Prepare for the New Year with some old ideas

I’d like to look at the table of contents from a great book on selling skills… Chapter 1…Begin by Talking

I’d like to look at the table of contents from a great book on selling skills… Chapter 1…Begin by Talking

You don’t want to miss this feel-good episode featuring Chad Pregracke, CEO of Green Current Solutions. With a unique background

The Association of American Railroads called on U.S. Customs and Border Patrol (CBP) to reopen international crossings at Eagle Pass

Each year, the American Rental Association (ARA) honors individuals for outstanding service to the association and the equipment and event

National Wreaths Across America Day sees the placement of three million sponsored Veterans’ wreaths at over 4,225 participating locations across

Is there never a “TAX TIME” in the U.S.? Don’t think so. And I believe “TAX TIME” is going to

Despite a more optimistic outlook, orders for manufacturing technology, measured by the USMTO report, continued to fall relative to 2022. Through

The International Warehouse Logistics Association (IWLA) recently added two staff members to its education department, bolstering the organization’s commitment to

“Call me after the holidays” is the second most-heard objection in sales. (First being, “Your price is too high.” Third

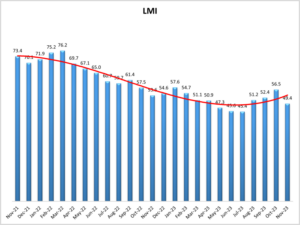

The road to recovery is not always linear – something that is clearly evidenced by the backwards step the Logistics

Each year, the American Rental Association (ARA) honors individuals for outstanding service to the association and the rental industry. This

The Women In Trucking Association (WIT) has announced Deb Beecher as its December 2023 Member of the Month. Beecher is an area

George Arrants, Vice President, ASE Education Foundation will present “What Makes Technicians Leave? and How to Stop Them” at the

ZAPI GROUP drives discussions on achieving an All-Electric Reality with industry experts and futurist Stefan Hyttfors ZAPI GROUP, a global

First the good news: Over the past decade (2011-2020) investment in corporate training has grown by about 30 percent. The

Kevin Looney will present “2nd Generation HEUI for International & Ford 6.7 troubleshooting and repair” for EPA 04, 07 and

Kyle Seitel, Vision Engineering Manager & Marketing Coordinator for Norwalt, named to PMMI’s Emerging Leaders Committee Norwalt, a specialist in

Over four-in-ten staffing firms report gains in new assignments Staffing employment inched up in the week of Nov. 13-19, with

You inspire people–whether you know it or not. You empower people, sometimes even if you’re not trying to. You guide

Recruit and retain top talent. Increase market share. Improve customer satisfaction. Expand into new geographic markets. Diversity product offerings. Reduce