Toyota Material Handling partners with Bastian Solutions on 100th AutoStore installation

Toyota enhances its world-class parts distribution center with advanced AutoStore integration Toyota Material Handling unveiled a significant upgrade to its

Toyota enhances its world-class parts distribution center with advanced AutoStore integration Toyota Material Handling unveiled a significant upgrade to its

Today, H&E Equipment Services, Inc. reported financial results for the third quarter, which ended on September 30, 2024. The report

Ivan K. Hill Park in Winfield, Alabama, won the $100,000 Bobcat Park and Rec Makeover Contest hosted by Bobcat Company. The

Handling Specialty Manufacturing Ltd., a provider of custom engineering solutions and specialized manufacturing, has announced the appointment of Ben D’Souza

Hangcha Forklift Canada is celebrating a significant milestone—five years since its establishment. Officially launched on October 18, 2019, with an

In 2022, FMH Material Handling Solutions changed ownership and remained under local management in El Paso, Denver, and Albuquerque. FMH

Effective October 21, 2024, H&E Rentals has announced the opening of its Kansas City South branch, the company’s fourth location

Today, Big Lift, LLC announced the appointment of Martin Boyd as Chief Marketing Officer and Jason Dunigan as Vice President

NOBLELIFT Opens New Facility in Korea and has a Grand Opening Ceremony. On September 25th, NOBLELIFT celebrated the official opening

Cyngn announced the expansion of its dealer network to include Raymond West. A leading distributor and integrator of intralogistics solutions,

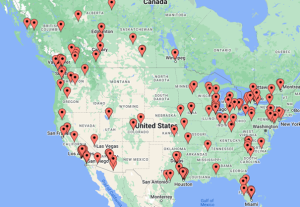

Forklift-International.com, the online marketplace for material handling equipment, has announced a major milestone for its U.S. operations. The platform currently

Yale Lift Truck Technologies announces that the ERC050-060VGL series of lithium-ion-powered lift trucks has received a 2024 Green GOOD DESIGN® award. The line

Bobcat Company has been selected as a Red Dot Award: Design Concept winner for RogueX2, an all-electric, fully autonomous concept

KION Group has signed a cooperation agreement with a manufacturer of pallet shuttle systems, Eurofork, in Frankfurt am Main, Germany

Hyster Company announces its selection as a 2024 Green Supply Chain Partner by Inbound Logistics magazine. The award honors Hyster for innovating clean power

Bobcat Company, a global brand of compact equipment, innovation, and worksite solutions, introduces its all-new TL623 telehandler. This telescopic tool carrier is loaded with premium performance

Hy-Brid Lifts announced that Charlie Haskin will be the director of sales covering the western United States. Haskin’s responsibilities include

Combilift, the Irish manufacturing giant, celebrated a landmark achievement at the prestigious Irish Exporter of the Year Awards 2024, becoming

The Raymond Corporation hosts students for onsite tours and demonstrations on National Manufacturing Day, highlighting the importance of skills development

Intella Parts Company declared a winner in its contest to find the oldest operating Toyota forklift. Alexander Toolsie from Burlington,