Polygon highlights High-Performance Composite Plain Bearings at CONEXPO 2020

Polygon Company, a producer of composite tubing, bearings, and pneumatic cylinders, announces will be highlighting its line of high-performance composite plain bearings at CONEXPO-CON/AGG 2020 on March 10-14, 2020, in Las Vegas, Nevada, South Hall 3, Booth #S82555. Polygon will also showcase its PolySlide® composite tubing for pneumatic and hydraulic cylinders. The high-performance custom-engineered and standard composite plain bearings on display are ideal for challenging construction equipment applications, including wheel loaders, excavators, back hoes, and compact track loaders, as well as other applications requiring pivot joints with a long life-expectancy. Featuring high load-bearing capacity, low frictional values, and corrosion resistance, the Polygon composite bearings are self-lubricated, requiring no greasing. This reduces maintenance labor costs and increases the interval before maintenance is required on rental equipment. It can also lower the number of greasing locations, ultimately resulting in fewer equipment warranty claims. Also on display will be PolySlide composite tubing for pneumatic and low-pressure hydraulic applications, including fifth wheel actuation, gate valve actuators, water treatment flow control mechanisms, and tie rod cylinders. PolySlide tubing replaces metallic material in a variety of cylinder applications. Supplied as a cylinder tube ready for customer assembly, or as fully engineered cylinder assemblies for equipment manufacturer applications, the tubing is made of continuous filament-wound glass fiber and polymer resins. The fiberglass filament and resin materials combine together to form a high strength component that exhibits dimensional stability, is non-corroding, impingement resistant and is non-conductive. PolySlide is the solution for service in harsh environments. The cylinder tubing performs in high and low temperatures, grease, grit, salt, chemicals and other extreme conditions.

Hamilton introduces new Heavy Duty Casters & Wheels built for 10-mph speeds

Hamilton Caster has introduced (4) new caster series and (5) new wheel series designed to transport heavy loads safely up to 10-mph. The new 10-mph speed-rated Spinfinity® XC Casters and Renegade™ Wheels are designed for heavy industrial applications with load requirement ranges from 1500 lbs. to 17,500 lbs. According to Jim Lippert, Hamilton’s VP of Sales, “Too many try to push their industrial casters beyond their typical 3-mph rating to no good end. Using these new casters and wheels designed specifically for 10-mph speeds, those days are over.” Hamilton’s engineering department began the design of the new Spinfinity® XC Caster Series with mounting plate and inner raceways that are forged steel formed from one piece then precision CNC-machined to provide a superior raceway for high-speed conditions. Next, engineers enhanced the casters with larger axles and massive double stacked precision ball bearings in the wheels to accommodate the higher speeds. Mindful of avoiding any downtime, engineers took the design a step further and added a new “V-Seal” for the swivel raceway. The new enhanced sealed raceway combined with the sealed precision ball bearings in the wheel qualify the casters to be 100% maintenance-free. All (4) caster series are offered in single-wheel and dual-wheel configurations. To pair with the new Spinfinity® XC Caster rigs, Hamilton is introducing (5) new heavy-duty Renegade™ Wheels offering (3) different polyurethane compounds and (2) different rubber compounds to cover a wide spectrum of industrial environments. The wheels are ultra-thick presson-tire-type with massive 1045 steel cores. Wheel diameters range from 9” up to 36” and load capacities span 1500 lbs. to 34,000 lbs. Additional non-stock sizes are also available. Check out a Spinfinity XC Caster in action on YouTube during road testing or learn more at Hamilton’s New 10-mph Caster and 10-mph Wheel landing pages. https://www.youtube.com/watch?v=TaZjS7sRJQk

Ergonomics testing reveals workers are injuring themselves more quickly than guidelines suggest

