Dr. Shrink, Inc. celebrates 30 years as a global provider in Shrink Wrap

Dedication to its customers, world-class customer service, premium product offerings, and willingness to provide experienced advice on the proper way

Dedication to its customers, world-class customer service, premium product offerings, and willingness to provide experienced advice on the proper way

Ideal Warehouse Innovations launches its new, No Boots on the Ground™ trailer support system for busy loading docks The product innovation

In December of 1980, I left college and got my first full-time job. We had just elected Ronald Reagan in

Renewable Lubricants new Bio-Blast™ Penetrant is a high-performance, fast-acting, biodegradable penetrant that eradicates rust and dirt to quickly free corroded

AttaBox® Enclosures, the world’s most specified polycarbonate, and non-metallic electrical and industrial enclosures have announced the latest product innovation for

Much has been written in the past decade about the demographic shift from “boomers” to “millennials”. I was born in

Happy New Year! I am sure that everyone reading this is trusting that the new year will hold fresh opportunities

TVH Americas, a global provider of quality replacement parts and accessories for the material handling, industrial, and light construction equipment

S.A.F.E. Structure Designs has announced the delivery of custom ergonomic maintenance stands to the Airbus Helicopters Maintenance Training center in

Force Control Industries introduces a quick ship program for MagnaShear™ motor brakes, with American-made parts ready for assembly in as

DELLNER BUBENZER Group has announced the acquisition of the business of Hydratech Industries, the Danish global supplier of high-end hydraulic

In my August 2021 column, I discussed the importance of deconstructing departmental silos in our dealerships. Silos, as we discussed,

New models can test a wide range of motor sizes on a single system SAKOR Technologies Inc., a recognized provider

Lifting and rigging equipment supplier Van Gool has marked a year since installing a new 350t capacity calibration rig at

Last month we discussed how the departments, or “profit centers” in our dealerships give rise to inter-departmental tension, and “silo-building”

Many of my readers have contacted me recently regarding the customer experience (CX) series that I featured in MHW earlier

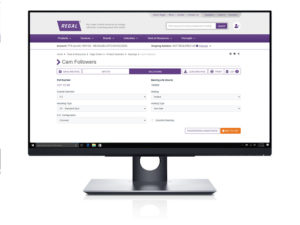

Resources offer a mobile-friendly experience for the company’s Power Transmission Solutions customers Regal Beloit Corporation, a global provider in the engineering

It always amazes me how as dealers, we all tend to organize ourselves the same way. I suppose I really

Last month I started a series on the customer experience (the CX). To refresh your memory (or if you missed

Vacuum handling systems in the industry must respond to very diverse requirements, gripping parts of different weights or materials, integration