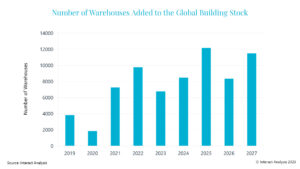

Poor economic climate knocks warehouse construction

Warehouses added to the global building stock in 2023 down 35% compared with 2022. 26% of warehouses are expected to

Warehouses added to the global building stock in 2023 down 35% compared with 2022. 26% of warehouses are expected to

The American Society of Safety Professionals (ASSP) has named Subba Rao Palagummi, CSP, CMIOSH, F.S. Eng., its 2023 Safety Professional of

The American Ladder Institute (ALI) spent last month marking National Ladder Safety Month, spreading the word about safe ladder practices, training opportunities, and more.

FHI Inc., a supply chain labor workforce services provider, is introducing FHI NOW, an on-demand labor solution, to help companies

The U.S. Economic Development Administration or EDA is now accepting applications for its FY23 STEM Talent Challenge to support programs to train

The Women In Trucking Association (WIT) announced the winner of its second truck giveaway in the last five years. WIT

The Women In Trucking Association (WIT) has welcomed Navistar Inc. as its newest Gold Level Partner, forming an industry alliance

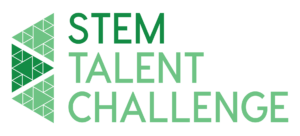

LMI® at 51.1 Growth is INCREASING AT AN INCREASING RATE for Warehousing Capacity and Transportation Capacity Growth is INCREASING AT

The American Society of Safety Professionals (ASSP) has named Terry W. Krug, M.S., CSP, the recipient of the 2023 Thomas F.

Every year in the spring, Amy B., a buyer for a large retail chain store, hosts an Easter egg decorating

Grant funding applications are now open for safety, efficiency, and reliability improvement projects The U.S. Department of Transportation Maritime Administration

Staffing employment eased for a seventh straight week in the week of Mar. 13-19, with the ASA Staffing Index decreasing

Applied Manufacturing Technologies (AMT), North America’s largest independent automation engineering company supporting manufacturers, robot companies, systems integrators, line builders, and

Technology changes have been talked about for the last ten years and probably more. Many of you have adopted newer

IMI SalesLeads has announced the February 2023 results for the new planned capital project spending report for the Industrial Manufacturing

The customer is always right. Except when they are wrong, which is most of the time. In sales right and

Your team is the heartbeat of your organization. No matter how sleek, modern, or powerful your equipment or systems appear,

The Association of American Railroads (AAR) has reported U.S. rail traffic for the week ending March 11, 2023. For this

The robotics industry’s most prestigious award will be presented Wednesday, May 24, at Automate in Detroit The Association for Advancing Automation

We tend to believe that famous innovators or other “creative” people have some inherent qualities that we don’t have. But