Caldwell launches custom lifting beam with LGH

A new lifting beam that enables forklifts to more efficiently carry longer loads is now in service. LGH approached Caldwell

A new lifting beam that enables forklifts to more efficiently carry longer loads is now in service. LGH approached Caldwell

YOKE Industrial Corp. has combined with global channel partners to stock more Grade 100 Eye Self-Locking Hooks at the point

Rick Mikut, Chad Rados, and Brian Meek are on the move Comings and goings at the ALL Family of Companies have

Compact, lightweight, electric-powered models designed to meet modern job site demands JLG Industries, Inc. has announced its newly rebranded JLG®

A Raimondi LR213 is currently operating at a height of 322m The deployment of the LR213 required extensive site planning

Carolina Handling has been named a top performer by Modula Inc., a manufacturer of vertical lift modules and automated storage

Dedicated to rewarding people-first culture PFlow Industries has announced that it has been named a 2025 Top Workplace winner, for

All Material Handling, Inc. (AMH) marks 22 years of unwavering commitment to customer satisfaction, quality products, and expert service. Founded

LGH (Lifting Gear Hire) has officially launched in Australia. Headquartered in Somersby, Central Coast, New South Wales, the Australian business will

WireCo® has announced the launch of OLIVEIRA Durascend, one of our latest rotation-resistant compacted ropes. After an extensive process of

Today, Oshkosh Corporation, an innovator of purpose-built vehicles and equipment, announced that Keith Allman, an Oshkosh director since 2015, has

When a landmark building in Nottingham required the replacement of its fabric tensile roof covering, the subcontractor tasked with this

Versatile VRC Improves Efficiency and Prioritizes Worker Safety PFlow Industries highlights the 21 Series Hydraulic Vertical Lift, an ideal solution for

William Hackett is expanding its customer offering with new digital solutions. The UK-based manufacturer adds RFID chips to its popular

NORD supplies complete drive solutions for crane applications, including powerful MAXXDRIVE industrial gear units, high efficiency geared motors, and drive

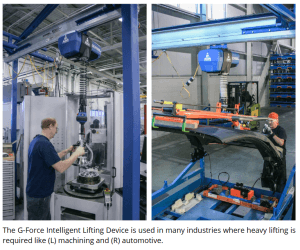

Gorbel® is set to celebrate the 25th anniversary of its groundbreaking G-Force® Intelligent Lifting Device. This device marked a significant

Visit booth #S1956 to see how versatile VRCs improve efficiency and worker safety PFlow Industries will showcase its vertical material

Peter Brettner, CEO of AMH, stated: “While there are numerous options available for good quality hoists, finding one with significant

William Hackett, a supplier of safety-critical lifting, rigging and chain solutions, has strengthened its customer offering through a new acquisition.

The Lifting Equipment Engineers Association (LEEA) has announced the return of Global Lifting Awareness Day (GLAD) 2025 on Thursday, June