capacity of 4,000 pounds when raised. Fully extended, the lifting table rises to 27 inches. A wide pedestal with vertical protrusions gives the lifting surface a saddle-like feel to allow for safely securing loads. Additionally, optional a flat tabletop and arm attachments can be used to better lift various components, such as rock guards, pumps, belly guards and engine covers. Actuated by a hand pump handle, the double-acting pump allows the operator to reach the maximum height in fewer pumps than competitive units on the market, saving time and effort. A simple pull of the ergonomic trigger lever gravity lowers the table to its compact 8.5-inch height. Four oversized swiveling casters (2 front swivels with brakes and 2 rear swivel locking) enhance maneuverability and positioning of the table. When not in use, the pump handle can be folded over the table for simplified storage. The LiftMaster4000 was initially designed and manufactured by a specific need in the field. Consequently, LM4000 has become a standard product for LiftWise. In addition to developing its own LiftWise line of products, the experienced technical staff at Diversified also offers engineering design services to help provide clients with innovative engineered solutions to solve unique jobsite problems.

The Crosby Group names new General Manager

The Crosby Group has appointed Thomas Dietvorst general manager, load monitoring, as David Ayling, the former owner of the Straightpoint (SP) company steps into a consultancy role. Dietvorst will take the reins at SP’s manufacturing facility and headquarters, co-located in Hampshire, UK that became Crosby’s center of excellence for load monitoring and measurement following the January 2019 acquisition. He will report to Jason Colwell, managing director, EMEA at Crosby. Ayling, meanwhile, will transition from his temporary role as global business development director for load monitoring solutions to long-term consultant. Dietvorst said: “There is no replacing someone who has lived the company for 20 years. I’m not trying to be the new Mr. Loadlink [Ayling’s blogging pseudonym]. The new leadership role is suited to my skill set, not David’s; we’re different but very similar. I wouldn’t be equipped to do what he does and vice versa. Our priority is to retain SP’s ‘secret sauce’, which is based on being agile, mobile and customer orientated. We’re looking at adding even more data and processes to the operation; there’s always room for improvement.” Dietvorst, 30, was previously a strategic marketing manager at Crosby, based in Belgium, having joined the company two years ago as product manager. Suitably, there has been a constant product centricity to his career, having overseen the launch of an 85-plus tonne shackle range and many other research and development programs. Additionally, he has led to marketing and training projects. Dietvorst, a Belgian, will relocate to the Havant area near SP’s facility, with travel and commitments at Crosby Europe in Heist-op-den-Berg in his home country making up the remainder of his time. He has a Masters in Science in Product Development (MSc) from the University of Antwerp, and a Masters in General Management (MBA) from the Vlerick Business School. Ayling said: “As I wrote in my final blog, an MBA without the DNA is useless, but Dietvorst brings the latter in spades. We couldn’t have found someone more suited to the role. Thomas can take the company in a direction that I wouldn’t have been able to as the owner of two decades. He sees things from an exciting, fresh perspective, which is great news for staff, distributors, end-users and the entire SP community.” Dietvorst acknowledged that there are challenges to face, and the early throes of leadership have been and will continue to be, impacted by the COVID-19 outbreak. He said: “We are keeping in regular contact with our customers. Our vertically integrated manufacturing structure will enable us to limit the negative impact on supply chains. “The more planned steps were to make sure the whole team is comfortable. The captain has left and a new—let’s be honest—the young guy has taken over. Importantly, David will be here in a supporting role so it’s not a case of ‘goodbye, you’re on your own’. The fact that he’s only seconds away at the end of the phone will be invaluable going forwards.” He continued: “While we are constantly looking for ways to improve, I don’t see any major recruitment or restructuring in the immediate future. I have to become accustomed to leading a larger group in the SP team but that’s a challenge I relish. I also need to adapt to a more electrical and digital world than the mechanical nature of Crosby products, while the respective customer bases are different in that both serve rigging shops but there is the weighing systems side to SP too. Of course, I need to learn and respect the differences between Belgian and English cultures as well.” Away from the workplace, Dietvorst is a self-confessed tinker-man; he enjoys building and enhancing sailing boats (Havant is on England’s southern coastline) and has a farmhouse at home that serves as an ongoing renovation and construction project. With a well-traveled father who spent years in the Middle East and Australia, Dietvorst considers himself an international citizen. He added: “We wouldn’t have arrived at this point via such smooth transition if it wasn’t for David’s vision, guidance and support over recent weeks. He is an impossible act to follow and only with continued access to his unrivaled insight can we be successful in the immediate and longer-term. I owe him a great deal of gratitude.”

