How Self-Nurturing Therapy can make you a better leader Seven steps to practice now

Navigating leadership brings a unique set of challenges and opportunities. A young executive, Sarah, faced complaints from her team, who

Navigating leadership brings a unique set of challenges and opportunities. A young executive, Sarah, faced complaints from her team, who

500 episodes! I cannot believe it, but here we are five years and 500 episodes later. I didn’t think the podcast

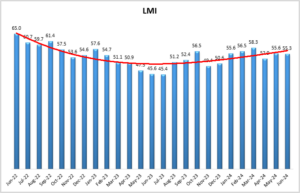

Growth is INCREASING AT AN INCREASING RATE for: Transportation Prices. Growth is INCREASING AT A DECREASING RATE for: Inventory Costs,

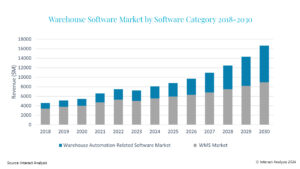

Warehouse software market to grow at a CAGR of 12.7% out to 2030 The standalone warehouse management system (WMS) market

AMT has announced the recent promotions of both Anna Jacobs and Mike Ingles to the roles of Engineering Services Business

Week-to-week: Staffing employment up one point, new starts up 10 points Staffing employment improved during the week of June 10-16,

The Women In Trucking Association (WIT) announced that J.B. Hunt Transport Services, Inc. has renewed its Gold Level sponsorship furthering

Raymond and BOCES’ 30-year collaboration supports the workforce of the future For more than 30 years, the Youth Apprenticeship Program has been an

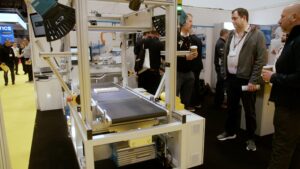

Coming to Florida on October 22nd and October 23rd – IntraLogisteX USA, is the logistics and supply chain management sector’s

Forklift battery chargers are essential for ensuring the top performance and longevity of lithium batteries. Understanding how to use and

Supply chain leaders are turning to automation and AI to enhance operational efficiency, reduce costs, and elevate the customer experience Automation

During my recent travels and meetings with industry colleagues, dealers, and OEMs, many discussions took place exploring the dynamics and

Technology Rules. Every business or industry publication you pick up states….IF YOU DO NOT START TAKING ACTION NOW YOU WILL

Hot prospect. You just made a good phone contact or had a brief meeting, and the prospect is interested in

First-of-its-kind research shows productivity and profitability loss caused by ‘dropped sessions’ StayLinked’s research report, titled ‘Dropped Sessions – The Hidden

Today’s episode of The New Warehouse Podcast features Anna Farberov, the General Manager at PepsiCo Labs. Anna is at the

Orders of manufacturing technology, measured by the U.S. Manufacturing Technology Orders Report published by AMT – The Association For Manufacturing

Conquer Your Equipment Dealership’s Sales with Powerful Strategies! Industry consultant George Keen has released his new paperback book to maximize

Forklifts are essential workplace vehicles that offer immense utility and productivity boosts. However, they are also associated with significant safety

Diversified Fall Protection (DFP) has named Kynan Wynne as Chief People Officer. This marks the first time in the company’s