Early findings indicate ISO push/pull standards need to be reevaluated and more testing is needed New findings suggest that the International Organization for Standardization (ISO) push/pull requirements might not go far enough to protect workers. More testing is needed to better represent real-life situations and in turn, become more effective for injury prevention. Caster Connection, manufacturer of casters and wheels, collaborated with the Spine Research Institute at The Ohio State University, in conjunction with the National Science Foundation (NSF) Industry/University Cooperative Research Center, who together, discovered the importance of replicating authentic movement for injury prevention in push/pull testing. “Occupationally-related low back disorders and shoulder musculoskeletal disorders are a leading cause of lost work days and are a costly occupational safety and health problem facing a variety of industries,” said Joe Lyden, president of Caster Connection. “These injuries occur because organizations vary in the type of push/pull gauge they’re using – varying test results from one organization to the next.” Additional findings include: In order to be accurate for real-life situations, acceleration in testing should be much higher than ISO guidelines advise Workers are injuring themselves more quickly than guidelines suggest and before they even realize it Current guidelines do not reflect how people are using carts in real-life situations The force required to push a cart differs from the force required to pull a cart and people don’t typically test pulling The objective of this particular study was to provide recommendations for practitioners in regard to push/pull force assessment that improves the accuracy and precision of hand force estimates, thus making the SRI push/pull guidelines more applicable. More testing is required to determine the gold standard for new guidelines. For more information about the early findings of the study, visit www.casterconnection.com/research. The study in its entirety will be available online in 2020.

Camso launches new non-marking press-on forklift tire series

Camso introduces the Solideal PON 555 NM and PON 550 NM by Camso, two new non-marking additions to the Solideal PON series. These new and improved non-marking press-on tires were developed to deliver increased energy efficiency and thermal performance. Both tires are designed to meet the growing needs of indoor applications and rental fleets with operations of medium intensity usage, offering customers a non-marking solution with industry-leading life. Indeed, companies don’t want to see tire marks or black rubber dust on the floor or on their goods, and a growing number of industries have set regulations that require the use of non-marking tires – but none of them can compromise on life or performance. “As more operations have moved indoors and require cleaner working environments, non-marking tires have become an imperative for approximately 30% of forklift applications,” says Thierry Miche, Product Line Executive Director – Material Handling, at Camso. “When combined with a rise in rental applications and a growing trend in electric forklifts, it’s no surprise that the demand for performing non-marking solutions is increasing. As a leader in the industry, we want to offer solutions that tackle new challenges as they arise.” A non-marking solution that is energy-efficient and reduces heat build-up, without compromising performance The Solideal PON non-marking series was developed to offer lower rolling resistance, which increases energy efficiency, an important feature when it comes to keeping fuel consumption and battery usage to a minimum. Furthermore, the improved natural rubber used in the non-marking compound reduces chunking and cutting, whilst the unique two-stage construction lowers heat build-up. Continuously improved thermal performance is a key requirement to decrease tire failure and eliminate forklift downtime. The new tires added to the PON series are: The Solideal PON 555 NM – smooth-surfaced tire: ensures clean working environment, low rolling resistance and improved thermal performance. It has been especially designed to provide maximum lifespan for medium intensity applications requiring non-marking press-on tires. The Solideal PON 550 NM – treaded tire: has all the features and benefits of the PON 555 NM, with a wide profile and flat footprint for increased stability and grip. It benefits from the company’s established tread pattern design, which has proven its reliability for over 25 years. Solideal PON series: a complete range of press-on forklift tires With these new non-marking forklift tires, life is now a given across Camso’s entire press-on line, which is available in standard black, non-marking, and Camso’s patented non-marking anti-static technology, delivering maximum life for any press-on application and intensity usage.

