2025 MHI Innovation Award finalists announced

MHI just released the list of finalists for the 2025 MHI Innovation Awards. After receiving 234 submissions for this year’s

MHI just released the list of finalists for the 2025 MHI Innovation Awards. After receiving 234 submissions for this year’s

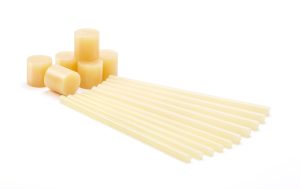

Brands, converters & packers can support the circular economy with latest adhesive innovation Marking a world-first, UK-headquartered Power Adhesives has

With hidden strobe technology Smart Vision Lights (SVL), a design and manufacture of innovative LED illumination solutions, has introduced the

Fairbanks Scales Inc., the oldest scale company in the U.S. and leader in weighing equipment, announces its new HC Lift

Noblelift 4-Wheel Electric Forklift One of the best values on the market, the FE4P55N 5,500lb capacity electric forklift provides powerful

Numina Group, an independent systems integrator, announces the release of Victory Voice, its advanced solution for creating the fully voice-enabled

RedLore, today at MODEX 2022 in Atlanta, GA, launched a high-resolution version of Locus Site, a patented solution for high-accuracy on-site positioning,

Murata Machinery USA, Inc. expands its logistics & automation product offerings with an extensive line of automated guided vehicles (AGVs).

At MODEX 2022 in Atlanta this week, MHS (www.mhsglobal.com), a provider of material handling automation and software solutions, unveils a

The Raymond Corporation, a Toyota Industries Company, will showcase innovative intralogistics solutions at MODEX 2022 held March 28 to 31 at

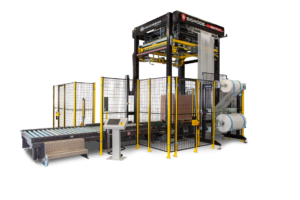

Signode, a global manufacturer of a broad range of automated packaging equipment, tools, consumables, packaging automation, and warehouse automation solutions,

New accessory improves operators’ ability to organize up to 100 pounds of material Hy-Brid Lifts, an industry provider in high-quality,

Couplings from JW Winco transmit rotary motions and torques from shaft to shaft. They also even out tolerances and mechanical

Second-generation lift features extended bin reachability, maximizing space and reducing costs Leading warehouse automation company, AutoStore, announces the launch of

Gorbel® Inc., an industry leader in overhead material handling, ergonomic lifting, and industrial fall protection, announces they will be showcasing

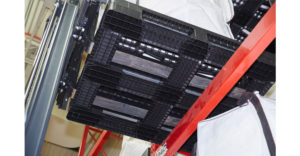

ORBIS® Corporation, an international leader in reusable packaging, will highlight the intersection of automation with sustainability in reusable packaging solutions at