MODEX attendees bring big spending plans to the biggest supply chain event of 2024

Attendees are looking to invest in automation, robotics, and tech solutions to improve the speed and resiliency of their supply

Attendees are looking to invest in automation, robotics, and tech solutions to improve the speed and resiliency of their supply

MHI has released the list of finalists for the 2024 MHI Innovation Awards. After receiving 192 submissions for this year’s

The fifth Global Lifting Awareness Day — #GLAD2024 — will take place on Thursday 18 July, represented by a new

The Association of American Railroads (AAR) today reported U.S. rail traffic for the week ending February 3, 2024, as well

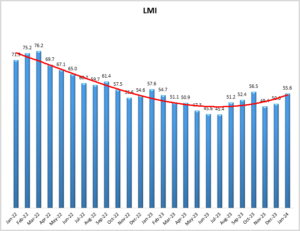

Growth is INCREASING AT AN INCREASING RATE for: Inventory Levels, Inventory Costs, Transportation Utilization and (making its first appearance in

The Association of American Railroads (AAR) today reported U.S. rail traffic for the week ending January 27, 2024. For this

ProVeyance Group will be exhibiting at MODEX 2024 from March 11th through March 14th at Georgia World Congress Center in

Sustaining STEM education ensures students are ready for innovative careers Bobcat Company is donating $250,000 to the University of Mary

LGH & Rotrex Group has appointed Russell Boswell-Munday as LGH’s new Sales Director for Europe and the UK. Russell has

In the dynamic landscape of today’s business world, change is inevitable. However, fear is one of the biggest obstacles to

Carolina Handling, a material handling industry, has received the 2024 Most Valuable Partner (MVP) Award from the Material Handling Equipment

Almost half of all staffing firms report gains in new assignments After the seasonal end-of-year dip in December, staffing employment

New solution helps engage operations and reinforce safety culture by streamlining safety inspections, audits, incident reporting and analytics, corrective actions

Alta Equipment Group Inc., a provider of premium material handling, construction, and environmental processing equipment, appointed Jeff Hoover as Chief

Industrial SalesLeads has announced the December 2023 results for the new planned capital project spending report for the Industrial Manufacturing

Are you using some form of database management to “control” your customer data? Customer Relationship Management or CRM has been

I spend a good couple of hours each day reviewing stock markets and other investment commentary. Always loved investment adventures

The American Society of Safety Professionals (ASSP) has opened registration for its signature safety education event, held two months later than usual

The Association of American Railroads (AAR) today reported U.S. rail traffic for the week ending January 13, 2024. For this

The scholarships celebrate the 10-year anniversary of Dematic’s Automated Storage Retrieval System in the Mary Idema Pew Library Dematic recently