MARTINS INDUSTRIES celebrates the addition of MAGNUM+

MARTINS INDUSTRIES has now integrated MAGNUM+ to its brand portfolio of tire equipment and products. MAGNUM+ is a brand of high-precision tire balancing beads that are a revolutionary alternative to traditional wheel weight balancing. Through the acquisition of M & R Tire Products, MARTINS wishes to expand an ever-growing product offer that caters to any type of business in the world that has to work with and handle tires. The main objective for MARTINS is to improve on an already successful business model. -The great synergy between MAGNUM+ and MARTINS INDUSTRIES on such things as corporate values, premium quality products, innovation and distribution channels is what motivated the acquisition in the first place. MARTINS’ worldwide distribution centers will ease the logistic and shipping for customers around the world, making it easy as free next-day shipping for any order size. Products will be stocked in Memphis, USA, Montreal, Canada, Tilburg, Netherlands and Sydney, Australia. MAGNUM+ will also benefit from a complete rebranding from the logo design, to the online experience, and all the way to product packaging. The MAGNUM+ brand refresh will be launched at the 2019 SEMA Show from November 5th in Las Vegas. MARTINS INDUSTRIES is a tire equipment and products manufacturer based in Farnham, Canada. Founded in 2002, MARTINS has designed, manufactured and sold over 2 million tire equipment products at all levels of the tire, car, fleet, trucking, OTR and aircraft industries throughout the world. They have distribution centers in the United States, Canada, Netherlands, UAE and Australia, along with manufacturing plants in Canada and China.

