Rice Lake’s new iDimension® Pallet Dimensioning System

Rice Lake Weighing Systems has launched a new pallet dimensioning system specifically designed for over-length freight. The iDimension LTL XL

Rice Lake Weighing Systems has launched a new pallet dimensioning system specifically designed for over-length freight. The iDimension LTL XL

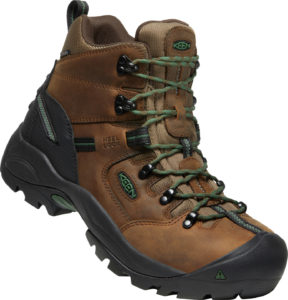

The KEEN Utility San Jose Oxford perfectly bridges the gap between board meeting and floor meeting. Introducing the fan favorite

You’ve probably experienced the frustration and inefficiency of not having fork extensions when you have a long or bulky load

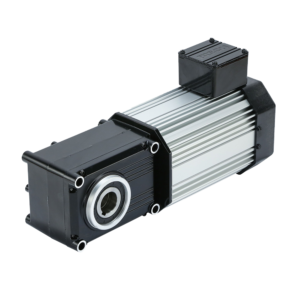

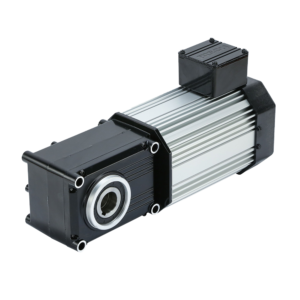

Bison Gear & Engineering Corp., a provider in the power transmission industry, announces its proven PowerSTAR® high-efficiency right angle gearmotor

It is an honor to be the newest Aftermarket columnist for Material Handling Wholesaler. When Dave reached out to inform

This month, Material Handling Wholesaler is recognizing the many contributions women make in the business. Here are a few of

The new machine improves product quality and increases production capacity Bison Gear & Engineering Corp., a provider in the power transmission industry,

Two key businesses within The Timken Company’s Industrial Motion group, belts and chains, gave back to the local community by

For the past six years, I have had the distinct honor of writing for Material Handling Wholesaler. When I left

Fairbanks Scales Inc., the oldest scale company in the U.S. and the world’s leader in weighing equipment, announces it will

Nilodor Waste Container and Dumpster System takes the guesswork out of clean The customer experience starts in the parking lot

TVH Americas, a global provider of quality replacement parts and accessories for the material handling, industrial, and construction equipment industries,

TrueSource, an OnPoint Group Company and the national leader in critical facility maintenance for retailers and property managers announced the

FSIP, (Flight Systems Industrial Products), a provider in manufacturing, remanufacturing, distribution, and electrical system design for the electric vehicle industry,

Bison Gear & Engineering Corp., a provider in the power transmission industry, announces its proven PowerSTAR® high-efficiency right angle gearmotor

With the release of the Pittsburgh Energy, KEEN Utility incorporates the proven work-hiker performance of the original Pittsburgh for a

Larson Electronics has introduced a Made in the USA product to keep your truck hole free when installing small equipment

AttaBox® Enclosures –- the world’s most specified polycarbonate and non-metallic electrical and industrial enclosures — introduces AttaBox SolarShield™ HMI Covers, providing the ultimate HMI

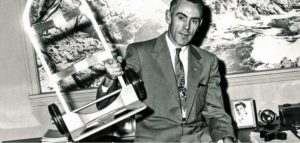

Friday, August 26th marks the 75th anniversary of Magline being incorporated. The history of lightweight magnesium and aluminum-based products produced

Motion Industries, Inc., a distributor of maintenance, repair, and operation replacement parts, and a premier provider of industrial technology solutions,