Gaylord Tilter loads conveyors and sorters quickly and easily

A new Gaylord Tilter from Southworth Products Corp is the fast, efficient way to get parcels and other items from gaylords and other large containers on to conveyors and automated sortation systems. The Model GTU-500 tilts loads up to 110˚ to provide controlled emptying of container contents. It features a unique pan-style platform that sits essentially flush with the floor when lowered, allowing gaylords to be placed and retrieved by a hand pallet truck – no forklift necessary. A steel retention bar prevents gaylords from falling even when the unit is tilted to the full 110˚. Unloading container contents with a tilt device like the GTU-500 makes work faster, safer and easier which translates into higher productivity and reduced workers strain and injury. The GTU-500 has a 500 lb. capacity when fully tilted. The 50” x 50” platform easily accommodates gaylords on 48” x 48” pallets. The tilt angle is operator adjustable via a foot control switch. A 1 HP power unit operates on 115/1/60 power. Compact size, just 62 1/2” x 66”, allows it to be used in confined spaces. Southworth employs the industry’s largest, most experienced engineering staff. When standard tipper products are not appropriate, they work closely with systems integrators to custom tailor unloading solutions specifically for application requirements including capacity, container dimensions, dumping speed, electrical controls, facility restrictions (ceiling height, etc.), and much more.

Pallet Leveler has operator controlled height adjustment

The Presto ECOA Lift P3 Operator Controlled Load Leveler increases productivity and improves worker safety in manual pallet loading and unloading operations. The unit can be raised or lowered at the touch of button to position the top layer of boxes at the most comfortable, easy-to-access height. It is the ideal load leveler choice when precise load positioning is required or when load weights, pallet sizes or product dimensions vary greatly and frequently. The P3 Operator Controlled Load Leveler’s platform has an integrated turntable that sits on anti-friction bearings, allowing users to spin the load so they are always loading and unloading from the same spot with no need to reach across or walk around the pallet. The unit’s base is equipped with fork pockets which provide exceptional stability – no lagging required – and allow it to be easily moved to a different location with a forklift or stacker. Two models are available with 2,000 or 4,000 pound capacities. Both units operate on standard 115V power. A 1 HP motor operates hydraulic cylinders which raise or lower the platform from a low height of 9-1/2” to 27 ¾”. Lifting and lowering is controlled via a footswitch or hand pendant. In addition to the standard configuration, P3 Operator Controlled units can be furnished with a wide variety of options including phenolic or solid steel disc covers, square or rectangular solid tops, bellows accordion skirting, one-touch auto leveling, an access step and special finishes including special paint colors, chemical resistant coatings, two-part epoxies, hot-dipped galvanizing and stainless steel construction.

Verti-Lift portable lift tables

The Verti-Lift Portable Scissor Lift Table Series is available as either Manual (foot pump) for heavy duty applications or Electric Hydraulic (push button hand pendant) for light duty and heavy duty. These units provide the flexibility of the scissor lift with the portability of an adjustable work platform, and are ideal when transporting heavy loads from work cell to work cell. Whether the objective is operator ergonomics or transferring a load from one work area to another, the Portable Scissor Lift Table provides both maneuverability and flexibility.

