3M announces departure of Chief Financial Officer

3M announced today that Monish Patolawala, President and Chief Financial Officer, will resign effective July 31, 2024, to pursue another

3M announced today that Monish Patolawala, President and Chief Financial Officer, will resign effective July 31, 2024, to pursue another

During my recent travels and meetings with industry colleagues, dealers, and OEMs, many discussions took place exploring the dynamics and

Jungheinrich, RAVAS EUROPE, SAFELOG with Mercedes, SSI Schäfer, and STILL have been announced as winners of the IFOY Award 2024.

Shipments of cutting tools, measured by the Cutting Tool Market Report compiled in a collaboration between AMT – The Association

In April’s edition, I wrote about the topic of data-driven decision-making. In one instance, I discussed how most dealerships I

NORD’s new gear motor QR codes link to convenient digital services for unit documentation, service and sales contact requests, and

The mini pump with max performance! The CMS M series, the latest addition to COVAL‘s range of multistage vacuum pumps

I recently attended MODEX 2024, and this year’s show was highly anticipated by professionals across our industry. Automation, robotics, software

Where are forklifts made? Contrary to the prevailing notion that little is manufactured in the USA nowadays, the majority of

Genuine Parts Company has announced its board of directors has appointed James F. Howe to the position of President, Motion, the

To celebrate the Iowa Hawkeyes and Iowa State Cyclones runs to the Sweet 16, the National Bobblehead Hall of Fame

One of the MHEDA’s 2024 Material Handling Business Trends states, ‘Technology is profoundly impacting the material handling industry including artificial

TVH Americas, a global provider of quality replacement parts and accessories for the material handling, industrial, and construction equipment industries,

As we are well into the first quarter of 2024, the subject of labor shortages continues to be a trend

Motion Industries, Inc., a distributor of maintenance, repair and operation replacement parts, and a premier provider of industrial technology solutions,

Can you believe we’re already in January? Cheers to the New Year! I hope as you read this, your business

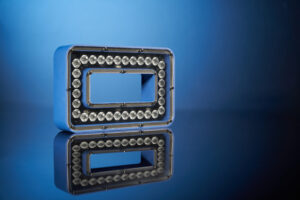

Smart Vision Lights (SVL) launched the JWL225-DO Lightgistics series light, which combines a linear light footprint with ring light functionality to deliver

CLARK Material Handling Company has announced the appointment of Jerry Dolan as Aftermarket Regional Sales Manager for CLARK North America.

December has arrived and as we close the books on another great year, there is again uncertainty for what is

OEM’s and Lift Truck dealers have always been paying close attention to what is happening in the auto industry, thinking