June 2023 Logistics Manager’s Index Report®

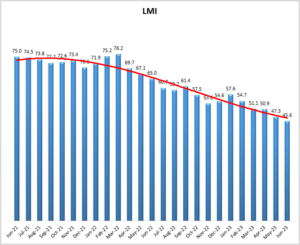

LMI® at 45.6 Growth is INCREASING AT AN INCREASING RATE for: Warehousing Capacity, Warehousing Utilization, Warehousing Prices, and Transportation Capacity

LMI® at 45.6 Growth is INCREASING AT AN INCREASING RATE for: Warehousing Capacity, Warehousing Utilization, Warehousing Prices, and Transportation Capacity

New orders of manufacturing technology totaled $365.9 million in May 2023, according to the latest U.S. Manufacturing Technology Orders Report

OSHA doesn’t list qualifications for forklift operators, requiring only that the employer certify the operator. The operator need not possess

When we think about famous visionary thinkers, we subconsciously assume that they have some magic characteristic that the rest of

The Board of Directors of the Material Handling Equipment Distributors Association (MHEDA) has announced the hiring of Jeannette Walker as

The signature event of the American Society of Safety Professionals (ASSP) attracted nearly 6,000 occupational safety and health professionals in

The Women In Trucking Association (WIT) is announcing the release of the findings of its 2023 WIT Index, which is

Dynamic Platform Features Essential Power Transmission/Motion Control Product Training PTDA Content with Expandable Library The Power Transmission Distributors Association (PTDA)

The American Society of Safety Professionals (ASSP) Foundation is awarding $334,500 in academic scholarships and career development grants to 153 individuals to

The American Rental Association (ARA) has announced that the 2023 Women in Rental and Young Professional Network (YPN) conferences will

In the latest episode, recorded at the Warehousing Education and Research Council (WERC) Conference 2023, we had the privilege of

April 2023 U.S. cutting tool consumption totaled $190.0 million, according to the U.S. Cutting Tool Institute (USCTI) and AMT –

Regional award places Moore in national competition, celebrates ambitious entrepreneurs who are building bolder futures During a celebration ceremony in

The Power Transmission Distributors Association (PTDA), an association for the industrial power transmission/motion control (PT/MC) distribution channel, welcomes two new

In today’s episode of The New Warehouse Podcast, we have a special guest, Rob Van Stratum, a managing partner and

The Power Transmission Distributors Association (PTDA) will convene for the PTDA 2023 Industry Summit in Amelia Island, Fla. on October

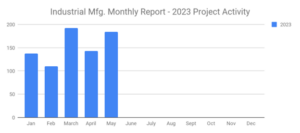

IMI SalesLeads has announced the May 2023 results for the new planned capital project spending report for the Industrial Manufacturing

Customer satisfaction is at an all-time high. Customer loyalty is at an all-time low. Why? Simple. Satisfied customers will shop

I am sitting at my computer on May 14 wondering if my T Bills will be worth anything two weeks

I recently attended the MHEDA’s Annual Convention and Exhibitor Showcase and as always, came home with some great takeaways and