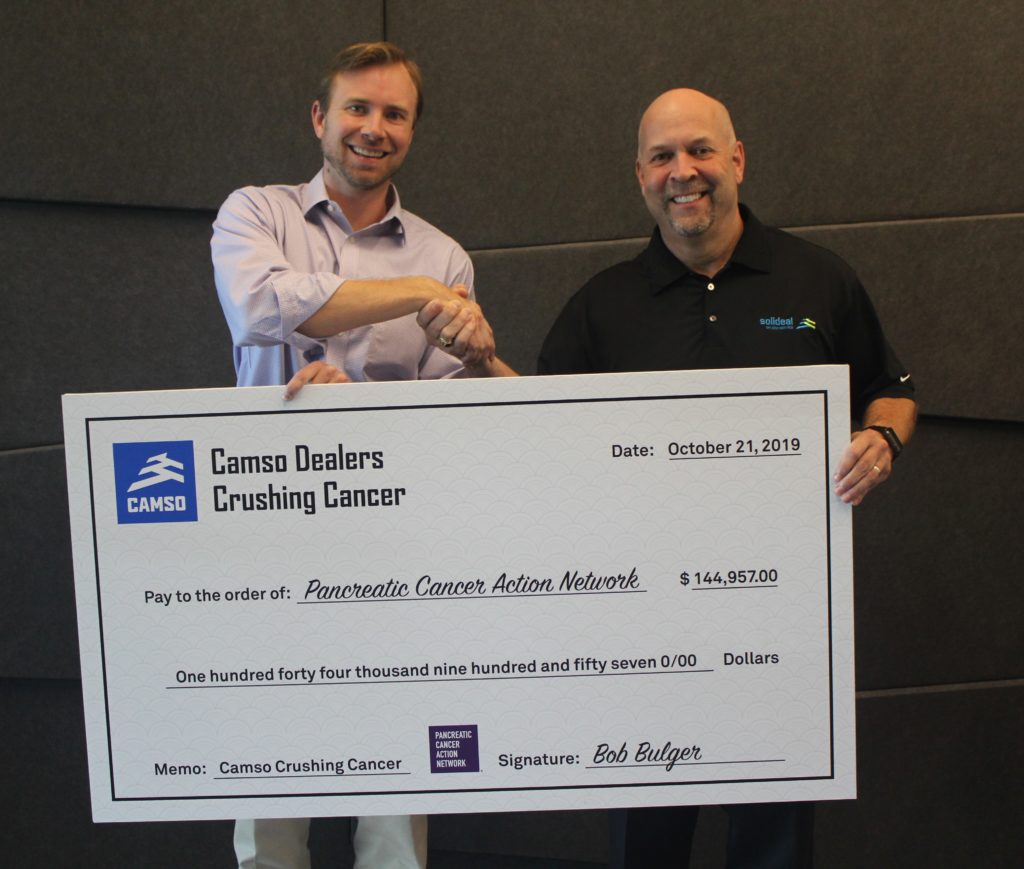

Camso and their dealers raise $144k for cancer network

Camso announces that 24 dealers across America joined its Camso Crushing Cancer 2019 program, raising a total of $144,957 that will be donated to the Pancreatic Cancer Action Network. The program ran for the months of August and September across Camso’s construction tire and track dealer network in the United States. During this period, on behalf of their dealers, the company donated a portion of the proceeds from the sale of select construction tires to the Pancreatic Cancer Action Network (PanCAN). “When we launched this program last August, little did we know that we would be able to raise such an important amount for our donation to the Pancreatic Cancer Action Network,” says Jim Donoghue, Director, Marketing and Sales Support – North America at Camso. “Most of us know families who have been affected by this disease, and we are proud to support this cause.” Camso would like to thank each dealer for their generosity in joining this cause: Best One Tire Blue Ribbon Tire Cassidy Tire Commercial Tire Dakota Tire Gallagher Tire Lapps Loader Service McCarthy Tire Midstate Tire Northwest Tire Factory Parkhouse Tire Pomps Tire Quality Tire Company Ray’s Tire Service Redburn Tire Company Royal Tire Service Tire and Truck Center Southern Tire Mart Sullivan Tire Tandem Tire TF Tire & Service Tiresoles Group United Tire Center Wingfoot “We are sincerely grateful for this generous gift from Camso and their dealers,” said Brooke Caviglia, PanCAN Associate Director, Community Engagement, “Their support will directly benefit thousands of pancreatic cancer patients and their families and will help in our fight against this deadly disease.” According to PanCAN, pancreatic cancer is currently the third leading cause of cancer-related death in the United States with a five-year survival rate of just nine percent. Funds raised for PanCAN through the Camso Crushing Cancer 2019 program will advance critical research programs, including PanCAN’s Clinical Trial initiative, Precision PromiseSM, Early Detection Initiative (EDI), precision medicine initiative Know Your Tumor®, additional field research, and other patient advocacy efforts – all to improve patient outcomes.

HEXPOL appoints new Controller of HEXPOL Engineered Products

HEXPOL, the parent company of Stellana US, has announced that Jim Stevens has been promoted to Controller of HEXPOL Engineered Products as of October 25, 2019. This change will support strategic growth in the Engineered Products division and further diversify Jim’s involvement across the business segment. In his new role, Jim will use data analysis to provide business insights that will grow the Engineered Products division. “We are happy to share this opportunity with Jim as he has proven himself to be a valuable asset to the HEXPOL organization. Throughout his employment at Stellana, Jim has continued to demonstrate success through his analytical thinking and leadership skills. I am confident that Jim will contribute to HEXPOL’s continued development in his new role.” – Gabriela Karlsson, Financial Director. Jim has extensive experience in accounting, management, and finance. Jim began his employment at Stellana in 2012 as an Accountant where he was further promoted to Controller at Stellana US and then Director of Finance and IT. In addition to his new responsibilities, Jim will retain his current role and duties. Jim holds a master’s degree in Business Administration from the University of Wisconsin – Parkside and an undergraduate degree in Accounting from Carthage College.

