Tetra Pak and University of Georgia launch North America’s first Tetra Recart trial facility

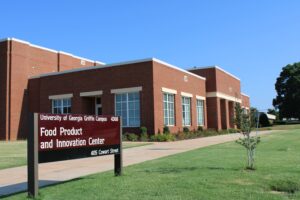

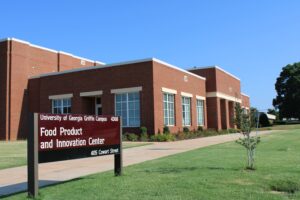

The Food Product Innovation and Commercialization Center (FoodPIC) supports the development of food products from concept to shelf Tetra Pak and

The Food Product Innovation and Commercialization Center (FoodPIC) supports the development of food products from concept to shelf Tetra Pak and

NPE2024 Captivates and Inspires Global Leaders and Rising Stars to Shape the Future of the Plastics Industry NPE2024: The Plastics

Company to showcase label feeders and product solutions to simplify automation. IDENTCO will highlight its automation capabilities and PCB labeling

The Marsh Bellofram Group of Companies has announced a reorganization of its sales territories and a new, more holistic approach

The largest plastics trade show in the Americas embraces learning & networking opportunities all week long NPE2024: The Plastics Show received

Robroy Industries® Enclosures Division has announced the appointment of Alex Erwin as its Central Region Business Development Manager. Erwin has

A team from the Columbia Machine Inc. Palletizer Division joins Techmatik S.A., a Columbia Machine Company, in Poland for Warsaw

The Plastics Industry Association (PLASTICS)has announced brand-new features ahead of its upcoming trade show, NPE: The Plastics Show, taking place from May 6-10,

ProMach has announced that it has acquired Etiflex. The addition of Etiflex further expands ProMach’s labeling and coding capabilities throughout North

Cabka, the market leader in reusable transport packaging made of recycled plastic publishes its Annual Report 2023. It includes both

Mark Hodgins brings unique experience and expertise to lead Company’s global marketing efforts Shurtape Technologies, LLC has announced the addition

Time Tested, Future Forward: Celebrating Corrugated’s Storied Past and Bright Future The organizers of SuperCorrExpo® has announced that registration for

By optimizing storage and distribution processes, the Spanish supermarket chain has improved productivity, waste reduction, customer satisfaction, and employee safety

DuraLabel has announced the immediate availability of its new Kodiak Max, industrial sign and label print systems. Kodiak Max allows

Loftware Cloud enables companies to conquer supply chain complexities, ensure supplier compliance, and improve traceability Loftware has unveiled Loftware Cloud at

ORBIS® Corporation has announced it is entering into a lease-to-own agreement for manufacturing space in Greenville, Texas, with EPM Partners of

Daubert Cromwell, a provider of anti-corrosion packaging for industry, has named Rodrigo Martinez to succeed retiring Luis Jacome as Daubert

Bedford Reinforced Plastics will showcase its ReadySeries lineup in booth A10005 at the MODEX trade show. This will be Bedford’s inaugural appearance at MODEX, held March

Numina Group’s alliance with Weber Packaging Solutions enhances its mission to offer fully integrated, end-to-end, top-tier warehouse automation solutions that

FOX IV Technologies, a label print and apply equipment design, will proudly introduce the FOX IV 6974 Label Printer-Applicator at