Wauseon Machine to showcase precision machining and fabrication capabilities at Design 2Part Shows (D2P)

Visit Booth #215 to connect with a Wauseon expert and find your next manufacturing solution Wauseon Machine, Inc. (WM) announced

Visit Booth #215 to connect with a Wauseon expert and find your next manufacturing solution Wauseon Machine, Inc. (WM) announced

In the latest episode of The New Warehouse Podcast, Kevin sits down with Radu Palamariu, the Managing Director of Alcott

136 local students receive assistance to study in trade-related fields The Port of Long Beach this week awarded $300,000 in

The American Society of Safety Professionals (ASSP) continues its planning for this summer’s Safety 2024 Professional Development Conference and Expo, which

The Association of American Railroads (AAR) has reported U.S. rail traffic for the week ending May 25, 2024. For this

Unirope Ltd. president Justin Brown has been nominated to the board of the International Organization for the Study of Ropes

In episode 489 of The New Warehouse podcast, Mark Stanton, President and General Manager of Elokon Group, joins to discuss

Bruce Main, P.E., CSP, a longtime member of the American Society of Safety Professionals (ASSP), earns the 2024 Prevention through

The German Design Council has honored LEIBINGER’s innovative, high-performance industrial printer, IQJET, with the Gold German Innovation Award on May

Casper, Phillips & Associates Inc. (CP&A) has delivered a presentation to port authorities titled, ‘Peer Review of Container Cranes’, to

In-person training, a deliberate hiring process, and ongoing safety conversations are a few of the ways some in the industry

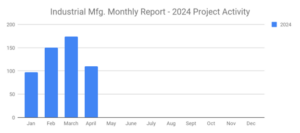

Industrial SalesLeads has announced the April 2024 results for the new planned capital project spending report for the Industrial Manufacturing

You do something wrong. The customer gets mad. You apologize and try to fix the problem, make nice, and hope

Tracking the markets as I do, the April results left me wondering what the heck is going on, especially when

To Be Hybrid Event June 11, 2024 | 9:00 AM – 11:00 AM Industrial Truck Association’s eleventh annual National Forklift

Industry-Wide Competition Celebrates Greatest Achievements and Innovations at SuperCorrExpo® TAPPI and AICC, co-producers of SuperCorrExpo®, have announced that entry for

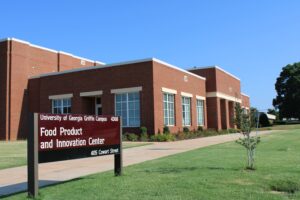

The Food Product Innovation and Commercialization Center (FoodPIC) supports the development of food products from concept to shelf Tetra Pak and

Occupational safety and health (OSH) professionals use collaboration and key insights to make smart decisions that can drive change across

The Material Handling Education Foundation, Inc. (MHEFI) has announced the distribution of $231,700 in scholarships to 61 material handling, supply

The Plastics Industry Association announced over 21,000 meals were packed at the first-ever community service event at NPE2024: The Plastics