Shaft Collars and Couplings for food processing and conveyors

A full line of shaft collars, rigid shaft couplings, and mounts that are corrosion-resistant for applications requiring frequent wash-down has

A full line of shaft collars, rigid shaft couplings, and mounts that are corrosion-resistant for applications requiring frequent wash-down has

Rice Lake Weighing Systems’ powerful line of dimensioning solutions now includes the iDimension® LTL XL, designed specifically for freight with

Renewable Lubricants new Bio-Blast™ Penetrant is a high-performance, fast-acting, biodegradable penetrant that eradicates rust and dirt to quickly free corroded

Mactac®, a LINTEC Company, announces it has completed the acquisition of Spinnaker Coating, LLC, representing $130 million of specialty revenue

The new Sparta 2 is a fresh update on KEEN Utility’s core athletic work sneaker, designed for light industrial tasks,

Ruland quick clamping shaft collars require no tools for installation, adjustment, or removal, making them a convenient and efficient choice

Renewable Lubricants presents patented Bio-Ultimax™ 1000, readily biodegradable biosynthetic formulas which perform like mineral oil-based hydraulic fluids but are environmentally

KION North America has announced that Dade Lift Parts & Equipment has joined the KION North America dealer network. Dade

Machines and systems always require stability. Heavy-duty, large-size elements also emphasize the quality of the objects they support. JW Winco

Unified branding, upgraded parts ordering website improve the parts buying experience for Hyster® and Yale® customers Hyster-Yale Group announces the launch of

AttaBox® Enclosures, the world’s most specified polycarbonate, and non-metallic electrical and industrial enclosures have announced the latest product innovation for

Helmar has lumber forks ready to ship in popular sizes. Lumber Forks are made in various widths with a typical

Much has been written in the past decade about the demographic shift from “boomers” to “millennials”. I was born in

DELLNER BUBENZER has announced the launch of the new SB 28.5 disc brake, which is now available to the global

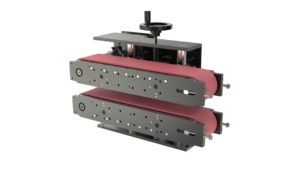

Caterpillar Pullers from Versa Pullers provide uniform pressure over the entire traction length, thus exerting greater pulling force without product

FSIP, a provider in manufacturing, remanufacturing, distribution, and electrical system design for the electric vehicle industry, announced the promotions of

Demand for industrial products has risen considerably over the past two decades — and with that, we’ve seen an increase

Pfannenberg, a global manufacturer of thermal management and signaling technologies, highlights the durable PA 1 PATROL Series Sounder, ideal for

Motion Industries, Inc., a distributor of maintenance, repair, and operation replacement parts, and a premier provider of industrial technology solutions,

Master Magnetics, Inc. announced the promotion of three team members to key positions on the senior management team. “In our