TractEasy, TLD’s new autonomous baggage tractor, comes equipped with Camso’s Solideal AIR 561

Camso’s Solideal AIR 561 ground support equipment tire has been singled out by TLD to equip its new driverless baggage tractor TractEasy – which has been developed in collaboration with EasyMile, as well as its Jet-16 baggage tractor, their flagship vehicle. Since June 2019, both ground support equipment come standard-fitted with Solideal AIR 561 full assemblies (tires and wheels). “We’re impressed with the dedication of Camso’s development team in designing not just a long-life solution, but one that tackles the specific challenges of ground support applications,” explains Yves Crespel, Communication Director at TLD. “With the Solideal AIR 561, we’re confident customers will be equipped with a performing solution that will lower their overall operating costs.” Camso’s ability to provide a long-lasting tire specifically designed for this GSE application was a determining factor in this partnership. The Solideal AIR 561 is the ideal solution to meet the baggage tractors’ unique set of requirements for versatility and manoeuvrability. These vehicles were previously equipped with block tread pattern tires, which are poorly suited for the high-speed, long distances, and short-turning radius of these machines, causing uneven wear of the tires, which leads to recurring vibration issues. In the case of the Jet-16, this affects driver comfort and results in lower tire life – all of which triggered TLD to investigate a more suitable and performing solution. Tackling challenges linked to GSE applications “We’re thrilled that Camso has been chosen as the tire provider for TLD’s new autonomous and zero-emission electric baggage tractors,” says Richard Philippe, OEM Sales Regional Director – EMEA at Camso. The Solideal AIR 561’s distinctive ribbed tread pattern minimizes vibration due to uneven wear and reduces snaking, two important challenges when operating on airport grounds. It provides greater stability, ensuring increased operator comfort and tire life. Its energy-efficient rubber compound also helps reduce wear and rolling resistance, while its unique “lug with sipes” design increases traction in low-grip conditions. “As a driverless vehicle that operates in normal traffic, without infrastructure modification and in all weather conditions, the need for a GSE tire that would excel in reliability, lifespan and versatility was critical. The field tests we conducted confirmed that Solideal AIR 561 was the right tire for the application, not only for our new autonomous vehicle, but also for our core product, the Jet-16,” adds Crespel. Global leading ground support equipment OEMs like TLD seek performing solutions that tackle the specific challenges of GSE applications: turning to tire specialists like Camso who focus on the highly specific needs of industrial niche markets is a natural fit.

GRI hires new head of global sales

GRI has recruited a new executive to its senior sales team to increase the company’s expansion with its portfolio of specialty tires. Rafael (Tony) Lugioyo, head of global sales, will be based in the United States and will be leading GRI’s efforts to expand its network to support its agriculture and construction tire segment. Lugioyo joins GRI with over 28 years of experience in the United States as well as international entrepreneurial sales and marketing. He was formerly the managing director of American Tire Distributors (ATD) of North Carolina. Prior to that, he was the managing director/equity partner of Hercules Tire and Rubber Company in Ohio and vice president/founding partner of Tire Distributor, Inc in Florida. He is fluent in English, Spanish and Italian and has managed international staff and country specific sales covering over more than 50 countries. Tony has been the co-founder and managing partner of four startup companies. He is experienced and is driven by investments that bring significant growth, profitability, efficiencies and shareholder value, according to GRI.

GRI expands operations in Cincinnati

GRI a specialty tire manufacturer from Sri Lanka with offices in six countries and sales in 50 countries around the world has expanded its footprint in the U.S. GRI FIT, the tire service division of GRI , has grown its operations into Cincinnati, Ohio. They already have locations in neighboring states of Indiana and Kentucky. GRI FIT in Cincinnati, offers the services of an on-site Tire Press Truck and experienced technicians who have the capability to work on-site or off-site, on tire fitment and servicing functions. GRI can now reach wider regional coverage, delivering the benefit of efficiency, convenience and flexibility to the consumer. “GRI FIT is continuing to look for potential markets, as this model is scalable and within our strategic corporate plans”, stated Tony Lugioyo, Head of Global Sales at GRI. “Due to the increase in demand for our tires, GRI FIT will soon be opening a new warehouse in Cincinnati for the distribution of GRI Tires, by mid-October,” stated Dr. Mahesha Ranasoma, CEO GRI. Last month, the company also announced its acquisition of the NORTIRE Group in Northern Europe. GRI is a leading producer of high-performance specialty tires in agriculture, construction and material handling tires.

