Keep forklift safety simple; no need for a 360° view

Forklifts are an essential tool for countless industries around the globe; however, they also present a significant risk to workplace

Forklifts are an essential tool for countless industries around the globe; however, they also present a significant risk to workplace

According to the U.S. Bureau of Labor Statistics, ladder deaths accounted for 161 on-the-job fatalities in 2020, the most recent

As lithium-ion power becomes more common in material handling industries, companies providing the batteries are working through current supply chain

The American Society of Safety Professionals (ASSP) has opened registration for its signature safety event. The Safety 2023 Professional Development Conference and Exposition will

Scott Walker, VP of Supply Chain Product Management at Powerfleet, joins The New Warehouse podcast to discuss their people-powered IoT

A new era in safety technology will be revealed at ProMAT 2023 by AME. AME has long proclaimed that safety

APS Resource announces the introduction of its newest innovation, the Vertical Aerial Safety Light which provides an extra layer of

The American Society of Safety Professionals (ASSP), the world’s oldest professional safety organization, is disheartened by newly released fatality data from the

Hikvision, a global manufacturer and supplier of security products and solutions that deliver the ideal combination of high performance and

The hand is the leading body part injured at work and treated in hospital emergency departments, with acute hand and

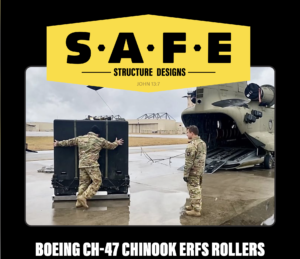

S.A.F.E. Structure Designs was awarded a $1.1 Million dollar contract to supply its patented CH-47 ERFS Tank rollers and shoring

The American Society of Safety Professionals (ASSP) opened registration today for a free daylong summit on diversity, equity, and inclusion (DEI)

Tim Hoj, CEO of Hoj Innovations, joins Kevin on today’s episode of The New Warehouse podcast to discuss everything from

Designed to increase employee awareness of forklift and pedestrian proximity in dynamic operating environments, iWAREHOUSE® FieldSense strengthens Raymond’s intralogistics capabilities

Occupational safety and health professionals create safe work environments in all industries around the globe, helping workers return home safe

Robust, Compact Vandal-Proof Unit Combines Access Control, Video Intercom, and Video Security Hikvision, a global manufacturer and supplier of security

OTR Wheel Engineering, Inc. (OTR) has successfully launched a program with Taylor Machine Works (TMW), the market-leading manufacturer of high-capacity

A new type of durable safety coating is increasing traction and reducing maintenance on floors, loading docks, platforms, ramps, walkways,

Total Control Access design prevents one gate from opening until the opposite gate is closed completely Mezzanine Safeti-Gates, Inc., an

WIKA Mobile Control has introduced the qSCALE I2 TH rated capacity indicator (RCI). The qSCALE I2 TH RCI system was