November 2024 Logistics Manager’s Index Report® LMI® at 58.4

Growth is INCREASING AT AN INCREASING RATE for: Inventory Costs, Warehousing Capacity, Warehousing Prices, Transportation Capacity, and Transportation Utilization. Growth

Growth is INCREASING AT AN INCREASING RATE for: Inventory Costs, Warehousing Capacity, Warehousing Prices, Transportation Capacity, and Transportation Utilization. Growth

It’s so frustratingwhen you’ve got a problem you need to solve, and nothing’s coming to you—no ideas that will help

The American Society of Safety Professionals offers an ASSP Education On-Demand Annual Pass for occupational safety and health professionals to

Brenda Lee Ryan of Cornelius, NC, left this earthly plain on November 9, 2024, after a courageous ten-year battle with

Shipments of cutting tools, measured by the Cutting Tool Market Report compiled in a collaboration between AMT and USCTI, totaled

The 2024 election results indicate the U.S. economy was the number-one issue. A majority of voters felt that inflation and

How goals, roles, and tasks transform teams Imagine a team starting a project with energy and optimism. Ideas are flying,

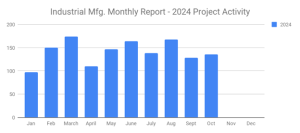

Industrial SalesLeads released its October 2024 report on planned capital project spending in the Industrial Manufacturing sector. The firm monitors

Last month, I suggested that dealers compare their 24 results against their peers’ accounting and cash flow budgets. I also

Are you ready for 2025? Here is a 60-question assessment of how well your business has adopted those fundamental Best

Imagine having access to the expertise of a lawyer, accountant, or warehouse manager, wherever and whenever you like, for pennies.

As another December has arrived and 2024 winds down, you may be reflecting on a year filled with growth, innovation,

In every company, there is one person you are certain that can make a decision…The CEO. Why start anyplace else?

Strong consumer demand drives trade headed into the holiday shopping season The Port of Long Beach moved nearly 1 million

The PTDA 2024 Industry Summit, held at The Broadmoor in Colorado Springs, Colo., brought together over 425 power transmission/motion control

The Plastics Industry Association (PLASTICS) has opened nominations for the Plastics Sustainability Innovation Awards, a program designed to honor pioneers advancing

Learn how to create a safe, productive workplace JLG Industries, Inc., an Oshkosh Corporation business and a manufacturer of mobile

The Women In Trucking Association (WIT) presented Tracy Rushing, Executive Director of Safety and Recruiting, RE Garrison Trucking, Inc. with

NORD provides their Authorized Distributors, sales partners, and internal team members with valuable, comprehensive training to ensure they can better

Orders of manufacturing technology, measured by the U.S. Manufacturing Technology Orders (USMTO) report published by AMT – The Association For