C&U Americas earns Eaton Corporation’s Highest Supplier Award

C&U Americas, LLC, the North American subsidiary of the C&U Group, one of the world’s top eight bearing manufacturers and China’s largest bearing producer, has received the 2018 “One Eaton Supplier Premier Award” from Eaton Corporation Inc. The award was given to C&U Americas in recognition of the company’s exceptional value and outstanding service to Eaton across a number of dimensions including quality, productivity, innovation, and technological advancements. Eaton presented the award to C&U Americas on August 28, 2019 during Eaton’s annual supplier conference at Eaton in Beachwood, Ohio. Accepting the award on behalf of C&U Americas were Jason Stocker, President of C&U Americas, and Brad Fagan, Strategic Account Manager. Eaton Corporation uses this award to honor and recognize strategic partners that go above and beyond in quality, performance, innovation, and delivery. “One Eaton Supplier Premier Award” is Eaton’s highest supplier award, and is only given to a select few organizations in the entire supply chain. Stocker spoke on accepting the award and noted, “C&U Americas is very thankful to receive this award from Eaton in recognition of our service during 2018. This award demonstrates our team’s commitment to excellence in providing high quality products and exceptional service to our strategic partners and helps showcase our position as an industry leader.”

Myers Industries announces resignation of CEO, names interim CEO

Myers Industries, Inc., an international manufacturer of polymer products for industrial, agricultural, automotive, commercial and consumer markets, today announced that Dave Banyard has resigned as President and Chief Executive Officer, effective October 25, 2019, to accept another professional opportunity. Andrean Horton, the Company’s Executive Vice President, Chief Legal Officer and Secretary, has been named Interim President and Chief Executive Officer. The Board of Directors will engage a global executive search firm to assist in identifying a new President and Chief Executive Officer. Chairman of the Board of Directors of Myers Industries F. Jack Liebau, Jr. commented, “On behalf of the Board of Directors, we would like to thank Dave for his leadership and contributions to Myers. We wish him well in his future endeavors. The Company will remain focused on executing its strategic initiatives, including the transformation underway in the Distribution Segment.”

Stellana Sweden is expanding capacity resulting in shorter lead times

Stellana Sweden just announced that they will be adding capacity to its Laxå facility. During the fourth quarter of 2019, this location will install a new 4K-casting machine to streamline MDI production. The new manufacturing line will expand the production of the wheels and rollers that are critical to the material handling industry. Erik Unnersjö, Sales and Marketing Director at Stellana Sweden, commented, “The new line will increase our capacity for MDI materials. These include our Powerthane, Powerfriction, and Powerthane Plus materials – which range in hardness from 65 to 95 Shore A. The increased capacity will also result in shorter lead times and improved customer service.” The investment will support growth across Stellana’s existing customer base while increasing its in-house manufacturing capabilities. An expanded manufacturing footprint will also allow Sweden’s technical team to continue developing existing and new materials. This facility has an experienced, well-trained staff that continues to build a reputation for manufacturing quality products. As we continue investing in our customer’s growth, we look forward to producing more of the premium polyurethane products Stellana is known for. Contact us today to get your future orders scheduled!

