Celebrate Propane’s Versatility and Reliability on National Propane Day, October 7th

The third annual celebration recognizes propane’s impact on powering Forklifts, Vehicles, and more The Propane Education & Research Council (PERC)

The third annual celebration recognizes propane’s impact on powering Forklifts, Vehicles, and more The Propane Education & Research Council (PERC)

In the latest episode of The New Warehouse podcast, Kevin welcomes an influential figure in the energy sector—Tucker Perkins, CEO

Forklifts are an everyday essential in material handling operations, which is why forklift safety is a top priority in the

Port Newark Container Terminal emissions data shows propane far surpasses diesel in terminal tractor emissions reduction New data released from

Grant funding applications are now open for safety, efficiency, and reliability improvement projects The U.S. Department of Transportation Maritime Administration

Forklifts are essential for any warehouse, distribution center, or production facility, and choosing the right energy source for forklifts has

The National Propane Gas Foundation Scholarship Fund (NPGF/SF) program kicked off on Dec. 15. Children of employees of NPGA member

New Crosby Balanced Diaphragm and Bellows leak detection pressure relief valve solutions improve performance, safety, and reliability while reducing emissions

Gavin Hale joined the Propane Education & Research Council as vice president in charge of business development, PERC President and

Fleets can take advantage of the credits starting in 2022 The Propane Education & Research Council (PERC) is encouraging warehouse

The Propane Education & Research Council (PERC) is celebrating its inaugural National Propane Day on October 7, 2022. PERC is

Hi Pro, Inc., a nationwide mail logistics contractor with a 40-year history of servicing the United States Postal Service, celebrated

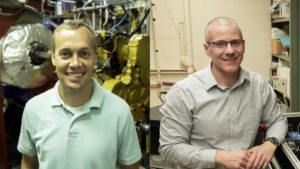

Mechanical Engineering Associate Professor Sage Kokjohn and Co-Investigator Professor Dave Rothamer recently received a grant from the Department of Energy – National Energy Technology Laboratory (NETL) to

The Propane Education & Research Council has introduced new training for cylinder delivery drivers which is now available in The

Why propane forklifts are cleaner and more productive Many challenges are facing material handling operations today—labor, rising energy costs, supply,

The Propane Education & Research Council (PERC) is hosting a new webinar focused on Forklift Safety as part of its Propane Presents Technology Series beginning

Supply chain professionals are facing many challenges right now—labor shortages, rising energy costs, and increased demand, just to name a

Research reveals low-emission propane forklifts can assist with decarbonization This Earth Day, the Propane Education & Research Council (PERC) is

Propane is uniquely positioned to deliver on the promises of landmark national initiative A new $1.2 trillion law to improve

Responding to California’s mandate to ban internal combustion engine forklifts in the near future, the Propane Education & Research Council