Wildeck, Inc. wins 2019 Elevator Industry Award

Company Takes First Place in “Best Supplier – Special Application Lifts” Category Elevator World, Inc. named Wildeck, Inc. “Best Supplier – Special Application Lifts” as part of their 2019 Elevator Industry Awards program. “The Ellies” is sponsored annually by Elevator World, Inc. to recognize North American elevator and escalator industry businesses that go above and beyond for their customers, employees, communities and the industry as a whole. To be eligible to receive this prestigious award, companies must be first nominated by a customer, employee or other professional with ties to the organization. “Our customers have always told us we design, build and market the best lifts in the industry,” said Dave Milner, Wildeck’s Vice President of Sales and Marketing. “We are grateful that our peers and clients reaffirmed our quality and workmanship with their votes.” Wildeck will be featured in the December 2019 issue of Elevator World and will receive a custom Ellies statuette to display in their office and at various industry events. Those interested in learning more about Wildeck’s comprehensive lifting line should plan to visit booth 207 at the National Association of Elevator Contractors’ (NAEC) 70th Annual Convention and Exposition in Grand Rapids, MI on September 16-19. Headquartered in Waukesha, WI, with additional manufacturing operations in Goodyear, AZ, Wildeck, Inc. is a member of MHI (Material Handling Industry Association), MHEDA (Material Handling Equipment Distributors Association), FMA (Fabricators & Manufacturers Association, International) and the NAEC (National Association of Elevator Contractors).

Packline Materials Handling announce the release of new Roll Handling Equipment

New to Packline Materials Handling and Ultrasource LLC is the fully motorised roll handling equipment with dual action powered lifting and rotation of large rolls of foil, film and packaging materials. This lifting equipment is manufactured mainly from stainless steel which makes it ideal for the pharmaceutical, food and drinks industries, and other hygienic applications. The vertical spindle attachment has been designed to suit the lifting and rotation of large rolls of film, foil, paper and various packaging materials which have a core diameter of three inches (76mm) or six inches (152mm). The dual action vertical spindle is fully motorized and allows the rolls to be lifted or lowered, as well as being rotated to and from the vertical and horizontal orientations. These actions can be carried out simultaneously. The lifting, lowering and rotation actions are achieved via a handheld ‘pendant’ which provides the operator with easy operation and precise control. In addition, a further powered drive is provided for the roll gripping and release actions with the rolls being securely gripped by the core. This mechanism has a torque limiter fitted so that the clamping fingers do not over or under tighten in the core. These features combine to enable the operator to lift and handle rolls with complete confidence and safety. The attachment has been specifically designed to provide a high load capacity with great strength and durability as well as improved wear resistance providing an enhanced ease of use with a simple and safe action. This roll lifter has a 200 kg maximum capacity however, larger capacities and to suit greater reel widths, may be available on request. This attachment is manufactured from stainless steel and anodised aluminium which makes it entirely suitable for the pharmaceutical and food industries and other hygienic applications. Furthermore, it is backed up by a full bespoke design service so ensuring that the right solution can be made to suit most reels. All Packline attachments are fully interchangeable and can be easily fitted or removed from any model of Compac lifting machine that is fitted with the quick release system. This stainless-steel roll lifting machine is suitable for use in the following industries: Food Drinks and Beverages Dairy Pharmaceutical Medical Chemical FMCG (Fast Moving Consumer Goods)