Magna Tyres announce strategic partnership in the USA

Magna Tyres Group has announced its first strategic cooperation and alliance in USA with Tires Direct, quickly after the earlier announcement of opening an U.S. office. Tires Direct is a very important partner in the US market for Magna Tyres Group to expand the business. Magna Tyres growth trajectory in the last half year has been significant and the partnership with Tires Direct is another milestone. They see that distribution and partnerships has played an important role in their brand growth story so far and believe that Tires Direct can spread it even more, with it’s nationwide warehouses all across USA, the commercial medium truck centers and wide network of dealers. Tires from The Netherlands & Thailand The new partnership will certainly create even more opportunities in the near future. The upcoming months, Magna Tyres Group will have and maintain a full range of our products in strategic warehouses across USA. The growing demand non-Chinese tires has increased in the last months. Due to this increasing, Magna Tyres has further expanded their production capacity in Holland & Thailand. The combination of their innovating European engineered technology and local Dutch production ensures the premium quality manufacturing requested by their USA customers. From their local USA warehouses, they can supply their customers in the USA: Mining & Earthmover tyres Port & Material Handling tyres Solid tyres Local Support Magna Tyres said that their customers deserve a high level of service and will deliver them improved product-servicing capacity, more efficient communications and cooperation, more personalized attention and local support on a 24/7-basis. With the opening of our new office and the cooperation with Tires Direct in the USA, their tires will be distributed via the following locations: Magna distribution warehouses: Los Angeles, CA Atlanta, GE Dallas, TX Jacksonville, FL Coldwater, OH Clayton, NC Chicago, IL Tires Direct Locations: College Park, GA Forest Park, GA Orlando, FL Tampa, FL Ft. Myers, FL Jacksonville, FL Miami, FL Houston, TX Dallas, TX La Porte, TX Los Angeles, CA Montebello, CA Cypress, CA

Laugfs Rubber introduces a line of pneumatic tires for forklifts and skid steer

LAUGFS Rubber is planning to launch its new pneumatic range of tires for forklifts and skid steer before end of 2019. The pneumatic tire market opens a very large opportunity for LAUGFS Rubber which the company will be vigorously pursuing in the coming years. LAUGFS Rubber is entering into the pneumatic market purely from the demand perspective to serve its customer base to the maximum extent. Initially, Company is planning to introduce all major sizes for industrial – forklift and construction – skid steer applications. Addition of pneumatic range to LAUGFS’s product portfolio will add synergy to its product offerings and add more value to its product strength, leading to improved customer satisfaction. During the past four years, market size maintained an average annual growth rate of 1.56% for pneumatic tires for industrial applications. Industry analysts believe that in the next few years, the market size will be further expanded for industrial pneumatic tire applications. The market size of the pneumatic tires for industrial applications will reach 1350 million in 2021 with the rising production of industrial equipment.

Martins Industries introduces the new and improved Tire Rider Tuff

Thanks to the tireless work of the MARTINS research and development team, tire industry workers will no longer have to worry about changing the tire cart’s gas cylinder – the piece of the mechanism that opens and closes the clamps to pick up the tires. The manufacturer has replaced the gas cylinder with a steel spring mechanism that is much more solid and durable and comes with a lifetime warranty. But the MARTINS INDUSTRIES team didn’t stop there. With its lofty quality standards, the manufacturer took the opportunity to revisit the whole product in order to build the strongest tire cart on the market. The improvements include an increased carrying capacity, which has grown from 109 kg (400 lb) to 250 kg (550 lb), and better handling due to the cart’s lighter weight (from 48 kg/106 lb to 36 kg/79 lb). All new components of the Tire Rider Tuff have been factory-tested, with very convincing results: Mechanism tests (breaking point): 756,000 opening cycles on the clamps, representing 31½ years of use at 100 strokes per day x 240 business days. Weight tests: 201,600 back and forth cycles with a load of 250 kg/550 lb. “Our painstaking, tireless work has paid off. The test results have exceeded our expectations. We are very pleased to offer our customers the ideal version of what a tire cart should be,” explained Ian Fournel from quality control and technical services at MARTINS. The tire cart, a greatly appreciated product The gas cylinder tire cart been on the market for a good 20 years. It is one of the products that is most appreciated by tire maintenance workers, since it can move up to eight tires at a time. It was also one of the first products sold by MARTIN INDUSTRIES. Two years ago, the manufacturer modified the colours of the product to make it easily identifiable. The only tire cart on the market to bear the orange and black, the Tire Rider Tuff and its colours will guarantee the best quality for industry workers from now on! https://www.youtube.com/watch?v=flZ7z7CDA3I