KEEN Utility introduces the Lansing Chelsea with pull-on convenience

With the release of the Lansing Chelsea, KEEN Utility brings its go-to work hiker with pull-on convenience while still providing

With the release of the Lansing Chelsea, KEEN Utility brings its go-to work hiker with pull-on convenience while still providing

The American Ladder Institute (ALI) is seeking sponsors for next year’s National Ladder Safety Month. New for 2024, the enhanced Top Cap

The American Society of Safety Professionals (ASSP) has welcomed a new chief financial officer. Steven M. Lothary, MBA, will lead

System provides controlled slowdown functionality and valuable data to help reinforce operator training for very narrow aisle lift trucks Continuing

The American Society of Safety Professionals (ASSP) is anchored to the Triangle Shirtwaist Factory fire that killed 146 garment workers

With the introduction of the Cincinnati 90 Degree, KEEN Utility now offers the fan favorite heavy-duty work boot with a

Many businesses are increasingly using temporary workers during the holiday season and throughout the year, making it challenging to provide

Mezzanine Safeti-Gates, Inc., an innovator in the design and manufacturing of pallet drop safety gates that provide fall protection in

Brass Knuckle® SmartCut™ (BKCR4420) adds grip, moisture protection, and high dexterity Application specific cut standards remain the only way to

The American Society of Safety Professionals (ASSP) is seeking a diverse group of occupational safety and health professionals to join

A worker who wears corrective lenses is not exempt from wearing proper eye protection. Typical corrective eyeglasses don’t provide the

Kenzen, an innovator in the field of heat safety solutions and occupational health, has announced that its flagship product has

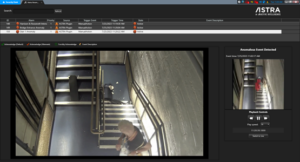

ASTRA™ delivers a true gateway to proactive video security Active Intelligence, pioneer of AI-powered anomaly detection software for physical security

New for Fall ‘23, KEEN Utility’s Arvada is designed for jobs requiring constant movement and long hours on your feet.

Traffic and Parking Control Co., Inc. (TAPCO), manufacturer, distributor and service provider of roadway safety innovations is excited to announce

Dematic announced the global launch of its Noise Reduction Portfolio, a comprehensive solution to address loud work environments across supply chain

OSHA doesn’t list qualifications for forklift operators, requiring only that the employer certify the operator. The operator need not possess

KEEN Utility, a provider in safety footwear and the work boot division of KEEN Inc. (KEEN), has announced several strategic

The signature event of the American Society of Safety Professionals (ASSP) attracted nearly 6,000 occupational safety and health professionals in

The American Society of Safety Professionals (ASSP) Foundation is awarding $334,500 in academic scholarships and career development grants to 153 individuals to