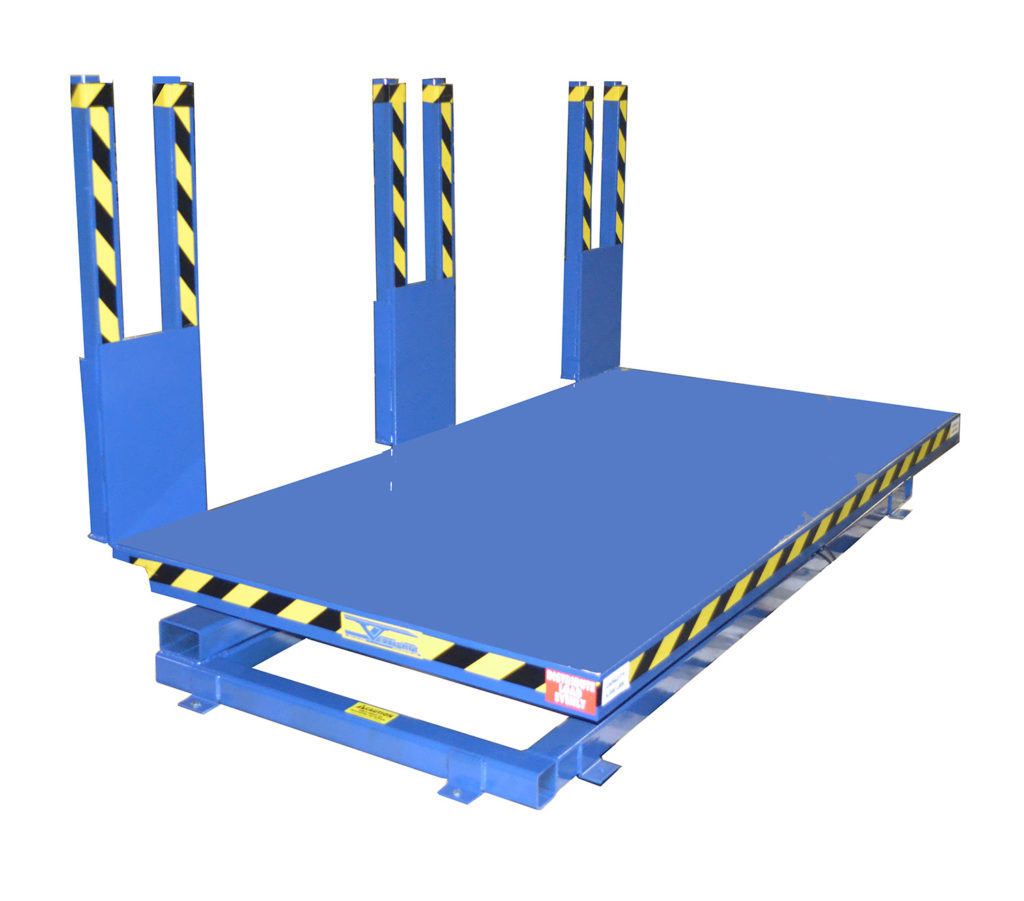

Verti-Lift Floor Level 90 Degree Tilt with Removable Forks

Making it easier, safer and more productive Verti-Lift presents versatile Floor Level 90 Degree Tilt Tables with Removable Forks. These are the ideal solution for any manufacturing or assembly application where the process requires work in the horizontal and vertical positions. With the flexibility of removable forks while in the horizontal position, and a range of 0 – 90 degrees, workers are allowed 360-degree access to the product while in the horizontal position, while the vertical position allows access to manufacturing and assembly processes of difficult to reach areas in the vertical position. Removable forks allow pallet jack or fork truck loading or unloading in the vertical position. Forks are ideal for applications where product (feet or wheels) need to be installed at the base of the product. Assembly can be accomplished in the horizontal position, the product rotated 90 degrees, and the product set on the floor where it can simply roll to the next process or be moved by pallet jack in areas where fork truck space is limited. Verti-Lift Floor level 90 Degree Tilt Tables with Removable Forks are the ideal solution for many applications including panel build, furniture manufacturing, locker or metal enclosure manufacturing and assembly, corrugated, wood, or sheet handling. Verti-Lift manufactures a complete line of standard and custom materials handling and ergonomic equipment including Hydraulic and Pneumatic Scissor Lift Tables, Hydraulic and Pneumatic Tilters, Hydraulic 90 Degree Upenders, Hydraulic and Pneumatic Work Positioners, Turntables, Operator Lifts, Platform Trucks, Work Stations, and much more. All products are made in the USA and are available through Material Handling Distributors nationwide.