Caster Concepts earns certification from Ergonauts for TWERGO® Ergonomic Caster Wheel

Certification Program focuses on ergonomic products that improve worker safety and productivity Caster Concepts, a manufacturer of industrial heavy-duty casters

Certification Program focuses on ergonomic products that improve worker safety and productivity Caster Concepts, a manufacturer of industrial heavy-duty casters

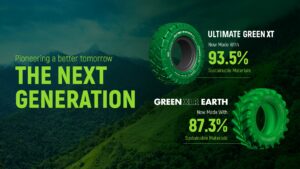

GRI, a producer of specialty tires for agriculture, material handling, and construction machines, unveiled its NEXT GENERATION of environmentally friendly

Global Rubber Industries or GRI, a specialty tire manufacturer, has appointed Barry Guildford as the Global Commercial Director (GCD), effective

Trelleborg Tires will showcase its full premium portfolio for material handling and logistics at LogiMAT 2024, the international trade fair

Caster Concepts, a manufacturer of heavy-duty casters and industrial caster wheels, has announced the completion of a 16,000 square foot

Yokohama TWS Sri Lanka has been recognized for its exceptional export achievements by receiving the prestigious ‘Best Exporter in the

Orbital wrapper manufacturer TAB Industries, LLC, Reading, Pa., has introduced portability retrofit kits. Developed to allow the company’s patented TAB

MARTINS has announced the launch of its three new sub-brands: tiretools, tirestow, and tiresupp. This expansion marks a significant milestone

Hamiliton Caster has sadly announced that Jim Lippert, Vice President of Sales died on August 11th. He was born on

Caster Concepts Inc., a global manufacturer in industrial caster solutions, has introduced the TWERGo® Xtreme caster for heavy duty material

I recently met with a customer discussing their service technician opportunities and while we were talking about this, we also

MARTINS, a global provider of high-quality tire equipment and supplies, has announced the addition of the Stud and Hub Cleaning

The Yokohama Rubber Co., Ltd. has acquired Trelleborg Wheel Systems from the Trelleborg Group for 2,074 million euro Yokohama TWS

Trelleborg has released its latest tire, CX940, made for maximum resistance in handling high-intensity jobs in busy ports and harbors, inland

Trelleborg just announced that it has once again joined Italy’s prestigious Giro d’Italia 2023 cycling race as an official partner

Trelleborg launches its newest tire, the XP900, made for high-intensity material handling applications. The new tire increases efficiency and performs

Trelleborg Wheel Systems is bringing a totally new dealer experience online, aimed at serving customers more effectively wherever they are

OTR Wheel Engineering, Inc. (OTR) is officially unveiling new branding at CONEXPO-CON/AGG 2023. This includes the new trade name, or

DoRodo has welcomed Mike Kulka and announced his appointment as Sales Manager – Business Development. Mike will be responsible for

DoRodo has announced the appointment of Jeremy Brault as Sales Manager – Distribution & National Accounts. Jeremy will be responsible