Yokohama TWS announces Elio Bartoli as Company President

Yokohama TWS has announced the appointment of Elio Bartoli as its new company President, effective December 1st. Elio Bartoli succeeds

Yokohama TWS has announced the appointment of Elio Bartoli as its new company President, effective December 1st. Elio Bartoli succeeds

Superior Tire & Rubber Corp. celebrates its 60th anniversary, commemorating six decades of dedication, innovation, and leadership in the polyurethane

Caster Concepts has introduced multiple casters designed for heavy-duty, extra-duty, and super-duty applications. With real-world capacities exceeding 100 tons, these

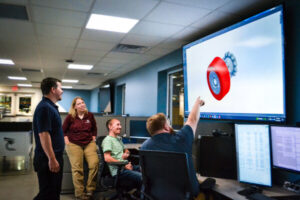

Caster Concepts has further expanded operations at their West Michigan Ave facility in Albion, Michigan to include a 3,000 square foot advanced

MARTINS Industries, a global provider of equipment and supplies for tires and wheels based in Farnham, Quebec, has announced that

Hamilton Caster & Mfg. Co., a 117-year-old industry leader in heavy-duty industrial casters, has announced enhancing its legacy Super Endurance

GRI has announced the appointment of Cara Junkins and Jeff Cole as National Sales Managers for the United States. These strategic

The modular all-in-one wheel, gearbox, drive, battery, and control solution is easily integrated into new or existing equipment to help

Patrick Sexton has joined OTR Engineered Solutions (OTR) as the company’s new Global Vice President of Engineering and Innovation. In

Yokohama TWS North America awarded for going ‘Above & Beyond’ in customer service for the Americas The top supplier award

Bridgestone contends with falling demand across multiple continents Bridgestone Americas will be laying off 118 workers at its Des Moines,

It’s time to rethink the way we make tires, and the off-highway segment is no exception to this global imperative, driven

OTR Engineered Solutions (OTR) has named Ben Brown as its new Global VP Sales & Marketing OEM. He will be

GRI has reached a significant milestone with its successful entry into the South American market, marking a new chapter of

Hamilton Caster has announced that Andy Stamp will serve as their new Director of Sales and Business Development. Stamp has

GRI has announced the appointment of Ydo Doornbos as Director of North America. With an illustrious career spanning 29 years

GRI and the Magri Group strengthened its position in Italy with a new strategic partnership that emphasizes its continued commitment

OTR Engineered Solutions (OTR) is offering its REAPER tire for multiple brands of zero-turn mowers and garden tractors. This tire

GRI has announced an expansion of its product portfolio with the addition of 23 new SKUs across its agriculture and

Hamilton Caster, manufacturer of heavy-duty industrial casters, wheels, carts, and trailers, has announced the expansion of its Nylast® wheel line