Enerpac Tool Group announces Scott Vuchetich appointed EVP – Marketing and President – Americas

Enerpac Tool Group Corp. has announced that Scott Vuchetich has joined the Company as EVP — Marketing and President –

Enerpac Tool Group Corp. has announced that Scott Vuchetich has joined the Company as EVP — Marketing and President –

TVH Americas, a global provider of quality replacement parts and accessories for the material handling, industrial, and light construction equipment

Force Control Industries announces the retirement of sales and marketing leader Stan Porter who will depart at the end of

TVH Americas, a global provider of quality replacement parts and accessories for the material handling, industrial and light construction equipment

Creform Corporation has designed and built a compact AGV with the fabricated cart that provides a manufacturer with the ability

TVH Americas, a global provider of quality replacement parts and accessories for the material handling, industrial, and light construction equipment

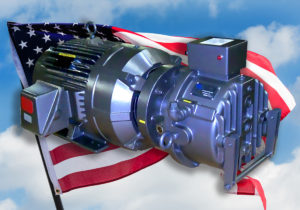

Force Control Industries introduces a quick ship program for MagnaShear™ motor brakes, with American-made parts ready for assembly in as

LEDtronics answers the call for low-cost, long-lasting, and reliable solutions to retrofit panel mount applications with their new PNL-1106 Series

Available in several blade designs and lengths from 10 – 40 inches Metal construction and precision cut rubber for durability

In my August 2021 column, I discussed the importance of deconstructing departmental silos in our dealerships. Silos, as we discussed,

Swapping out a forklift, order picker, or other electric machinery battery once per work shift is time-consuming and involves inherent

TVH Americas, a global provider of quality replacement parts and accessories for the material handling and industrial equipment industries, offers

Wherever something needs to be adjusted, you will often find locking joints at work with serrations that define specific angle

Based in Lancaster, Pa. for more than 45 years, Lumsden Corporation will remain a part of the Central Pennsylvania business

TVH Americas (TVH), a global provider of quality replacement parts and accessories for the material handling and industrial equipment industries,

Major trailer manufacturers are taking initiatives to increase safety for passenger vehicles by reinforcing their rear impact guard (RIG) bars

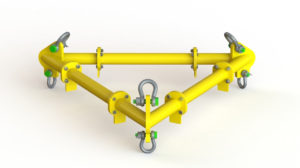

Modulift, a technical expert and manufacturer in the lifting industry based in the UK, has added a new product to

The Crosby Group, a global manufacturer of rigging, lifting and material handling hardware, is proud to team up with Bridges

Creform Corporation, a manufacturer of unique products for the design and building of material handling structures and automated guided vehicles

Expanding their product offering, Panacea Aftermarket Co. presents to you their BEAST Smart Forklift Scales. All metal construction, 3.5-inch tough