Orbital Wrapper Manufacturer introduces dual dispensing on fully automated wrapping system

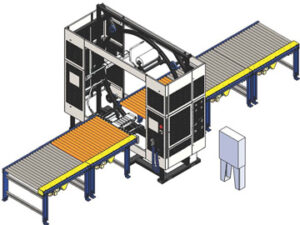

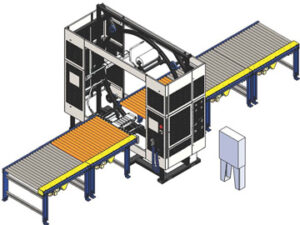

TAB Wrapper Tornado Perfect Storm applies two stretch wrap rolls at the same time Orbital wrapper manufacturer TAB Industries, LLC,

TAB Wrapper Tornado Perfect Storm applies two stretch wrap rolls at the same time Orbital wrapper manufacturer TAB Industries, LLC,

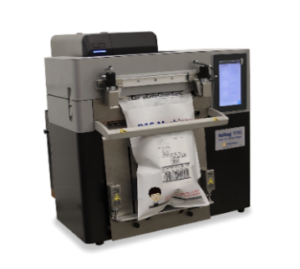

Confidential and complimentary, new GHS L.A.B.E.L. Profile helps companies labeling hazardous chemicals follow compliance best practices. Reliance Label Solutions, which

New, reusable bulk container offers increased shipping efficiencies and storage optimization across various industries ORBIS® Corporation adds a new pallet, top

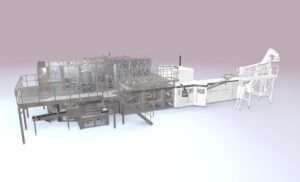

ProMach, a processing and packaging solutions, has announced that it has acquired Zanichelli Meccanica S.p.A. Known to the market as

IDENTCO also will demonstrate its robust VortexID automated wire marking system, and PCB label series with company-exclusive substrate. IDENTCO, a

Engineered to load and unload trailers or floor-loaded products, the Destuff-it™ offers an ergonomic solution for an industry facing rapid

Supply chain leaders and executives attending MODEX 2024 this March will have the opportunity to see the latest in sustainably

Enhancements include faster packing speeds and several new programming modes. HexcelPack, a developer of eco-friendly, paper-based protective packaging solutions to

Myers Industries, Inc., a manufacturer and distributor of industrial products, has announced that it has completed its acquisition of Signature

MODEX 2024 booth #B6019, attendees will discover how Cimcorp’s automation helps grocery retailers, bakeries, and dairies improve speed, sanitation, and

Experienced sales executive Matthew Powers will lead sales efforts for prominent packaging machinery provider throughout the North-Central United States Omega

ProVeyance Group will be exhibiting at MODEX 2024 from March 11th through March 14th at Georgia World Congress Center in

Darrin Snarr has been appointed Regional Sales Manager for Orion, a role in which he will serve as an advisor

Another year, another record for the patented TAB Wrapper Tornado. Packaging machinery manufacturer TAB Industries, LLC has broken its record for

Sensitive beverages and flexible systems and solutions are the topics in focus at the KHS trade show booth for this

PAC Machinery, a packaging industry with a range of equipment, will exhibit at MODEX 2024 several packaging options that save

SupplyOne, Inc., an independent supplier of corrugated and other value-added packaging products, equipment, and services in the U.S., announced that

Assessing the plastics industry landscape in 2023 reveals a year marked with nuanced shifts across various sectors. From the fluctuations

Episode 448 of The New Warehouse Podcast features an engaging conversation with Nick DiNatale, co-founder and CEO of ShipPlug. ShipPlug

December is the time for holiday giving, but one Connecticut manufacturing company has been giving back to those who served